Oral lung inhalation aerosol powder

A powder aerosol, lung inhalation technology, applied in the field of inhalation powder aerosol and its preparation, can solve the problems of adverse reactions to the lung, difficult industrialization, affecting the treatment effect, etc. Effect of Pulmonary Deposition Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

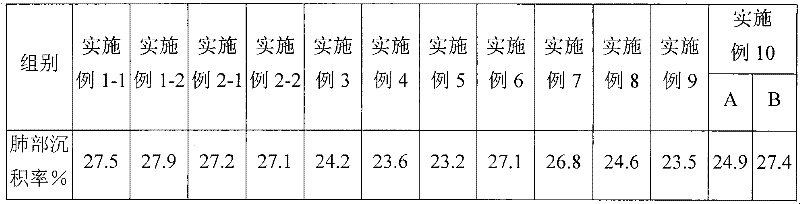

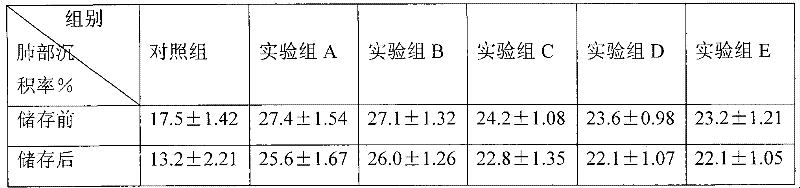

Examples

Embodiment 1-1

[0025] Micronize 0.2 g of budesonide with a flow energy mill so that the average particle size reaches 2 μm, and micronize 10 g of lactose with a flow energy mill to an average particle size of 20 μm. After mixing, pass through a 200-mesh sieve for 3 times before mixing Packed in capsule size 3.

Embodiment 1-2

[0027] According to the formulation of Example 1-1, budesonide was micronized with a flow energy mill to make the average particle size reach 1 μm, and the carrier was changed to octaacetate-D-cellobiose ester with an average particle size of 25 μm, according to Example 1- The process of 1 prepares the powder spray.

Embodiment 2-1

[0029] Dissolve 0.1 g of mometasone furoate in ethanol, filter, spray-dry the filtrate, and micronize it so that the average particle size reaches 4 μm, and micronize 20 g of lactose to an average particle size of 30 μm with a fluid energy mill, mix well, and use 200 Mesh sieve 3 times and mix evenly, then pack into No. 3 capsules.

[0030] The process conditions are as follows: inlet temperature is 105°C, outlet temperature is 68°C, air flow rate is 90%, nozzle outlet inner diameter is 0.1cm, nozzle air flow rate is 800ml / min, and sample injection speed is 50mL / h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com