Sand making machine capable of adjusting sand granularity

A sand making machine and sand grain technology, which is applied in the field of sand making machines that can adjust the sand grain size, can solve the problems of large sand grain size, uneven and fine sand grains, etc., and achieve the effect of uniform sand grains, simple structure, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

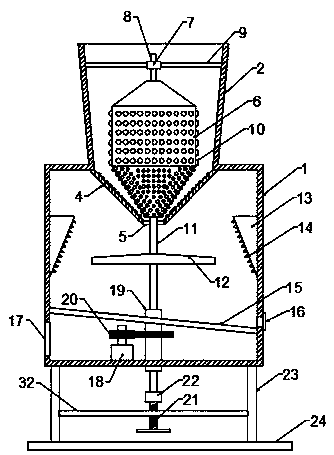

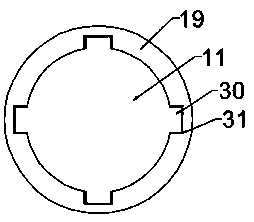

[0021] see Figure 1~3 , in an embodiment of the present invention, a sand making machine that can adjust the sand particle size includes a sand making cylinder 1 and a feeding cylinder 2, and the feeding cylinder 2 is arranged on the upper end of the sand making cylinder 1 and the lower end is connected to the The inside of the sand cylinder 1 is connected, and the diameter of the feed cylinder 2 gradually decreases from top to bottom. The inside of the feed cylinder 2 is provided with a grinding cylinder 6 that coincides with its axis, and the bottom end of the grinding cylinder 6 is fixed. A rotating shaft 11 coaxial with it is connected, and the lower end of the rotating shaft 11 passes through the bottom wall of the sand making cylinder 1, and the outer side of the lower end of the rotating shaft 11 is provided with a rotating sleeve 19, and the outer wall of the rotating sleeve 19 Rotation is installed on the bottom wall of the sand making cylinder 1, and the inner wall ...

Embodiment 2

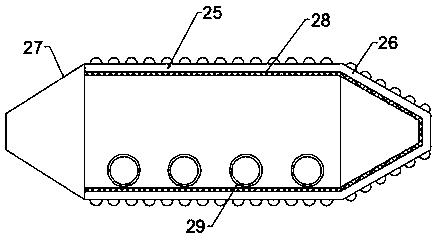

[0025] This embodiment differs from Embodiment 1 in that: the cylinder 25 and the grinding column head 26 are both hollow, and elastic pads 28 are attached to the inside, and a plurality of impact balls 29 are arranged inside the cylinder 25. When the grinding column When the body 6 rotates, the impact balls 29 collide with each other on the side wall of the cylinder 25 and the grinding column head 26, thereby preventing the sand particles from being adsorbed on the outer side wall of the grinding column 6. The fastening mechanism of the cylinder 6, the fastening mechanism includes a guide rod 8 fixed on the top of the grinding cylinder 6, the outer wall of the guide rod 8 is rotatably connected with a plurality of 9, and the other end of the fixed connecting rod 9 is fixed to the feeding cylinder On the side wall of the body 2, the stable rotation of the grinding cylinder 6 can be ensured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com