Novel double-doped chalcogen superconducting material and preparation method thereof

A superconducting material, double-doped technology, applied in the field of new double-doped chalcogen superconducting materials and their preparation, can solve the problem of low superconducting temperature, and achieve the effect of uniform distribution, large size and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

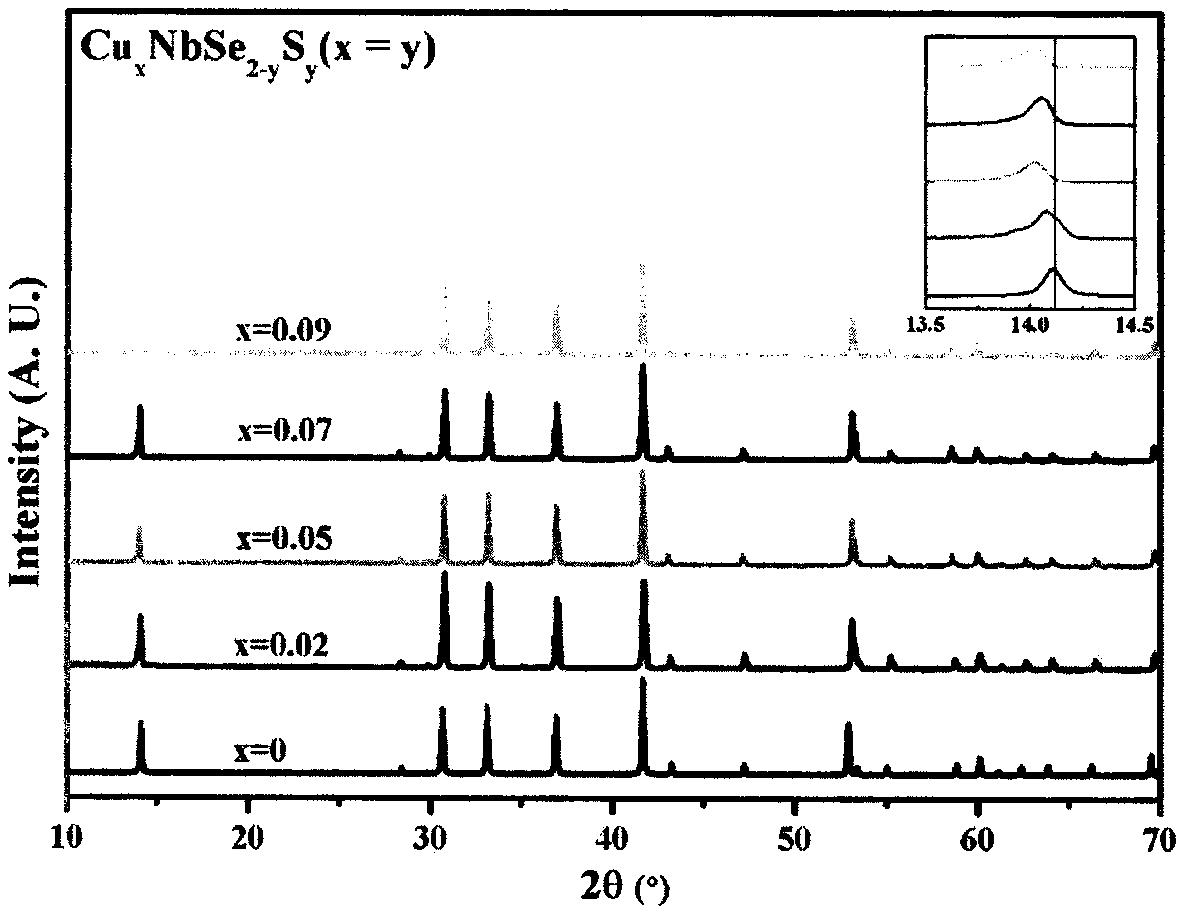

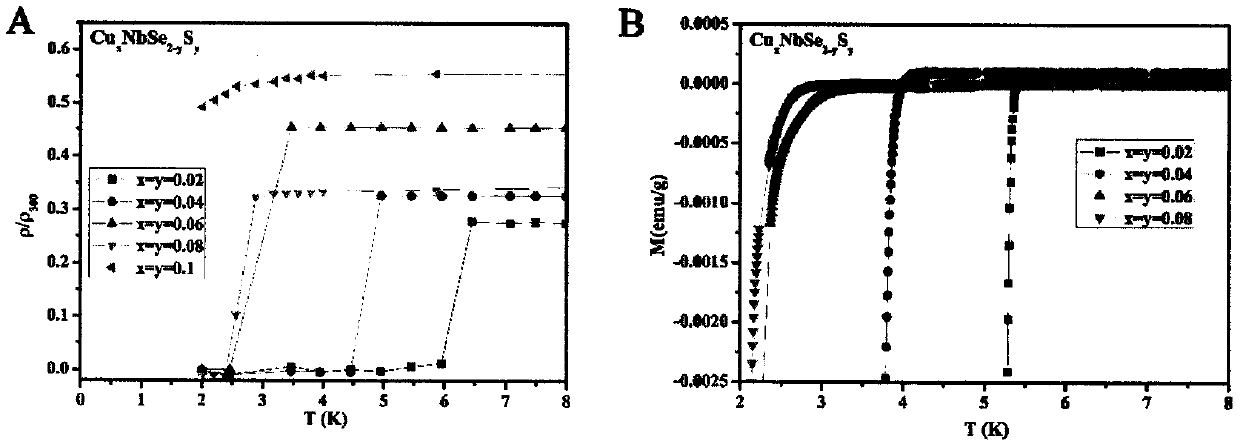

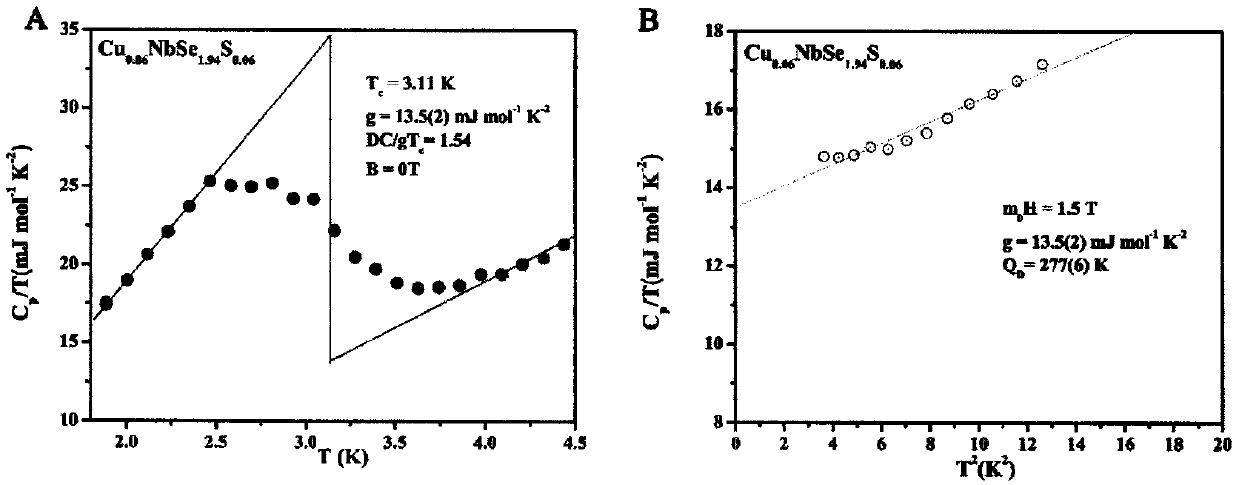

[0027] Accurately weigh 0.0025g Cu, 0.185g Nb, 0.3312g Se, and 0.0013g S and place them in a quartz tube. After fully grinding, evacuate to a vacuum of 1×10 under the vacuum line system. -5 Torr sealed the tube with an acetylene flame; then placed the sealed quartz tube in a muffle furnace at 850°C for four days, and then opened the quartz tube to fully grind the obtained powder to obtain Cu x NbSe 2-y S y (0≤x=y≤0.1) polycrystalline powder; then use X-ray powder diffraction (PXRD) to determine the purity of the respective component powders, feed into the quartz tube according to the polycrystalline powder and iodine elemental mass ratio 20:1, And pumped to a vacuum of 1×10 under the vacuum line system -5 Torr seals the tube with an acetylene flame; put the sealed quartz tube in a tube furnace with two temperature zones at 700°C and 600°C for one week, and slowly cool down to room temperature to obtain the single crystal material of each component ; Finally, the physical pr...

Embodiment 2

[0029] Accurately weigh 0.003g Cu, 0.1108g Nb, 0.1846g Se, and 0.0016g S and place them in a quartz tube. After fully grinding, pump them under the vacuum line system to a vacuum of 1×10 -5 Torr sealed the tube with an acetylene flame; then placed the sealed quartz tube in a muffle furnace at 850°C for four days, and then opened the quartz tube to fully grind the obtained powder to obtain Cu x NbSe 2-y S y (0≤x=y≤0.1) polycrystalline powder; then use X-ray powder diffraction (PXRD) to determine the purity of the respective component powders, feed into the quartz tube according to the polycrystalline powder and iodine elemental mass ratio 20:1, And pumped to a vacuum of 1×10 under the vacuum line system -5Torr seals the tube with an acetylene flame; put the sealed quartz tube in a tube furnace with two temperature zones at 700°C and 600°C for one week, and slowly cool down to room temperature to obtain the single crystal material of each component ; Finally, the physical pro...

Embodiment 3

[0031] Accurately weigh 0.0045g Cu, 0.1107g Nb, 0.1825g Se, and 0.0023g S and place them in a quartz tube. After fully grinding, pump them under the vacuum line system to a vacuum of 1×10 -5 Torr sealed the tube with an acetylene flame; then placed the sealed quartz tube in a muffle furnace at 850°C for four days, and then opened the quartz tube to fully grind the obtained powder to obtain Cu x NbSe 2-y S y (0≤x=y≤0.1) polycrystalline powder: then use X-ray powder diffraction (PXRD) to determine the purity of the respective component powders, then feed into the quartz tube according to the polycrystalline powder and iodine elemental mass ratio of 20:1, And pumped to a vacuum of 1×10 under the vacuum line system -5 Torr seals the tube with an acetylene flame; put the sealed quartz tube in a tube furnace with two temperature zones at 700°C and 600°C for one week, and slowly cool down to room temperature to obtain the single crystal material of each component ; Finally, the ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com