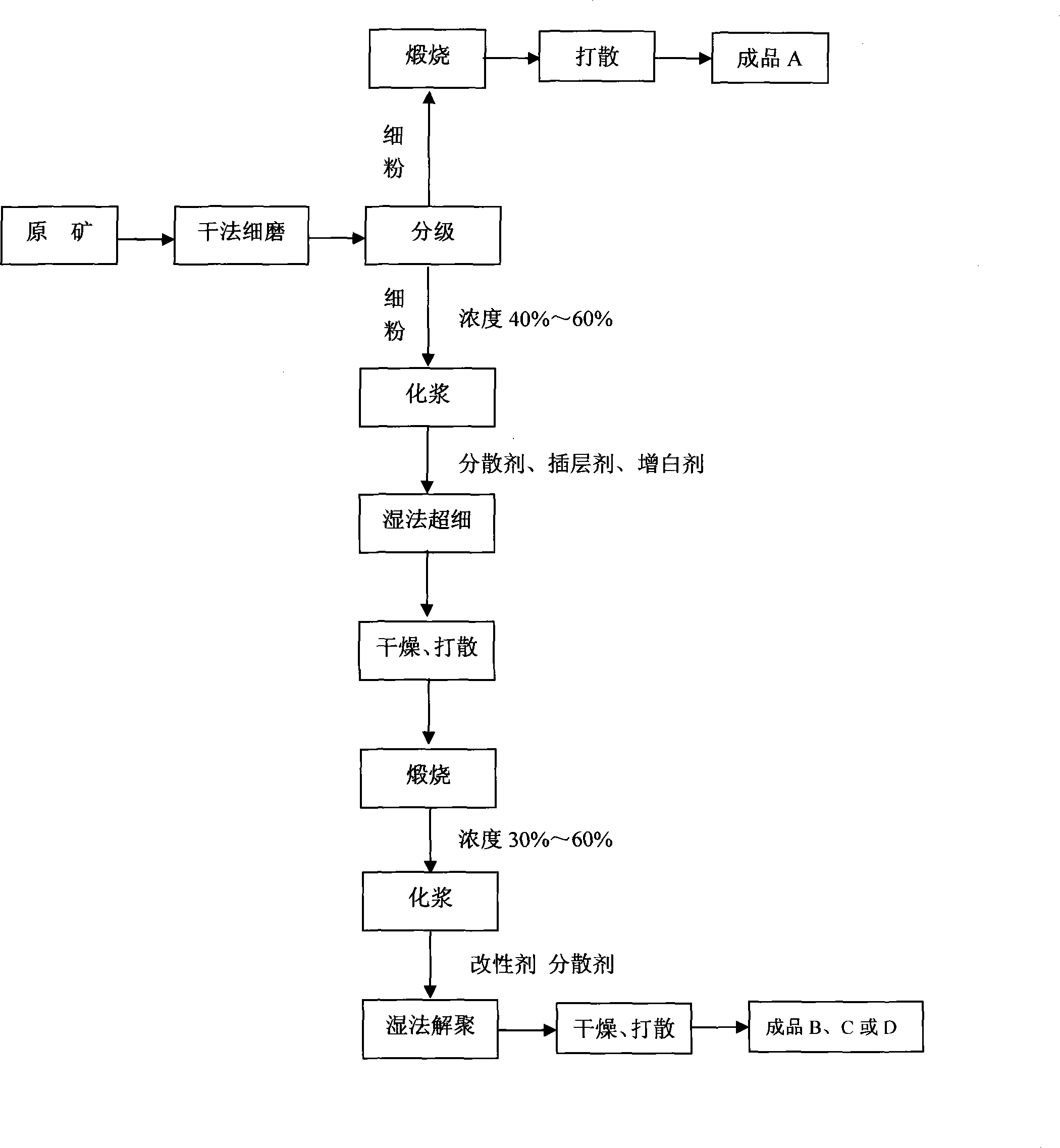

Method for producing ultra-fine calcination white bole with combination of dry and wet method

A technology of calcined kaolin and dry-wet combination, which is applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of inability to guarantee the calcined whiteness of products, inability to solve product calcined agglomeration, poor stability and adaptability, etc., to achieve The effect of shortening the production process, broadening product performance, and reducing modification costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The coal series kaolin in Wuhai area of Inner Mongolia is selected as the raw material. Grind the raw materials into 600-mesh powder. After the particles are classified, the kaolin powder above 1250 mesh is directly fed into the rotary kiln for calcination to become a product. The kaolin powder below 1250 mesh is processed in the following order:

[0024] a. Add dispersant, intercalation agent and whitening agent according to the weight ratio of kaolin powder:

[0025] Dispersant: sodium hexametaphosphate, the addition amount is 2%;

[0026] Intercalation agent: urea and ammonium acetate are mixed in a weight ratio of 5:1, and the addition amount is 2%;

[0027] Whitening agent: potassium chloride, the addition amount is 2%;

[0028] Prepare a slurry with a water content of 40%;

[0029] b. Grinding for 10 minutes;

[0030] c. The slurry is dried and scattered and sent to the rotary kiln for calcination, the calcination temperature is 950-960°C, and the calcinatio...

Embodiment 2

[0034] The coal series kaolin in Wuhai area of Inner Mongolia is selected as the raw material. Grind the raw materials into 6000-mesh powder. After the particles are classified, the kaolin powder above 1250 mesh is directly sent to the rotary kiln for calcination to become a product. The kaolin powder below 1250 mesh is processed in the following order:

[0035] a. Add dispersant, intercalation agent and whitening agent according to the weight ratio of kaolin powder:

[0036] Dispersant sodium hexametaphosphate, the addition amount is 0.1%;

[0037] The intercalation agent urea and ammonium acetate are mixed in a weight ratio of 1:5, and the addition amount is 0.1%;

[0038] Whitening agent: sodium chloride, the addition amount is 0.1%;

[0039] Prepare a slurry with a water content of 60%;

[0040] b. Grinding for 150 minutes;

[0041] c. The slurry is dried and dispersed and sent to the rotary kiln for calcination, the calcination temperature is 950-960°C, and the calc...

Embodiment 3

[0045] The coal series kaolin in Wuhai area of Inner Mongolia is selected as the raw material. The raw materials are ground into 2000-mesh powder, and after the particles are classified, the kaolin powder above 1250 mesh is directly sent to the rotary kiln for calcination to become a product, and the kaolin powder below 1250 mesh is processed in the following order:

[0046] a. Add according to the weight ratio of kaolin powder:

[0047] Dispersant sodium polyacrylate, the addition amount is 1%;

[0048] Prepare a slurry with a water content of 50%;

[0049] b. Grinding for 50 minutes;

[0050] c. The slurry is dried and scattered and sent to the rotary kiln for calcination, the calcination temperature is 800°C, and the calcination time is 80 minutes;

[0051] d. Put the calcined kaolin into the pulper, add water and stir to make a slurry with a water content of 40%; at the same time, add 0.8% of sodium polyacrylate as a dispersant and 2% of silane as a surface modifier; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com