A kind of manufacturing method of pure glass fiber reinforced plastic fan

A manufacturing method and technology of glass fiber reinforced plastics, which can be applied to other household appliances, household appliances, household components, etc., and can solve the problems that the tensile strength and impact toughness cannot meet the requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

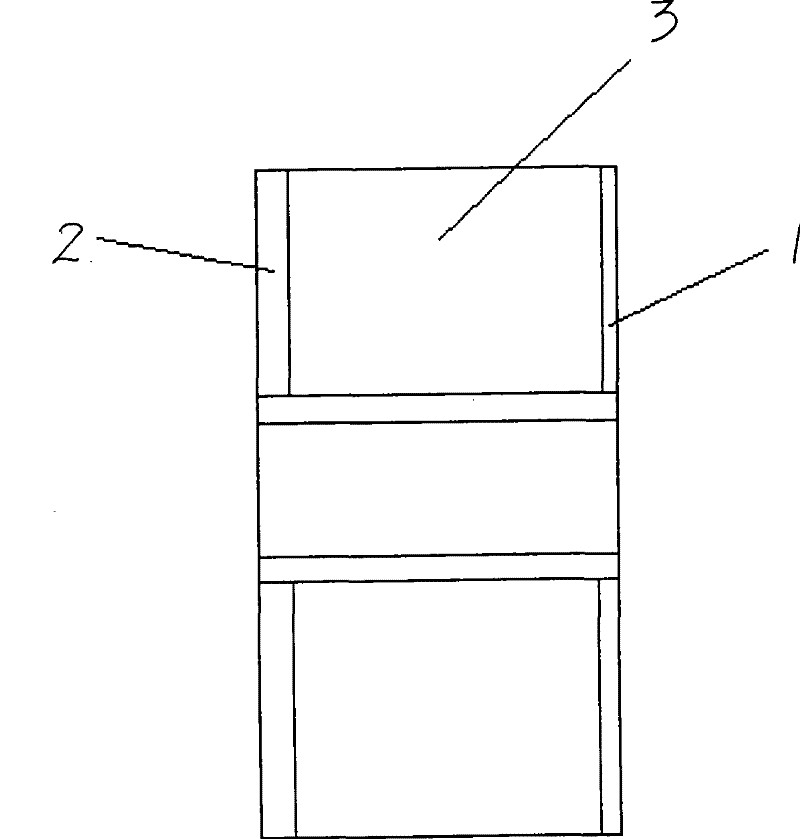

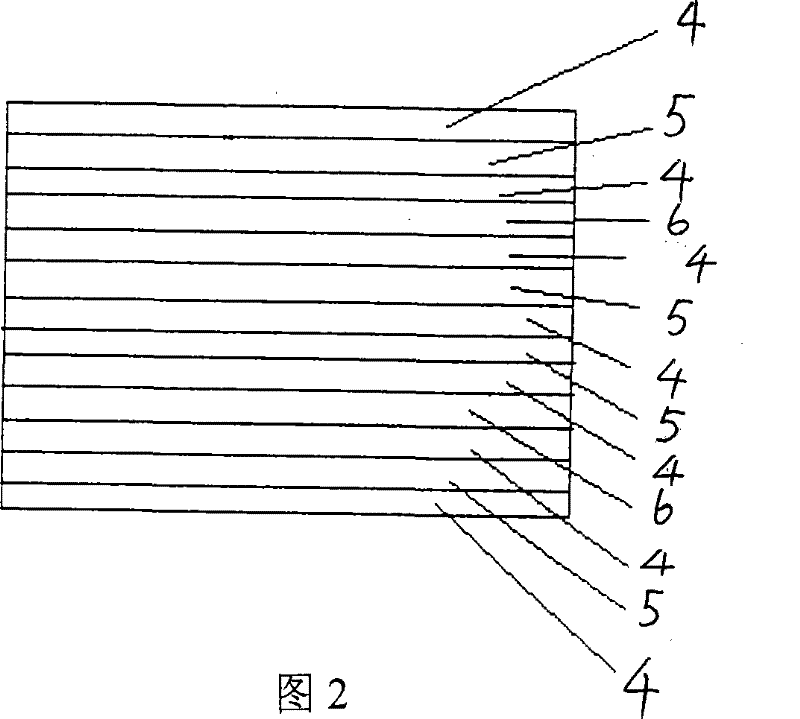

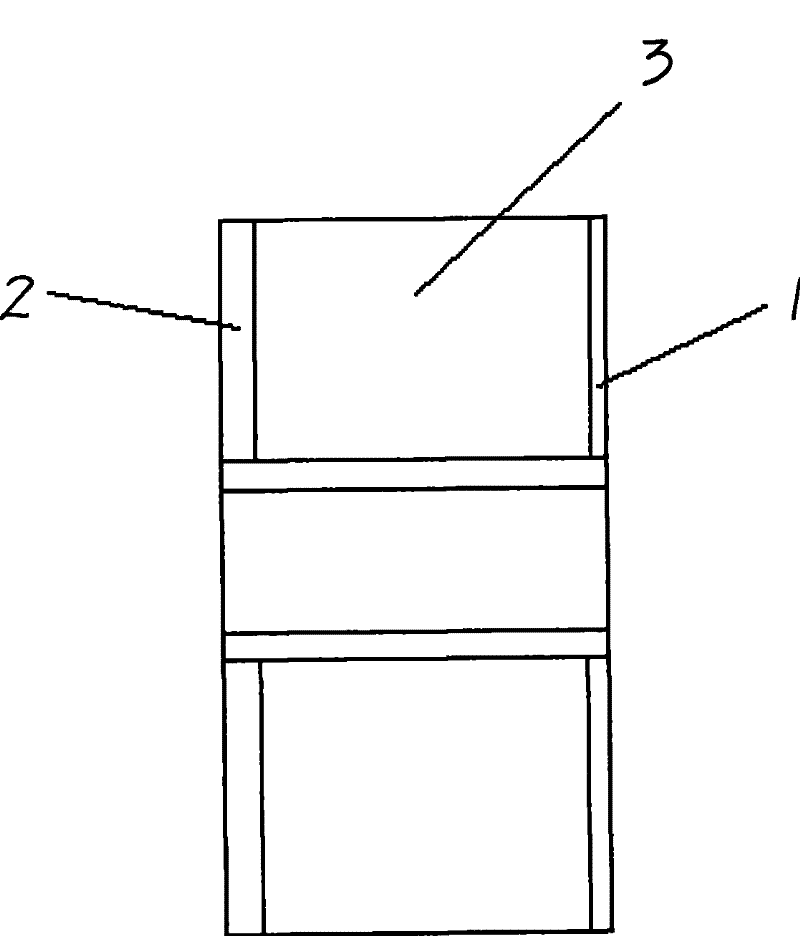

[0008] In actual manufacturing, first use wooden molds to make corresponding manufacturing models, which are the shell, blades, rear plate, and front plate of the fan. After coating a layer of anti-adhesive silicone oil on the surface of the wooden mold, start to paste the glass fiber reinforced plastic. After 4 and platinum fiber cloth 5 and steel wire cloth 6 are impregnated with resin, then start to paste on the model from felt 4, and then paste platinum fiber cloth 5 and felt 4 alternately inward. In order to strengthen the structural strength, several layers of steel wire cloth 6 can be used to replace several layers of symmetrically arranged platinum fiber cloth 5. Generally, fans with a power of 2-3 kilowatts can only use two layers of steel wire cloth 6 to replace the symmetrically arranged two layers of platinum fiber cloth. Fiber cloth5. Pay attention to the pasting between the felt 4, the platinum fiber cloth 5, and the steel wire cloth 6 when pasting. If one layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com