Aerosol powder valve

A technology for aerosols and aerosol containers, applied in the field of valves for dispensing products, can solve problems such as non-level sealing surfaces, achieve the effect of eliminating powder accumulation and maintaining continuous circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

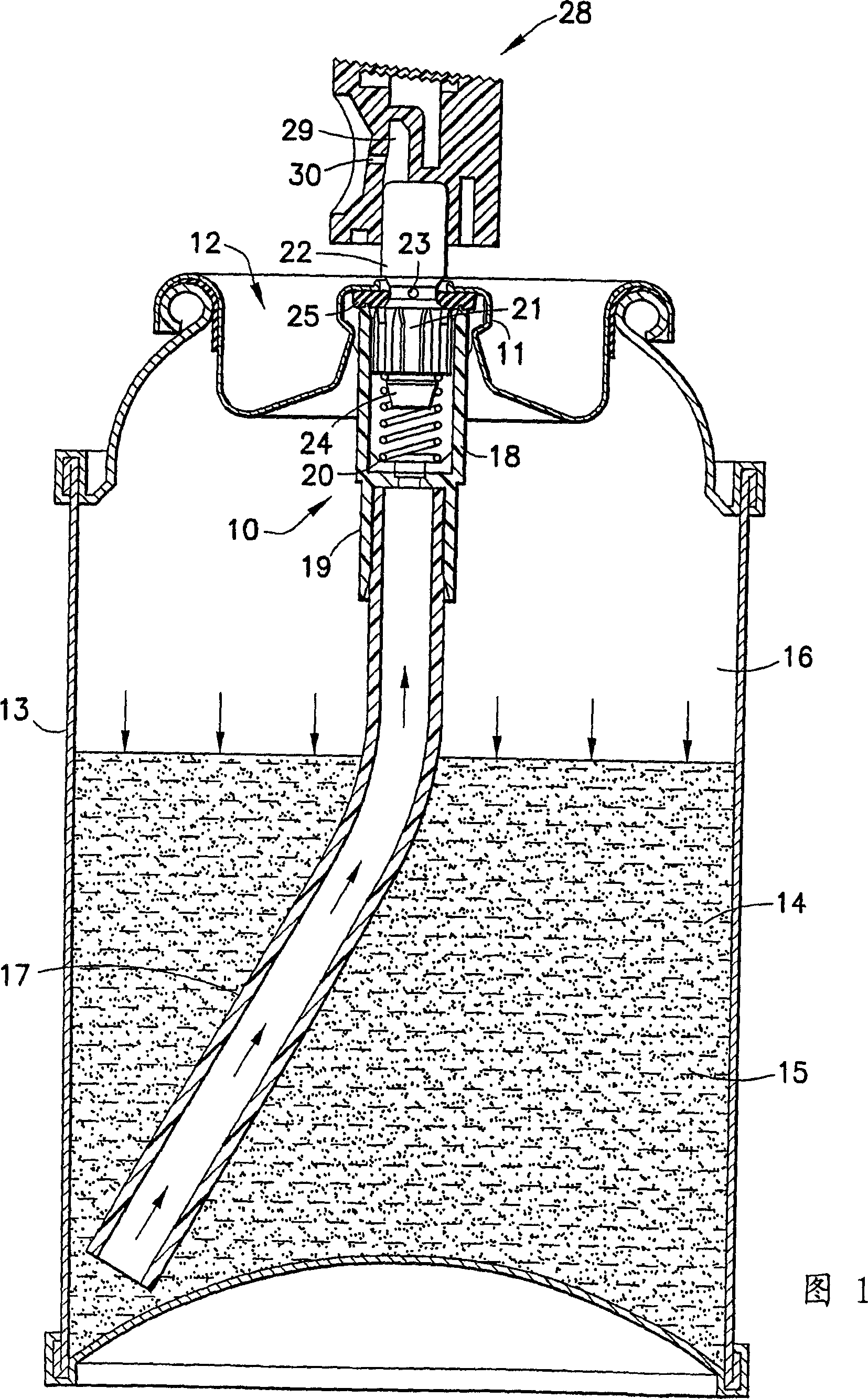

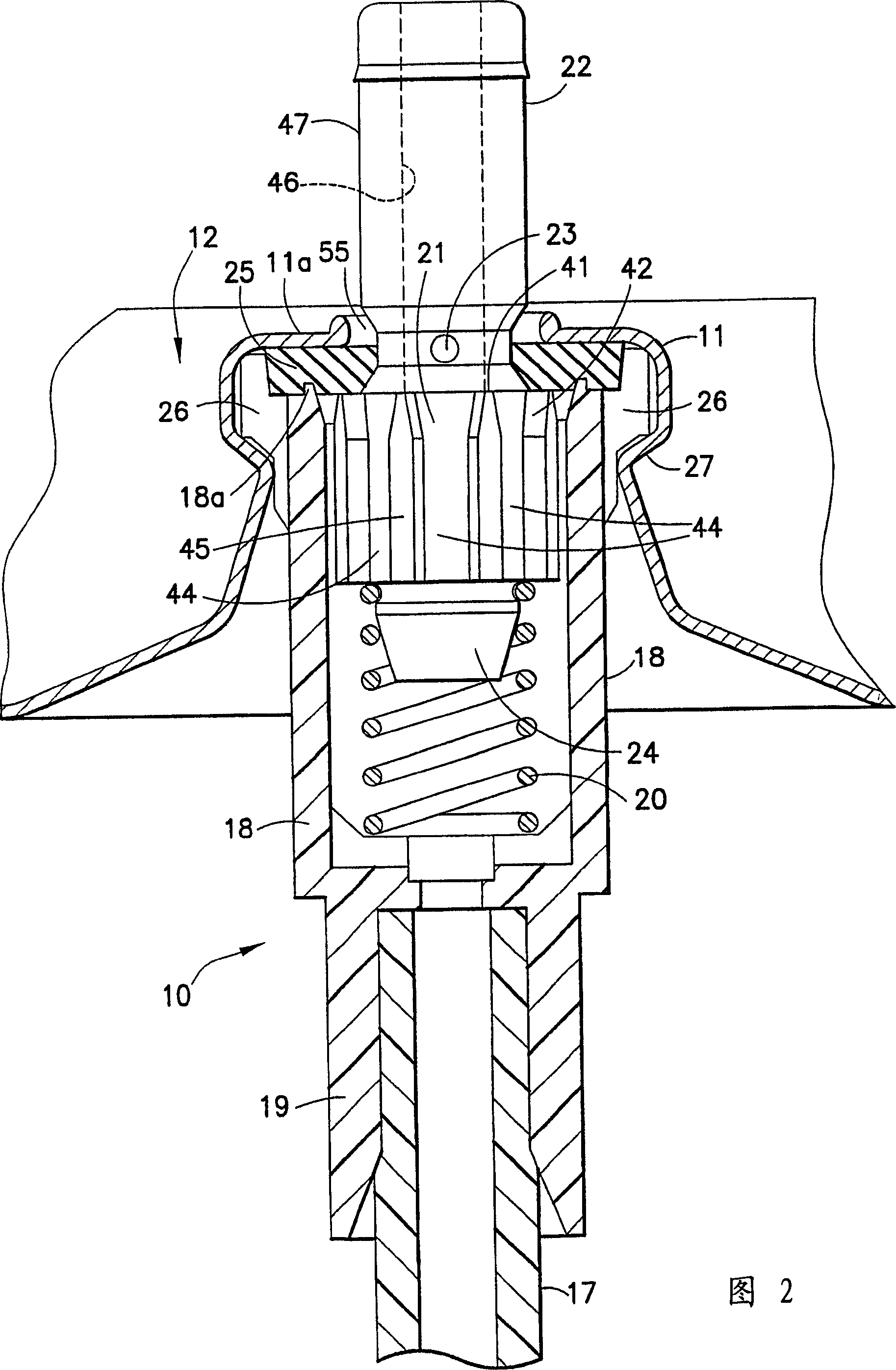

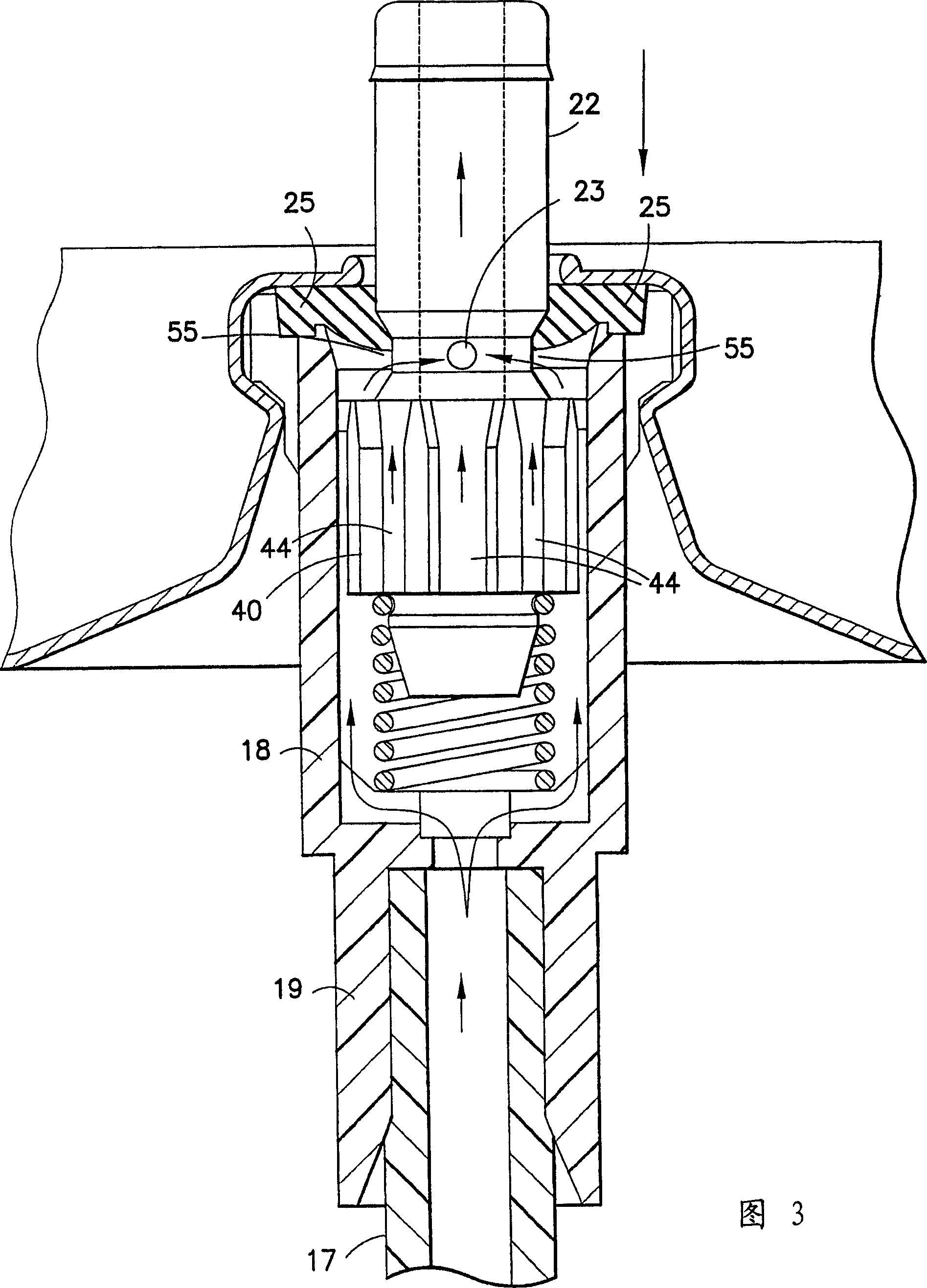

[0023] Referring to FIGS. 1-4 , an aerosol valve assembly, indicated generally at 10 , is mounted and crimped to a base portion 11 of a pressurized container 13 where a cup closure 12 is mounted. The container 13 contains a liquid propellant 14, in which is suspended a powder product 15, and a gas-phase propellant 16 above the liquid propellant.

[0024] Valve assembly 10 generally includes a dip tube 17 , a valve housing 18 , a dip tube receiving passage 19 at the bottom of valve housing 18 , valve closing coil spring 20 , and valve body 21 . The valve body 21 has a hollow valve stem 22 extending upwardly from the valve body 21 and including two transverse holes 23 which enter the interior of the valve stem 22 from the valve stem groove 55 . The protrusion 24 extends downward from the valve body 21 and occupies and centers the top of the coil spring 20 .

[0025]A resilient annular gasket 25 surrounds the valve stem 22, extends into an annular groove 55 of the valve stem 22,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com