Structural alloy material and preparation method thereof

An alloy material and a preparation process technology, applied in the field of structural alloy materials and their preparation, can solve the problems of poor impact resistance, low hardness, and cannot improve the stability of equipment structural parts, and achieve improved hardness and impact toughness, strong impact The effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] (1) Take Mg as 0.6 wt%, Rb as 0.4 wt%, Hf as 0.1 wt%, Pd as 0.3 wt%, Co as 0.8 wt%, Ni as 3.3 wt%, and the balance as Fe, Mg, Rb , Hf, Pd, Co, Ni and Fe elements are put into the vacuum melting furnace;

[0016] (2) Adjust the temperature of the vacuum melting furnace to 1150°C to melt various metal components;

[0017] (3) Adjust the temperature of the vacuum smelting circuit to 1650°C, and fully smelt various metal components;

[0018] (4) The alloy material is subjected to hot-press forming. After the hot-press forming, the alloy material is cooled to 600° C., kept for 4 hours, and then gradually cooled to room temperature.

Embodiment 2

[0020] (1) Take 0.8wt% of Mg, 0.3wt% of Rb, 0.2wt% of Hf, 0.3wt% of Pd, 0.5wt% of Co, 3.4wt% of Ni, and Fe as the balance, Mg, Rb , Hf, Pd, Co, Ni and Fe elements are put into the vacuum melting furnace;

[0021] (2) Adjust the temperature of the vacuum melting furnace to 1250°C to melt various metal components;

[0022] (3) Adjust the temperature of the vacuum smelting circuit to 1600°C, and fully smelt various metal components;

[0023] (4) The alloy material is subjected to hot-press forming. After the hot-press forming, the alloy material is cooled to 600° C., kept for 4 hours, and then gradually cooled to room temperature.

Embodiment 3

[0025] (1) Take 0.7wt% of Mg, 0.4wt% of Rb, 0.1wt% of Hf, 0.2wt% of Pd, 0.7wt% of Co, 3.6wt% of Ni, and Fe as the balance, Mg, Rb , Hf, Pd, Co, Ni and Fe elements are put into the vacuum melting furnace;

[0026] (2) Adjust the temperature of the vacuum melting furnace to 1200°C to melt various metal components;

[0027] (3) Adjust the temperature of the vacuum smelting circuit to 1550°C, and fully smelt various metal components;

[0028] (4) The alloy material is subjected to hot-press forming. After the hot-press forming, the alloy material is cooled to 600° C., kept for 4 hours, and then gradually cooled to room temperature.

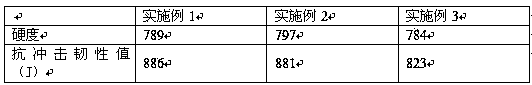

[0029] The hardness and impact toughness values of the structural alloy materials of Example 1, Example 2, and Example 3 are shown in the following table, and the impact toughness value is measured according to GB / T1817-1995.

[0030]

[0031] The prepared structural alloy material has high hardness and impact resistance toughness, and can be u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com