Preparation method of composite potassium monopersulfate and antibacterial application thereof in water treatment

A technology of potassium monopersulfate and compound salt, which is applied in botany equipment and methods, sterilization/microdynamic water/sewage treatment, application, etc., and can solve the problems of violent reaction, strict reaction conditions, and many by-products , to achieve the effect of simple production process, low requirements for preparation conditions and strong oxidation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

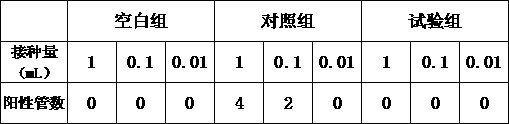

Examples

Embodiment 1

[0026] A preparation method of potassium monopersulfate composite salt, including the following steps:

[0027] Step a: Add 12.25 mL of 30wt% hydrogen peroxide into a 250ml three-necked flask with mechanical stirring and a thermometer, and use a low-temperature thermostat to control the temperature so that the temperature of the system reaches 0°C. Under 200r / min stirring conditions, the reaction 10.87 mL of 98wt% concentrated sulfuric acid was added dropwise to the vessel, the dropping time was 40 minutes, and the temperature was kept for 1 hour to obtain the peroxide reaction liquid;

[0028] Step b, controlling the temperature in the reactor to 8°C, adding 16.5852 g of potassium carbonate to the peroxidation reaction solution, and controlling the addition time to 60 minutes to obtain a neutralization reaction solution;

[0029] Step c: cooling the neutralization reaction solution to -4°C for crystallization, with a crystallization time of 12h, suction filtration, and drying at 55°...

Embodiment 2

[0031] A preparation method of potassium monopersulfate composite salt, including the following steps:

[0032] Step a: Add 12.25 mL of 30 wt% hydrogen peroxide into a 250ml three-necked flask with mechanical stirring and a thermometer, and use a low-temperature thermostat to control the temperature so that the system temperature reaches 0°C. Under 200r / min stirring conditions, 10.87 mL of 98wt% concentrated sulfuric acid was dropped into the reactor, the dropping time was 40 minutes, and the temperature was kept for 1 hour to obtain the peroxide reaction liquid;

[0033] Step b, controlling the temperature in the reactor to 8°C, adding 13.821 g of potassium carbonate to the peroxidation reaction solution, and controlling the addition time to 50 min to obtain a neutralization reaction solution;

[0034] Step c: Cooling the neutralization reaction solution to -8°C for crystallization, with a crystallization time of 13 hours, suction filtration, and drying at 55°C to obtain 10.6427g of...

Embodiment 3

[0036] A preparation method of potassium monopersulfate composite salt, including the following steps:

[0037] Step a: Add 10.28 mL of 30 wt% hydrogen peroxide into a 250ml three-necked flask with mechanical stirring and a thermometer, and use a low-temperature thermostat to control the temperature so that the temperature of the system reaches 8°C. Under 200r / min stirring conditions, 10.87 mL of 98wt% concentrated sulfuric acid was dropped into the reactor, the dropping time was 50 minutes, and the temperature was kept for 1 hour to obtain the peroxide reaction liquid;

[0038] Step b, controlling the temperature in the reactor to 8°C, adding 16.5852 g of potassium carbonate to the peroxidation reaction solution, and controlling the addition time to 70 minutes to obtain a neutralization reaction solution;

[0039] Step c, cooling the neutralization reaction solution to -8°C for crystallization, with a crystallization time of 12 hours, suction filtration, and drying at 50°C to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com