Temperature-controllable rotating pulverized coal combustion system integrating powder making, storage and supply

A technology of combustion system and powder storage, applied in combustion methods, combustion equipment, block/powder supply/distribution, etc., can solve the problem that the powder storage tank cannot meet the requirements of use, safety measures are difficult to achieve, and the project cost is high problems, to achieve the effect of increased safety factor, convenient control, and reliable combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

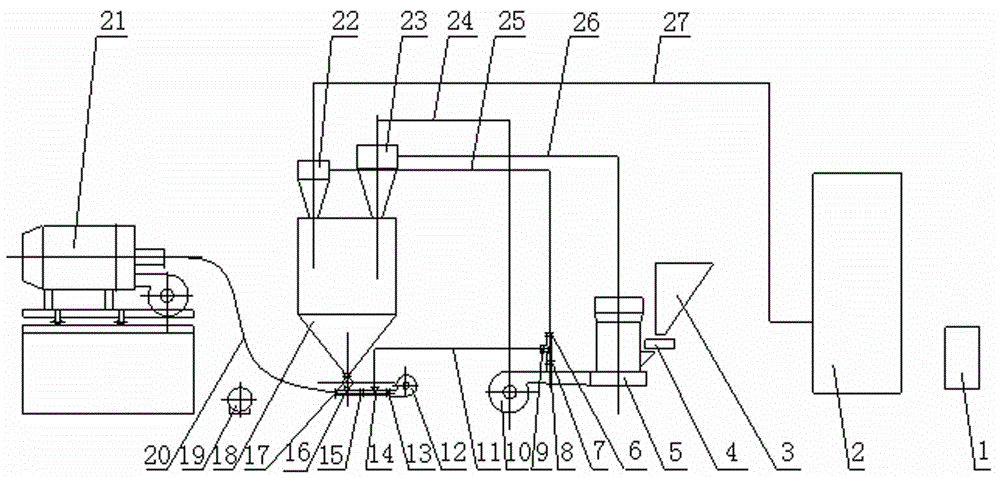

[0011] The structure of the temperature-controllable rotary pulverized coal combustion system of the present invention, which integrates pulverization, storage and supply of pulverized coal, will be described in detail below in conjunction with the accompanying drawings.

[0012] see figure 1 , the structure of the present invention, which integrates pulverization, storage and powder supply, and a temperature-controllable rotary pulverized coal combustion system includes a pulverizer 5, a powder storage tank 18 and a burner 21, and the furnace of the burner 21 is a rotary furnace, so Ensure reliable combustion, high efficiency and not easy to slagging. An analyzer is arranged above the pulverizer 5, and the pulverizer 5 grinds the lump coal into coal powder. The particle size and output of the pulverized coal can be controlled by adjusting the speed of the analyzer on the upper part of the pulverizer 5. The cover of the pulverizer 5 There is a feed hopper on the side of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com