Nanometer semiconductor solar cell and preparation method thereof

A technology of solar cells and nano-semiconductors, applied in semiconductor/solid-state device manufacturing, semiconductor devices, circuits, etc., can solve the problems of low photoelectric conversion efficiency and large series resistance, etc., and achieve improved photoelectric conversion efficiency, small series resistance and energy consumption low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

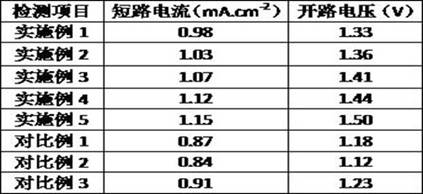

Examples

Embodiment 1

[0030] A nano-semiconductor solar cell and its preparation method, characterized in that it includes a planar electrode and a semiconductor battery slurry; the semiconductor battery slurry is made from the following components in parts by weight: 3 parts of conductive agent, heterogeneous 5 parts of doped inorganic semiconductor particles, 3 parts of organic semiconductor nanowires, 6 parts of film-forming substances, 0.8 parts of hyperbranched polyaniline modified carbon nanotubes, and 8 parts of solvent.

[0031] The solvent is a mixture formed by mixing isopropanol, ethanol, ethylene glycol, and hyperbranched polyglycerol at a mass ratio of 3:1:1:2; The method in embodiment 1 is made; Described film-forming substance is chitosan quaternary ammonium salt; The degree of substitution of described chitosan quaternary ammonium salt is 60%, and number average molecular weight is 80,000. The organic semiconductor nanowires are prepared according to the method of Example 1 in CN 10...

Embodiment 2

[0035] A nano-semiconductor solar cell and a preparation method thereof, characterized in that it includes a planar electrode and a semiconductor battery slurry; the semiconductor battery slurry is made of the following components in parts by weight: 3.5 parts of a conductive agent, a heterogeneous 6 parts of doped inorganic semiconductor particles, 3.5 parts of organic semiconductor nanowires, 7 parts of film-forming substances, 0.9 parts of hyperbranched polyaniline modified carbon nanotubes, and 9 parts of solvent.

[0036] The solvent is a mixture formed by mixing isopropanol, ethanol, ethylene glycol, and hyperbranched polyglycerol in a mass ratio of 3.5:1:1.2:2; The method in Example 1 is made; the film-forming substance is polyvinyl alcohol; the number average molecular weight of the polyvinyl alcohol is 1000; the organic semiconductor nanowire is made according to the method of Example 1 in CN 102738416 A .

[0037] The preparation method of the heterogeneously doped in...

Embodiment 3

[0040] A nano-semiconductor solar cell and its preparation method, characterized in that it includes a planar electrode and a semiconductor battery slurry; the semiconductor battery slurry is made of the following components in parts by weight: 4 parts of conductive agent, heterogeneous 6.5 parts of doped inorganic semiconductor particles, 4 parts of organic semiconductor nanowires, 8 parts of film-forming substances, 1.2 parts of hyperbranched polyaniline modified carbon nanotubes, and 11 parts of solvent.

[0041] The solvent is a mixture formed by mixing isopropanol, ethanol, ethylene glycol, and hyperbranched polyglycerol in a mass ratio of 4:1:1.5:2; The method in Example 1 is made; the film-forming substance is poly-N-methylpyrrolidone; the number-average molecular weight of the poly-N-methylpyrrolidone is 900; the organic semiconductor nanowire is implemented according to CN 102738416 A The method of example 1 is made.

[0042] The preparation method of the heterogeneo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com