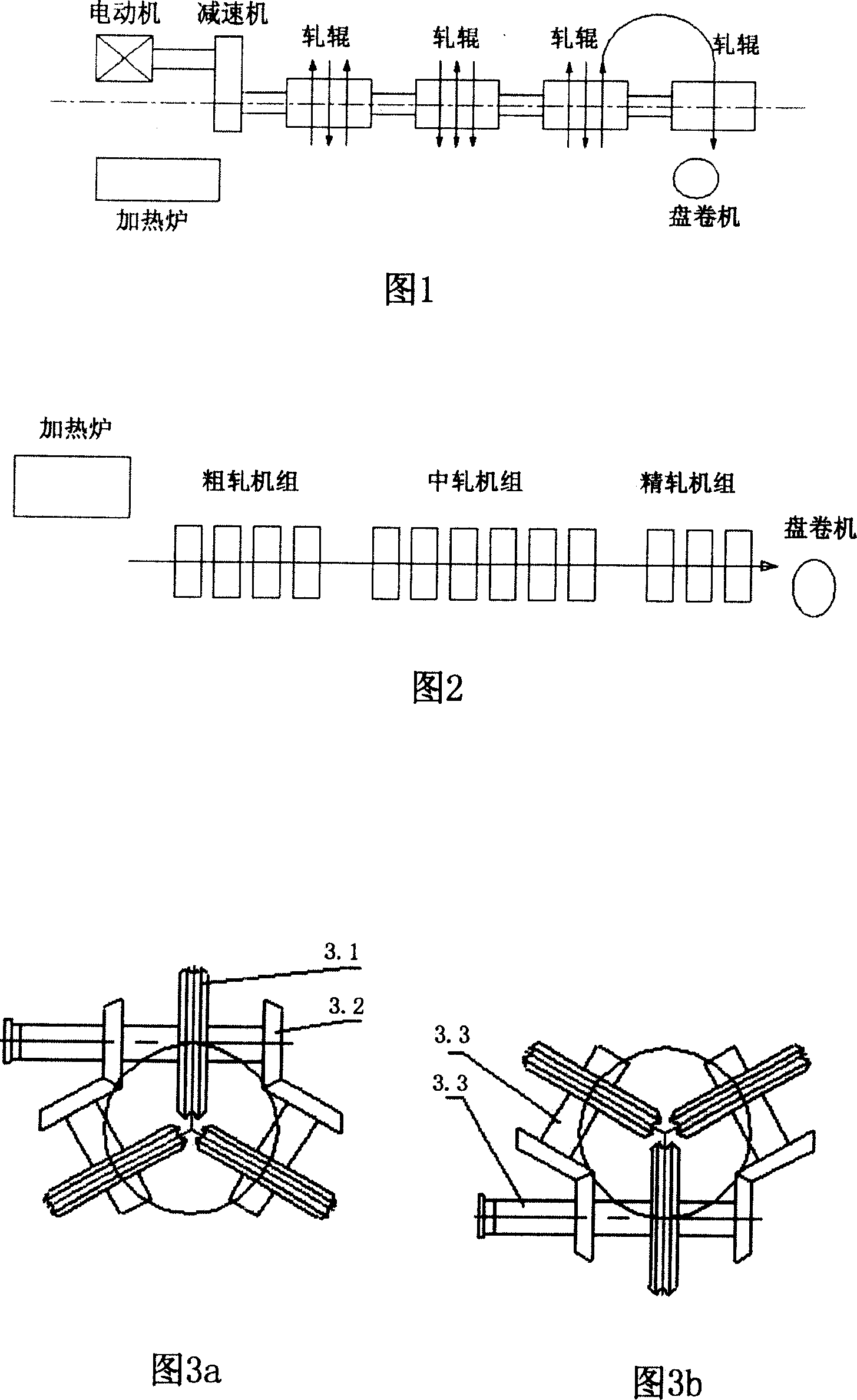

Method for rolling titanium and titanium alloy bar wire bar with three-roller type Y continuous rolling mill

A technology of continuous rolling mill and titanium alloy, which is applied in the direction of rolling mill control device, metal rolling, roll speed control, etc., and can solve the problems of relying too much on the skills of operators, unstable production, and unstable rolled pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

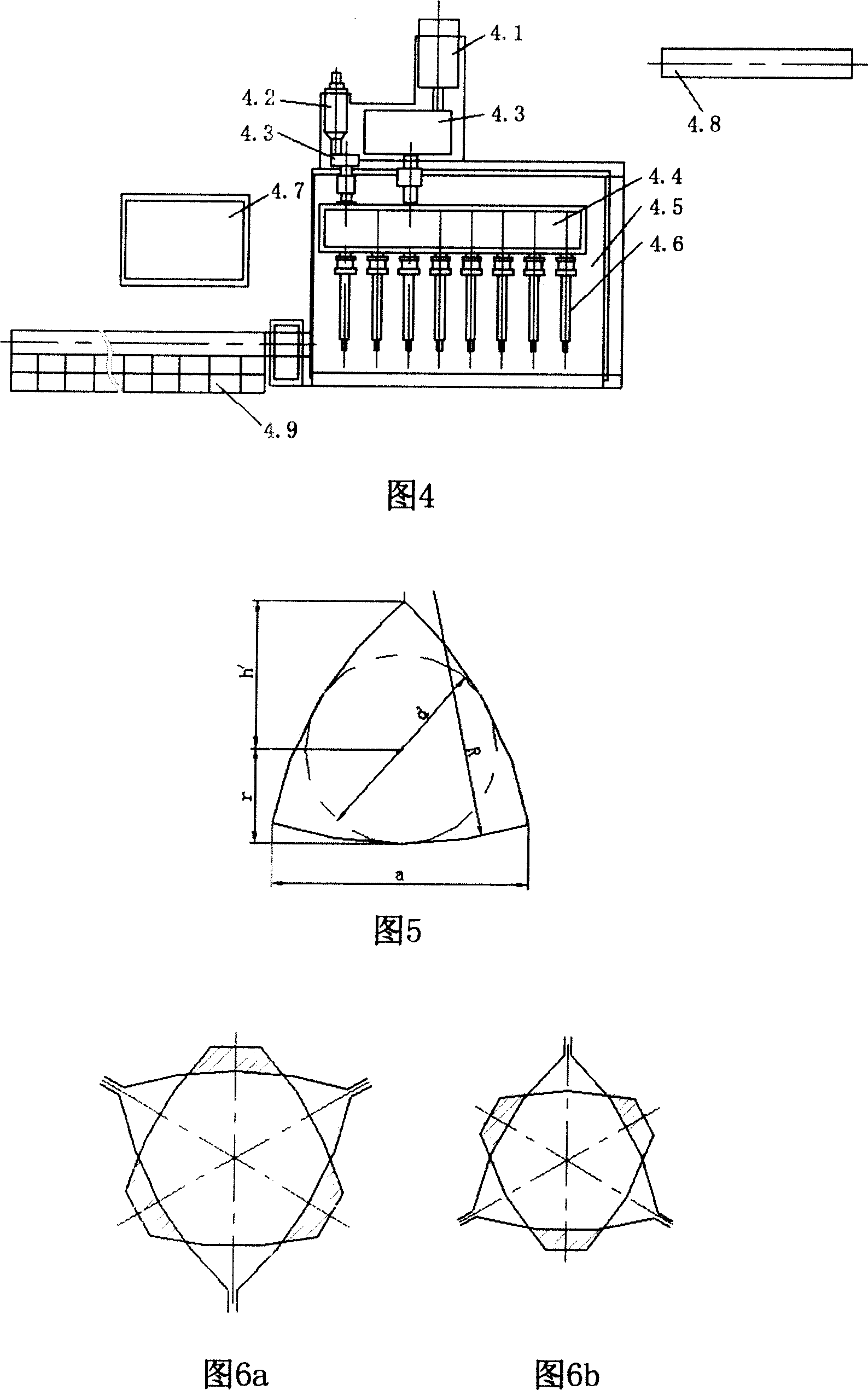

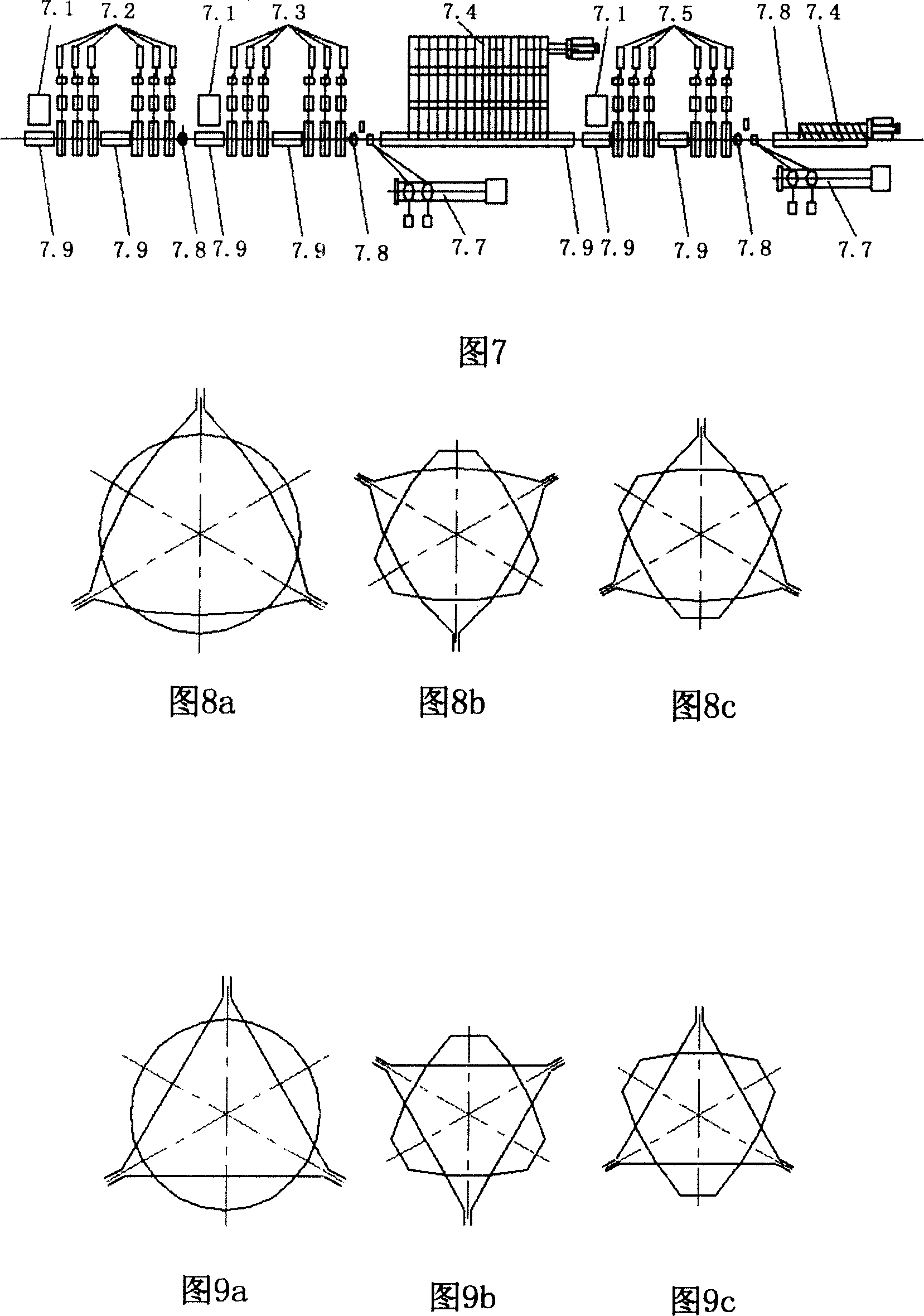

Embodiment Construction

[0054] The following is a description of the equipment of the three-roll Y-rolling mill line composed of trolley heating furnace, three-roll Y-rolling unit, flying shear, cooling bed, coiler, and raceway:

[0055] Trolley heating furnace:

[0056] The main technical parameters:

[0057] Model: HL-180

[0058] Rated power: 360-180kw

[0059] Rated voltage: 380V

[0060] Number of phases: 3N

[0061] Frequency: 50HZ

[0062] Rated temperature: 1100℃

[0063] Number of heating zones: 12-6

[0064] Heating element connection: Y

[0065] Working size: 14000-7000×500×500mm(L×W×H)

[0066] Empty furnace heating time: ≤2-4h (20℃→1100℃)

[0067] Furnace temperature uniformity: ±10℃

[0068] Temperature control accuracy: ±1°C

[0069] Surface temperature rise: (side wall) ≤50°C

[0070] Trolley

[0071] The trolley is mainly composed of a chassis, a fire-resistant insulation layer and a drive system;

[0072] ◆The chassis is made of steel plate and section steel with a box...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com