Carburant granulation system for comprehensive utilization of fine powder of coal calcination furnace

A technology of carburizing agent and coal furnace, which is applied in the direction of mold extrusion granulation, dryer, lighting and heating equipment, etc., can solve the problems of waste heat waste, difficult processing and utilization of pulverized coal, serious dust in the factory area, etc. The effect of improving the amount of powder, improving the utilization rate of waste heat and improving economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In this patent, "raw coal" refers to the coal bought back from upstream enterprises to be processed into calcined coal or carburant.

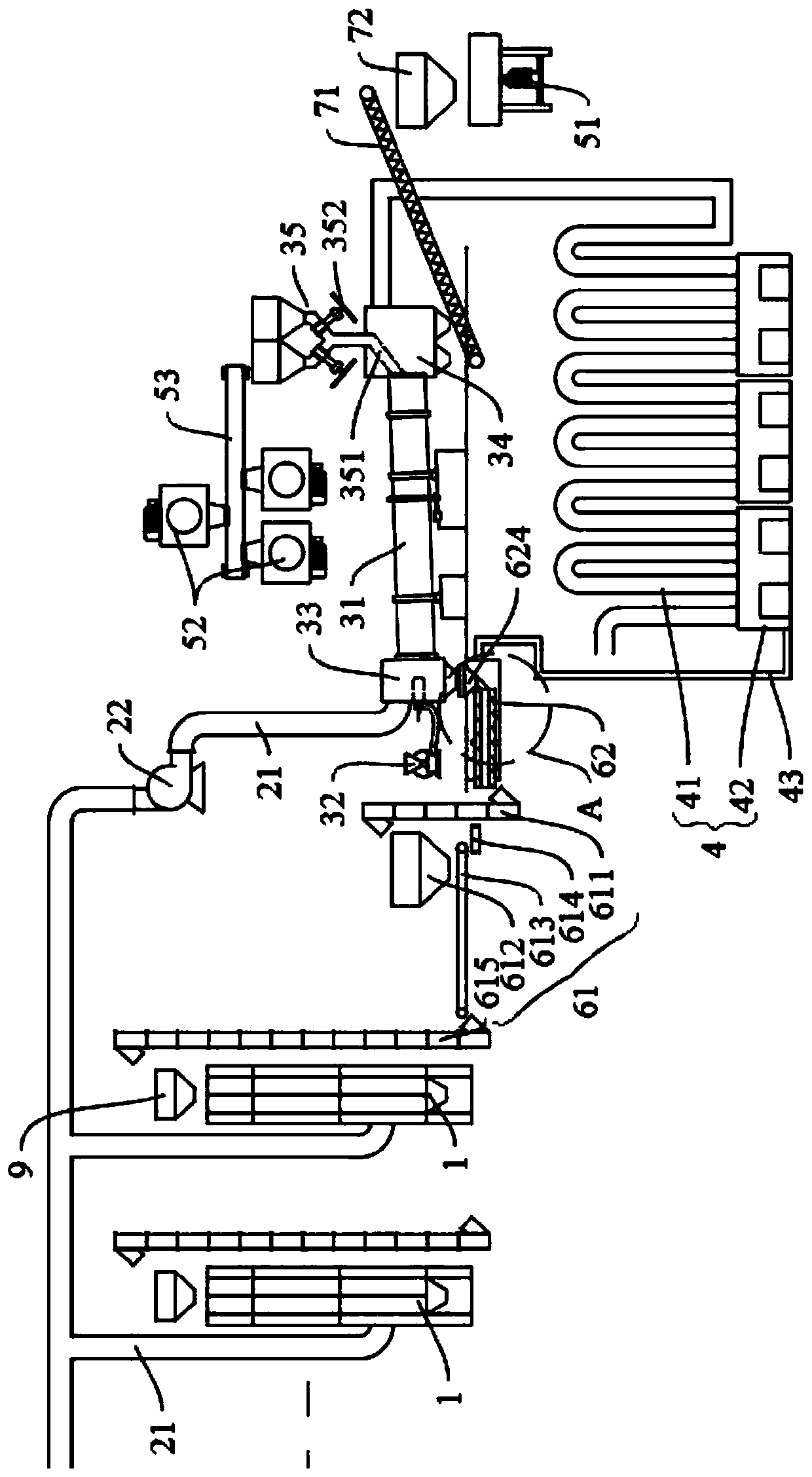

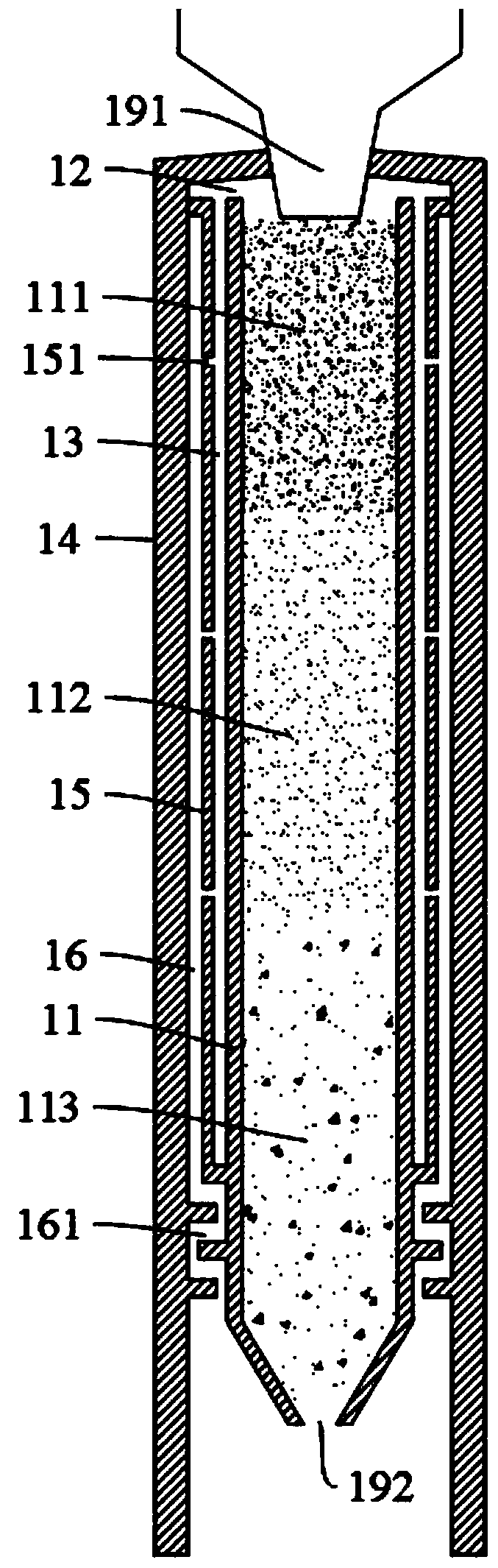

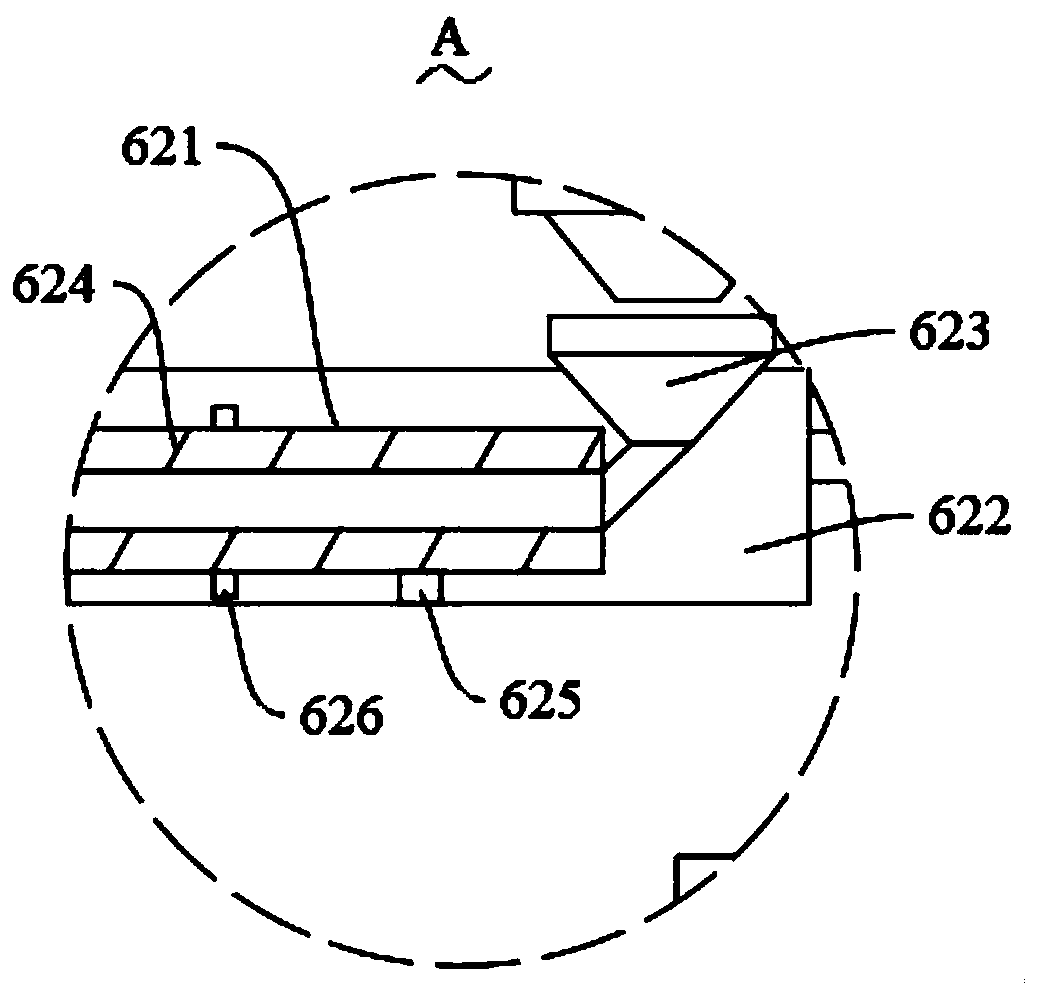

[0024] as attached Figure 1~3As shown, a carburant granulation system that comprehensively utilizes coal calciner fine powder includes: coal calciner 1, heat preservation pipe 21, high temperature fan 22, rotary kiln 31, pulverized coal burner 32, discharge room 33, Settling chamber 34, drying material bin 35, surface cooler 4, mixer 51, granulator 52, first feeding device 61, water-cooled feeding device 62, second feeding device 53, third feeding device 71, granulation raw material warehouse 72; wherein, the exhaust port of calciner 1 is connected to the rotary kiln 31 through the heat preservation pipe 21 through the high-temperature fan 22 and the discharge room 33, and the discharge port of the rotary kiln 31 is connected to a wall of the discharge room 33 by sealing and rotating , the other wall opposite to the wall is connected w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com