Method and apparatus for preparing high-purity gallium

A high-purity, container technology, applied in the field of high-purity gallium preparation, can solve the problems of unstable crystal interface, many factors affecting quality, low purification efficiency, etc., to reduce the possibility of impurity introduction, good product stability, and improve purification. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

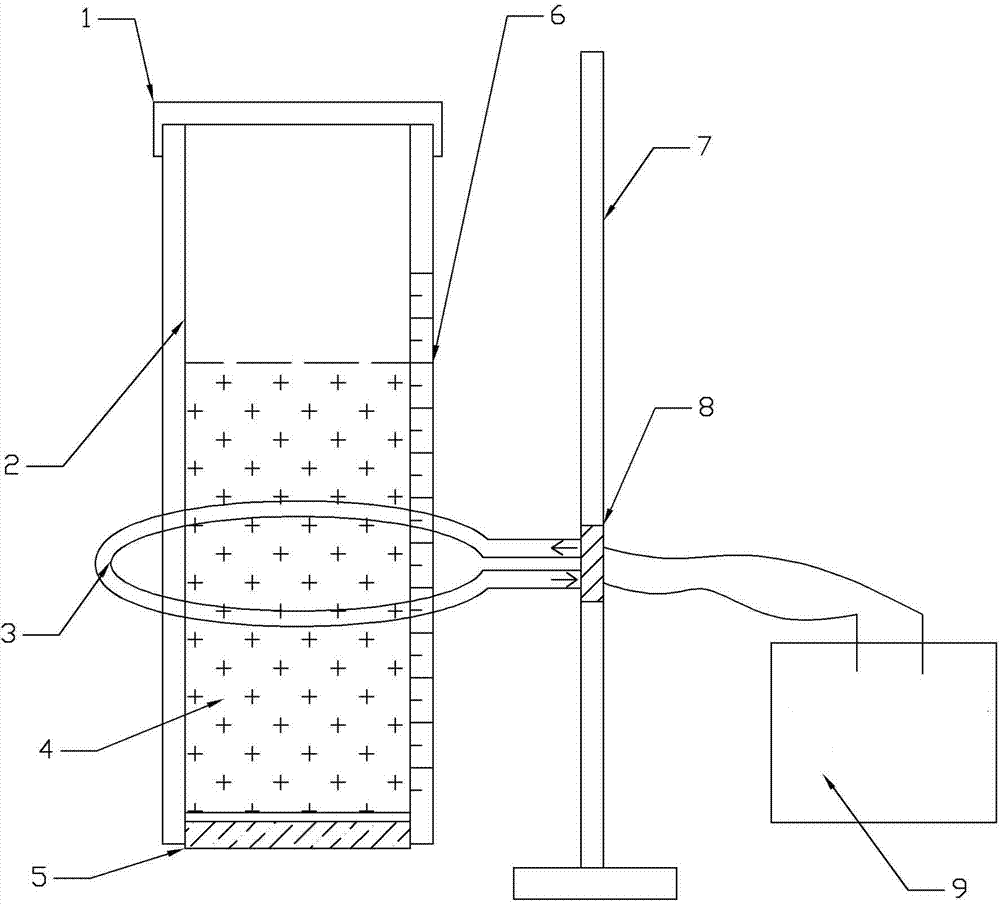

[0030] Such as figure 1 As shown, the method for preparing high-purity gallium is to first place liquid high-purity metal gallium at the bottom of the cooling container 2, and cool it as a seed crystal; pour liquid metal gallium into the cooling container, and apply a constant temperature cold source 5 at the bottom of the cooling container. , carry out cooling and crystallization; after the liquid metal gallium is completely crystallized and solidified, turn on the heat source coil 3 to make the coil move from the bottom to the top of the container, and control the temperature and moving speed of the coil through the control device 9 to maintain the solid-liquid interface during the solidification process Stable; repeat the heat source coil moving operation many times to achieve the purpose of purification, the crystallization interception rate is 70%-90%, and metal gallium above 6N can be obtained.

[0031] This device for preparing high-purity gallium includes a cooling con...

Embodiment 2

[0033] The device for preparing high-purity gallium is the same as in Example 1. A constant-temperature cold source is applied to the bottom of a cylindrical cooling container made of plexiglass. The temperature of the cold source is 3°C. The ethylene glycol refrigerant is provided to the cold end of the container through copper heat conduction. 5g of high-purity liquid gallium with a purity of 6N is coated on the bottom of the container to form a seed crystal, and liquid metal gallium with a purity of 4N is added at a temperature of 35°C. Move from bottom to top, control the temperature of the heat source coil at 40°C, the moving speed at 1cm / h, and the temperature of the bottom cold source at 3°C. After repeating the operation of moving the heat source coil 4 times, intercept 80% of gallium metal to obtain 6N high-purity gallium.

Embodiment 3

[0035] The device for preparing high-purity gallium is the same as in Example 1. A constant-temperature cold source is applied to the bottom of a cylindrical cooling container made of plexiglass. 5g of high-purity liquid gallium with a purity of 6N is coated on the bottom of the container to form a seed crystal, and liquid metal gallium with a purity of 4N is added at a temperature of 40°C. Move from bottom to top, control the temperature of the heat source coil at 50°C, the moving speed at 0.5cm / h, and the temperature of the bottom cold source at 0°C. After repeating the operation of moving the heat source coil 4 times, intercept 85% of the gallium metal to obtain a 6N high pure gallium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com