Double-layer-flow purification working table

A workbench, double-layer flow technology, applied in workbenches, manufacturing tools, clean rooms, etc., can solve the problems of chaotic airflow in the working chamber and rapid discharge of unfavorable volatile substances, and achieve the effect of avoiding airflow reflection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

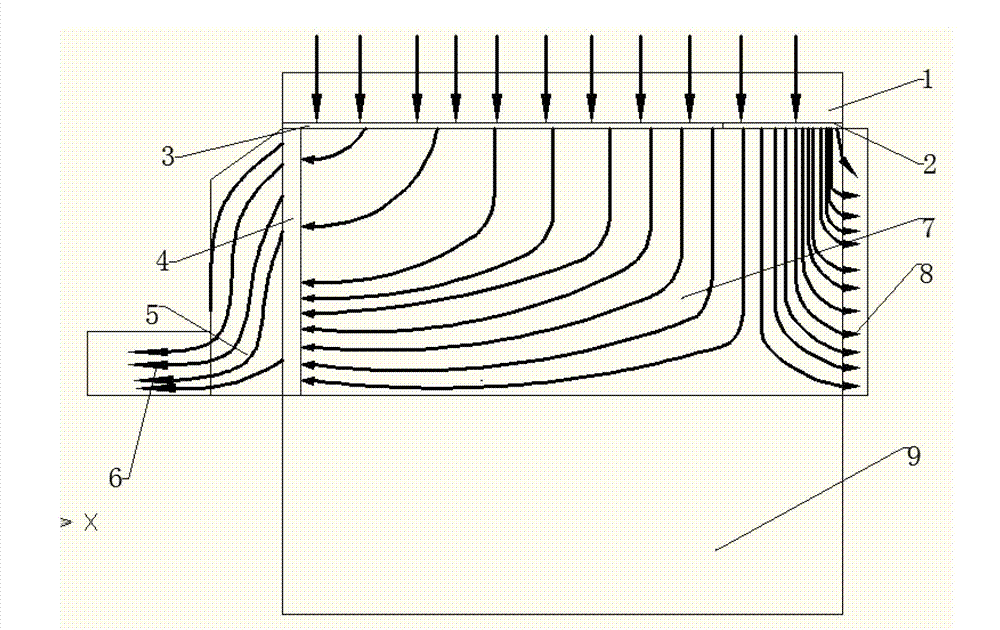

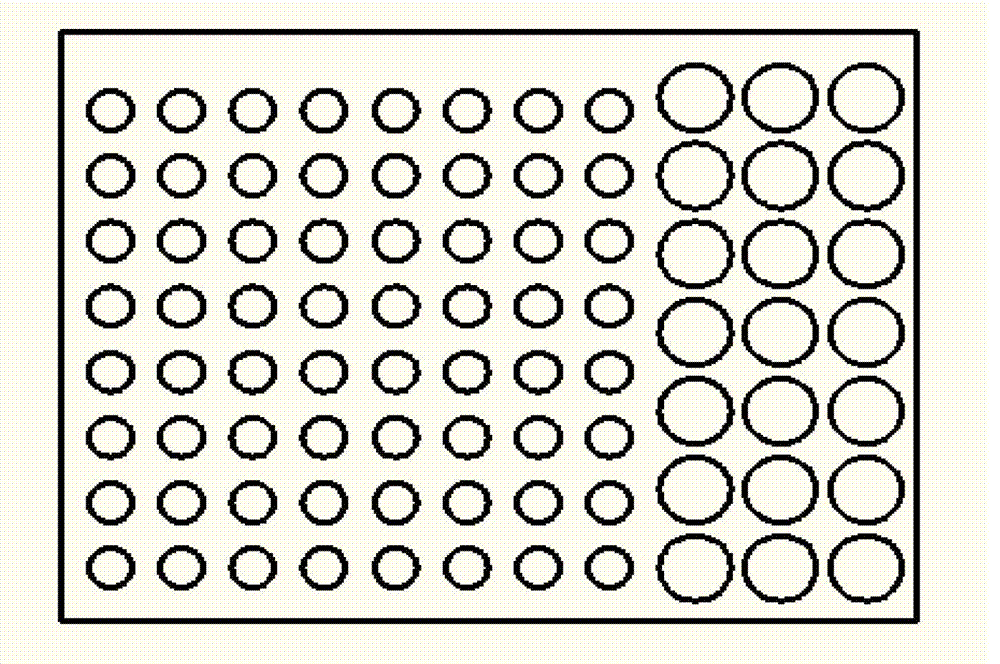

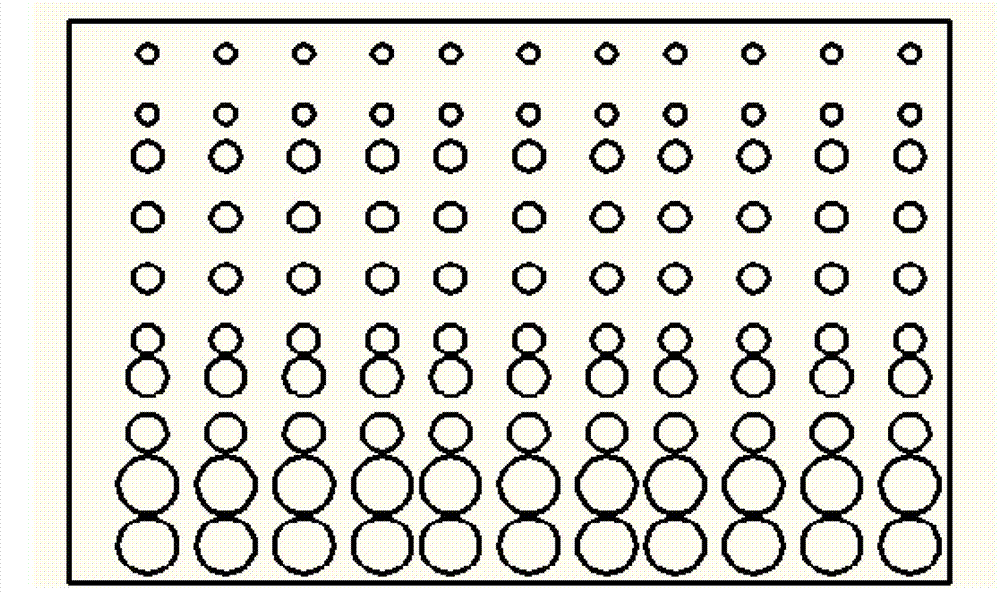

[0023] Such as figure 1 As shown, the double-layer flow purification workbench of the embodiment of the present invention includes an air intake system 1 and an exhaust system. A diffuser plate 3 is provided below the air intake system 1, and a working cavity 7 is located below the diffuser plate 3. The working cavity 7. The outer side is the glass sliding door 8, and the lower part of the working chamber 7 is the bracket 9. The side of the diffuser 3 close to the staff is provided with a large hole in the horizontal direction. The diameter of the large hole is 20mm. , the aperture of the small hole is 10mm, the exhaust system includes a collector plate 4 positioned in the working cavity 7 and placed vertically, the collector plate 4 is located on the side away from the staff in the working cavity 7, the collector plate 4 The opening gradually...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com