Production process method for machine-made sand aggregate

A production process and sand aggregate technology, applied in the field of machine-made sand aggregate production process, to achieve the effects of reliable sealing, moderate water volume and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

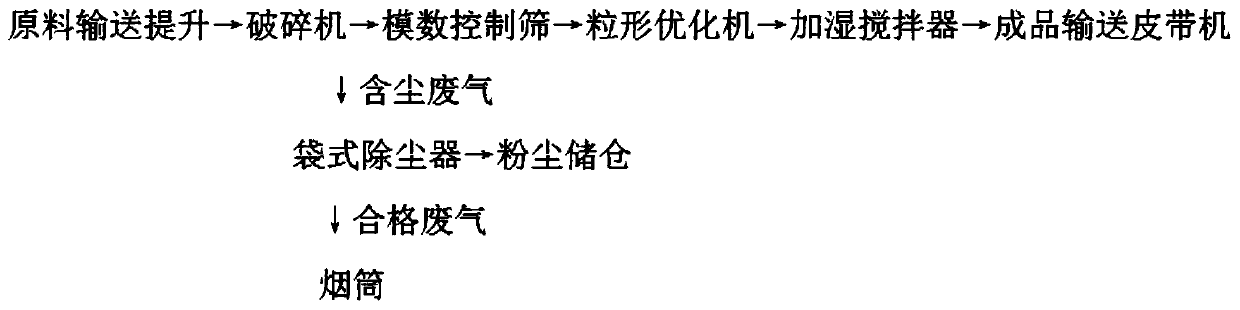

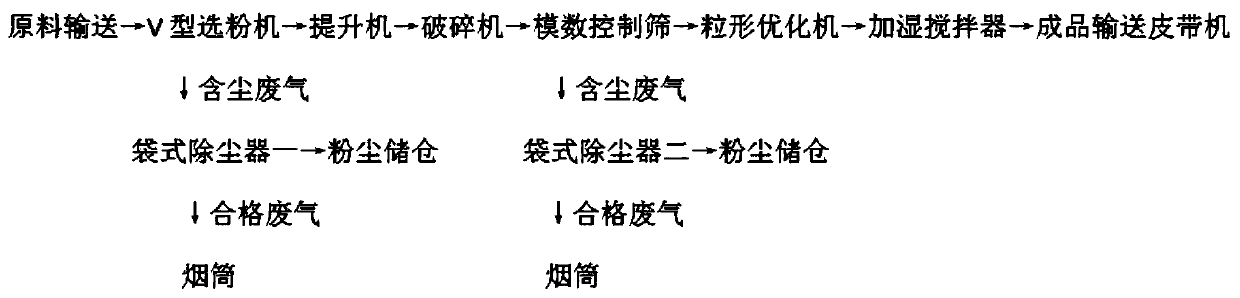

[0039] as attached figure 2 Shown, machine-made sand aggregate production process method of the present invention, the method steps are as follows:

[0040] S1. Transport the raw materials to the V-type powder separator for powder selection to obtain pretreated raw materials; the powder selection process of the V-type powder separator is as follows:

[0041] S101, V-type powder classifier The position of the outlet of the lower body of the powder separator is equipped with a grinding and shaping device. The grinding and shaping device includes a movable shaft, a rubbing block and a rubbing ring, and the rubbing block and the rubbing ring are installed through the movable shaft. The relative extrusion movement between them realizes rubbing and shaping the materials passing through the outlet of the lower body, and produces a retreat buffer for the passing materials to prevent excessive wear of materials and equipment damage caused by forced extrusion;

[0042] S102. The size ...

Embodiment 2

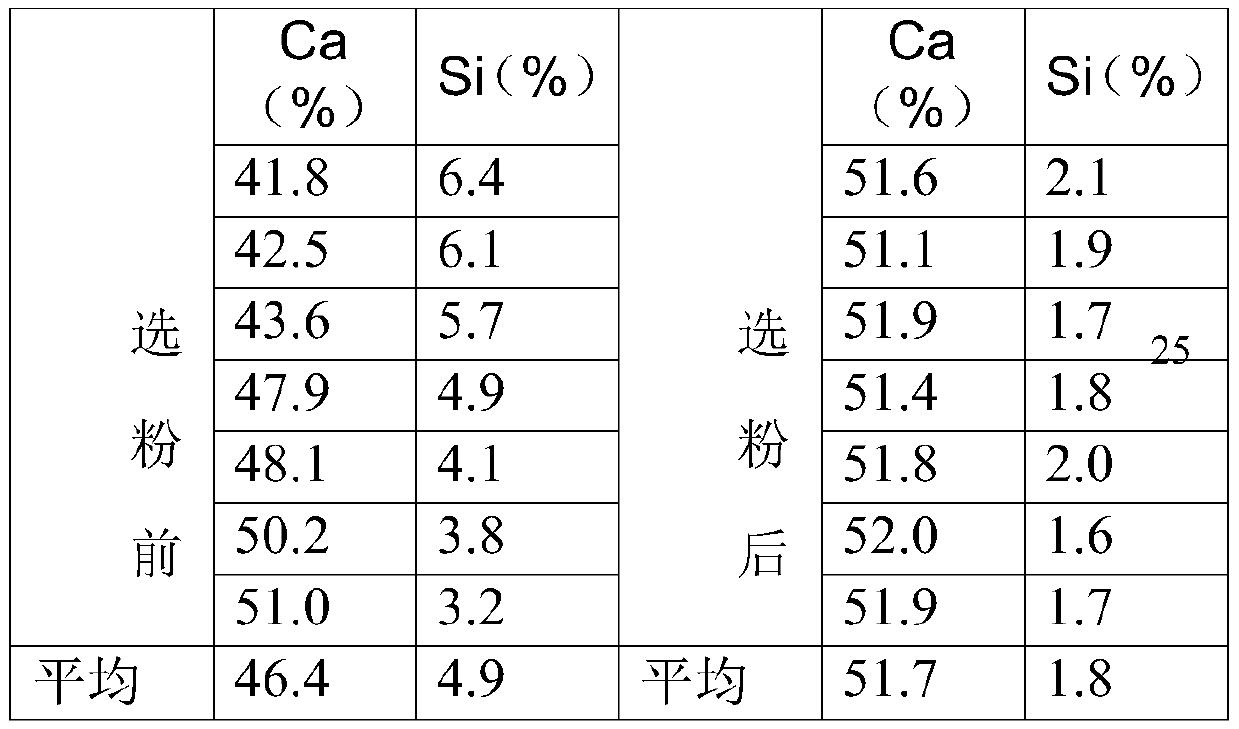

[0053] The quality of limestone raw materials determines the quality of machine-made sand, especially when the clay content is high, resulting in increased water demand for concrete and mortar, large plastic shrinkage, and cracking of components. After the limestone mixture is selected by the V-type powder classifier, the quality has been greatly improved and stabilized after repeated tests and comparisons.

[0054] Comparison of Ca (limestone) and Si (clay) content before and after powder selection:

[0055]

[0056] It can be seen from the table that after the powder selection process, the clay content of the product is significantly reduced, which not only increases the output of the machine-made sand aggregate, but also improves the quality of the machine-made sand aggregate.

[0057] In addition, the machine-made sand produced by the traditional process is not good in shape, with sharp edges and corners, rough surface, too many needles and flakes, a large fineness modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com