Boiler device with wall fitted burner for preventing water-cooled wall corroded by high-temp and slagging scorification

A technology for high-temperature corrosion and boiler equipment, which is applied to the combustion of block fuels and liquid fuels, the combustion of block fuels and gaseous fuels, the combustion of liquid fuels and gaseous fuels, etc. Slag and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

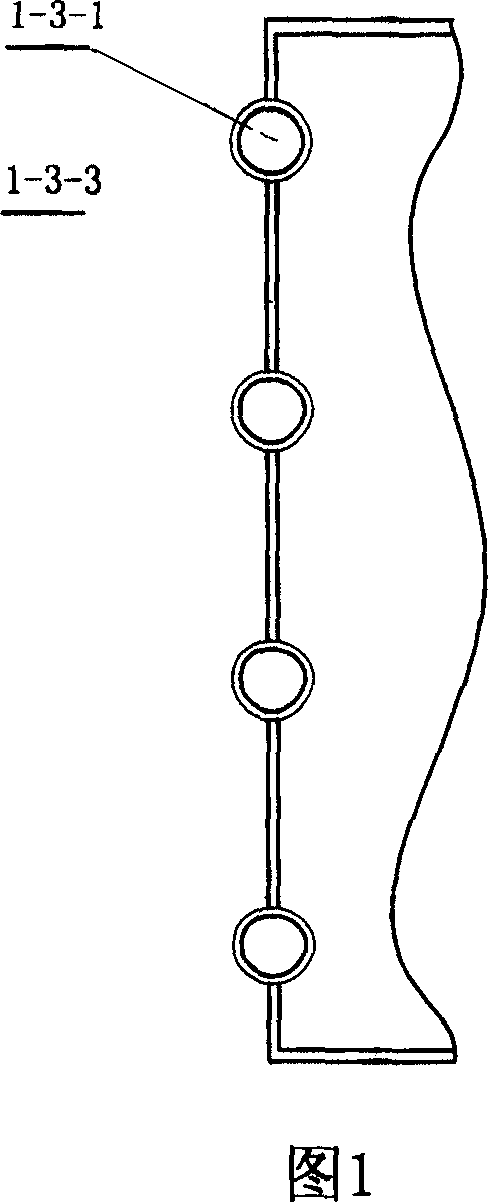

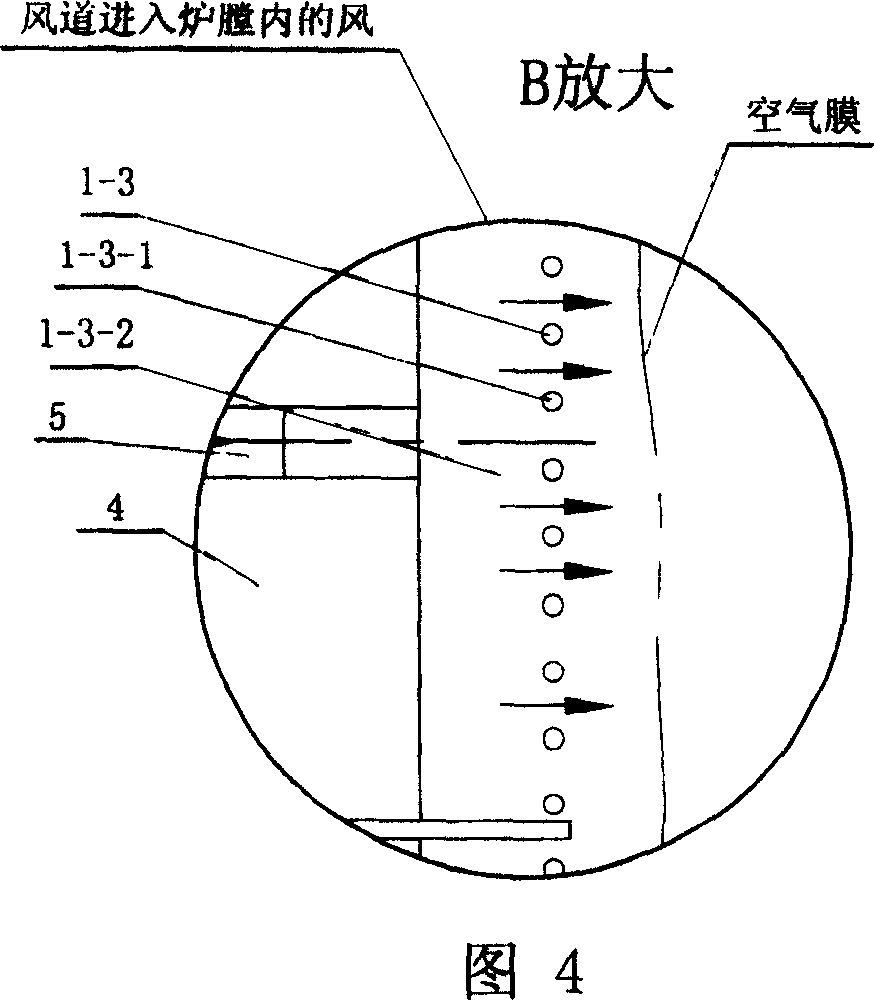

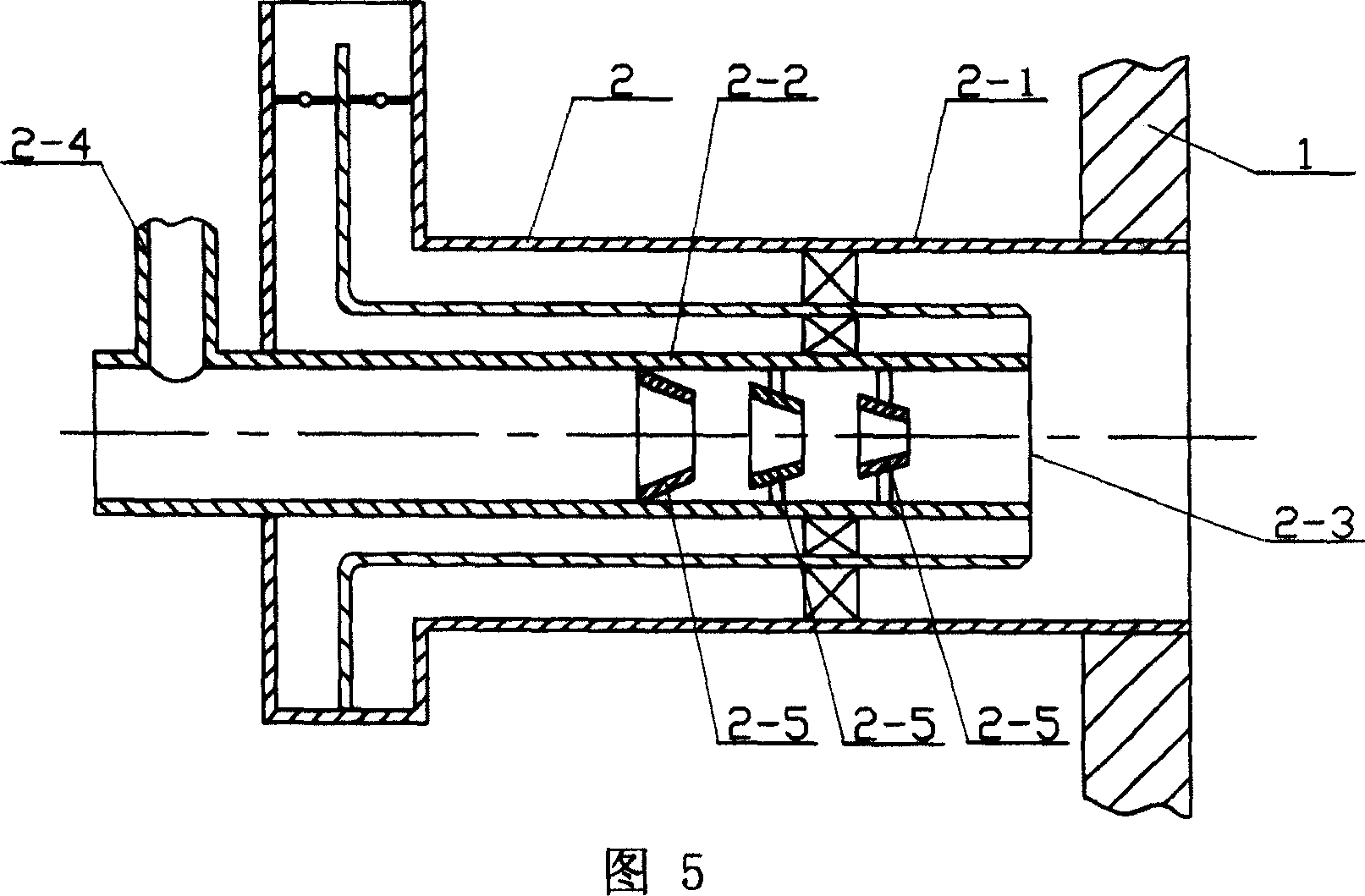

[0005] Specific Embodiment 1: Referring to Fig. 1 and Fig. 2, this embodiment prevents high-temperature corrosion and slagging of the water-cooled wall. The wall 1-1, the rear wall 1-2, and the side wall 1-3 are composed of the water cooling wall composed of the water cooling wall tube 1-3-1 and the fin 1-3-3 closely connected. The side walls 1-3 communicate with the secondary air duct 7 through the wall-mounted wind box 4, the air duct 5 connecting the wall-mounted wind box 4 and the secondary air duct 7, and the fins on the side walls 1-3 1-3-3 Remove forming gap 1-3-2. On the two side walls 1-3, a wall-mounted wind box 4 is installed, and the wall-mounted wind box 4 communicates with the air duct 5, and the other end of the air duct 5 is arranged in the secondary air duct 7, and a hot air damper is installed on the air duct 5 5-1. Four flue gas composition online samplers 6 are installed in the boiler burner area of the furnace body 1. When the flue gas composition on bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com