Method for recycling wastes of high-temperature alloy powder

A superalloy and scrap recycling technology, applied in the field of superalloy powder recycling, can solve the problems of large elastic after-effect, mold deformation and damage, and achieve the effects of low hardness, low cost and fast forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

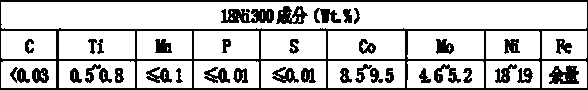

[0019] This embodiment provides a waste recovery method of 18Ni300 superalloy powder. The nominal composition of 18Ni300 superalloy powder is as follows:

[0020] Table 1

[0021]

[0022] Firstly, 18Ni300 is sieved, and the powder with a particle size between 15μm and 53μm is sieved and recovered. The powder with a particle size less than 15μm and a particle size greater than 53μm is 18Ni300 waste.

[0023] Then, the scrap of 18Ni300 and the iron powder with a particle size of less than 75μm (the pure metal powder of the base of 18Ni300) are mixed uniformly in a weight ratio of 8:2 to obtain the first powder mixture.

[0024] Select a single mold to produce a mold with a diameter of Φ40mm and a height of 20mm, and a press with a pressure of 315 tons to mold the first powder mixture at a pressing rate of 4 times / min.

[0025] Then, according to the composition requirements in Table 1, other components other than iron powder are added to the above-mentioned compression-molded first powde...

Embodiment approach 2

[0028] This embodiment provides a waste recovery method of the superalloy powder of the brand CoCrW. The nominal composition of the superalloy powder of the brand CoCrW is shown in Table 2:

[0029] Table 2

[0030]

[0031] First, the CoCrW superalloy powder is sieved, and the powders with a particle size between 15μm and 53μm are sieved and recovered. The powders with a particle size less than 15μm and a particle size greater than 53μm are the waste of CoCrW superalloy powder.

[0032] Then, the scrap of 18Ni300 superalloy powder and cobalt powder (the pure metal powder of the base of CoCrW superalloy powder) with a particle size of less than 150 μm are uniformly mixed in a weight ratio of 9:1 to obtain a first powder mixture.

[0033] Select a single mold to produce a mold with a diameter of Φ40mm and a height of 20mm, and a 315-ton pressure press to mold the first powder mixture at a pressing rate of 6 times / min.

[0034] Then, in accordance with the composition requirements in Tabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com