Heterogeneous condensation gas source system with adjustable granularity, concentration and flow

A concentration and gas source technology, applied in the field of heterogeneous condensing gas source system, can solve the problems of poor practicability, non-adjustability, poor stability, etc., achieve controllable temperature and humidity, clear division of labor, and improve adjustability and accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further illustrate the features, process flow, specific advantages and functions of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

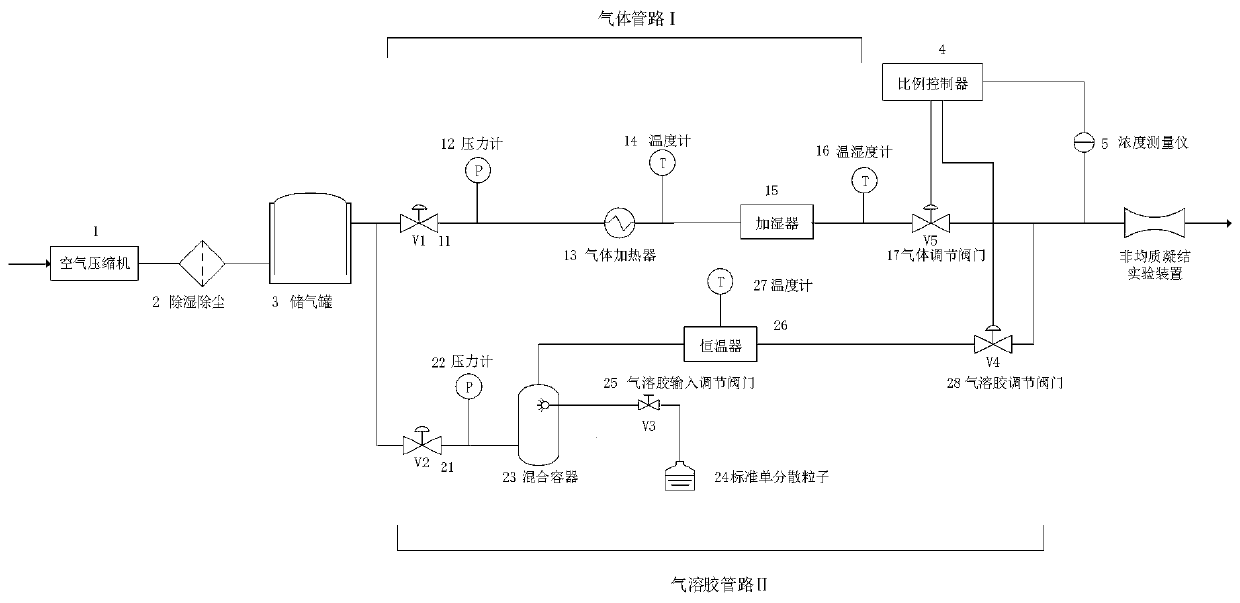

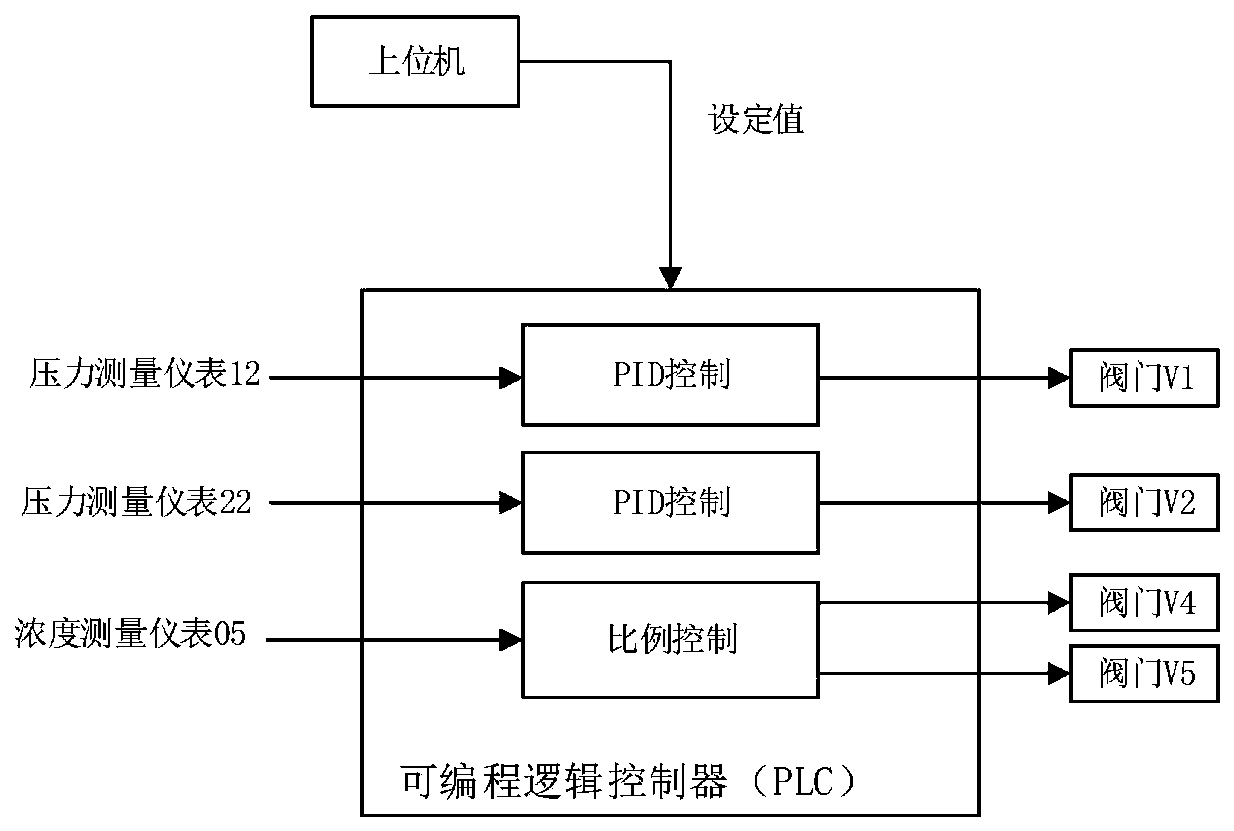

[0018] see figure 1 , multi-parameter adjustable heterogeneous condensing air source system, the unified compressor 1 provides air, which simplifies the system pipeline, and enters the air storage tank 3 after passing through the dehumidifier and dust collector 2, and then divided into two pipelines, respectively For gas lines and aerosol lines. Set at the inlets of the two pipelines: regulating valves and pressure gauges for detection components; the specific process is: the pressure gauge detects the current pipeline pressure value, and then transmits the pressure signal to the PLC, which is the control part, and the PLC according to the set value and actual measurement Value deviation, output a control signal to the valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com