Preparation method of spherical titanate cellulose composite aerogel capable of adsorbing radioactive ions and heavy metal ions

A technology of composite aerogel and heavy metal ions, applied in aerosol preparation, alkali metal compounds, radioactive pollutants and other directions, can solve the problems of difficult post-processing, difficult recovery, easy loss, etc. The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

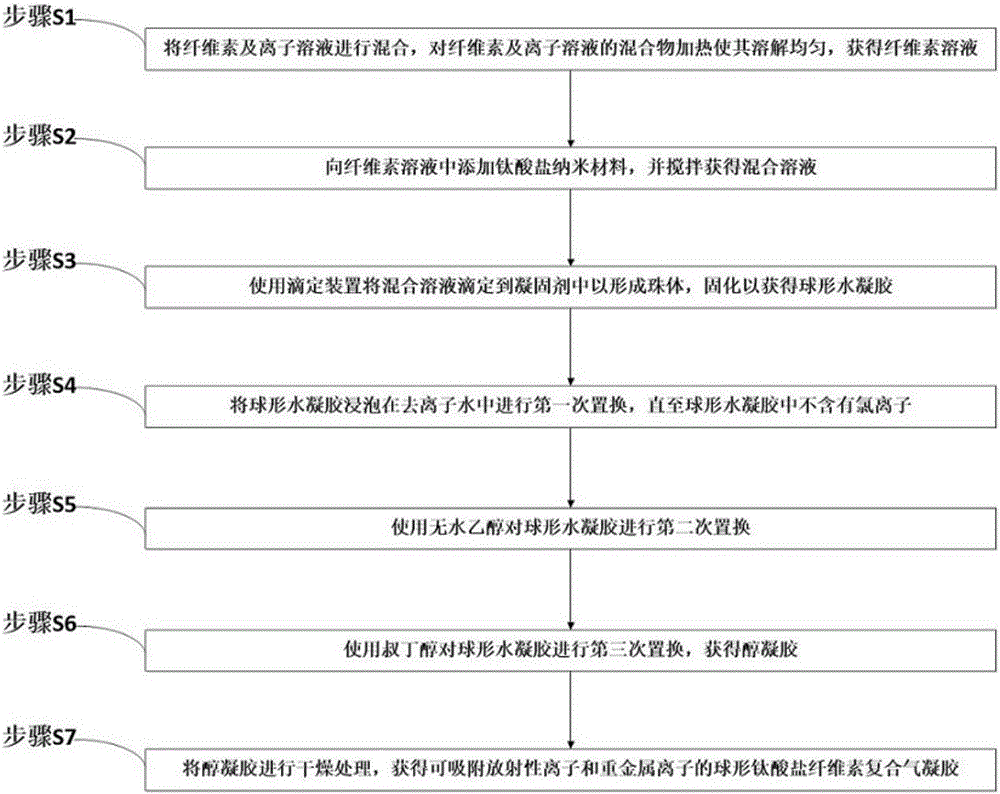

[0026] figure 1 It is a process flow chart of a preparation method of a spherical titanate cellulose composite airgel capable of absorbing radioactive ions and heavy metal ions provided by an embodiment of the present invention. see figure 1 , including the following steps:

[0027] Step S1, adding cellulose and ionic solution to the reaction vessel for mixing, heating the mixture of cellulose and ionic solution to 40-200°C to dissolve it evenly, and obtaining a cellulose solution, wherein the fiber The mass ratio of element to the ion solution is 0.02-0.4:1;

[0028] Step S2, adding titanate nanomaterials to the cellulose solution, and stirring for 5-100 min to obtain a mixed solution, wherein the mass ratio of the titanate nanomaterials to the cellulose is 0.1-50:1 ;

[0029] Step S3, using a titration device to titrate the mixed solution into a coagulant to form beads, and solidify for 6-12 hours to obtain a spherical hydrogel, wherein the coagulant is deionized water; ...

Embodiment 1

[0050] 1. Add cellulose and ionic solution to the reaction vessel for mixing, heat the mixture of cellulose and ionic solution to 40°C to dissolve it uniformly, and obtain a cellulose solution, wherein the cellulose and the ionic solution The mass ratio of the ion solution is 1:50, and the cellulose is bamboo cellulose;

[0051] 2. Add titanate nanomaterials to the cellulose solution, and stir for 5 minutes to obtain a mixed solution, wherein the mass ratio of the titanate nanomaterials to the cellulose is 1:10, and the titanate The salt nanomaterial is a titanate nanofiber, and the agitation is achieved by mechanical agitation;

[0052] 3. Use a titration device to titrate the mixed solution into a coagulant to form beads, and solidify for 6 hours to obtain a spherical hydrogel, wherein the coagulant is deionized water, and the titration device is a rubber dropper ;

[0053] 4. Soak the spherical hydrogel in deionized water for the first replacement, and replace the deioniz...

Embodiment 2

[0058] 1. Add cellulose and ionic solution to the reaction vessel for mixing, heat the mixture of cellulose and ionic solution to 80°C to dissolve it uniformly, and obtain a cellulose solution, wherein the cellulose and the ionic solution The mass ratio of the ion solution is 1:10, and the cellulose is wood cellulose;

[0059] 2. Add titanate nanomaterials to the cellulose solution, and stir for 10 minutes to obtain a mixed solution, wherein the mass ratio of the titanate nanomaterials to the cellulose is 1:1, and the titanate The salt nanomaterial is a titanate nanotube, and the stirring is achieved by glass stirring;

[0060] 3. Use a titration device to titrate the mixed solution into a coagulant to form beads, and solidify for 8 hours to obtain a spherical hydrogel, wherein the coagulant is deionized water, and the titration device is a syringe;

[0061] 4. Soak the spherical hydrogel in deionized water for the first replacement, and replace the deionized water every 7 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com