Phase-transition energy-storage microcapsules and their preparing process

A phase-change energy storage and phase-change material technology, applied in the field of phase-change energy storage materials and their preparation, can solve the problems of inability to use for a long time, poor chemical stability, poor heat resistance of organic polymers, etc., and achieve easy industrialization and promotion. , the effect of easy industrial production and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] a) Emulsification of phase change materials

[0029] Dissolve 1.5g of CTAB in 30mL of hot water at 50°C. After complete dissolution, add 8mL of 25# phase-change paraffin and 0.5g of n-amyl alcohol, and emulsify for 2min under stirring at 12000 rpm to obtain a milky white emulsion.

[0030] b) Prepolymerization of the cyst wall

[0031] Add 5mL of industrial water glass into 30mL of distilled water, after dissolving, add 1.5mL of 1:1 hydrochloric acid under the condition of stirring, and obtain the water glass prepolymer.

[0032] c) Encapsulation of phase change materials

[0033] Slowly add the emulsion obtained in a) into the water glass prepolymer b), then slowly add 4mL5mol / L NH 4 HCO 3 The solution was placed in a water bath at 50°C and stirred for 3 hours. After filtering and washing, the phase change energy storage microcapsules are obtained.

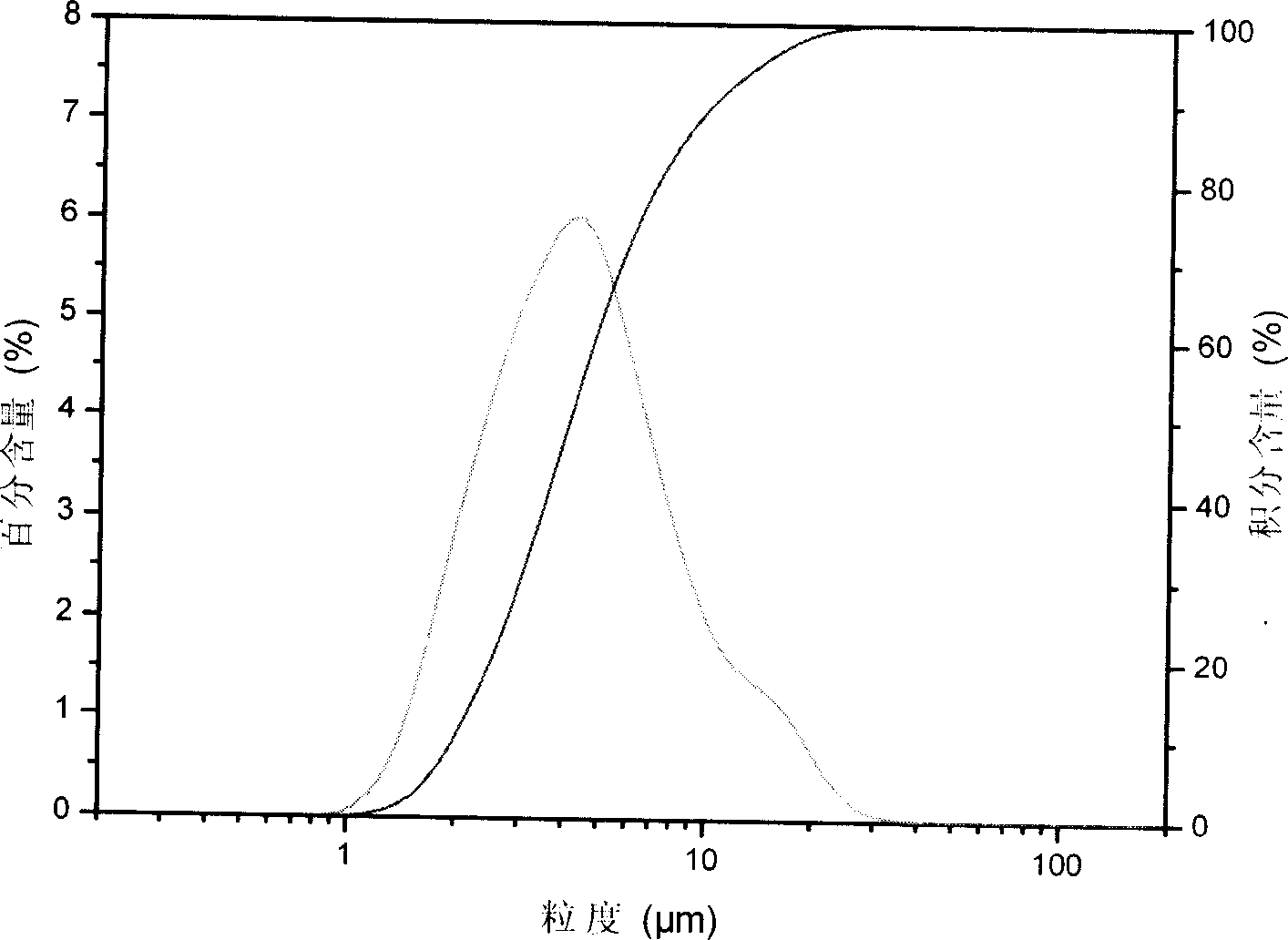

[0034] The particle size distribution of the prepared microcapsule phase change energy storage materials is as foll...

Embodiment 2

[0036] 8mL of dodecanol was used as the phase change material, and its phase change temperature was 24°C. Other preparation steps and conditions were the same as in Example 1.

[0037] D of the prepared phase change energy storage microcapsules 50 =8.68 μm, the phase change enthalpy of the microcapsule is 116.49 J / g, and the phase change enthalpy of dodecanol is 216.80 J / g, so the content of the phase change energy storage material is 53.7%.

Embodiment 3

[0039] a) Emulsification of phase change materials

[0040] Dissolve 3g of CTAB in 30mL of hot water at 50°C, add 11mL of 25# phase-change paraffin and 1g of n-pentanol after complete dissolution, and emulsify for 2min under stirring at 12000 rpm to obtain a milky white emulsion.

[0041] b) Prepolymerization of the cyst wall

[0042] Add 5mL of industrial water glass into 30mL of distilled water, after dissolving, add 1.1mL of 1:1 hydrochloric acid under the condition of stirring, and obtain the water glass prepolymer.

[0043] c) Encapsulation of phase change materials

[0044] Slowly add the emulsion obtained in a) into the water glass prepolymer b), then slowly add 10mL5mol / L NH 4 HCO 3 The solution was placed in a water bath at 50°C and stirred for 5 hours. After filtering and washing, the phase change energy storage microcapsules are obtained.

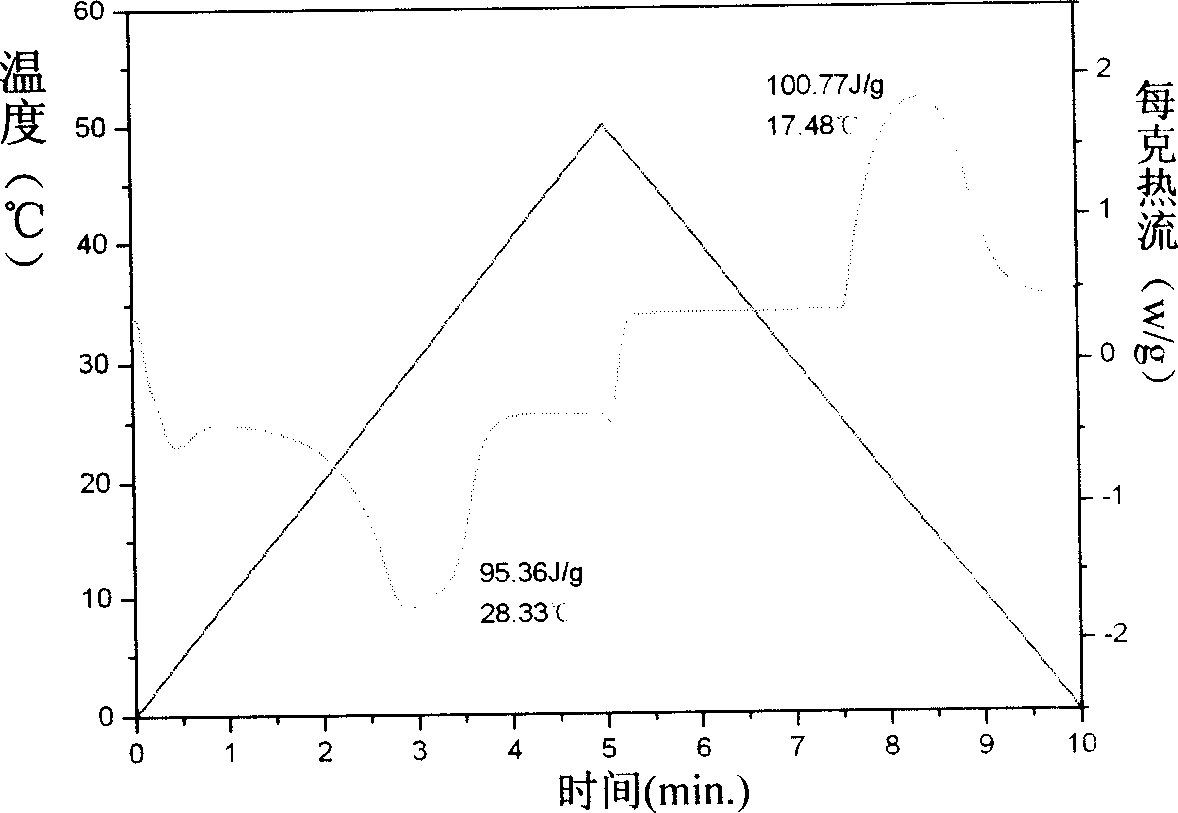

[0045] D of the prepared phase change energy storage microcapsules 50 =6.06μm, the phase change enthalpy of the microcaps...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com