Smoke and dust control system in coke oven carbonization chamber based on gas separation and recovery

A recovery system and carbonization chamber technology, applied in coke ovens, furnaces to prevent/remove fouling, energy input, etc., can solve the problems of increasing wastewater treatment costs, subsequent blockage of related units, environmental pollution, etc., to reduce the difficulty of wastewater treatment and cost, reduction of smoke or fire, and reduction of explosion accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

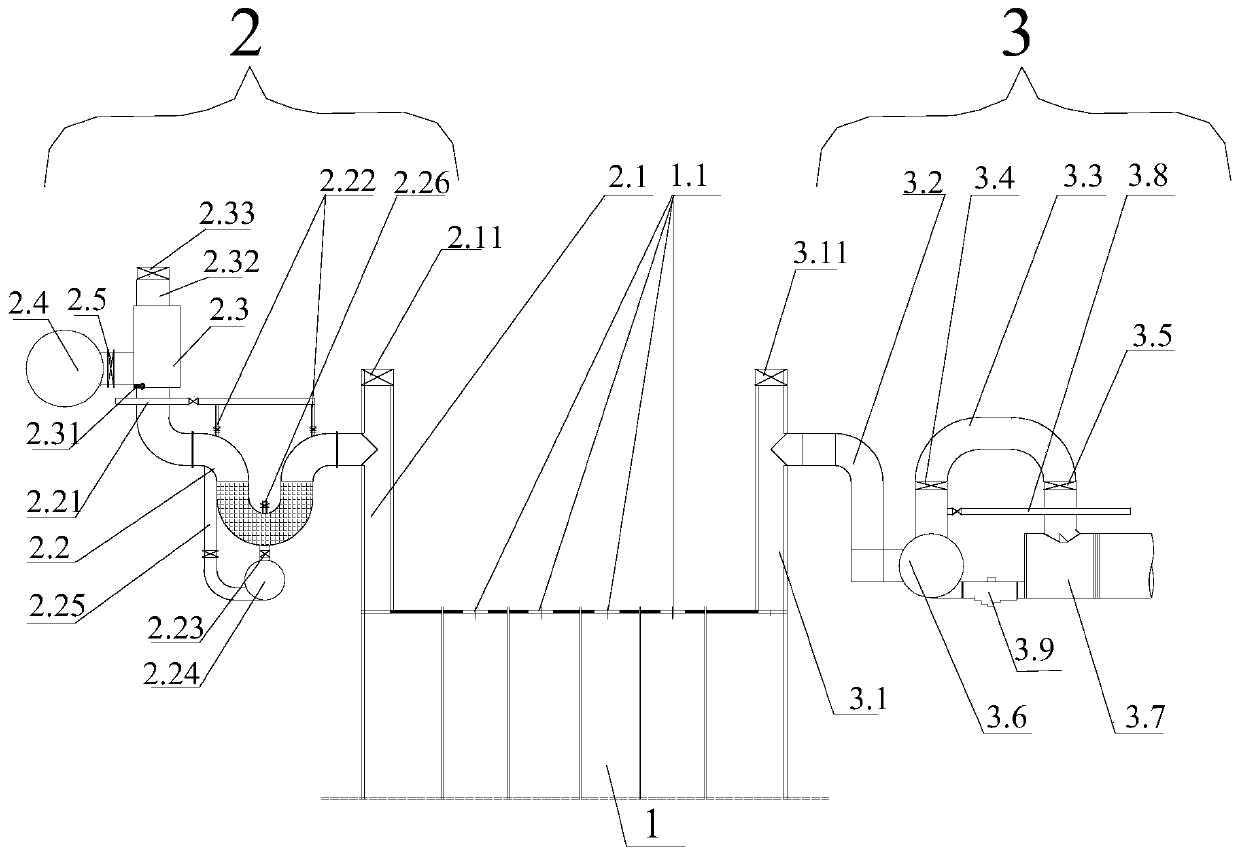

[0060] Each coke oven of the present invention includes several coke oven carbonization chambers and coke oven combustion chambers, and the coke oven carbonization chambers and coke oven combustion chambers are distributed alternately, ensuring that a A coke oven combustion chamber; and each coke oven coking chamber is equipped with a coke-side coal-charging soot recovery system and a machine-side coke oven gas recovery system.

[0061] Such as figure 1 As shown, this embodiment discloses a coke oven carbonization chamber smoke and dust treatment system based on gas separation and recovery, which includes a coke oven carbonization chamber 1 and a coke side coal charging dust recovery system respectively arranged on the coke side of the coke oven carbonization chamber 1 2 and the machine-side coke oven gas recovery system 3 on the machine side, the top of the coke oven carbonization chamber 1 is provided with several coal charging holes 1.1 for adding coking coal to the coke ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com