Building energy-saving thermal insulation material and preparation method thereof

A thermal insulation material and building energy-saving technology, applied in the field of building materials, can solve the problems of lignocellulose flame retardant effect and aging resistance performance, mechanical properties and thermal insulation performance need to be further improved, to achieve freeze-thaw resistance and reliable High performance, low device dependence, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

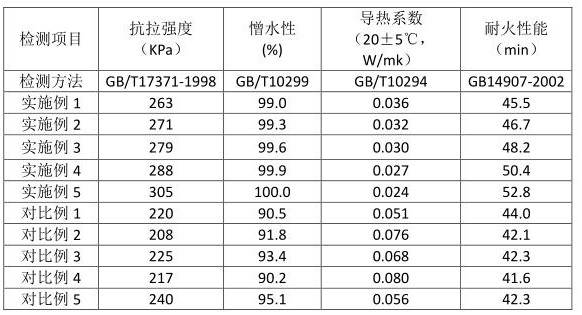

Examples

Embodiment 1

[0031] Embodiment 1 provides a building energy-saving thermal insulation material, which is characterized in that it is made of the following raw materials in parts by weight: 15 parts of cement, 15 parts of blast furnace slag, 35 parts of pozzolan, surface function modified porous hollow alumina nanofibers 5 parts, 2 parts of rare earth fluoride hollow nano-ion, 3 parts of permethrin modified aminated aminated β-cyclodextrin, 1 part of coupling agent; the coupling agent is silane coupling agent KH550.

[0032] The preparation method of the permethrin-modified aminated β-cyclodextrin comprises the following steps: hepta(6-amino-6-deoxy)beta-cyclodextrin (CAS: 30754-24-6) 1. Permethrin is added to the organic solvent, stirred and reacted at 40°C for 6 hours, and then the solvent is removed by rotary evaporation to obtain permethrin modified aminated aminated β-cyclodextrin; the seven (6-amino The mass ratio of -6-deoxy)beta-cyclodextrin, permethrin, and organic solvent is 1:0.2...

Embodiment 2

[0037] Embodiment 2 provides a building energy-saving thermal insulation material, which is characterized in that it is made of the following raw materials in parts by weight: 18 parts of cement, 17 parts of blast furnace slag, 36 parts of pozzolan, surface function modified porous hollow alumina nanofibers 6 parts, 2.5 parts of rare earth fluoride hollow nano-ion, 4 parts of permethrin modified aminated aminated β-cyclodextrin, 1.5 parts of coupling agent; the coupling agent is silane coupling agent KH560.

[0038] The preparation method of the permethrin-modified aminated β-cyclodextrin comprises the following steps: hepta(6-amino-6-deoxy)beta-cyclodextrin (CAS: 30754-24-6) 1. Permethrin is added to the organic solvent, stirred and reacted at 45°C for 6.5 hours, and then the solvent is removed by rotary evaporation to obtain the modified aminated β-cyclodextrin of permethrin; the seven (6-amino The mass ratio of -6-deoxy)beta-cyclodextrin, permethrin, and organic solvent is ...

Embodiment 3

[0043] Embodiment 3 provides a building energy-saving thermal insulation material, which is characterized in that it is made of the following raw materials in parts by weight: 20 parts of cement, 17.5 parts of blast furnace slag, 38 parts of pozzolan, surface function modified porous hollow alumina nanofibers 6.5 parts, 3 parts of rare earth fluoride hollow nano-ion, 4.5 parts of permethrin modified aminated aminated β-cyclodextrin, 2 parts of coupling agent; the coupling agent is silane coupling agent KH570.

[0044] The preparation method of the permethrin-modified aminated β-cyclodextrin comprises the following steps: hepta(6-amino-6-deoxy)beta-cyclodextrin (CAS: 30754-24-6) 1. Permethrin is added to the organic solvent, stirred and reacted at 50°C for 7 hours, and then the solvent is removed by rotary evaporation to obtain the modified aminated β-cyclodextrin of permethrin; the seven (6-amino The mass ratio of -6-deoxy)beta-cyclodextrin, permethrin, and organic solvent is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com