Preparation method of self-doped anatase type titanium dioxide film

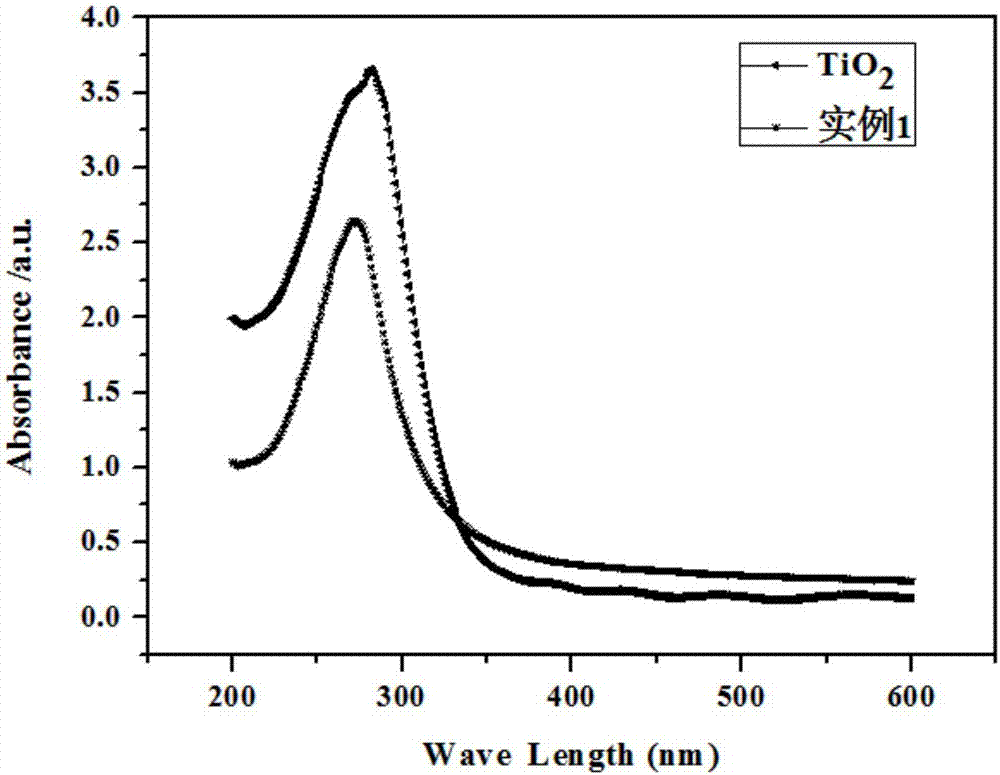

A technology of titanium dioxide and anatase type, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., to achieve the effects of good crystallinity, improved absorption efficiency, and wide spectral absorption range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

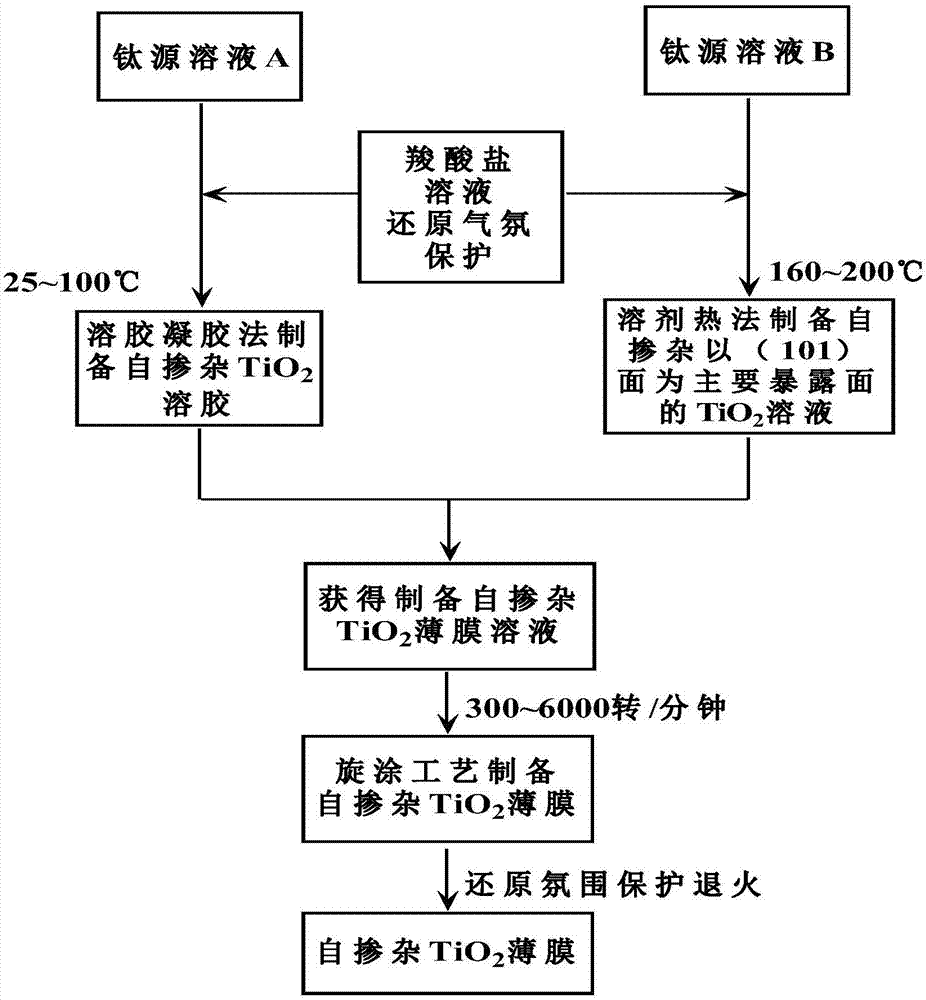

Method used

Image

Examples

Embodiment 1

[0040] In the titanium source alcohol solution formed by mixing tetrabutyl titanate and isopropanol, add a certain amount of deionized water, acetic acid and acetylacetone, and finally add a zinc acetate organic solution with a molar concentration of 2mol / L. Under pressure and 40°C, the pH of the reactant was controlled to 3, nitrogen was introduced, and stirred for 8 hours to obtain a black stable anatase-type self-doped titanium dioxide alcohol phase solution A. Add titanium sulfate dropwise to the organic solution mixed with oleic acid and cyclohexane, stir and mix, then add a certain amount of deionized water and hydrolysis inhibitor, and finally add a magnesium acetate organic solution with a molar concentration of 2mol / L. Stir at normal pressure and 40°C for 6 hours, and stir at 80°C for 2 hours. Add argon to control the pH of the reactant to 3 to obtain a black stable B solution. Place solution B with titanium sulfate solution as the titanium source in a reaction kettle ...

Embodiment 2

[0042] In the titanium source alcohol solution formed by mixing titanium isopropoxide with a mixed solution of isopropanol and n-butanol, add a certain amount of deionized water and ethyl acetate, and finally add zinc acetate with a molar concentration of 1.5 mol / L In the organic solution, the pH value of the reactant is controlled to be 4 under normal pressure and 40° C., nitrogen is introduced, and stirred for 8 hours to obtain a black stable anatase-type self-doped titanium dioxide alcohol phase solution A. Add titanium sulfate dropwise to the organic solution mixed with oleylamine and n-hexane, stir and mix, then add a certain amount of deionized water and hydrolysis inhibitor, and finally add a zinc acetate organic solution with a molar concentration of 1.5mol / L. Stir at normal pressure and 40°C for 6 hours, and stir at 80°C for 2 hours. Then, argon gas is introduced to control the pH of the reactant to 4 to obtain a black stable B solution. Place the solution B with the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com