A friction electrification test device

A test device and friction electrification technology, applied in the direction of measuring device, adopting mechanical device, measuring electric variable, etc., to achieve the effect of easy manufacture, high experimental precision and accurate test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

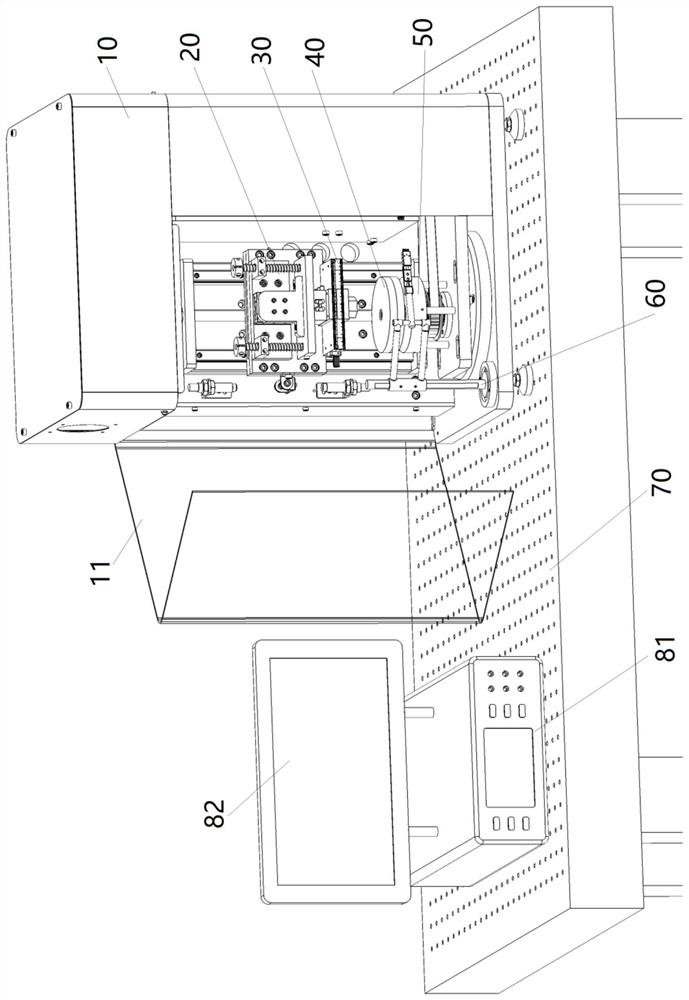

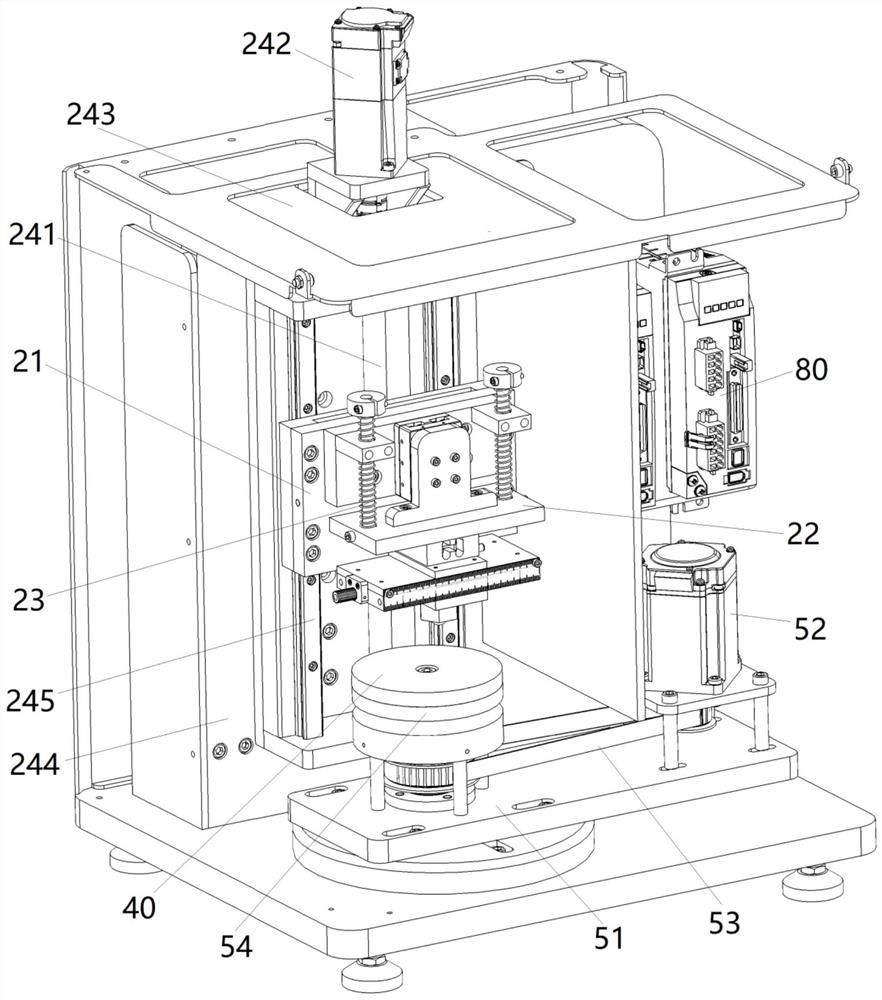

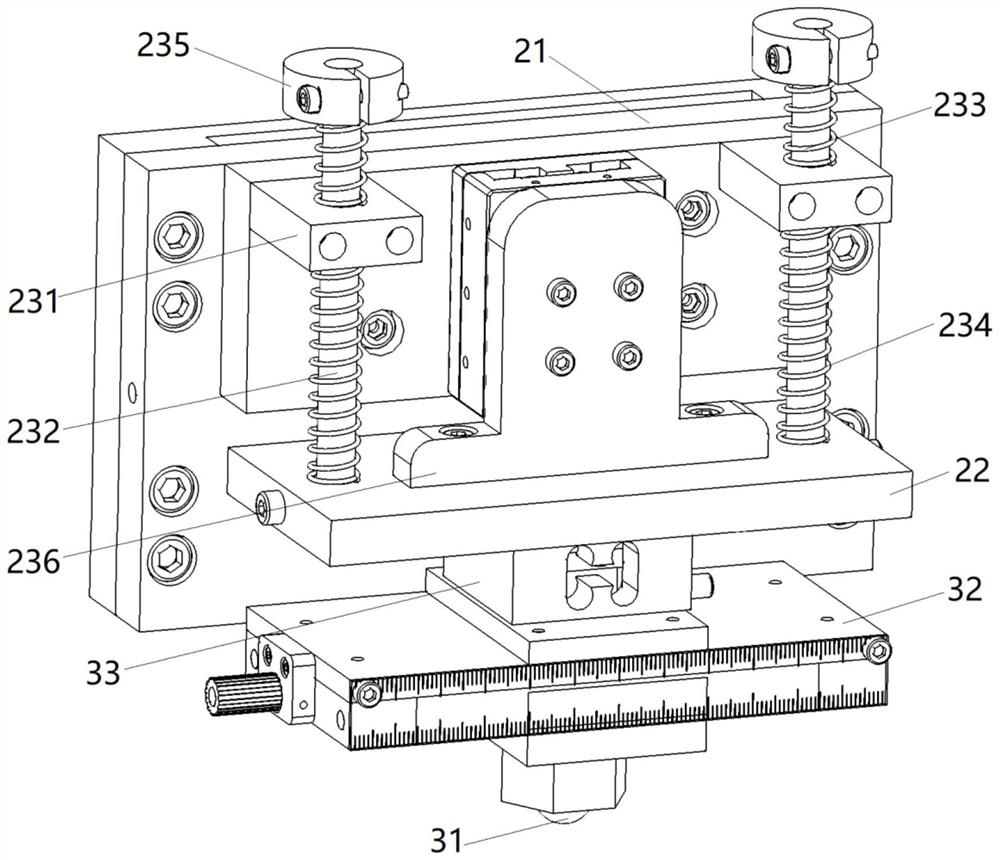

[0025] see Figure 1 to Figure 6 , a kind of triboelectrification test device described in the present invention, comprises test box 10 and the loading mechanism 20 that is located in test box 10, upper sample clamp 30, lower sample 40, rotating mechanism 50 and electric measuring clamping mechanism 60. The entire test device is installed on the vibration-absorbing workbench 70. The test box 10 is used for internally installing a cooling fan and improving human-computer interaction. The loading mechanism 20 includes a vertical loading plate 21 and a horizontal loading plate 22 , and the vertical loading plate 21 is arranged in the test box 10 so as to be movable up and down. The vertical loading plate 21 and the horizontal loading plate 22 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com