Preparation method of iron-containing dust sludge pellets

A technology for iron dust sludge and pellets, which is applied in the field of metallurgy, can solve the problems of increasing the smelting cost of steel in the steelmaking process, affecting the quality of molten iron, and having a large impact on smelting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

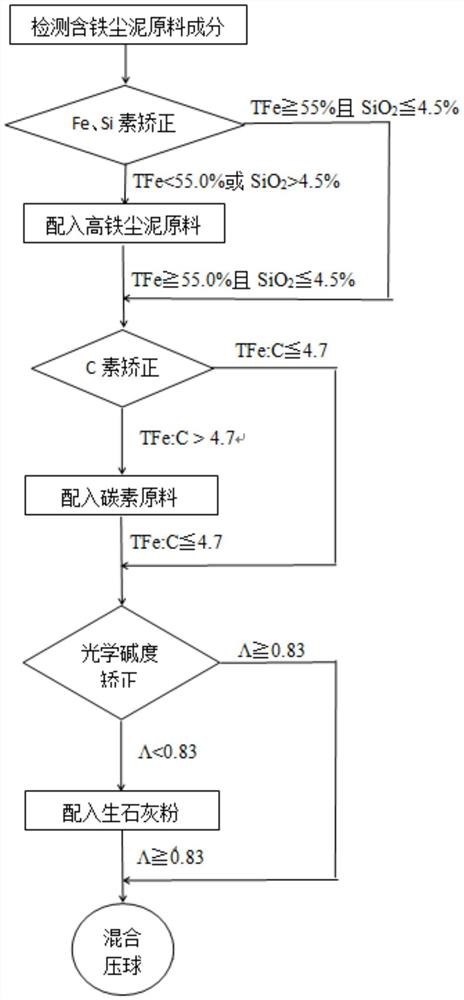

[0065] Embodiment one (as figure 1 shown):

[0066] A) The ingredients of the iron-containing dust sludge used in the test are: TFe 31.7%, CaO 12.8%, MgO 5.1%, SiO2 13.7%, Al2O3 6.4%, MnO 0.6%, K2O 0.9%, Na2O 0.7%, S 1.8%, P2O5 0.2%, CaF20.4, Zn 1.8%, C 13.2%, moisture 0.5%, the particle size characteristics of the iron-containing dust sludge raw material are: 100 mesh sieve residue = 10.0%, 20 mesh sieve residue = 0.8%, TFe4.5%, it needs to be mixed with high iron dust sludge raw materials;

[0067] The raw material composition of high iron dust sludge is: TFe 69.7%, CaO 1.5%, MgO 0.6%, SiO 2 1.2%, Al 2 o 3 0.4%, MnO 0.2%, K 2 O 0.3%, Na 2 O 0.4%, S 0.5%, P 2 O0.1%, CaF 2 0.1, Zn 0.0%, C0.2%, moisture 0.5%, the particle size characteristics of high iron dust sludge raw materials are: 100 mesh sieve residue = 9.0%, 20 mesh sieve residue = 0.8%;

[0068] Mix the iron-containing dust sludge raw material and the high-iron dust sludge raw material at a ratio of 1:3, and...

Embodiment 2

[0094] A) The ingredients of iron-containing dust sludge used in the detection are: TFe 40.5%, CaO 5.2%, MgO 2.3%, SiO25.1%, Al2O3 1.2%, MnO 0.3%, K2O 0.4%, Na2O 0.3%, S 1.3%, P2O5 0.1%, CaF2 0.2, Zn 2.1%, C 25.7%, moisture 0.4%, the particle size characteristics of iron-containing dust sludge raw materials are: 100 mesh sieve residue = 9.0%, 20 mesh sieve residue = 1.0%, TFe2 >4.5%, it needs to be mixed with high-speed iron dust and mud raw materials;

[0095] The raw material composition of high iron dust sludge is: TFe 70.5%, CaO 1.6%, MgO 0.5%, SiO 2 0.8%, Al 2 o 3 0.5%, MnO 0.2%, K 2 O 0.3%, Na 2 O 0.3%, S 0.1%, P 2 o 5 0.0%, CaF 2 0.0, Zn 0.0%, C0.2%, moisture 0.7%, the particle size characteristics of high iron dust sludge raw materials are: 100 mesh sieve residue = 8.0%, 20 mesh sieve residue = 1.0%;

[0096] Mix the iron-containing dust sludge raw material and the high-iron dust sludge raw material at a ratio of 1:1, and the chemical composition of the obtai...

Embodiment 3

[0120] A) The ingredients of the iron-containing dust sludge used in the test are: TFe 47.9%, CaO 10.8%, MgO 3.9%, SiO 27.4%, Al2O3 4.1%, MnO 0.8%, K2O 0.5%, Na2O 0.8%, S 1.7%, P2O5 0.4%, CaF2 0.2, Zn 2.3%, C 2.2%, moisture 0.4%, the particle size characteristics of iron-containing dust and sludge raw materials are: 100 mesh sieve residue = 8.0%, 20 mesh sieve residue = 0.9%, TFe2 >4.5%, it needs to be mixed with high-speed iron dust and mud raw materials;

[0121] The raw material composition of high iron dust sludge is: TFe 71.3%, CaO 1.2%, MgO 0.4%, SiO 2 0.7%, Al 2 o 3 0.3%, MnO 0.3%, K 2 O 0.2%, Na 2 O 0.2%, S 0.1%, P 2 o 5 0.0%, CaF 2 0.0, Zn 0.0%, C0.0%, moisture 0.6%, the particle size characteristics of high iron dust sludge raw materials are: 100 mesh sieve residue = 10.0%, 20 mesh sieve residue = 0.7%;

[0122] Mix the iron-containing dust sludge raw material and the high-iron dust sludge raw material at a ratio of 1:1, and the chemical composition of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com