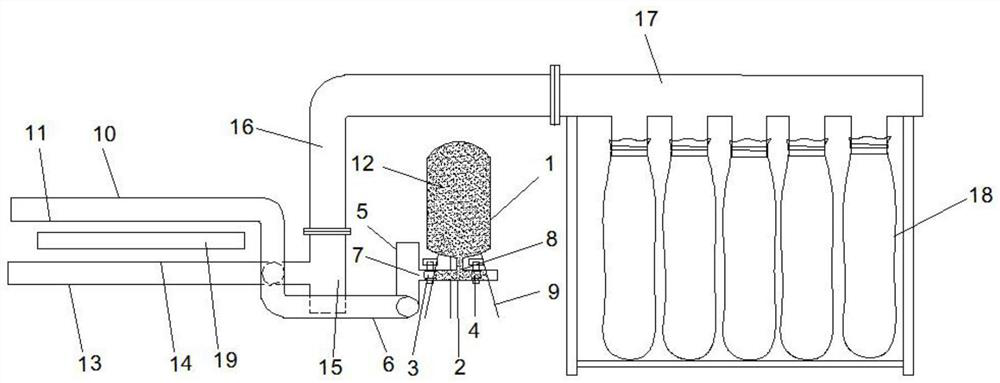

Glass fiber needled felt silicon-based nano aerogel powder spraying and collecting device

A technology of nano-airgel and glass fiber, which is applied to the device and coating of the surface coating liquid, which can solve the problems of low heat insulation efficiency and large heat loss, so as to prevent heat loss, reduce production costs, The effect of preventing air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The powder inlet 7 is arranged in the center of the side wall of the shell of the powder spraying fan 5 facing the axis of the impeller and communicated with the powder inlet pipe 2 .

Embodiment 2

[0028] During the dusting operation, the intake valve 4 is in a normally open state, air is mixed through the intake pipe 9 communicating with the intake valve 4, and the intake valve 4 is in a closed state when the dusting operation is completed.

Embodiment 3

[0030] During the dusting operation, the control valve 3 is in a normally open state, and the opening degree of the control valve 3 corresponds to the control of the air flow rate of the pneumatic conveying dust.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com