Method for preparing Ti2AlC ceramic powder through aluminothermic reduction

A ceramic powder and thermite technology, which is applied in the field of preparation of Ti2AlC ceramic powder by thermite reduction, can solve the problems of high raw material cost and high process cost, and achieve the effect of low cost, high purity and simple raw material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

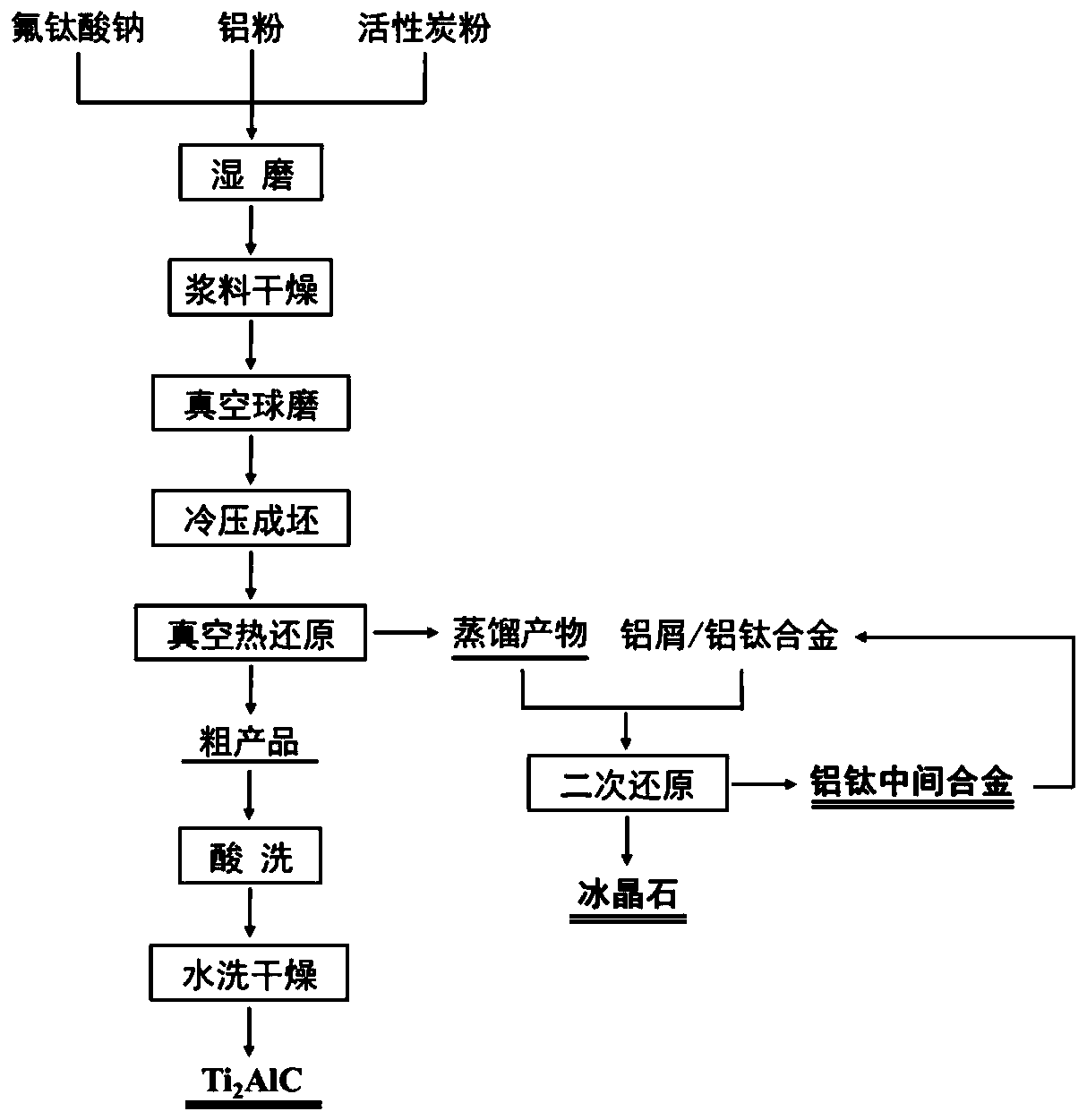

[0049] Specific embodiments: a kind of aluminothermic reduction prepares Ti 2 The method of AlC ceramic powder, process such as figure 1 shown, including the following steps:

[0050] Step 1: Mix sodium fluorotitanate, aluminum powder and activated carbon powder that meet the ratio requirement of 1:(0.16-0.38):(0.02-0.05) and then wet grind them first. The wet grinding time of materials is 2-8 hours. After the slurry is dried, it is activated by dry milling under vacuum or inert atmosphere, and the dry milling time is 4-12 hours;

[0051] Step 2: Put the mixed and ground material into the mold, and cold press it under the condition of 40-120MPa to obtain a green body;

[0052] Step 3: Put the green body in a vacuum reduction furnace for thermal reduction, the reduction temperature is 800-1500°C, and the vacuum degree is 10 -4 -10Pa, the reduction time is 1-6 hours;

[0053] Step 4: After the reduction, control the temperature at 1000-1350°C for vacuum distillation, the dis...

Embodiment 1

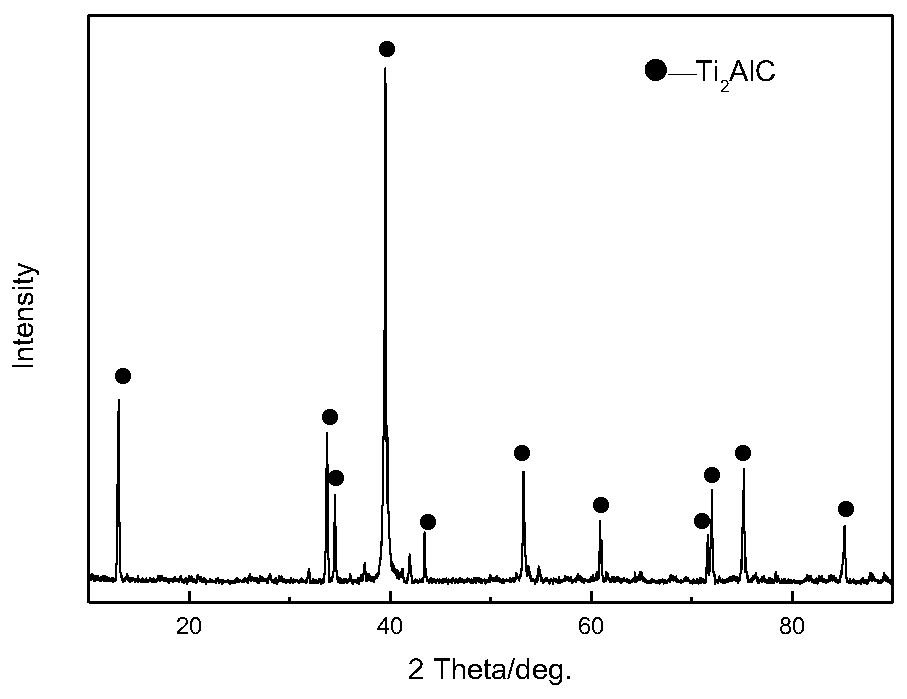

[0061] On the basis of meeting the above specific implementation methods, the following requirements are implemented: 300 grams of sodium fluotitanate, 74.3 grams of aluminum powder and 8.8 grams of activated carbon powder are mixed, in anhydrous ethanol medium, the ratio of material to ball is 2:1, and planetary The ball mill was wet milled for 4 hours, followed by vacuum drying at 60°C for 12 hours; the dried mixed material was placed in a high-energy ball mill, and high-energy activation was performed under a high-purity argon atmosphere for 8 hours; the activated mixed material was Put it in a steel mold and cold press it into a billet under a pressure of 50 MPa; then put the billet in a reduction furnace for thermal reduction under vacuum conditions, the reduction temperature is 1250 ° C, and the vacuum degree is 10 -3 Pa, the reduction time is 3 hours; after the reduction process ends, the vacuum system is turned on for vacuum distillation, the distillation temperature is...

Embodiment 2

[0064] On the basis of meeting the above-mentioned specific embodiments, the following requirements are implemented: 616.3 grams of sodium fluotitanate, 152.5 grams of aluminum powder and 18.1 grams of activated carbon powder are mixed, in anhydrous ethanol medium, the ratio of material to ball is 2:1, and planetary The ball mill was wet-milled for 5 hours, followed by vacuum drying at 60°C for 16 hours; the dried mixture was placed in a high-energy ball mill for high-energy activation under vacuum for 10 hours; the activated mixture was placed in a steel In the mold, the billet is cold-pressed under a pressure of 50 MPa; then the billet is placed in a reduction furnace for thermal reduction under vacuum conditions, the reduction temperature is 1250 ° C, and the vacuum degree is 10 -3 Pa, the reduction time is 4 hours; after the reduction process ends, the vacuum system is turned on for vacuum distillation, the distillation time is 7 hours, the control system is closed after co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com