Method for preparing aerogel by supercritical drying method and device for supercritical drying

A technology of supercritical drying and airgel, which is applied in the direction of dry gas arrangement, aerosol preparation, chemical instruments and methods, etc., can solve the problem that the uniformity of pore structure distribution is not enough, the structural strength of airgel, the drying efficiency and separation efficiency, and the inability to Directly obtain airgel and other issues to achieve the effect of enhanced supercritical chemical reaction structure, high separation efficiency and fluid recovery efficiency, and high pore structure strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

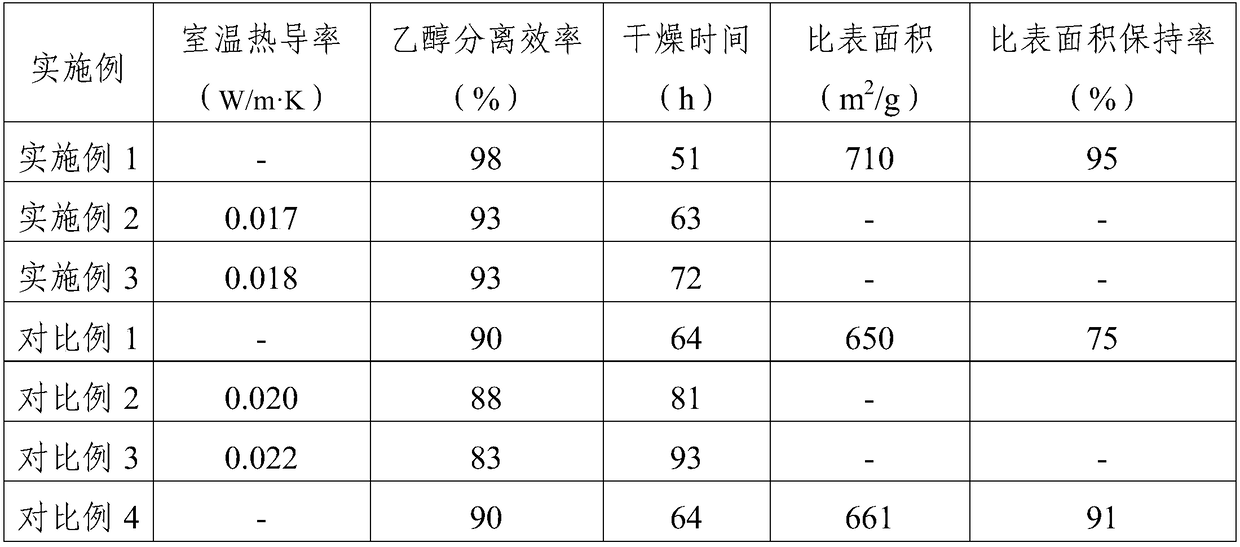

[0084] Embodiment 1: the preparation of airgel material

[0085] Add ethanol solution (40% by volume) of tetraethyl orthosilicate to the preparation container, then add water, add ammonia water (1mol / L) and ammonium fluoride aqueous solution (0.1mol / L) dropwise while stirring, and start gelation reaction. Wherein, the molar ratio of substances is tetraethyl orthosilicate: water: ammonia water: ammonium fluoride = 100:400:1:1, after mixing evenly, continue stirring for 5 minutes to obtain a sol.

[0086] At room temperature, the gel continued to age for 1 day, after which the mold was removed, the wet gel was taken out, and solvent replacement was performed in absolute ethanol. Change the ethanol every 48 hours until the water content in the ethanol is lower than 1% as measured by a Karl Fischer moisture titrator.

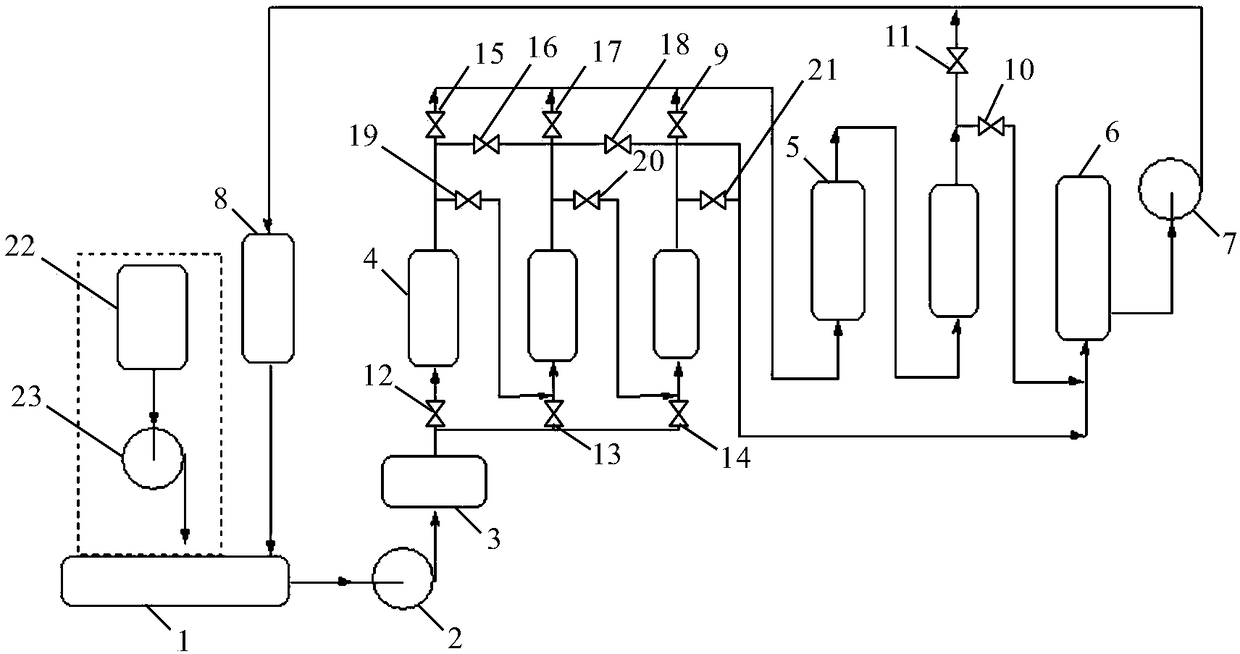

[0087] Put the wet gel that has completed the solvent replacement into the drying kettle, and adopt the method as in the present invention figure 1 The device st...

Embodiment 2

[0090] Embodiment 2: Preparation of glass wool reinforced airgel composite

[0091] Embodiment 2 is substantially the same as embodiment 1, and the difference is: the impregnated bulk density is 0.1g / cm with the obtained sol 3 glass wool felt. Put the glass wool felt into the mold cavity first, then slowly add the above solution into the mold cavity to make the glass wool felt absorb the sol. After the glass wool felt is soaked in the sol, close the mold. After gelling at room temperature, a glass wool felt-reinforced silica wet gel is obtained.

[0092] At room temperature, the wet gel was further aged for 1 day, and then the mold was removed, and the wet gel was taken out, and put into absolute ethanol for solvent replacement. Change the ethanol every 48 hours until the water content in the ethanol is lower than 1% as measured by a Karl Fischer moisture titrator.

[0093] The glass wool felt-reinforced silica wet gel that has undergone solvent replacement is dried with s...

Embodiment 3

[0098] Example 3: Preparation of Basalt Wool Reinforced Airgel Composite

[0099] Spread the cut basalt wool into the corresponding mold cavity and close the mold. Inject 0.2MPa helium into the mold and ensure that the airtightness is intact.

[0100] Add ethanol solution (40% by volume) of tetraethyl orthosilicate to the preparation container, then add water, add ammonia water (1mol / L) and ammonium fluoride aqueous solution (0.1mol / L) dropwise while stirring, and start gelation reaction. Wherein, the molar ratio of substances is tetraethyl orthosilicate: water: ammonia water: ammonium fluoride = 100:400:1:1, after mixing evenly, continue stirring for 5 minutes to obtain a sol.

[0101] Connect the pressure injection device, put the prepared sol into the pressure tank, turn on the helium source and slowly increase it to 0.2MPa, then slowly open the injection valve and keep the glue outlet valve closed, and start pressure injection. The device is disassembled, and the presse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com