Technique for producing cold-bonded pellets from steel converter dust removal ash

A technology for steel-making converter and cold-solidified pellets, which is applied in the field of steel-making converter dust removal and production of cold-solidified pellets, can solve the problems of secondary pollution, recycling, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

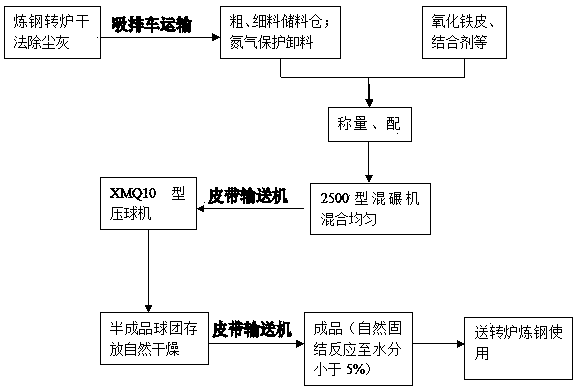

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] see figure 1 Process flow chart of the present invention, steelmaking converter dedusting ash production cold solidification pellet process method, it is characterized in that:

[0034] 1. Collect steelmaking converter dust to obtain coarse dust and fine dust, or after sieving to obtain coarse dust and fine dust. The particle size of the coarse dust is between 80-150 mesh, and the fine dust is The particle size is between 150-320; in steelmaking converter production, coarse dust removal and fine dust removal are separated, and generally collected separately to obtain coarse dust removal and fine dust removal with different particle sizes; or through sieving

[0035] 2. Weigh the iron oxide scale, coarse dust and fine dust according to the mass ratio (10~50):(20~80):(20~70), and mix them evenly; you can use a 1600-type mixing m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com