Nano titanium nitride-based composite photocatalytic material as well as preparation method and application thereof

A nano-composite material, nano-titanium nitride technology, applied in the direction of light water/sewage treatment, etc., can solve the problems of inactivation of microbial pathogens, efficient utilization of solar energy, etc., and achieve the effects of easy control, composite and interface protection, and composite structure stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

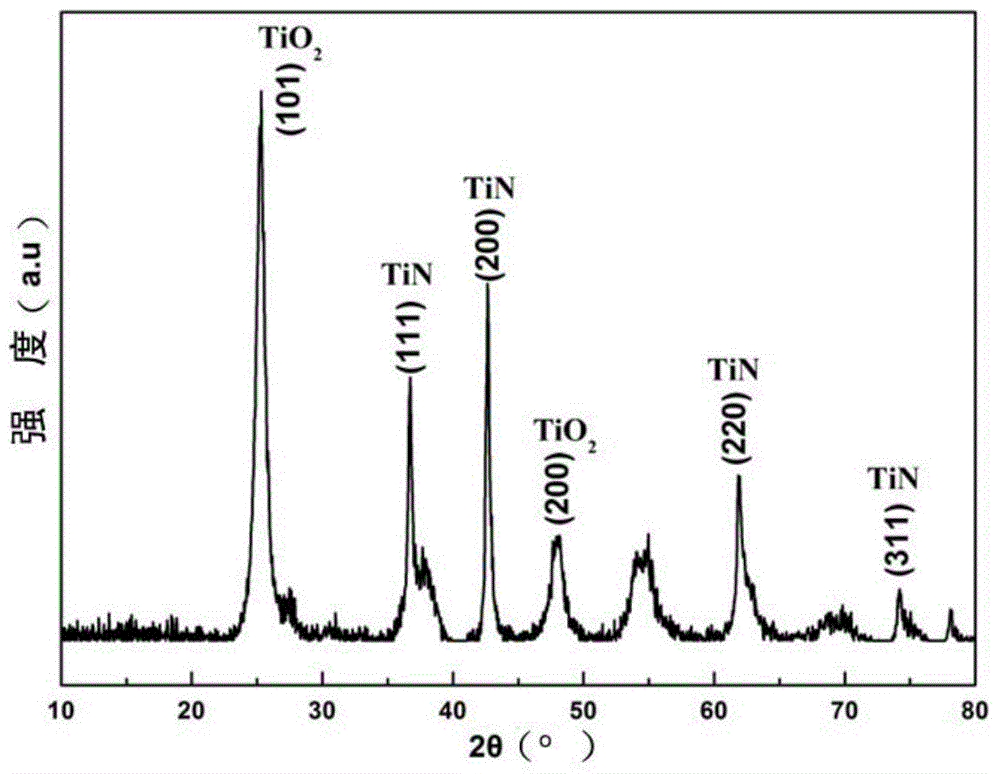

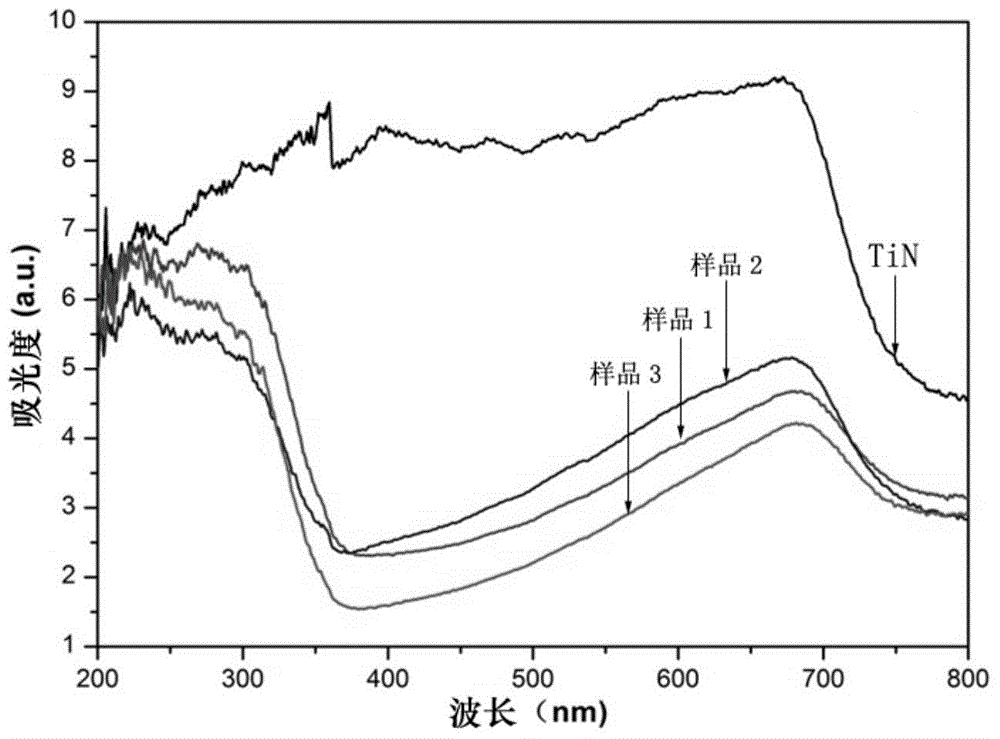

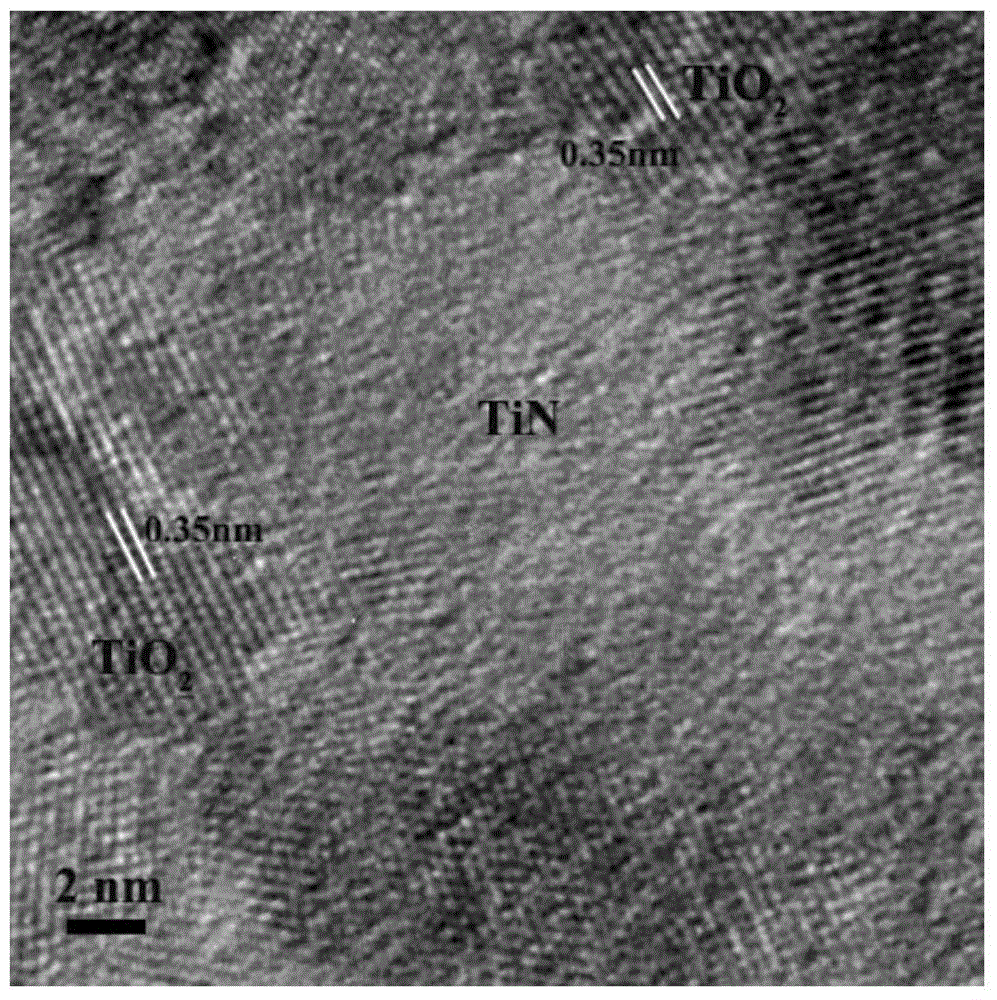

Embodiment 1

[0037] 1). According to 5mg / cm 2 Ratio, the nano-titanium nitride powder is evenly placed on the bottom of the crucible;

[0038] 2). Put the crucible into a reaction furnace with a temperature of 400°C to keep warm, and keep warm for 60 minutes in an oxygen-containing atmosphere (oxygen content 20vol.%);

[0039] 3). The crucible was taken out and air-cooled, and collected after cooling to room temperature to obtain a nano-titanium nitride-based composite material, marked as sample 1.

Embodiment 2

[0041] 1). According to 5mg / cm 2 Ratio, the nano-titanium nitride powder is evenly placed on the bottom of the crucible;

[0042] 2). Put the crucible into a reaction furnace with a temperature of 450°C to keep warm, and keep warm for 15 minutes in an oxygen-containing atmosphere (oxygen content 20vol.%);

[0043] 3). The crucible was taken out and air-cooled, and collected after cooling to room temperature to obtain a nano-titanium nitride-based composite material, marked as sample 2.

Embodiment 3

[0045] 1). According to 5mg / cm 2 Ratio, the nano-titanium nitride powder is evenly placed on the bottom of the crucible;

[0046] 2). Put the crucible into a reaction furnace with a temperature of 500°C to keep warm, and keep warm for 5 minutes in an oxygen-containing atmosphere (oxygen content 20vol.%);

[0047] 3). The crucible was taken out and air-cooled, and collected after cooling to room temperature to obtain a nano-titanium nitride-based composite material, marked as sample 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com