Preparation method for noble metal modified titanium anode materials

A precious metal and titanium anode technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of time-consuming 3-10 hours, many operating process control parameters, and shortened life of anode materials, etc., to achieve low consumption of pure titanium , Reduce acid consumption, reduce the effect of precious metal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

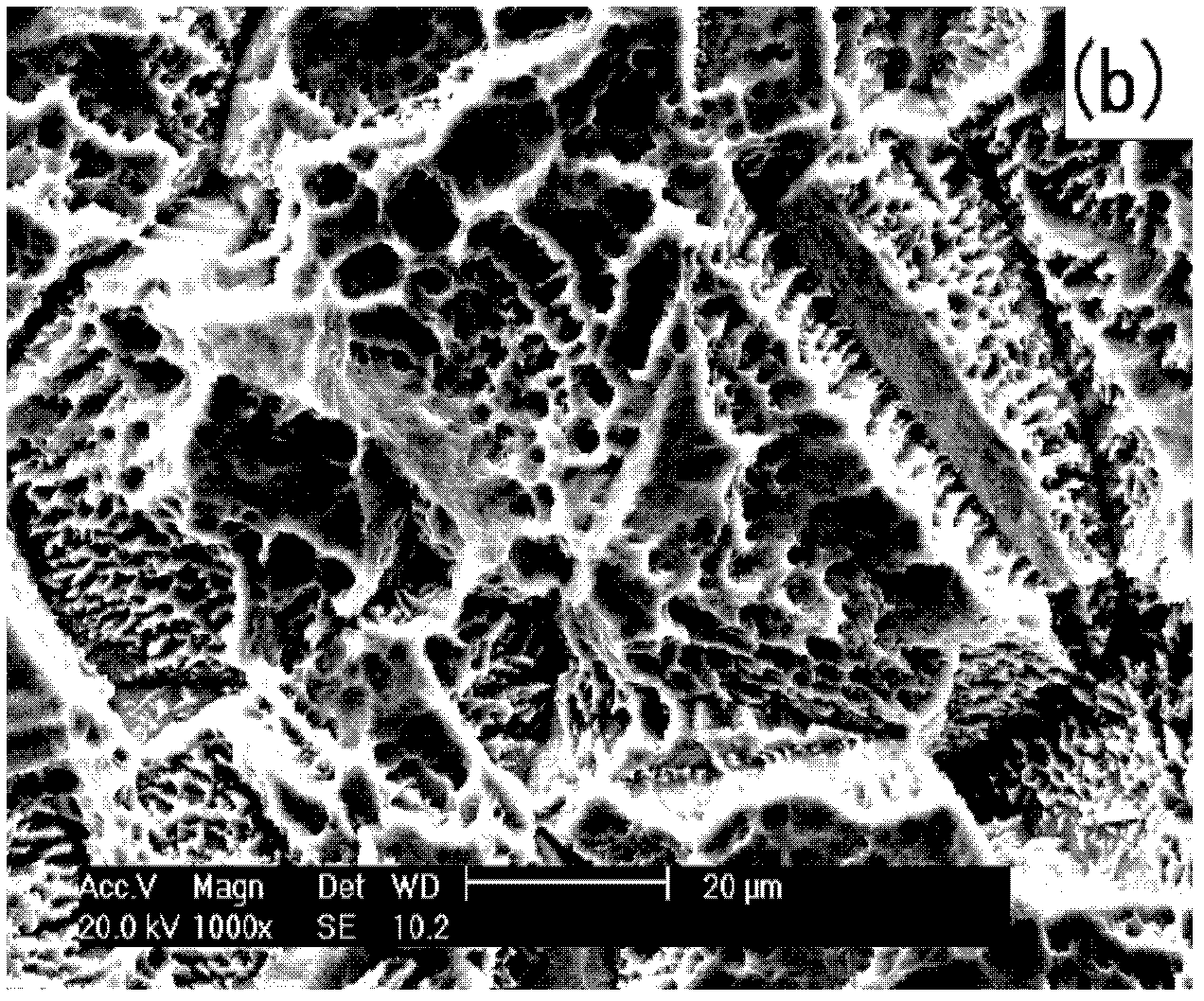

[0061] The preparation method of the noble metal modified titanium anode material adopts the noble metal organic complex as the precursor, and the precursor is dissolved in an organic solvent and then atomized into an atomized gas flow, deposited on the surface of the titanium metal plate, thermally decomposed and cooled in the presence of an inert gas, The three consecutive steps of deposition, thermal decomposition and cooling are repeated more than once, and the finished product is obtained after post-processing.

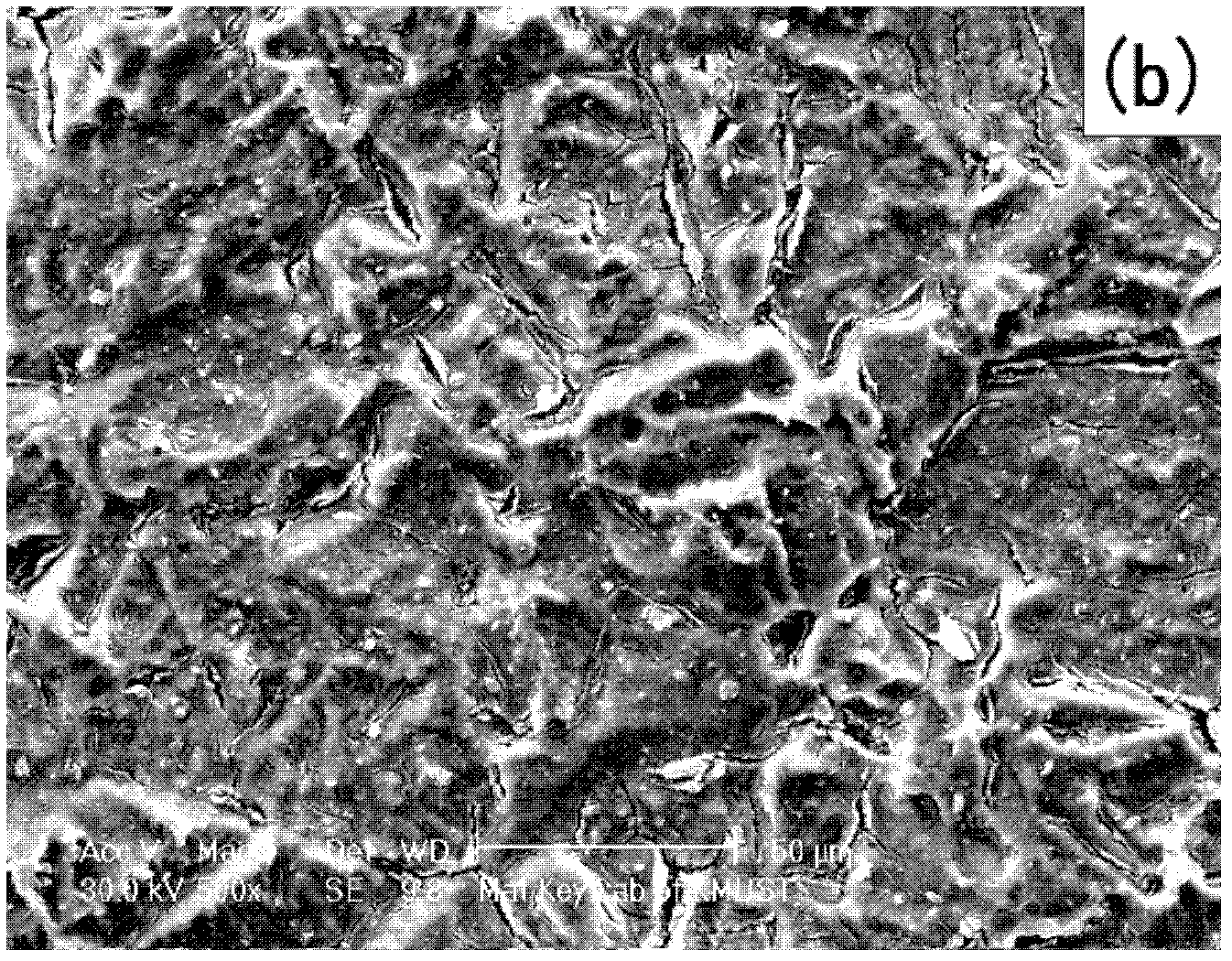

[0062] In order to obtain a metal coating with good adhesion to the substrate, a series of pretreatment and surface modification are required for titanium metal, including: sandblasting, alkaline cleaning and degreasing, and ultrasonic acid etching activation. The ultrasonic acid etching activation is to place the metal titanium substrate in oxalic acid with a concentration of 10-20% by volume, the ultrasonic frequency is 30-120kHz, the ultrasonic power is 20-2000...

Embodiment 1

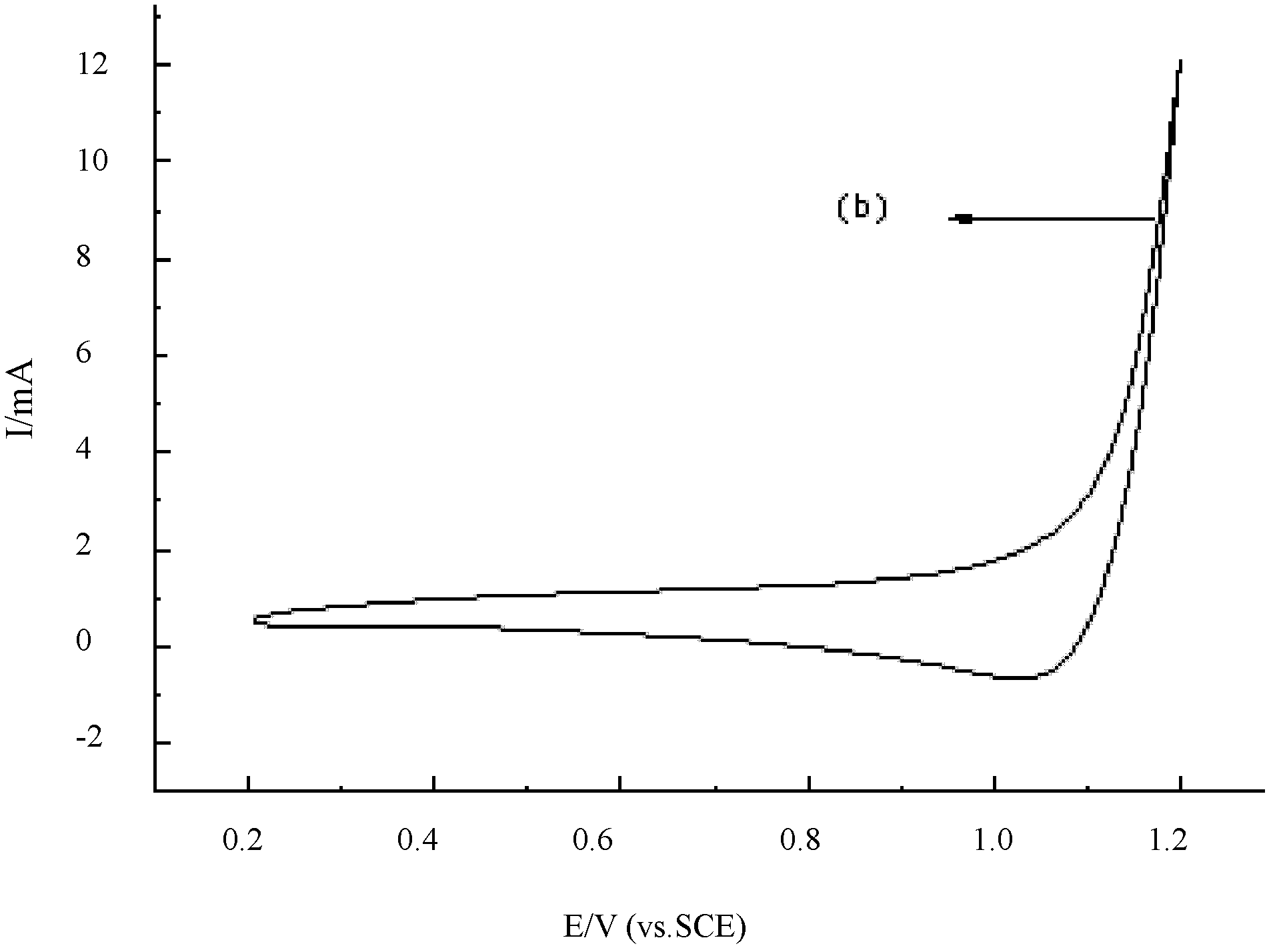

[0069] Embodiment 1 Single noble metal coated titanium anode

[0070] Industrial titanium (brand TA2) with a cutting size of 100×30×1.5 (mm) was used as a metal titanium substrate. After the surface was sandblasted, it was soaked in 5% NaOH solution at 70°C for 20 minutes to remove oil. Then, an ultrasonic instrument with an ultrasonic frequency of 50 kHz and an ultrasonic power of 100 W was selected for ultrasonic activation etching, and a 10% oxalic acid solution with a concentration of 10% by weight at 70° C. was used for ultrasonication for 30 minutes. The pretreated titanium metal substrates were stored dry in a vacuum oven at 10°C.

[0071] Using iridium acetylacetonate as a precursor, it was dissolved in dimethyl sulfoxide and diluted to a concentration of 3% by weight. Place the diluted solution in a high-efficiency ultrasonic atomization device to make the solution into an atomized gaseous state, and use argon as a carrier gas to guide the atomized gas flow into the ...

Embodiment 2

[0073] Embodiment 2 Single noble metal coated titanium anode

[0074] Industrial titanium (brand TA2) with a cutting size of 100×30×1.5 (mm) was used as a metal titanium substrate. After the surface was sandblasted, it was soaked in 5% NaOH solution at 70°C for 20 minutes to remove oil. Then, an ultrasonic instrument with an ultrasonic frequency of 50 kHz and an ultrasonic power of 100 W was selected for ultrasonic activation of etching, and an oxalic acid solution with a concentration of 15% by weight at 60° C. was used for ultrasonication for 45 minutes. The pretreated titanium metal substrate is dried and stored in a low-temperature vacuum oven.

[0075] Ruthenium acetylacetonate was used as a precursor, which was dissolved in dimethyl sulfoxide and diluted to a concentration of 4% by weight. Place the diluted solution in a high-efficiency ultrasonic atomization device to make the solution into an atomized gaseous state, and use nitrogen as a carrier gas to guide the atomi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com