A Calibration Test Device for Medicated Powder Aerosol Concentration Sensor

A technology of concentration sensor and test device, applied in the field of medical instruments, can solve the problems of poor stability of airflow velocity and pressure of calibration device, error of calibration result, waste of experimental materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

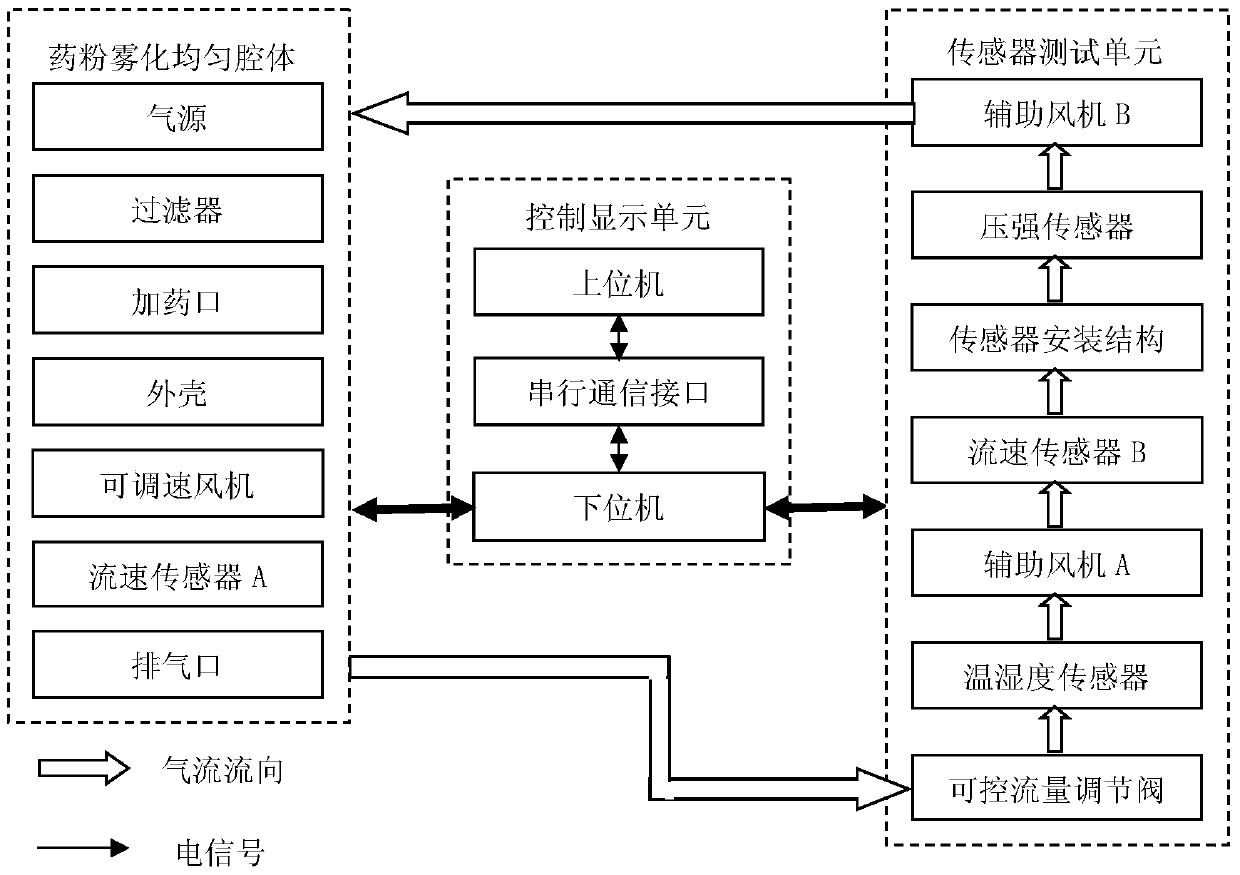

[0042] Such as figure 1 As shown, a calibration test device for aerosol concentration sensor of powdered medicine is composed of uniform chamber for powder atomization, sensor testing unit, control and display unit, splitting plate and deflector for adjusting airflow.

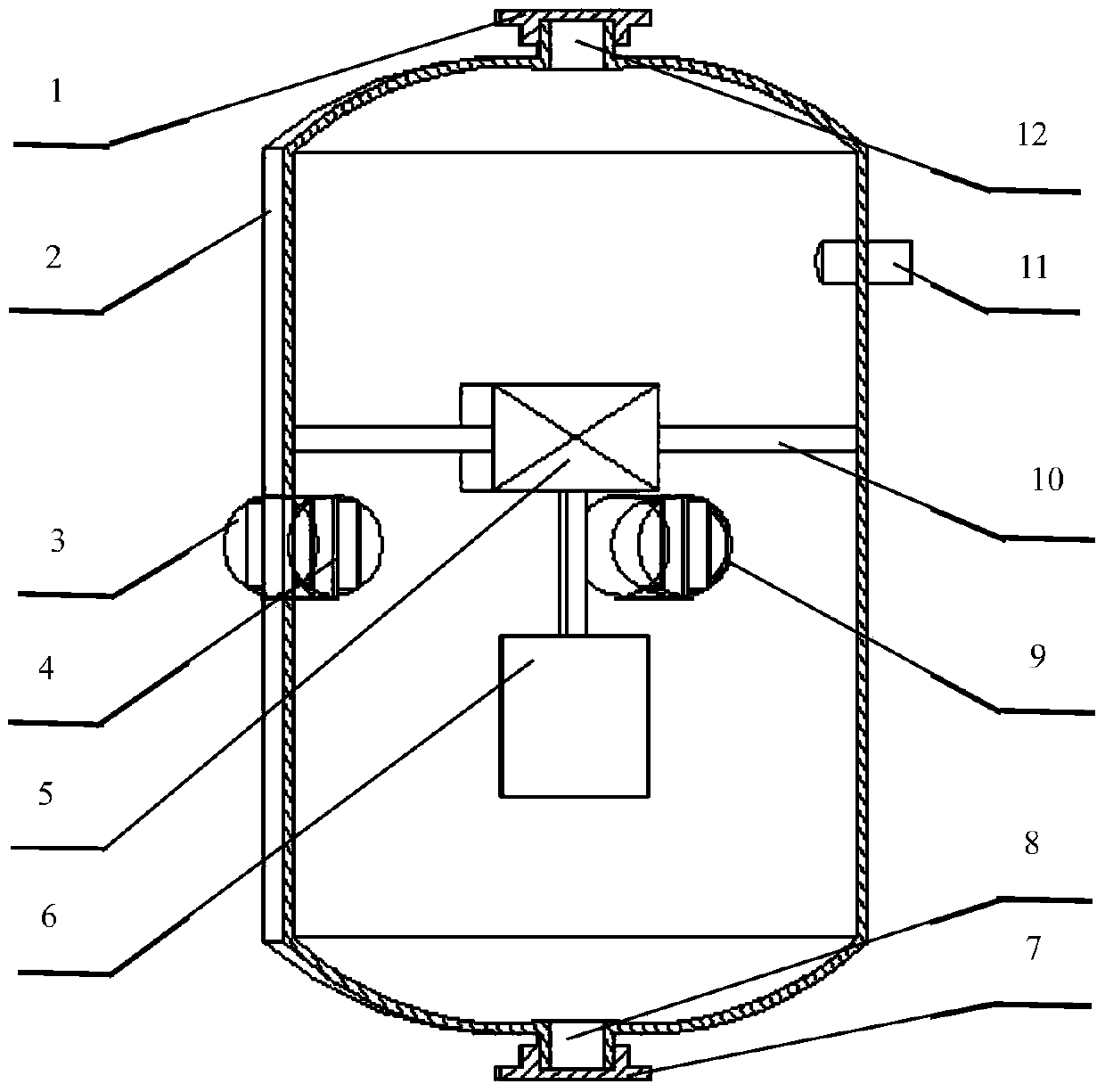

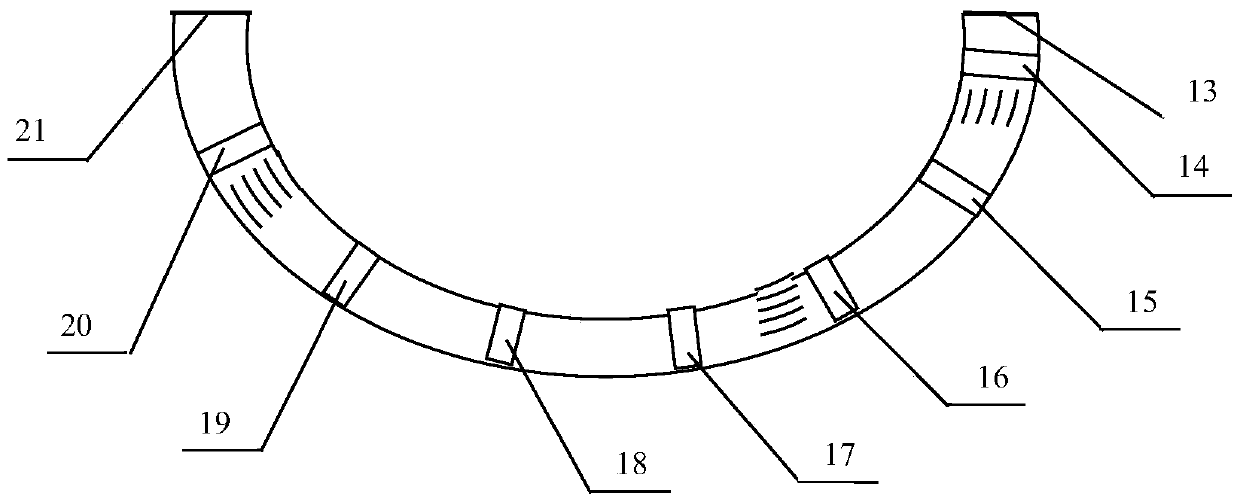

[0043] Such as figure 1 with figure 2As shown, the uniform powder atomization cavity mainly includes an air source, a filter, a dosing port 11, a casing 2, an adjustable-speed fan 5 installed inside the casing 2 by using an adjustable-speed fan mounting bracket 10, and a flow rate sensor A11 and exhaust port 8. Wherein, the top and the bottom of the shell 2 adopt arc-shaped structure; the dosing port 11 and the exhaust port 8 are respectively located at the top and the bottom of the shell 2; the gas source and the dosing port 11 are connected together through a det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com