Patents

Literature

42 results about "Aerosol powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous slurry material containing silicon dioxide aerosol, preparation method and application thereof

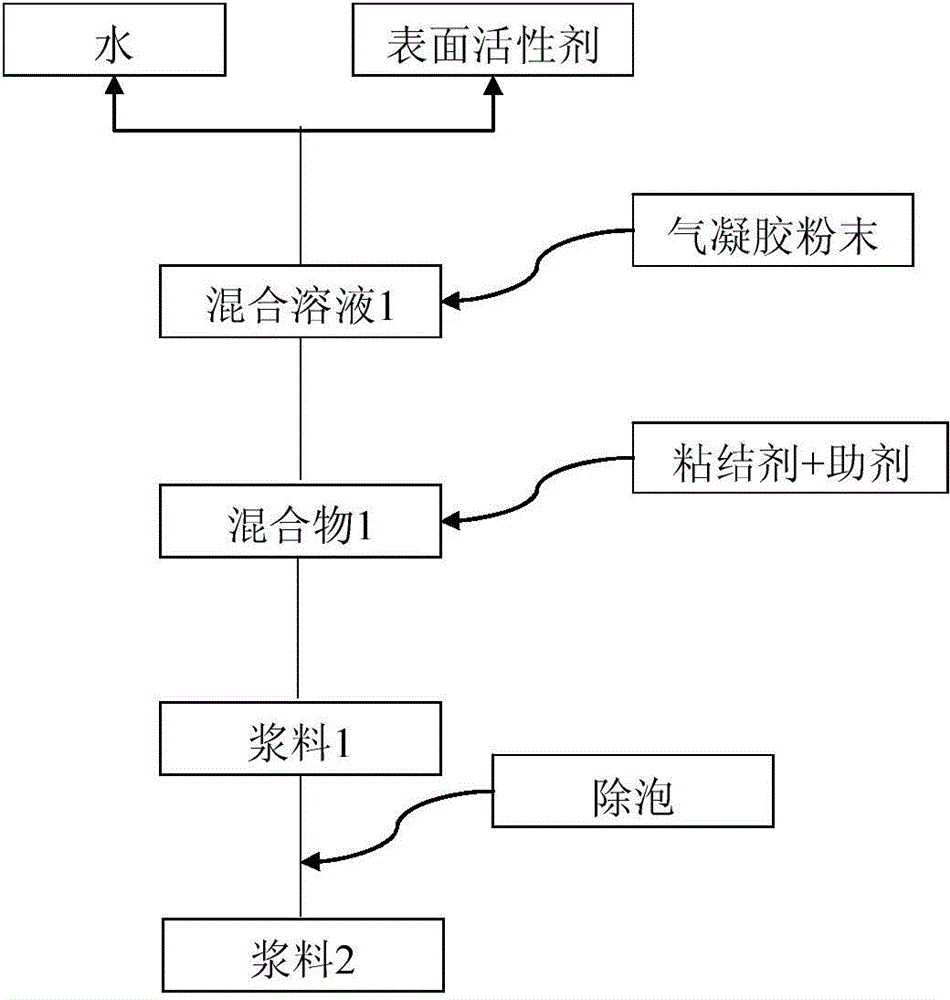

The invention discloses an aqueous slurry material containing silicon dioxide aerosol, a preparation method and an application thereof. The aqueous slurry material is a stable dispersion system formed by uniformly mixing silicon dioxide aerosol powder, a surfactant, a bonding agent and water. The preparation method includes following steps: mixing water with the surfactant uniformly, adding the aerosol powder and mixing the mixture uniformly to obtain a suspension liquid, and adding the bonding agent and adding or not adding an additive, and uniformly mixing the mixture to obtain the aqueous slurry material. The aqueous slurry material is free of asbestos and other harmful fiber materials, is convenient to transport and construct, is free of cutting and can be easily controlled in thickness of a produced heat-insulating material, can be used through an optimized construction scheme freely, is simple in preparation process and low in cost, and is suitable for large-scale industrial production. The aqueous slurry material can be used for coating the surface of a base material and can form a coating after drying, which is flat in surface, is excellent in heat-insulating performance and is strong in bonding force, and also can be mixed with other structural materials to prepare an aqueous composite material.

Owner:苏州同玄新材料有限公司

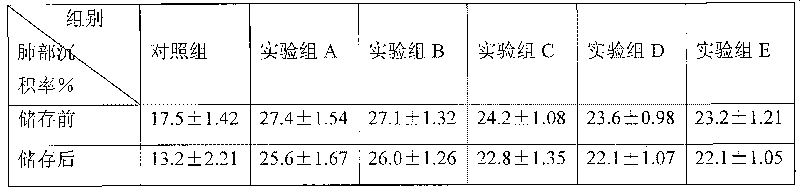

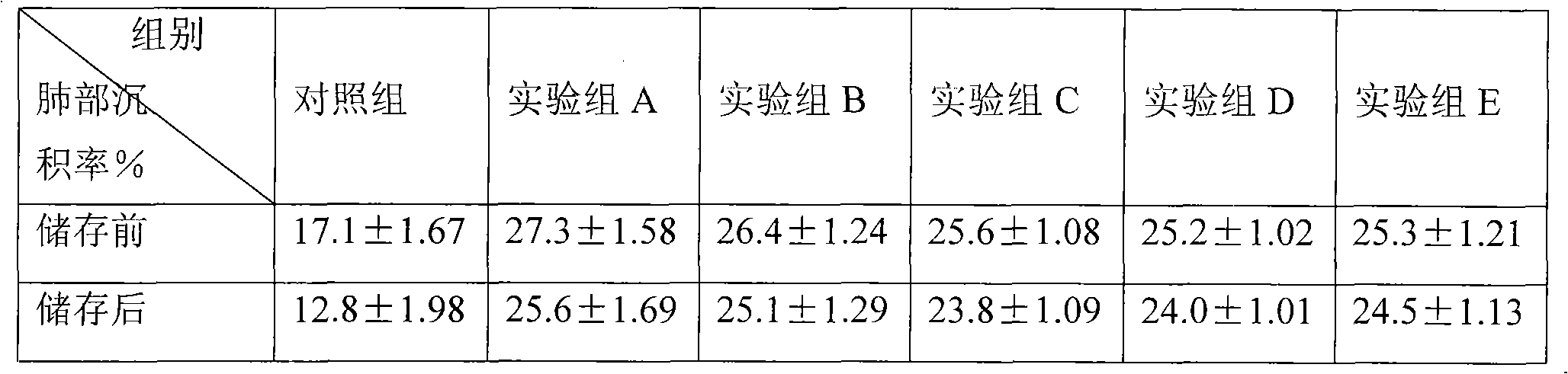

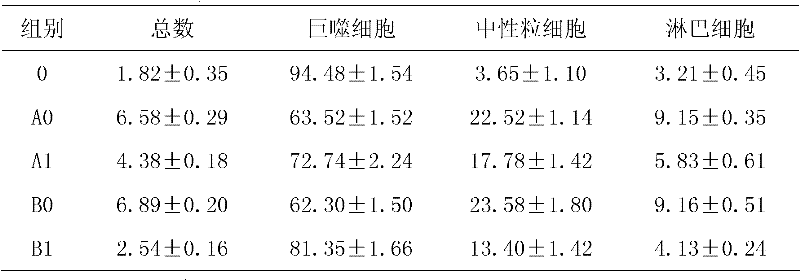

Oral lung inhalation aerosol powder

ActiveCN101756942ALittle side effectsReduce dosagePharmaceutical delivery mechanismPharmaceutical non-active ingredientsMedicineBULK ACTIVE INGREDIENT

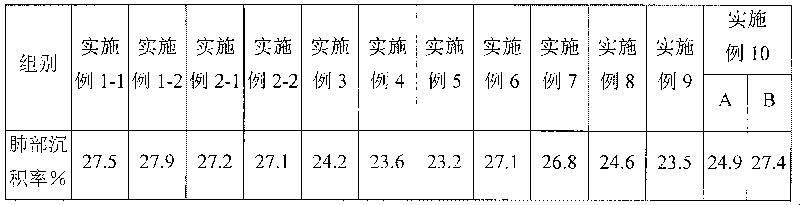

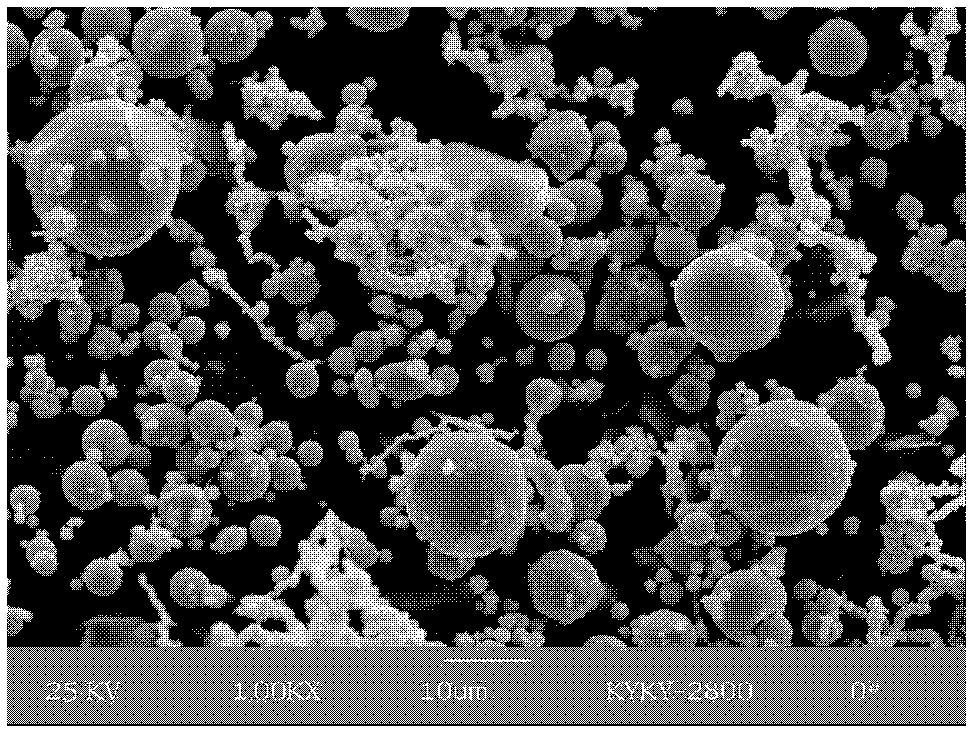

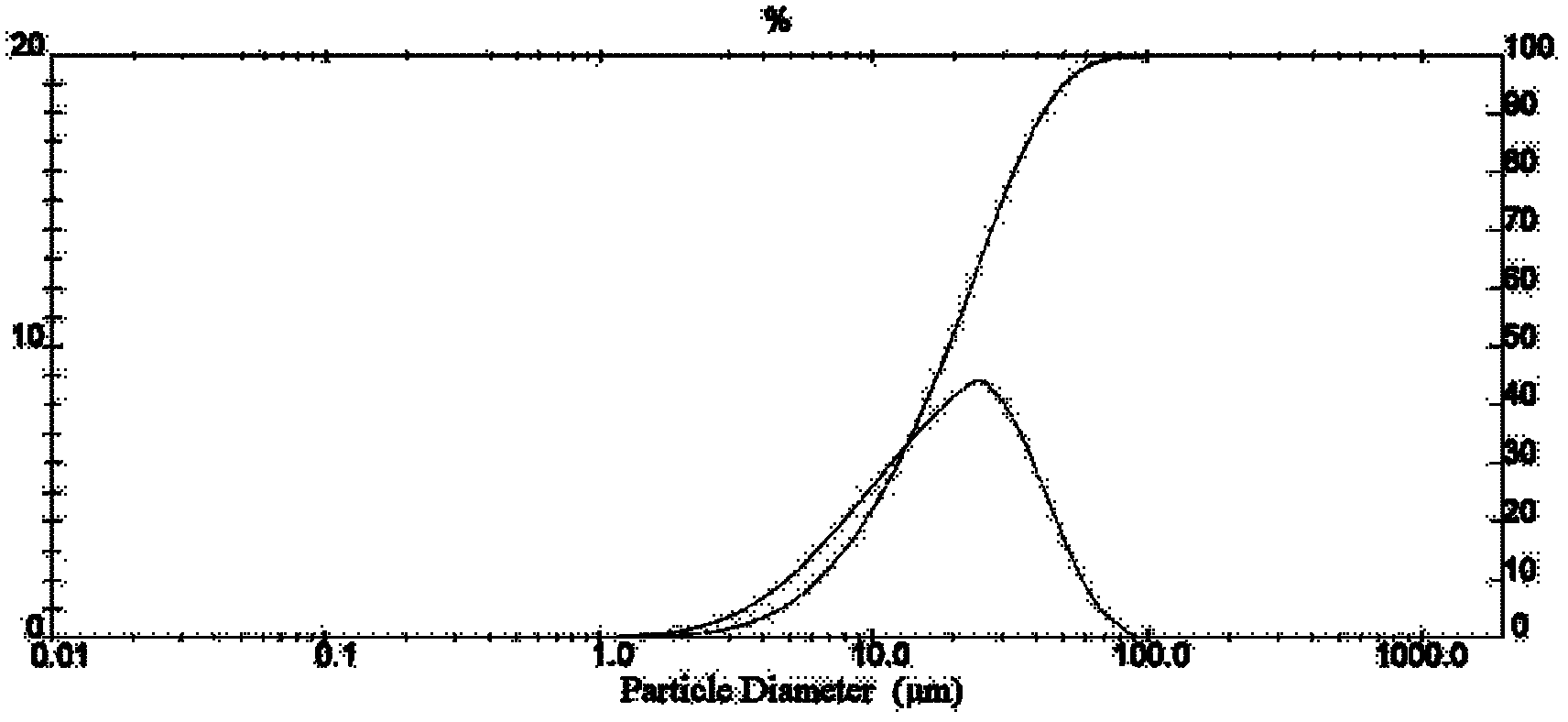

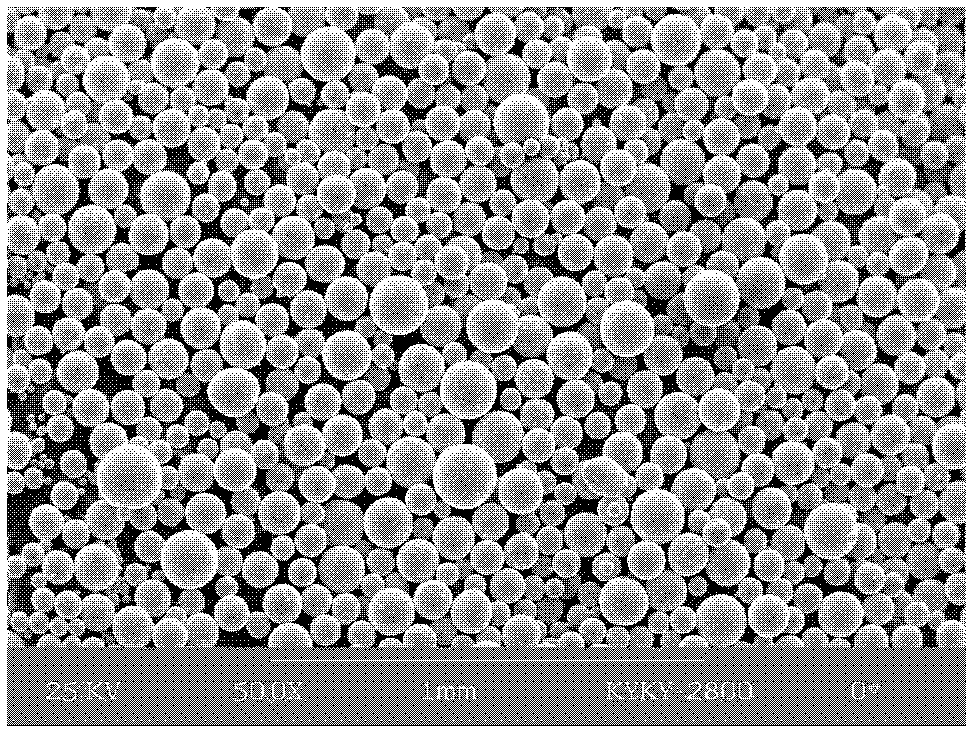

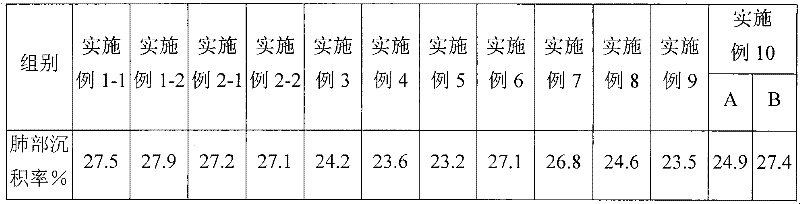

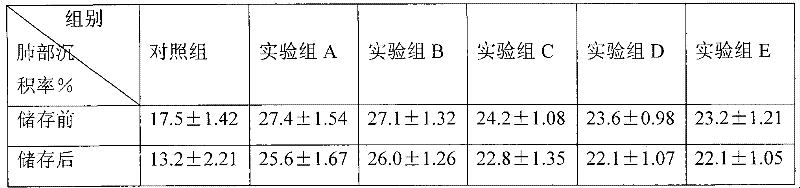

The invention discloses an oral lung inhalation aerosol powder, which can improve the lung deposition rate of active ingredients of the aerosol powder, avoid the deposition of carrier micropowder in the lung, and increase the stability of the composition. The oral lung inhalation aerosol powder consists of the active ingredients and the carrier micropowder. The oral lung inhalation aerosol powder is characterized in that: the mean grain size of the micropowder of the active ingredients is between 0.5 and 10 mu m, and the mean grain size of the carrier micropowder is between 20 and 45 mu m.

Owner:TIANJIN JINYAO GRP

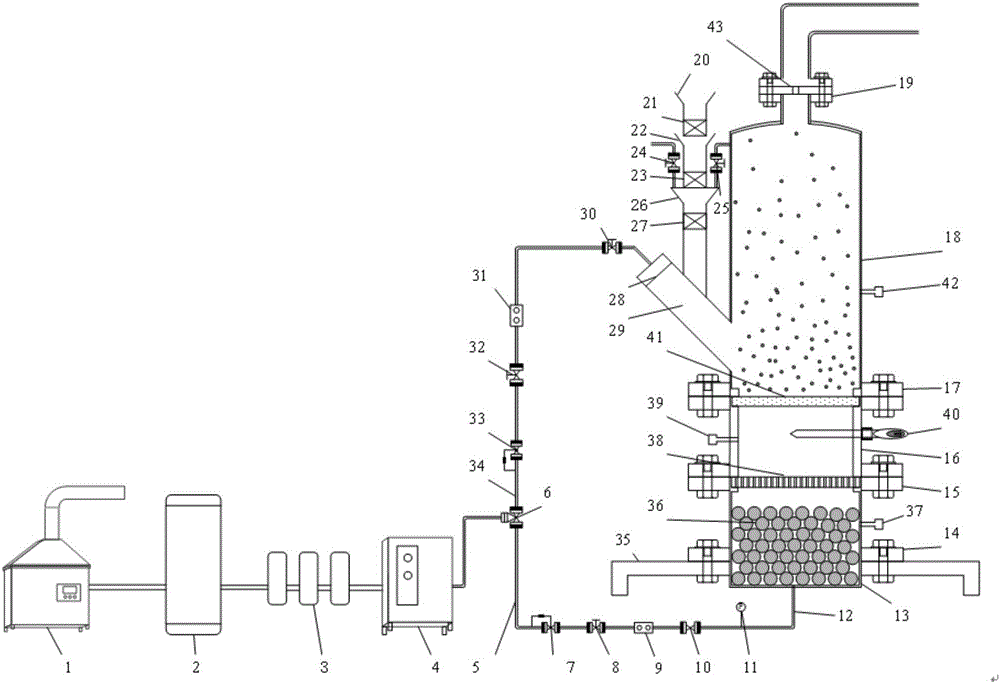

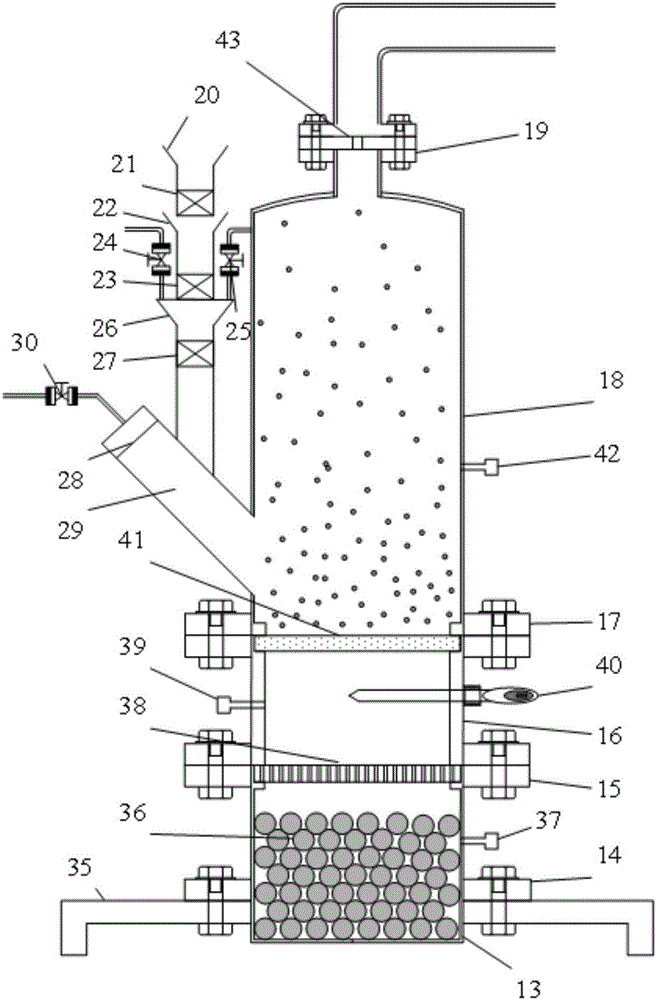

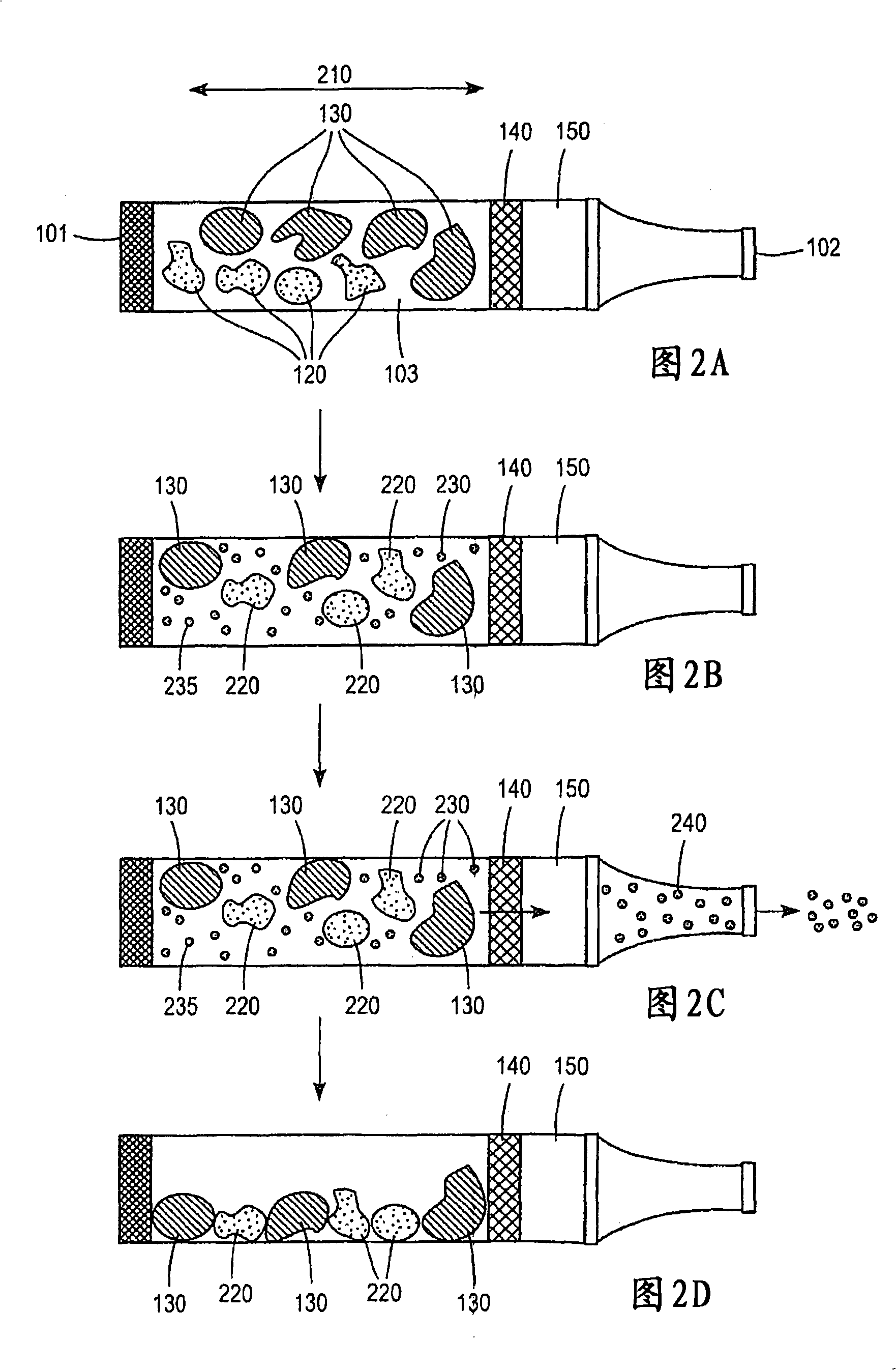

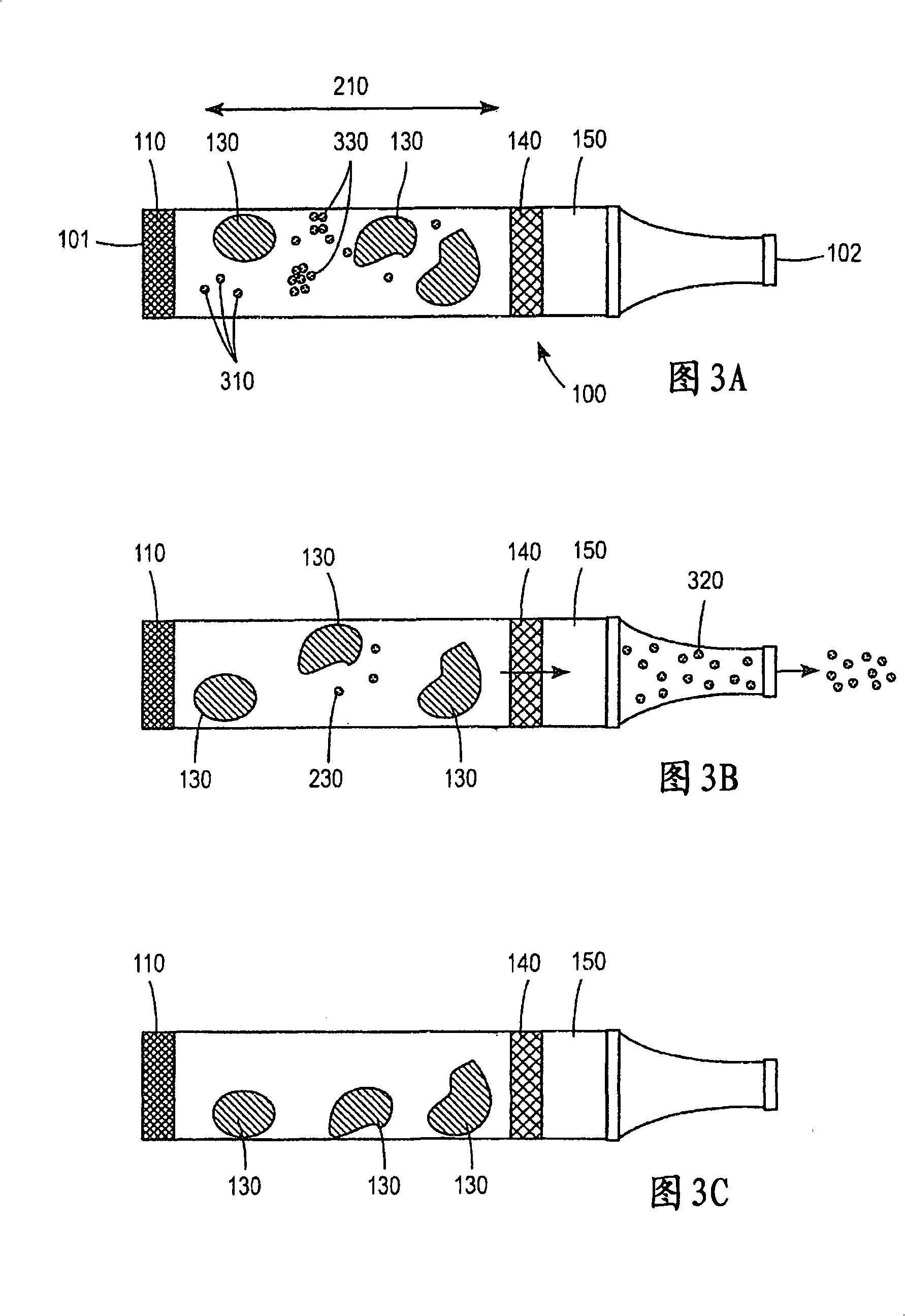

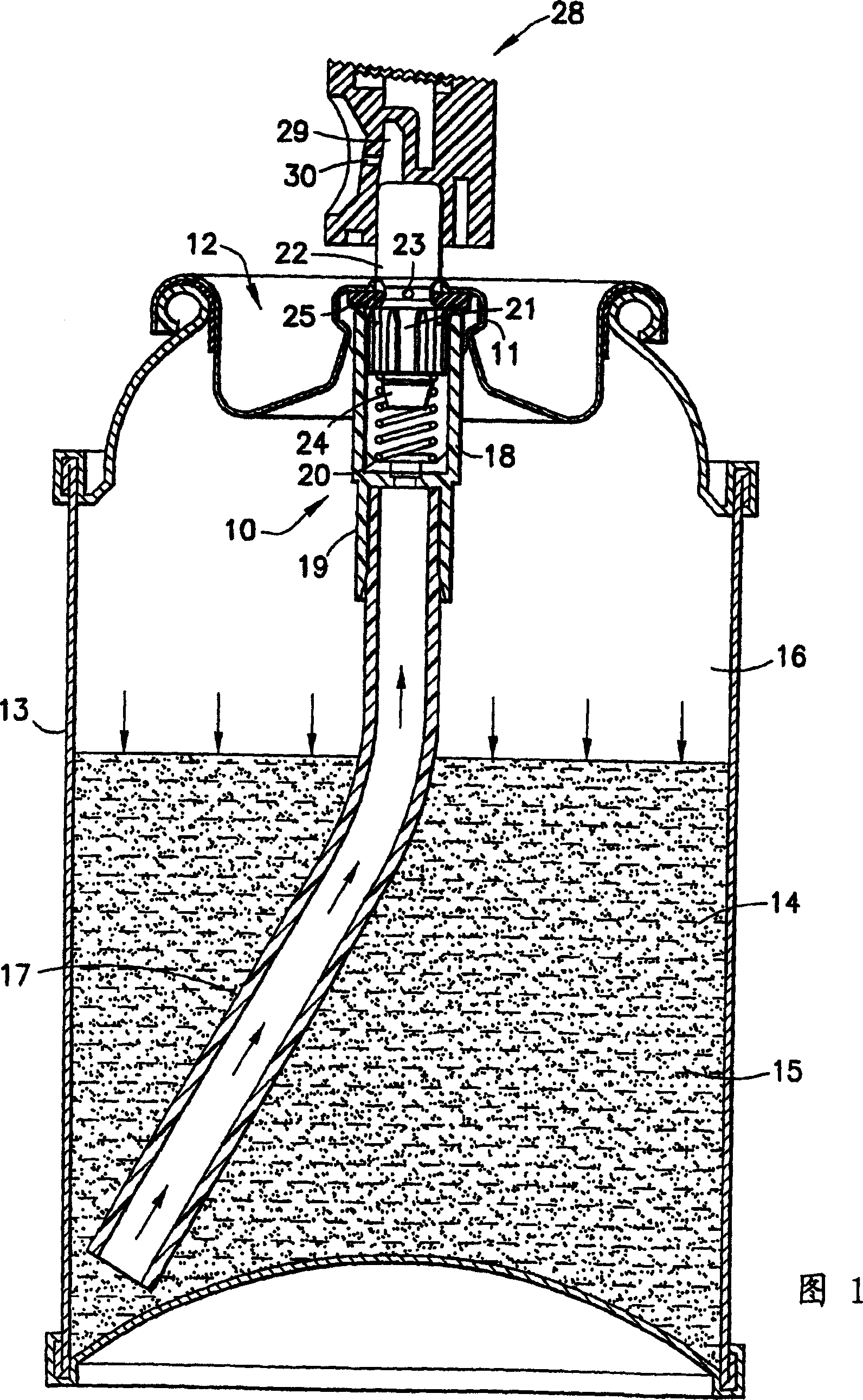

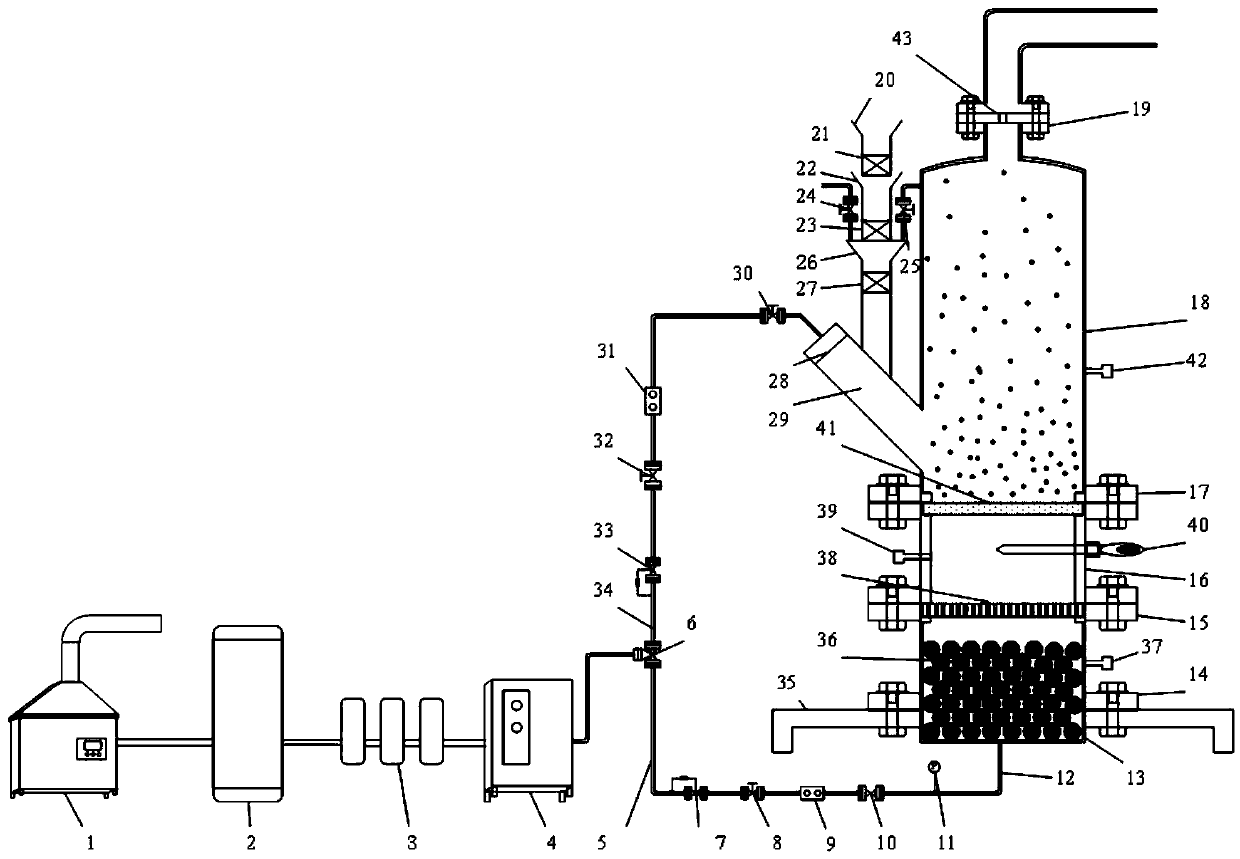

Long-term fluidized aerosol generating device with self-dispersing function

ActiveCN106512872AImprove uniformityAvoid cloggingColloidal chemistry detailsAerosol preparationEngineeringAerosol powder

The invention provides a long-term fluidized aerosol generating device with a self-dispersing function. The long-term fluidized aerosol generating device consists of an airflow supply part, an airflow drying part, a powder ebullition fluidizing part, a powder self-dispersing part and a powder online continuous supply part. Due to the unique design of the airflow drying section and an ebullition fluidizing plate, powder can be in a fluidized state under the action of the bubbling airflow of the fluidizing plate. In the self-dispersing section, part of lumpy powder is further dispersed under the action of high-speed airflow, so that the problems of viscous powder aggregation, clustering, vibrating caking and water absorbing deliquescence are effectively solved, the problems of particle unevenness and powder discharging discontinuity, which occur in the aerosol powder supply process, are effectively avoided, and the even and continuous supply of aerosol powder is ensured.

Owner:HARBIN ENG UNIV

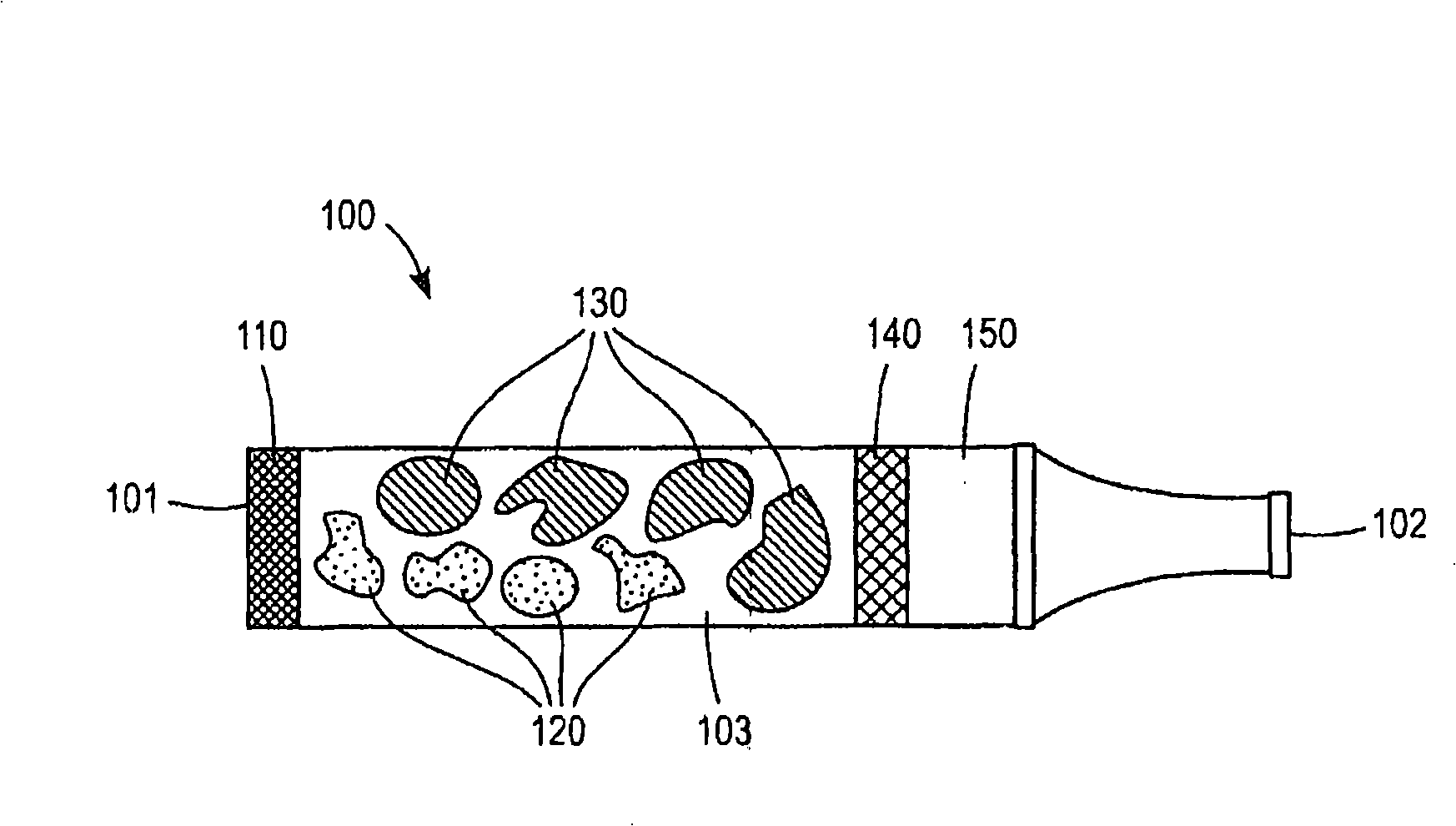

Aerosol powder delivery device

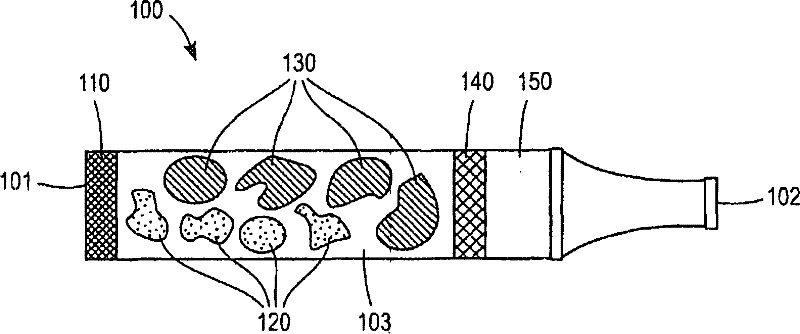

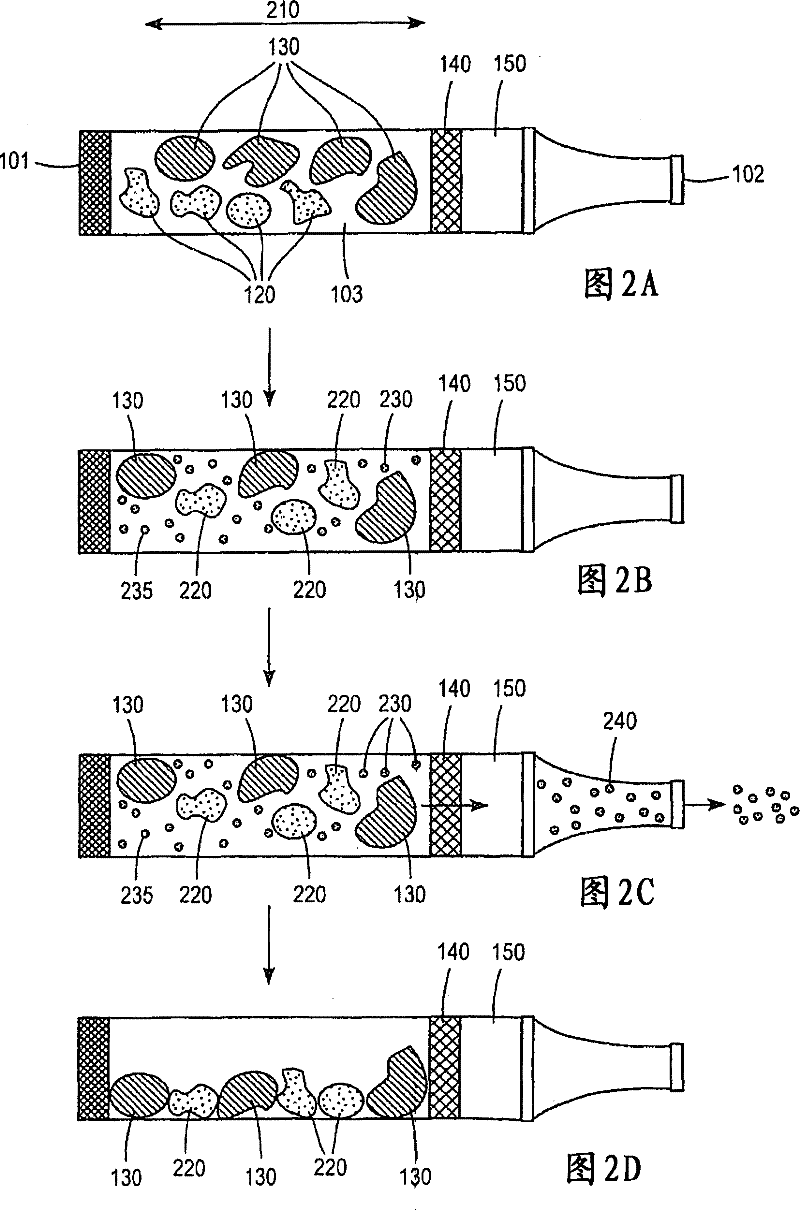

An aerosol powder delivery device, a method of producing or delivering aerosol particles, a method of making a delivery device, and an inhaler kit are provided. The device can be used to produce an aerosolizable powder by breaking or deagglomerating the aerosolizable powder into aerosol particles for inhalation. The aerosol particles can be produced by mechanically agitating or shaking a hollow device with the aerosolizable powder and a second powder to mechanically break or loosen aerosol particles from the aerosolizable powder. Thus, a small, lightweight, simple, sealed and stable device without complex moving parts, external power sources or heat is provided to aerosolize powder into aerosol particles for transmucosal delivery into a mouth upon inhalation.

Owner:PHILIP MORRIS PROD SA

Manufacture process of changeable geometrical cross-section turbocharger nozzle blade

ActiveCN102211193AImprove thermal fatigue resistanceEvenly distributedTurbinesInternal combustion piston enginesParaffin waxInjection pressure

The invention discloses a manufacture process of a changeable geometrical cross-section turbocharger nozzle blade. The manufacture process comprises the steps of: adding 0.2-1.5% of Ti into HK30 aerosol powders; mixing 10-15% of polyethylene glycol, 15-30% of vegetable oil, 10-15% of polyethylene, 5-20% of polypropylene and 25-45% of paraffin wax for 1-2 hours at 140-160 DEG C; mixing weighed (80-95):(20-45)% binder with the HK30 and Ti powders, wherein the mixing temperature is 130-170 DEG C, the rotation speed of a mixing mill is 50-70r / min, the mixing time is 1.0-2.0 hours, and the mixture is prepared to be feedings after being cooled and crushed; injecting the manufactured feedings into an injection molding machine, wherein the injection temperature is 120-165 DEG C, the injection pressure is 60-120MPa, the mold temperature is 30-60 DEG C, and blanks are injection molded; dissolving the paraffin wax and vegetable oil components of the blanks, and degreasing after the blanks are dried; heating up to 840-860 DEG C at a speed of 8-12 DEG C / min for presintering; heating up the blanks to W-E DEG C at a speed of 5-9 DEG C / min, and cooling the blanks with the furnace after the temperature is maintained for Y-T minutes. The product in the invention has the advantages of high size precision and surface precision, high thermal fatigue resistance and long service life.

Owner:湖南英捷高科技有限责任公司

Zanamivir capsule type inhalation aerosol powder and preparation method thereof

The invention relates to a zanamivir capsule type inhalation aerosol powder and a preparation method thereof. The capsule type inhalation aerosol powder comprises a capsule shell and a capsule content, wherein the capsule content is composed of 5 parts by weight of zanamivir super micropowder, 10-18 parts by weight of inhalation crystallization lactose and 2-10 parts by weight of inhalation grinding lactose 40M, and average particle size of the zanamivir super micropowder is less than 5mu m and particle size of an excipient is within the range of 40-100mu m. The zanamivir capsule type inhalation aerosol powder provided by the invention has a simple preparation process, good mobility, low hygroscopicity, high content uniformity and high deposit rate on an effective part.

Owner:SHANDONG NEWTIME PHARMA

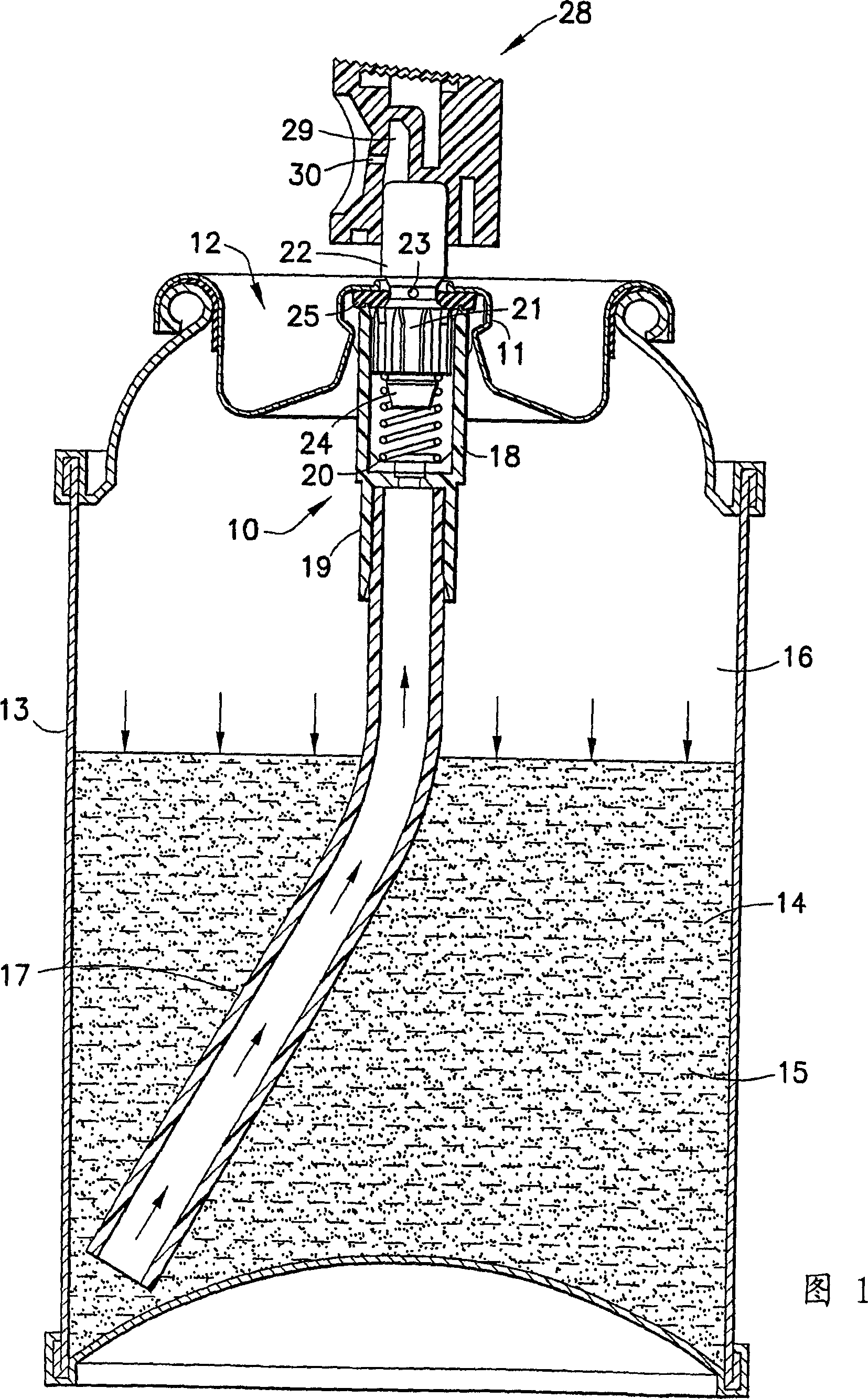

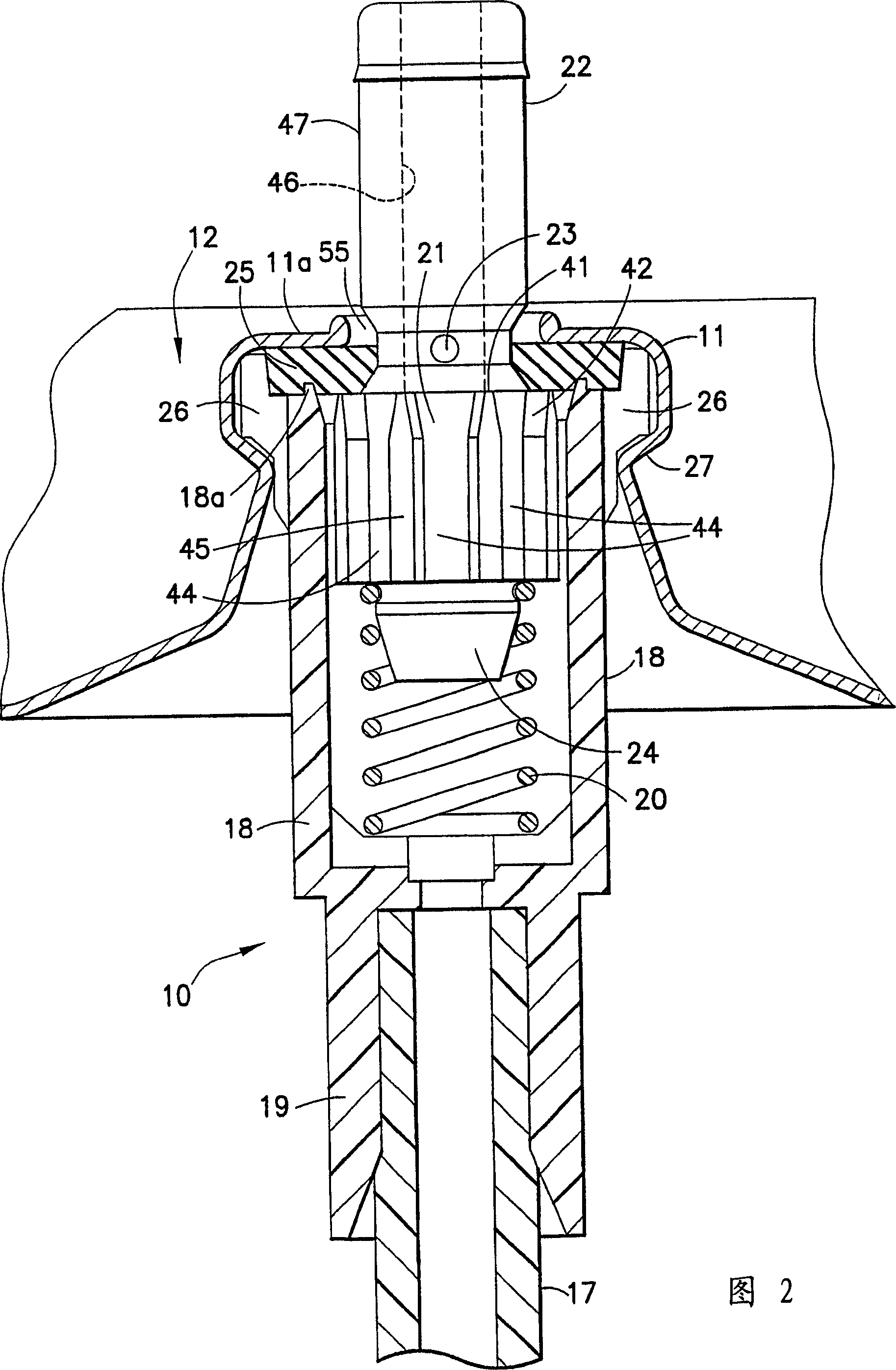

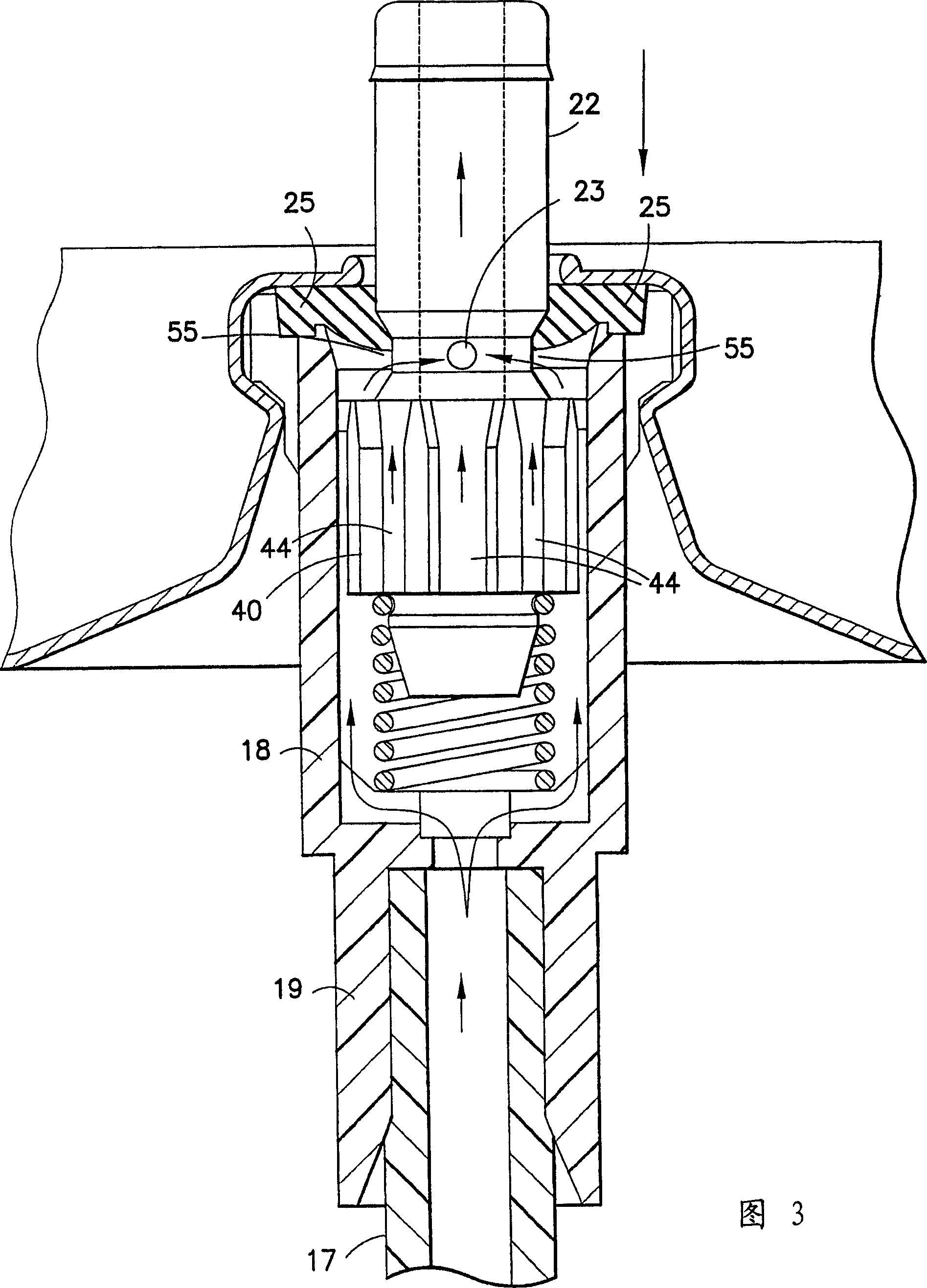

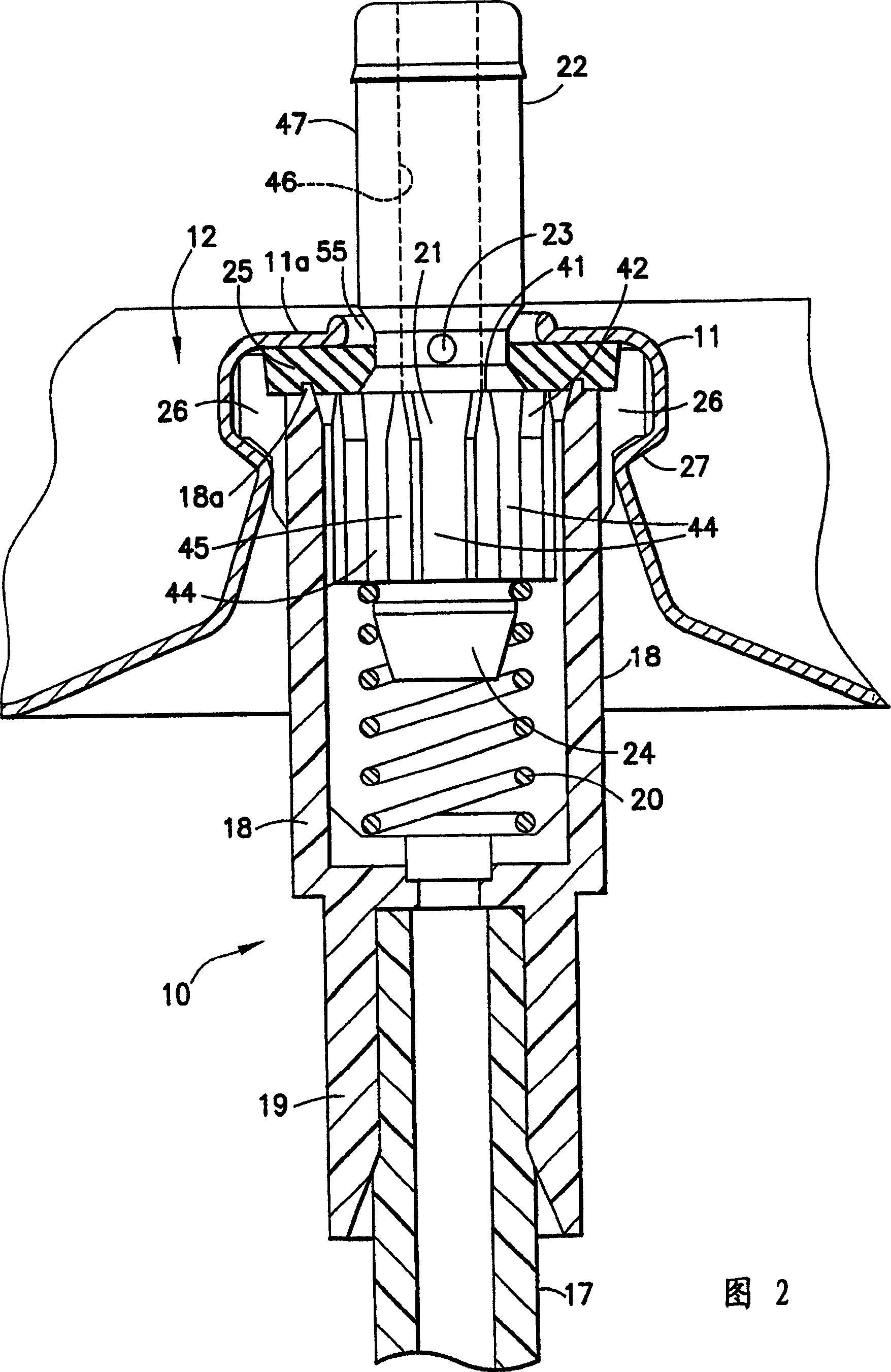

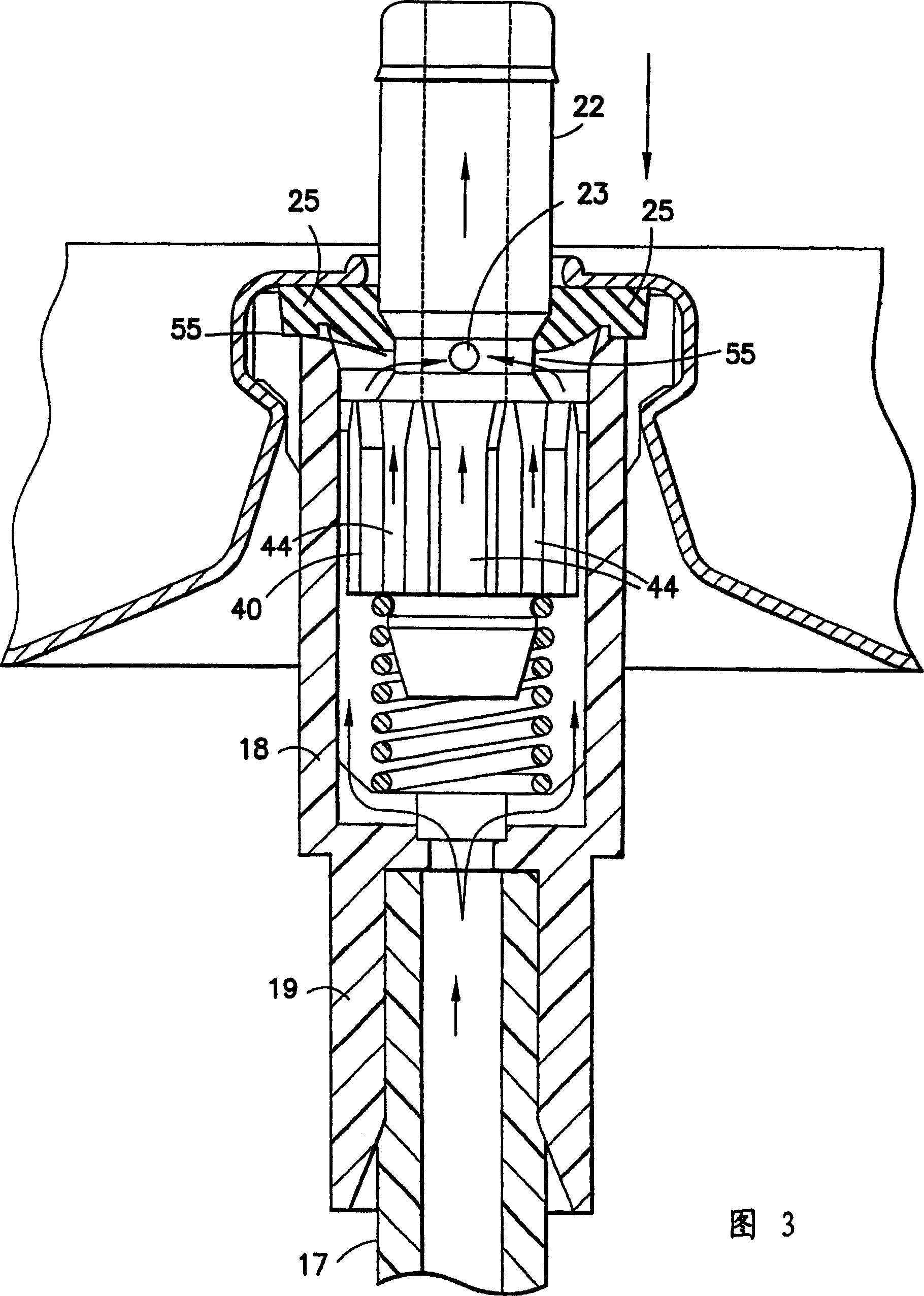

Aerosol powder valve

InactiveCN1615255AEliminate accumulationKeep loopingLiquid spraying apparatusLiquid dispensingAerosol sprayAcute angle

An aerosol powder valve (10) having a valve body (21) under a groove (55) with a plurality of vertical splines (40) having a top surface of minimum area (41), against the washer (25) in the closed position. The groove (55) has an upper annular surface (56), a central neck (57) with the valve hole (23) and a lower annular surface (58) extending downward from the neck at an acute angle relative to the horizontal and extend outwards to the valve body (21), connecting the outer peripheral surface of the valve body at the height of the top of the spline. The acute-angled annular lower groove surface (58) is frusto-conical or convex and has no horizontal or concave portions for powder accumulation. The gasket seals against the lower surface of the groove in the valve closed position and, as the valve moves from the open position to the closed position, sweeps the lower surface of the groove outward so that powder on the groove falls into the circumferential spaces between the splines middle.

Owner:PRECISION VALVE CORP

Ciclesonide capsule type inhalation aerosol powder and preparation method thereof

InactiveCN101766586AOvercome the problem of prone to electrostatic accumulationLittle side effectsPowder deliveryOrganic active ingredientsActive componentMedicine

The invention discloses ciclesonide capsule type inhalation aerosol powder and a preparation method thereof. The ciclesonide capsule type inhalation aerosol powder can improve the deposition rate of ciclesonide in the inhalation aerosol powder in lung, avoid the deposition of carrier micropowder in the lung, improve the stability of a composition and consists of an active component and micropowder of a carrier and is characterized in that the average particle diameter of the micropowder as the active component is 0.5-10mu m and the average particle diameter of the micropowder of the carrier is 20-45mu m.

Owner:TIANJIN JINYAO GRP

Inhalation serrapeptase preparation

InactiveCN102416172AQuick effectPeptide/protein ingredientsPharmaceutical delivery mechanismInhalationRespiratory disease

The invention discloses an inhalation serrapeptase preparation. The inhalant serrapeptase preparation comprises but is not limited to inhalation aerosol powder, and inhalation aerosol. In the inhalation serrapeptase preparation, serrapeptase is micronized, and the particle size is 1 to 100 microns, preferably 3 to 50 microns. The serrapeptase preparation can be inhaled to treat inflammation, edema and expectoration difficulty which are caused by various respiratory diseases.

Owner:FUKANGREN BIO PHARMA

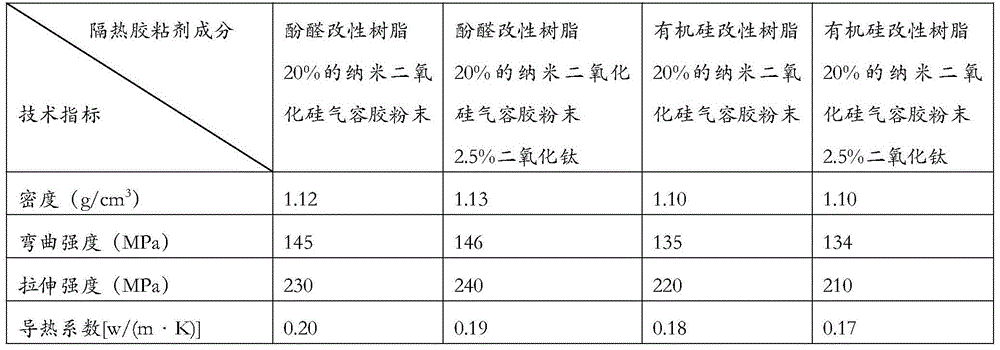

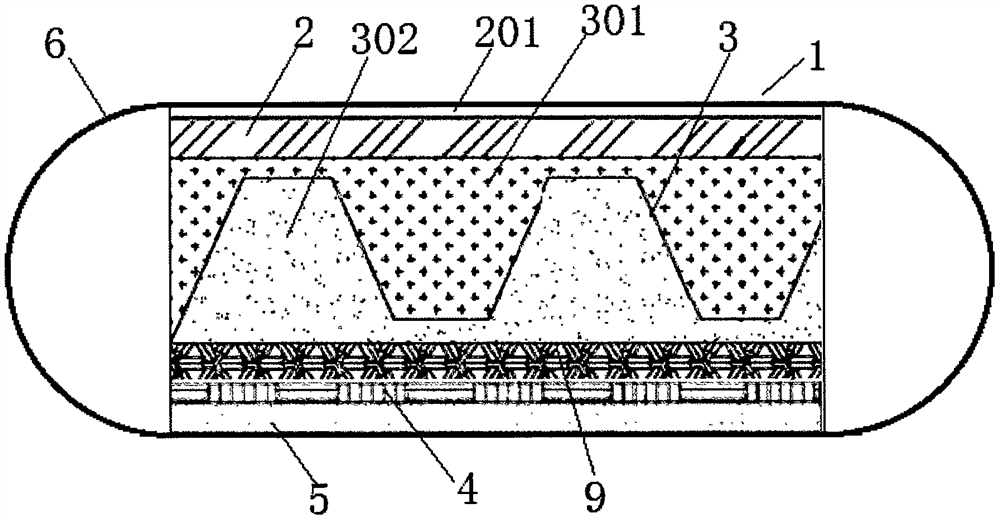

Preparation method of heat insulation pad and heat insulation pad prepared thereby

InactiveCN104553225AGood thermal insulation propertiesImprove performanceNon-macromolecular adhesive additivesLaminationFiberAdhesive

A preparation method of a heat insulation pad relates to the field of composite material and comprises the following steps: a, blending a heat insulation adhesive; b, brushing with the heat insulation adhesive to prepare woolen fabrics; c, laying and folding the woolen fabrics; and d, carrying out compression molding. According to the heat insulation pad prepared by the method, ceramic fiber or glass fiber fabrics are used as carriers, each piece of carrier is brushed with the adhesive for multiple times to be used as the woolen fabric; the adhesive is formed by adding a nano silica aerosol powder with the mass 10-30% that of modified resin into the modified resin and then mixing evenly, and the control amount of the adhesive is 500-900 g / m<2>; the heat insulation pad is formed by laying and folding multiple layers of woolen fabrics and then carrying out compression molding. The produced heat insulation pad has a better heat insulation characteristic, and besides, also can provide good bending strength, tensile strength and compressive strength for a heat insulation system; the preparation method is simple to operate; and the heat insulation pad is good in performance and low in cost, fills a research and development blank in the domestic heat insulation field, and can be widely applied to the heat insulation system in high temperature environments.

Owner:AVIC GUIZHOU AIRPLANE

Application of modified PET (Polyethylene Terephthalate) polyester

ActiveCN108409947AEvenly dispersedIncrease the rate of crystallizationFlame-proof filament manufactureSilicon compoundsPolyethylene terephthalate glycolSlurry

The invention relates to application of modified PET (Polyethylene Terephthalate) polyester and belongs to the field of modified polyester. The modified PET polyester comprises aerogel particles and polyethylene terephthalate; the aerogel particles are uniformly dispersed among molecular chains of the polyethylene terephthalate; the size of the aerogel particles is 2-3 microns; and the content ofthe aerogel particles in the modified PET polyester is 1-10wt%. The modified PET polyester is prepared by the following steps of adding aerosol powder in ethylene glycol, putting a mixture in a grinder for grinding to prepare a mixed slurry, mixing the mixed slurry with terephthalic acid, and performing esterification reaction and polymerization reaction on a mixture to prepare modified PET; and performing slicing, metering, silk spurting, cooling, oil application, stretching, heat setting and winding formation to prepare modified PET fibers. By introducing the aerogel particles before polymerization of PET polyester, the prepared modified PET is good in spinnability, can be used for producing the modified PET fibers with various thicknesses so as to be wide in application range and can meet the production demands for various fabrics.

Owner:天津朗华科技发展有限公司

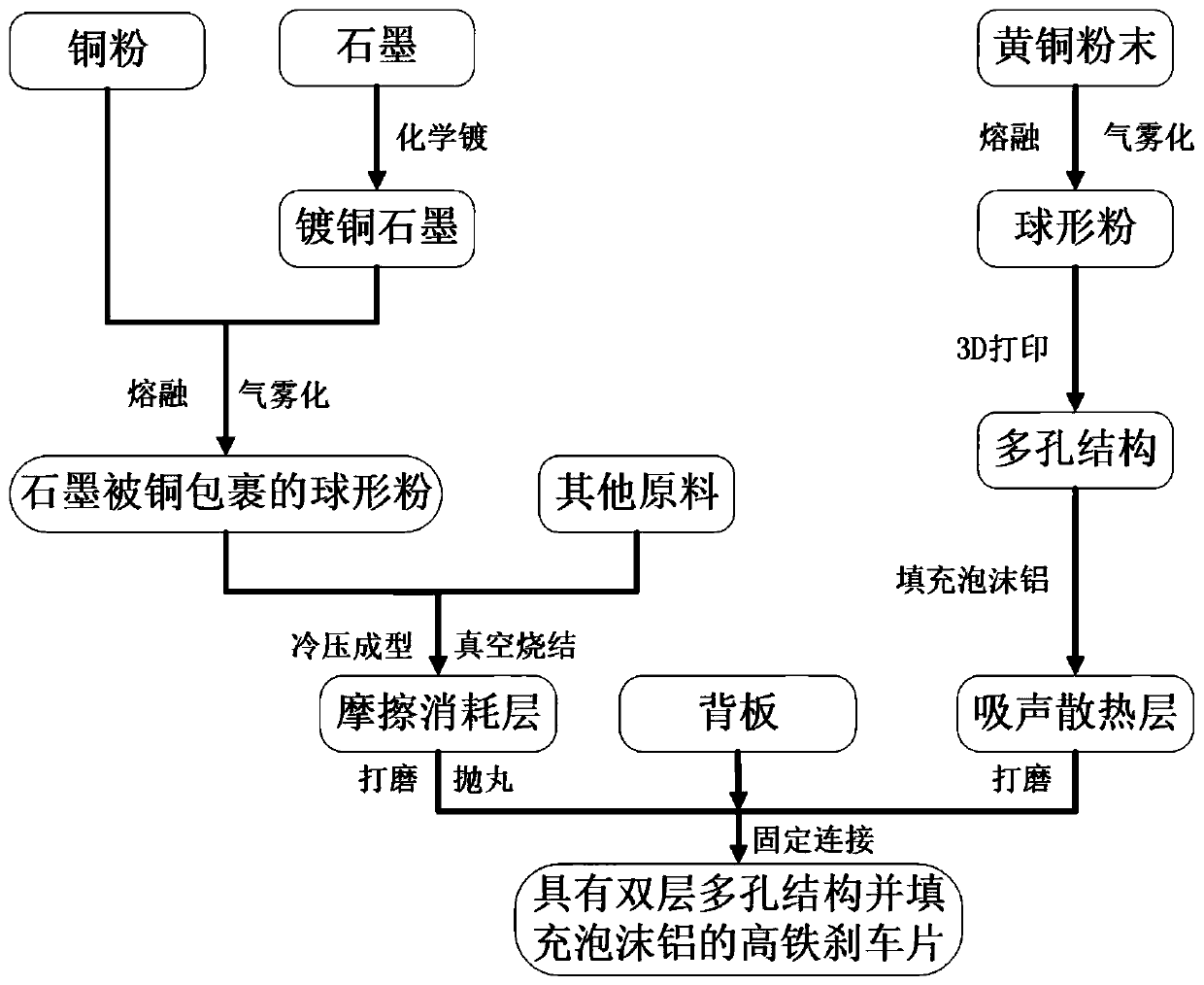

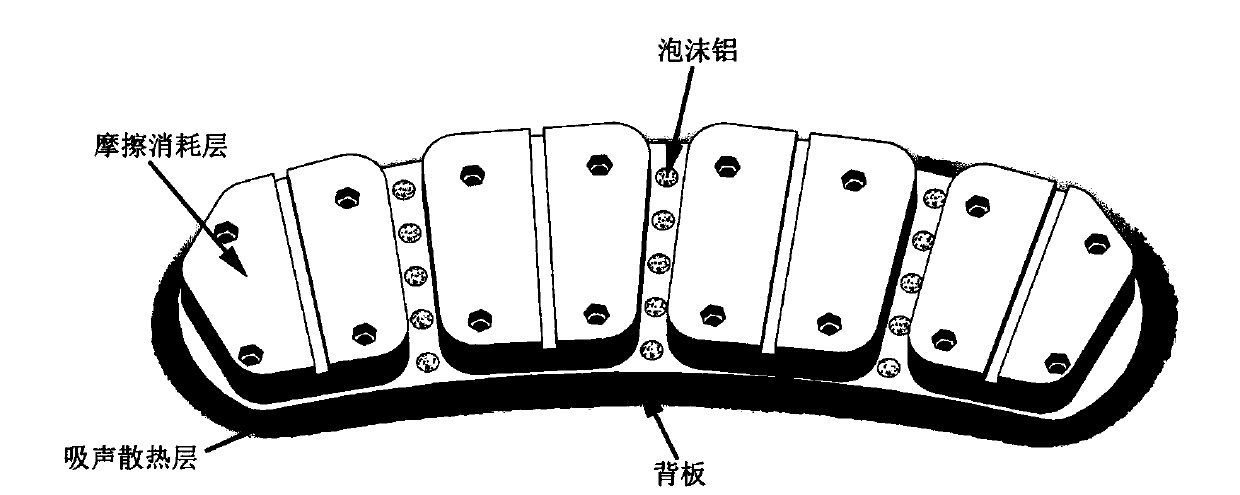

Environmentally-friendly low-dust and low-noise novel brake pad for high-speed railway and preparation method thereof

ActiveCN110375023AWith wear resistanceWith sound absorption and noise reduction performanceAdditive manufacturingTransportation and packagingLow noiseChemical plating

The invention discloses an environmentally-friendly low-dust and low-noise novel brake pad for a high-speed railway and a preparation method thereof. The novel brake pad for the high-speed railway comprises a friction consumption layer and a sound absorption heat dissipation layer and meanwhile has good wear resistance and sound absorption and noise reduction performances. The preparation method comprises the following steps that cold press molding is carried out on a raw material of the friction consumption layer, and vacuum sintering is carried out so as to obtain the friction consumption layer, wherein the existence state of graphite in the friction consumption layer is that copper plating is carried out on the surface of the graphite by adopting chemical plating, then composite spherical powder of copper and the copper-plated graphite is prepared through an aerosol powder preparation method, and the graphite is tightly combined with the copper; and an H62 copper alloy substrate ofa porous structure is obtained through the sound absorption and heat dissipation layer through a 3D printing technology, and then pores are filled with foamed aluminium, so that the effect of reducingthe noise pollution is achieved. The brake pad for the high-speed railway has the advantages of being simple in formula, high in production efficiency, small in dust pollution, low in brake noise andgood in heat dissipation performance.

Owner:WUHAN UNIV OF TECH

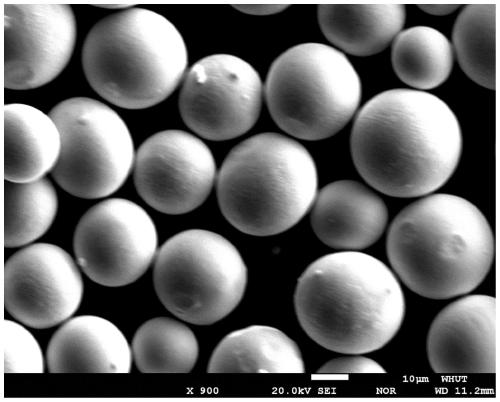

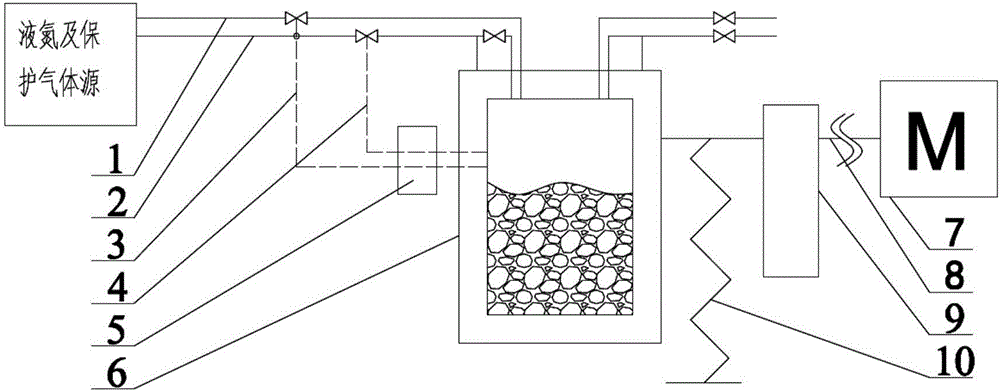

Equipment and method for preparing nanocrystal powder through vibration type copious cooling ball milling

ActiveCN106623951AImprove thermal stabilityPrecise control of particle size rangeShielding gasFeedback circuits

The invention relates to the field of low-temperature ball milling, in particular to equipment and method for preparing nanocrystal powder through vibration type copious cooling ball milling. The equipment comprises a protective gas introduction pipeline, a liquid nitrogen introduction pipeline, a temperature feedback circuit, a pressure feedback circuit, a ball mill tank, a spring, an eccentric wheel, a spindle, a tank interior pressure and temperature control system, a driving motor, a liquid nitrogen and protective gas source and the like. The nanocrystal powder is prepared through the method combining the vibration type ball milling with liquid nitrogen refrigerating, according to the commercial aerosol powder, the raw material particle size is 5-50 microns, and the grain size is 0.5-5 microns. Different from existing planetary type or stirring type low-temperature ball milling equipment, vibrating squeezing and crushing as well as compacting are taken as the principal things of the ball milling principle of the equipment, the ball milling atmosphere can be controlled flexibly, and the nanocrystal powder which is controllable in particle size and appearance, intensive in particle size distribution and high in thermal stability is prepared in a short time by adjusting the ball milling parameters.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

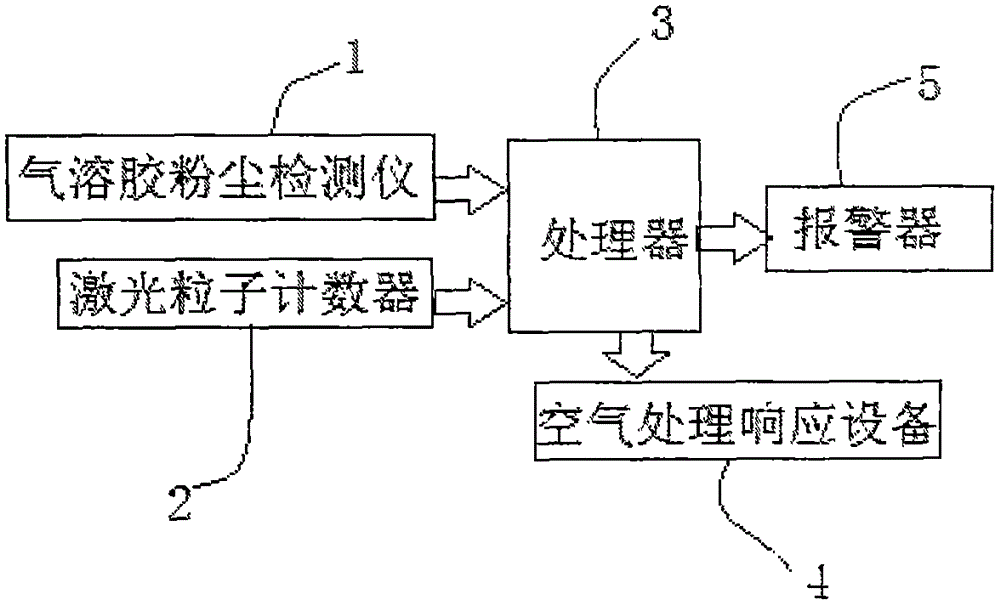

Measurement and control method and device for particle concentration of indoor air

InactiveCN105571997AReduce contentImprove living comfortMechanical apparatusSpace heating and ventilation safety systemsSuspended particlesParticulates

The invention discloses a measurement and control method and device for the particle concentration of indoor air. The method includes the first step of setting up measurement environments, the second step of measuring data by means of a control variable method, the third step of managing the data, the fourth step of forming indoor air combination paths, and the fifth step of performing indoor air optimization. The device of the measurement and control method for the particle concentration of indoor air comprises an aerosol dust detector, a laser particle counter, a processor electrically connected with the aerosol dust detector and the laser particle counter, and air treatment response equipment electrically connected with the processor. According to the measurement and control method and device for the particle concentration of indoor air, for factors including indoor activity and indoor air and outdoor air exchange influencing indoor total suspended particles, which factors can influence the indoor air particle content are determined, and thus the indoor air particle content can be reduced in a targeted mode.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Anti-chafing aerosol powder

A composition and method which prevents or mitigates irritation on the skin of a subject by protecting against or relieving chafing, itching and moisture, and which provides a cooling sensation where applied.

Owner:JOYCE LABS

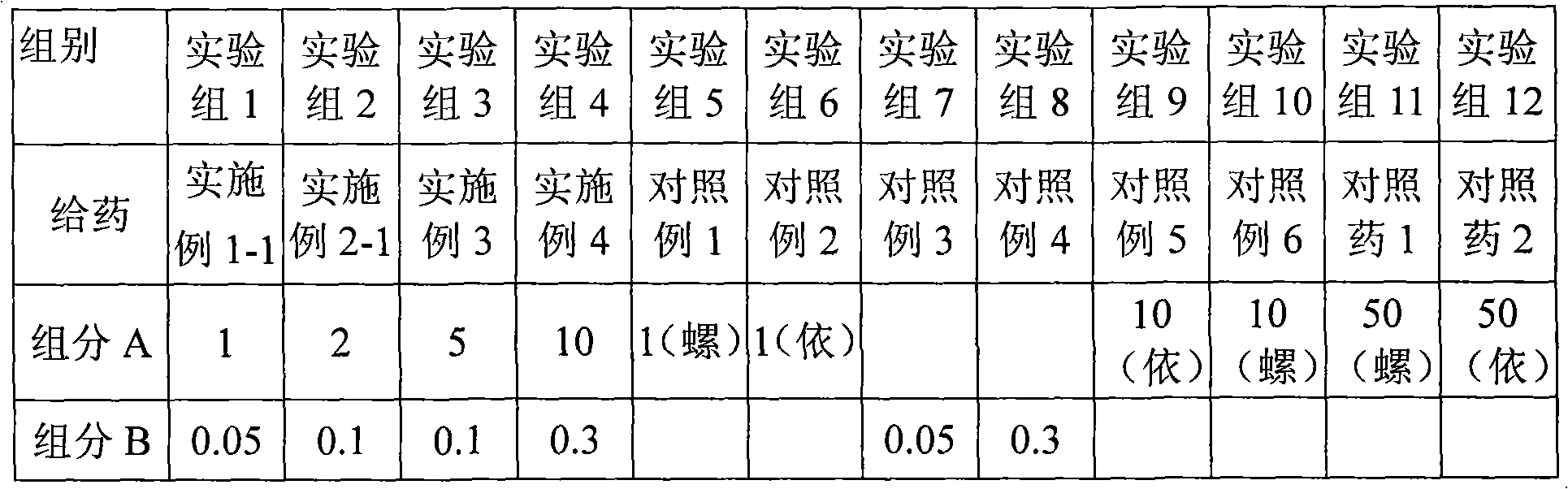

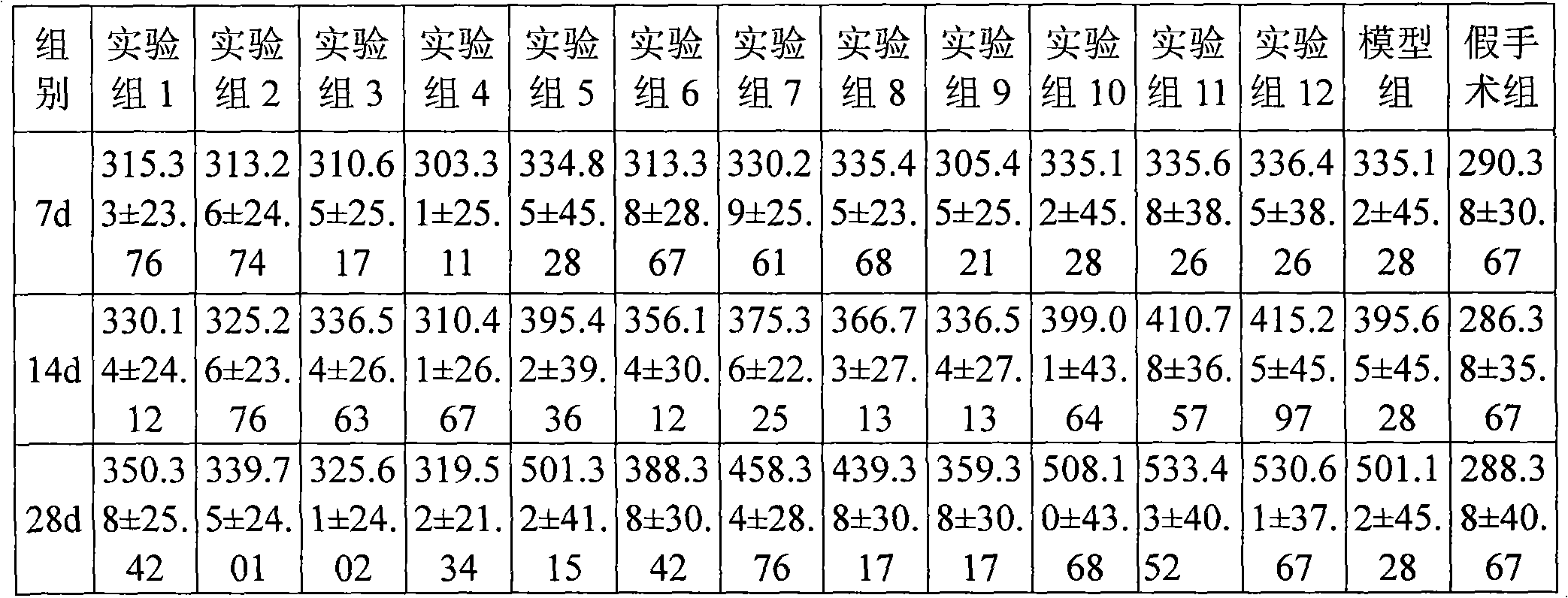

Inhalation medicinal composition prepared from eplerenone and glucocorticoid serving as active ingredients

ActiveCN102370984AInhibit compensatoryLittle side effectsOrganic active ingredientsRespiratory disorderFlunisolideGlucocorticoid

The invention discloses an inhalation medicinal composition prepared from eplerenone and glucocorticoid serving as active ingredients. The inhalation medicinal composition consists of eplerenone, glucocorticoid and one or more carriers suitable for inhalation administration. The glucocorticoid is one or more of ciclesonide, desonide, fluticasone propopnate, mometasone furoate, beclomethasone dipropionate, flunisolide, and triamcinolone acetonide and medicinal salts or esters thereof; the inhalation medicinal composition is preferably prepared into aerosol powder which consists of eplerenone, glucocorticoid and carrier micro powder; the average grain diameter of the eplerenone and glucocorticoid micro powder is 0.5 to 1.0 mu m; and the average grain diameter of the carrier micro powder is 20 to 45 mu m.

Owner:TIANJIN JINYAO GRP

Aerosol powder delivery device

An aerosol powder delivery device, a method of producing or delivering aerosol particles, a method of making a delivery device, and an inhaler kit are provided. The device can be used to produce an aerosolizable powder by breaking or deagglomerating the aerosolizable powder into aerosol particles for inhalation. The aerosol particles can be produced by mechanically agitating or shaking a hollow device with the aerosolizable powder and a second powder to mechanically break or loosen aerosol particles from the aerosolizable powder. Thus, a small, lightweight, simple, sealed and stable device without complex moving parts, external power sources or heat is provided to aerosolize powder into aerosol particles for transmucosal delivery into a mouth upon inhalation.

Owner:PHILIP MORRIS PROD SA

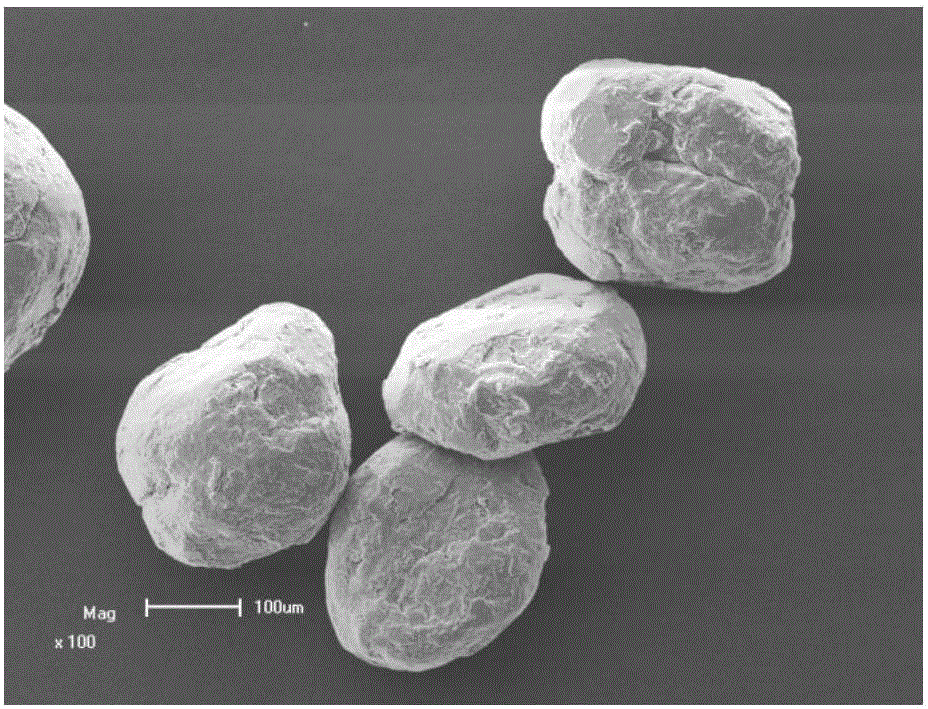

Aerosol porous particle and application in cigarette

ActiveCN103752260AUniform sizeStable physical and chemical propertiesTobacco smoke filtersSilicon compoundsAdhesiveSilica gel

The invention discloses an aerosol porous particle and application in a cigarette. The aerosol porous particle is prepared by the fluidized bed top shower process taking aerosol powder of 120-300 meshes as the raw material and sodium carboxymethyl starch as an adhesive. The particle has a coarse surface and relatively high specific surface area, can obviously increase the effective contact area between a particular material and the smoke of the cigarette, and is able to selectively absorb hydrogen cyanide in the smoke; and the aerosol porous particle has both functions of reducing harm and lowering the irritation of the smoke of the cigarette. The production process of the aerosol porous particle is simple, the operability and normativity are high, the raw material is easily available, the cost is low, the industrial production can be conveniently realized, and a good application prospect is brought.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

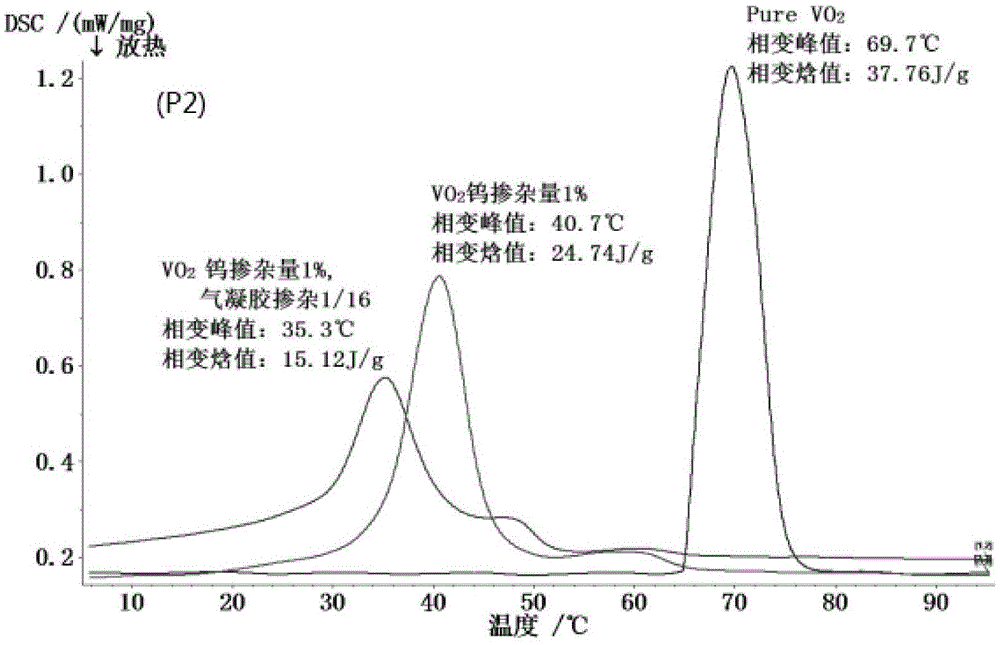

Preparation method of tungsten-doped vanadium dioxide superfine powder

The invention relates to a preparation method of tungsten-doped vanadium dioxide superfine powder, comprising the following steps: step 1, dissolving vanadyl sulfate trihydrate in distilled water, adding a soluble hexavalent tungsten compound accounting for 0.1-5 % of total molar weight of vanadium, adding an alkaline solution, adjusting solution PH to 6-7 to obtain a suspension, and suction filtering, washing and drying to obtain tungsten-doped precursor powder; step 2, pulverizing silica aerosol, screening with a screen to obtain silica aerosol powder; step 3, mixing the tungsten-doped precursor powder obtained in step 1 and the silica aerosol powder obtained in step 2 according to a weight ratio of 1-10:1 to obtain blend powder; step 4, thermally treating the blend powder obtained in step 3 under the protection of an inert gas, and then cooling, wherein thermal treatment temperature is 600-1000 DEG C and thermal treatment takes 3-8 h; step 5, screening the blend powder cooled in step 4 by using a 1000- to 3000-mesh screen so as to remove silica aerosol powder large in particle size.

Owner:GUANGZHOU UNIVERSITY

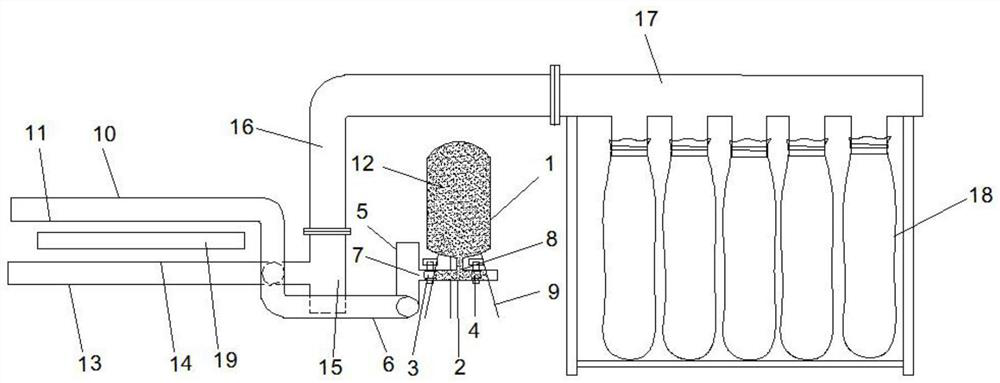

Glass fiber needled felt silicon-based nano aerogel powder spraying and collecting device

PendingCN114653554AAvoid pollutionAvoid wastingLiquid surface applicatorsCoatingsGlass fiberControl valves

A glass fiber needled felt silicon-based nano aerogel powder spraying and collecting device comprises a powder spraying device and a powder collecting device, the left side of a powder spraying pipe of the powder spraying device is communicated with a powder conveying pipe, the powder conveying pipe is communicated with a powder spraying fan, a powder inlet is formed in a shell body, wrapping an impeller, of the powder spraying fan, the powder inlet is communicated with a powder inlet pipe, and the powder inlet pipe is communicated with a horizontal left pipe of a three-way pipe; a control valve is arranged between the powder inlet pipe and the three-way pipe, a horizontal right pipe of the three-way pipe is communicated with the air inlet valve and the air inlet pipe, a branch pipe of the three-way pipe is communicated with the bottom of the powder storage tank, and a powder spraying hole array is arranged at the bottom of the powder spraying pipe; a negative-pressure dust suction groove is formed under the powder spraying pipe, a powder suction hole array is formed in the upper end face, right facing the powder spraying pipe, of the negative-pressure dust suction groove, the right end of the negative-pressure dust suction groove is communicated with an air inlet of a powder collecting fan shell, an air outlet of the powder collecting fan shell is communicated with a second powder conveying pipe, the second powder conveying pipe is communicated with a powder collecting distribution pipe, and all branches of the powder collecting distribution pipe are communicated with powder collecting filter bags respectively. The powder collecting filter bag collects nano aerosol powder and allows filtered air to pass through.

Owner:潜江市金铃汽车内配材料有限公司

Aerosol powder valve

InactiveCN1329257CEliminate accumulationKeep loopingLiquid spraying apparatusLiquid dispensingAerosol spraySharp angle

An aerosol powder valve (10) has a valve body (21) below a groove (55) with a plurality of vertical splines (40) having minimal area top surfaces (41) abutting a gasket (25) in a closed position. The groove (55) has a top annular surface (56), an intermediate neck portion (57) with the valve orifice(s) (23), and a lower annular surface (58) extending downwardly and outwardly at a sharp angle to the horizontal from the neck portion to the valve body (21) to join the valve body outer circumference at the level of the tops of the splines. The sharply angled annular lower groove surface (58) is frustoconical or convex, and has no horizontal or concave components for powder accumulation. The gasket seals the groove lower surface in the closed valve position and wipes the groove lower surface outwardly when the valve moves from open to closed so powder on the groove falls into the circumferential spaces between the splines.

Owner:PRECISION VALVE CORP

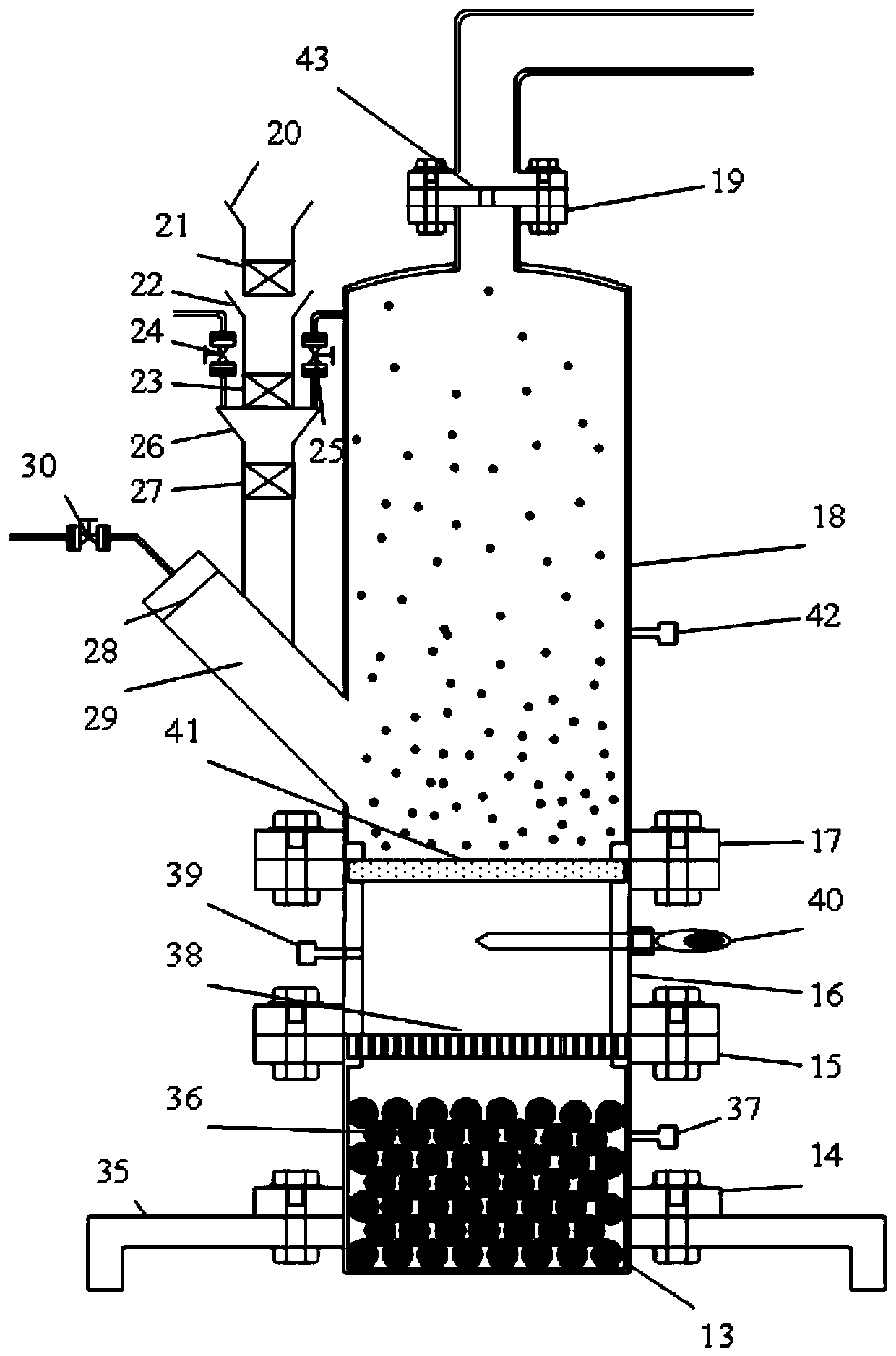

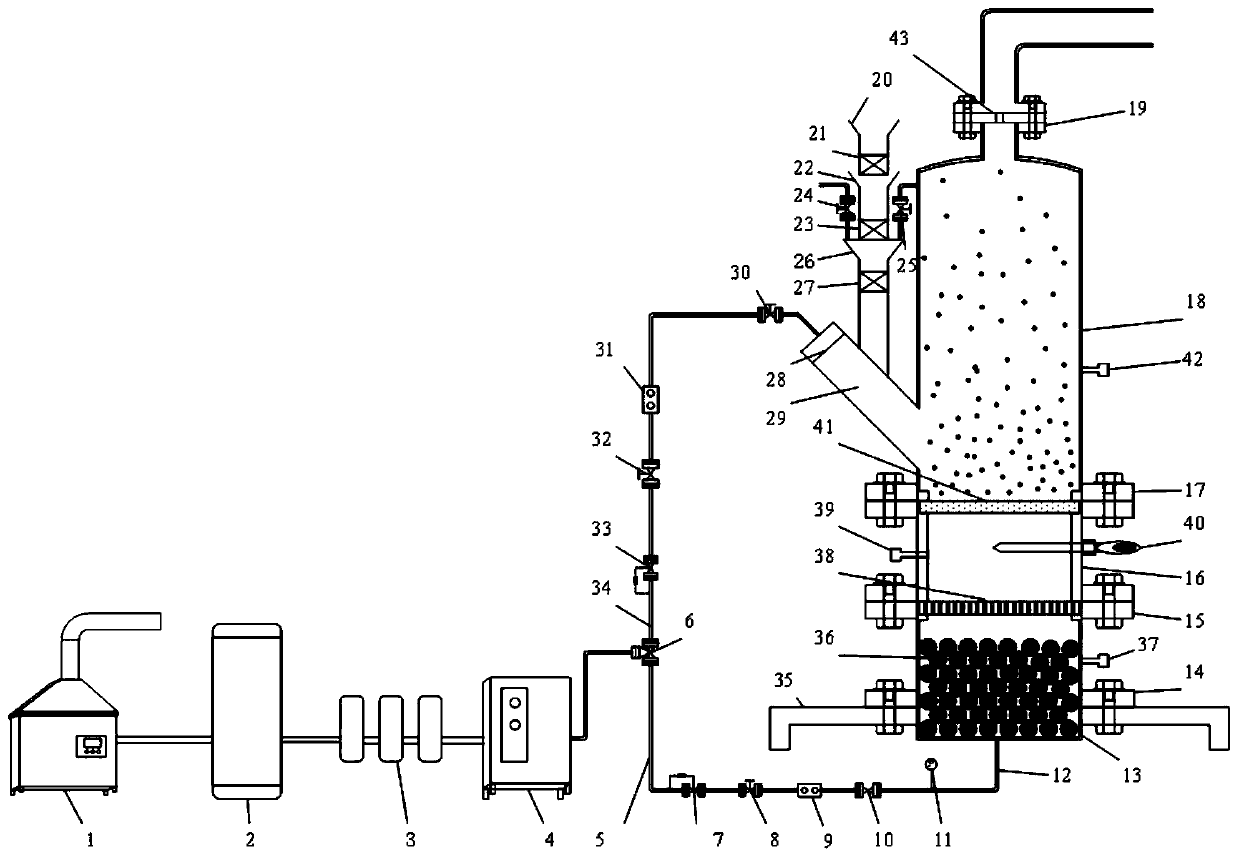

A long-term fluidized aerosol generating device with self-dispersion function

ActiveCN106512872BImprove uniformityAvoid cloggingColloidal chemistry detailsAerosol preparationEngineeringAerosol powder

The invention provides a long-term fluidized aerosol generating device with a self-dispersing function. The long-term fluidized aerosol generating device consists of an airflow supply part, an airflow drying part, a powder ebullition fluidizing part, a powder self-dispersing part and a powder online continuous supply part. Due to the unique design of the airflow drying section and an ebullition fluidizing plate, powder can be in a fluidized state under the action of the bubbling airflow of the fluidizing plate. In the self-dispersing section, part of lumpy powder is further dispersed under the action of high-speed airflow, so that the problems of viscous powder aggregation, clustering, vibrating caking and water absorbing deliquescence are effectively solved, the problems of particle unevenness and powder discharging discontinuity, which occur in the aerosol powder supply process, are effectively avoided, and the even and continuous supply of aerosol powder is ensured.

Owner:HARBIN ENG UNIV

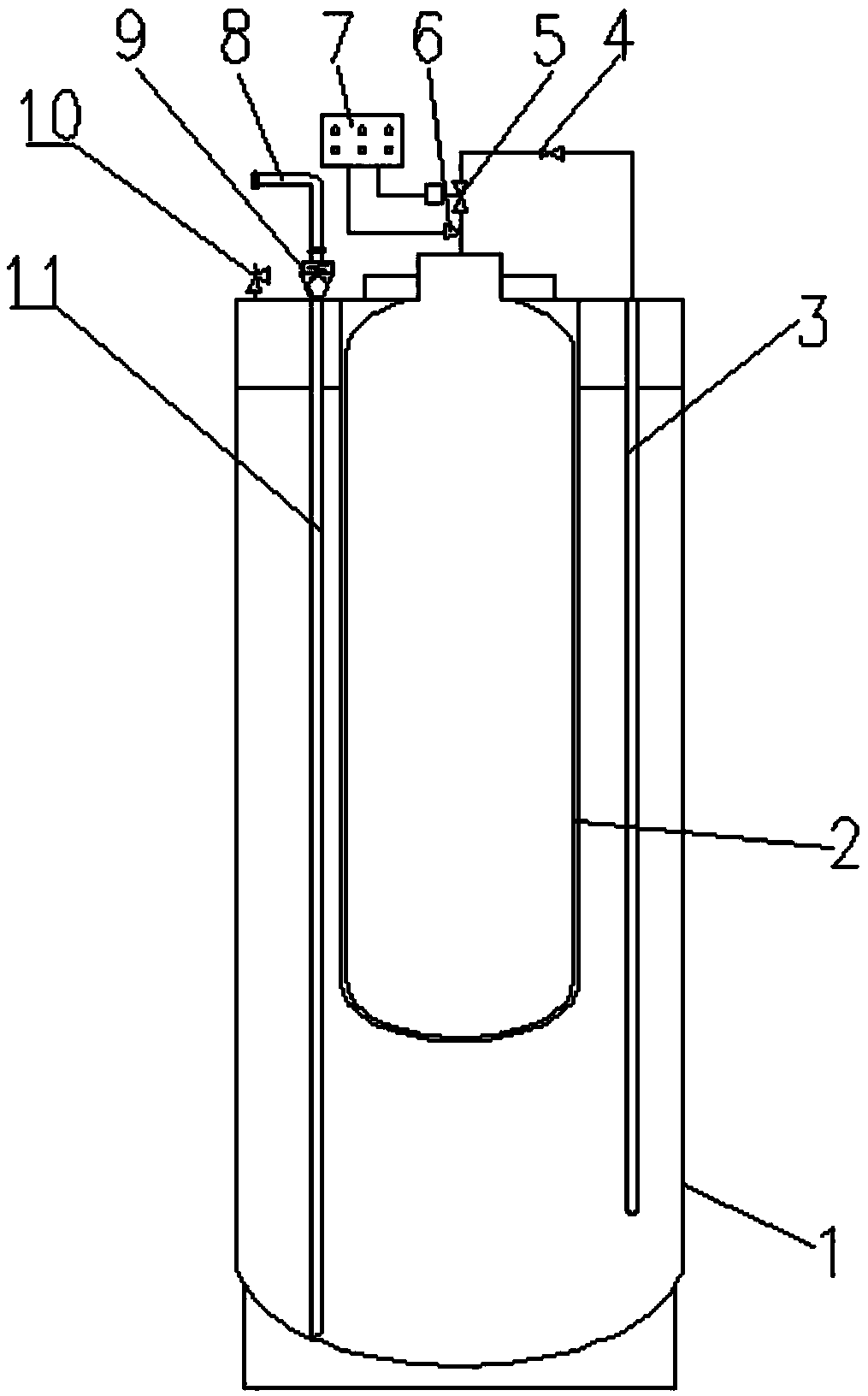

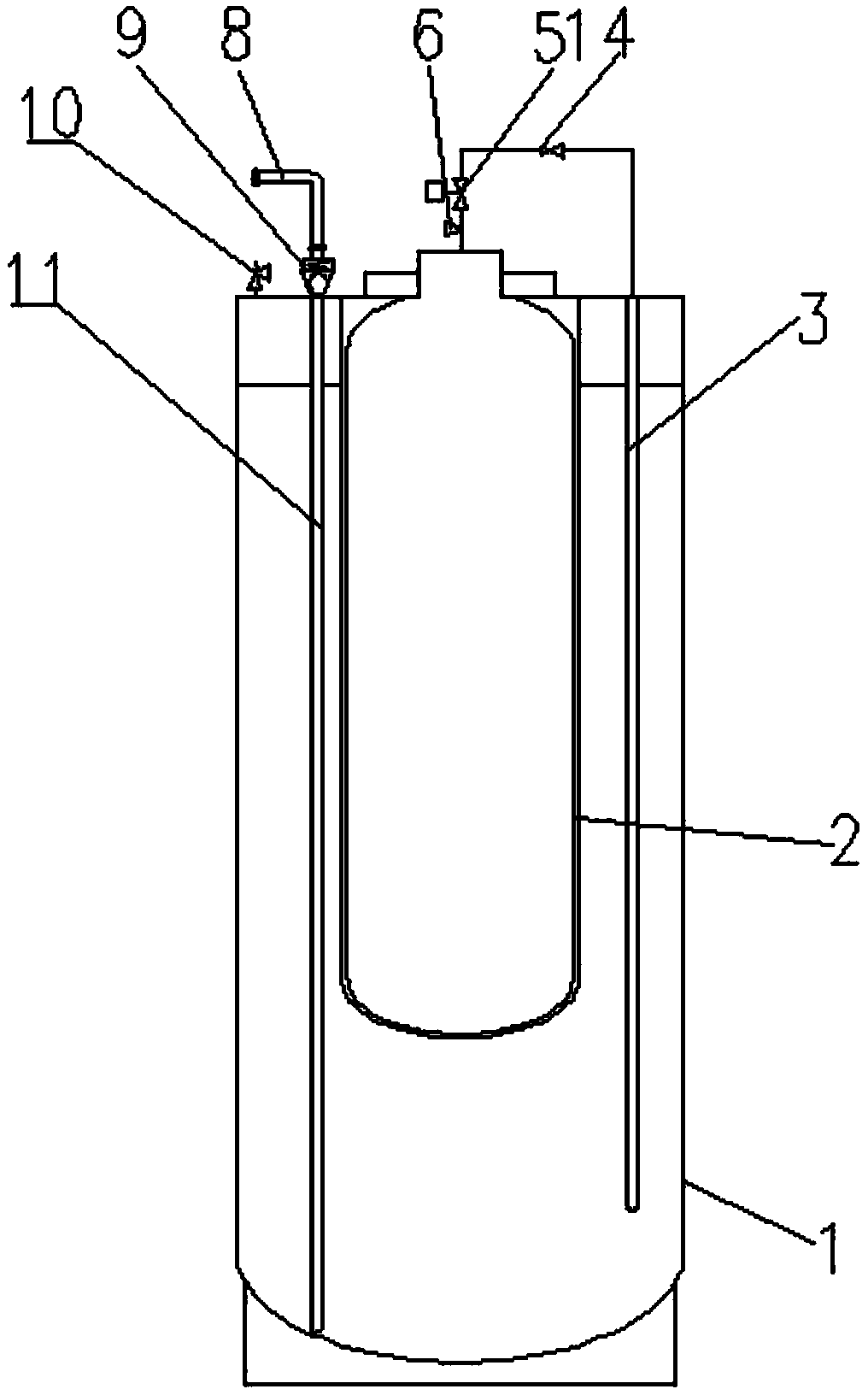

Controllable spraying cold aerosol fire extinguishing device

The invention relates to a fire extinguishing technology, and discloses a controllable spraying cold aerosol fire extinguishing device. The device is characterized by comprising a sprayer, a control valve, a pressure switch, a closed container, a driving gas cylinder, a powder blowing pipe and a siphon, wherein dried cold aerosol powder is accommodated in the closed container; the driving gas cylinder, the powder blowing pipe and the siphon are arranged in the closed container; an opening of the driving gas cylinder is communicated with an inlet end of the powder blowing pipe through a gas pipeline, and the pressure switch, the control valve and a reducing valve are arranged on the gas pipeline sequentially; the pressure switch is connected with the control valve; and an inlet end of the siphon extends into the bottom of the closed container, and an outlet end of the siphon is communicated with the sprayer through a cold aerosol pipeline. According to the controllable spraying cold aerosol fire extinguishing device, the driving gas cylinder is arranged in a powder storage tank, so that the size of the integral device is greatly reduced, and the controller is used for controlling switching off of an electromagnetic valve according to the preset spraying time during fire extinguishing, so that a fire extinguishing agent can be sprayed for multiple times.

Owner:XIAN XINZHU FIRE & RESCUE EQUIP

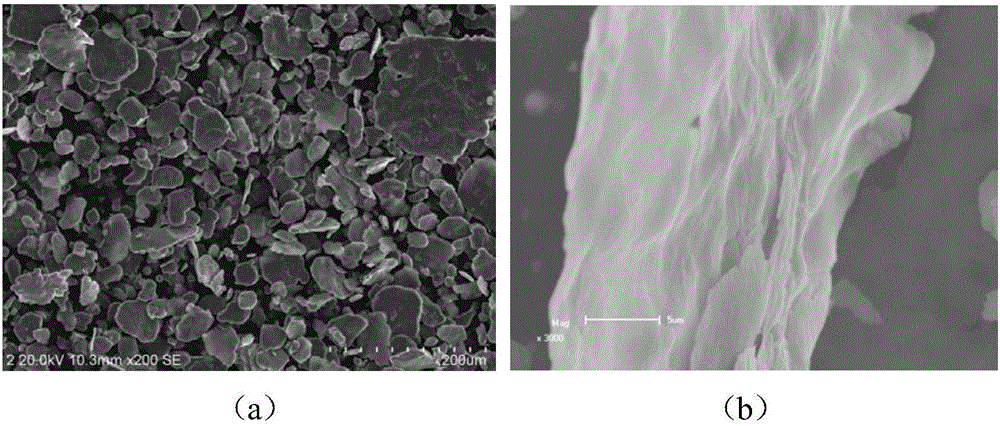

Novel insulin inhalation aerosol powder and preparation method thereof

InactiveCN102058565ASimple process conditionsAvoid residuePeptide/protein ingredientsMetabolism disorderThroatInhalation

The invention discloses novel insulin inhalation aerosol powder, which is characterized by comprising the following components in percentage by weight: 3 to 20 percent of insulin micro powder and 50 to 96 percent of medicinal carrier material. A preparation method comprises the following steps of: (1) preparing the insulin micro powder by using supercritical fluid technology; and (2) preparing the novel insulin inhalation aerosol powder. The invention has the advantages that: the method for preparing the insulin particles by adopting the supercritical fluid technology has simple process conditions, is safe and non-toxic, and has short operation time; the obtained product has round and smooth micro shape, good powder flowability and high yield; and the novel inhalation aerosol powder is prepared by mixing the particles prepared by the supercritical fluid technology and carrier particles with big particle diameters, and the big carrier particles are deposited on the throat and do not enter the lung during inhalation, so the influence of a large amount of irrelevant compounds on the normal function of the lung is avoided, and the novel inhalation aerosol powder has high safety.

Owner:CHINA NAT ACAD NANOTECH & ENG

Tiotropium bromide capsule-type inhalation aerosol powder

ActiveCN102451173BPharmaceutical delivery mechanismPharmaceutical non-active ingredientsMedicineActive component

The invention relates to tiotropium bromide capsule-type inhalation aerosol powder and a preparation process thereof. The bromide capsule-type inhalation aerosol powder comprises a capsule shell and a capsule content, wherein the capsule content is prepared from tiotropium or tiotropium monohydrate, inhalation crystal lactose and inhalation grinding lactose in a certain proportion. The preparation process of the triotropium bromide capsule-type inhalation aerosol powder is simple, the particles have excellent liquidity, active components are uniformly distributed, and the effective part has high sediment yield.

Owner:SHANDONG NEWTIME PHARMA

Aerosol porous particle and application in cigarette

ActiveCN103752260BUniform sizeStable physical and chemical propertiesTobacco smoke filtersSilicon compoundsPrillAdhesive

The invention discloses an aerosol porous particle and application in a cigarette. The aerosol porous particle is prepared by the fluidized bed top shower process taking aerosol powder of 120-300 meshes as the raw material and sodium carboxymethyl starch as an adhesive. The particle has a coarse surface and relatively high specific surface area, can obviously increase the effective contact area between a particular material and the smoke of the cigarette, and is able to selectively absorb hydrogen cyanide in the smoke; and the aerosol porous particle has both functions of reducing harm and lowering the irritation of the smoke of the cigarette. The production process of the aerosol porous particle is simple, the operability and normativity are high, the raw material is easily available, the cost is low, the industrial production can be conveniently realized, and a good application prospect is brought.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

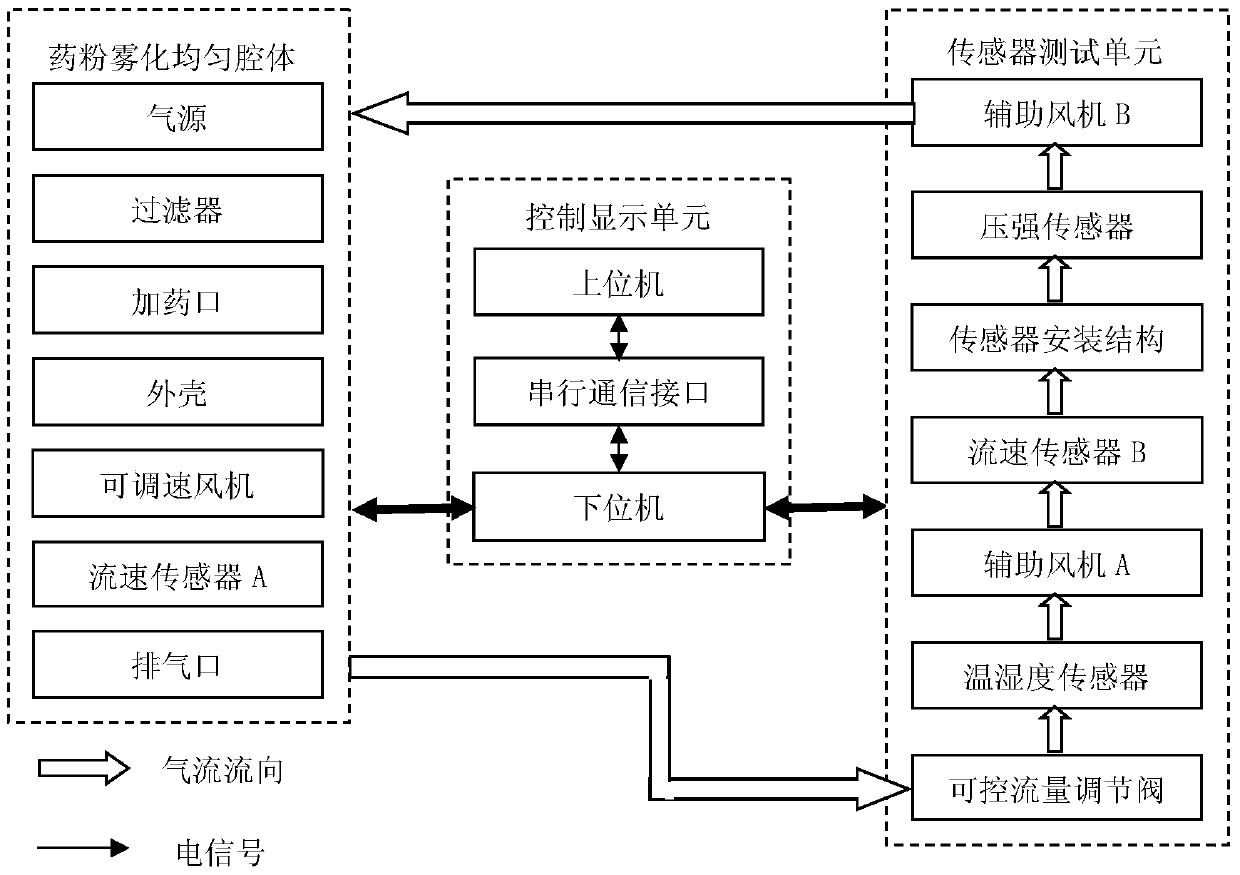

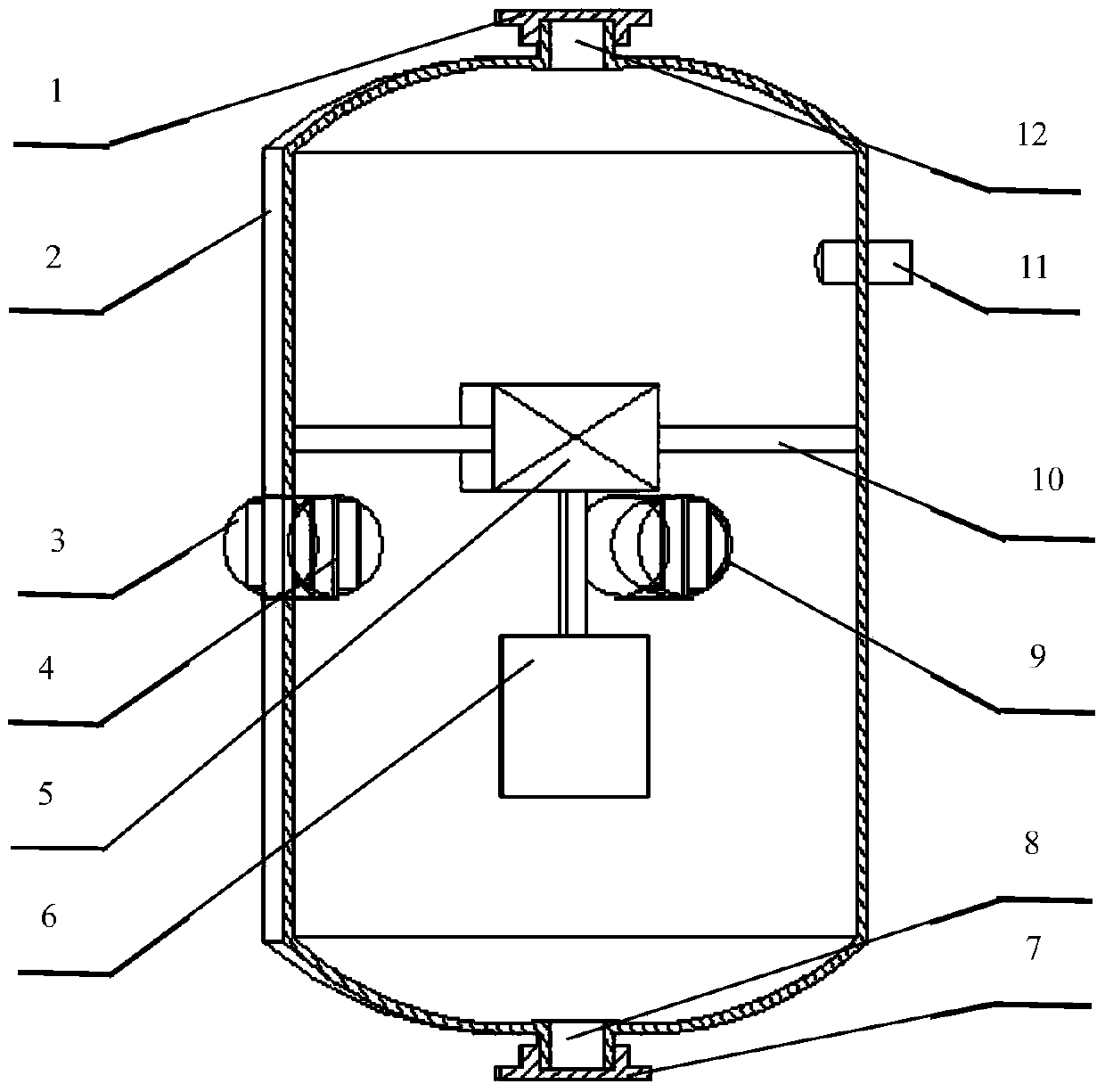

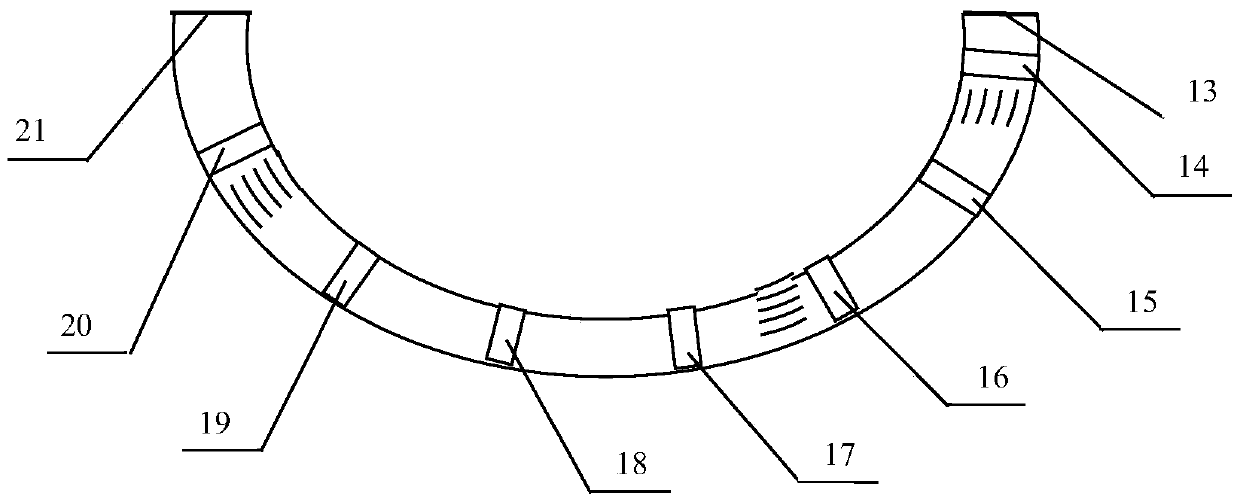

A Calibration Test Device for Medicated Powder Aerosol Concentration Sensor

The invention discloses a calibration test device for a drug powder aerosol concentration sensor. The control and display unit is used for the setting, collection, display and adjustment control of parameters such as airflow velocity and pressure in the device, for data calculation processing and device cleaning; the uniform chamber for powder atomization is used to complete the rapid atomization of drug powder and aerosol of drug powder Mix evenly; use the sensor test unit to simulate the state of the powder aerosol in the output pipeline of the medical nebulizer, and use the concentration, flow rate and pressure of the powder aerosol as variables to calibrate the sensor to be calibrated. The standard medicament powder aerosol prepared by the invention has good uniformity and stability, can be used for calibration tests of various influencing parameters of the sensor to be calibrated, and improves the calibration accuracy of the medicament powder aerosol concentration sensor.

Owner:JIANGSU UNIV

Cable fireproof coating blanket

PendingCN112152165AImprove flame retardant performanceGuaranteed to workElectrical apparatusFire rescueElastomerEngineering

The invention discloses a cable fireproof coating blanket, which relates to the technical field of cable protection and comprises a rectangular blanket body coated with fireproof cotton. The blanket body is sequentially connected with a heat insulation outer layer, a fire extinguishing agent mixed material laying layer, a slow middle layer and a supporting layer from top to bottom in a stacked mode, the fire extinguishing agent mixed material laying layer comprises a superfine dry powder non-woven fabric bag and an aerosol non-woven fabric bag, and the superfine dry powder non-woven fabric bagis filled with superfine dry powder. The aerosol non-woven fabric bag is filled with aerosol powder, and the superfine dry powder non-woven fabric bag and the aerosol non-woven fabric bag are sequentially arranged in a staggered and matched mode. An elastomer is arranged in the slow middle layer and is uniformly filled with a flame retardant; a plurality of buckles are arranged on the two sides of the blanket body in an S-shaped crossed mode, and binding belts for binding the blanket body to a cable are connected to the buckles. The cable is good in heat insulation and fire resistance and safer to use.

Owner:GUANGDONG ANNUO NEW MATERIAL TECHNOLOYG CO LTD

Zanamivir capsule type inhalation aerosol powder and preparation method thereof

The invention relates to a zanamivir capsule type inhalation aerosol powder and a preparation method thereof. The capsule type inhalation aerosol powder comprises a capsule shell and a capsule content, wherein the capsule content is composed of 5 parts by weight of zanamivir super micropowder, 10-18 parts by weight of inhalation crystallization lactose and 2-10 parts by weight of inhalation grinding lactose 40M, and average particle size of the zanamivir super micropowder is less than 5mu m and particle size of an excipient is within the range of 40-100mu m. The zanamivir capsule type inhalation aerosol powder provided by the invention has a simple preparation process, good mobility, low hygroscopicity, high content uniformity and high deposit rate on an effective part.

Owner:SHANDONG NEWTIME PHARMA

Oral lung inhalation aerosol powder

ActiveCN101756942BLittle side effectsReduce dosagePharmaceutical delivery mechanismPharmaceutical non-active ingredientsMedicineBULK ACTIVE INGREDIENT

Owner:TIANJIN JINYAO GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com