Ring forging and rolling processing method of bearing ring parts used for large-scale wind turbine unit

A technology of wind turbines and processing methods, applied in applications, household appliances, and other household appliances, can solve problems such as high cold brittleness, poor ability to resist harsh environments, and complicated processes, and achieve strong toughness, good hardenability, and reduced cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

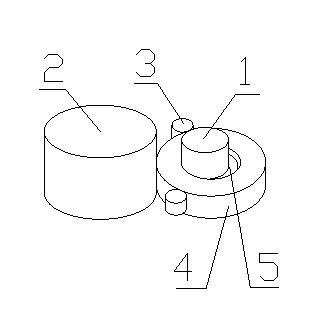

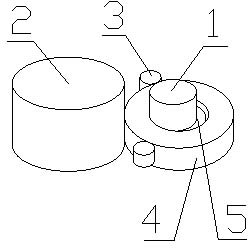

[0026] The invention discloses a processing method of a bearing ring for a large-scale wind power generating set which is processed by forging and rolling the ring. The method mainly adopts the processing process of hot rolling and heat treatment, and cooperates with a specially designed composite mold to achieve To achieve the purpose of obtaining two bearing rings in one roll, the main steps are:

[0027] 1) Cutting: The steel ingot is cut according to the required thickness of the bearing rings for two large wind turbines to make a billet. The raw material is 42CrMo4, of which C0.41%, Si0.26%, Mn0.75%, P0.011 %, S0.005%, Ni0.02%, Cr1.09%, Mo0.17%, O≤0.0025%, N≤0.009%, H≤0.0002%, V0.005%, Cu0.014%, Al0.024 %, Ti0.003%, first calculate the weight of the two bearing rings, and then based on twice the weight, plus 2.5% consumption, that is the weight of the blank.

[0028] 2) First heating: heat the billet to 1220°C by the heating furnace, keep it for 150 minutes, and take it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com