Method for simultaneously rolling and expanding two trapezoid-cross-section flange ring forge pieces

A trapezoidal section, ring forging technology, applied in gas flame welding equipment, metal rolling, manufacturing tools, etc., can solve the problems of low utilization rate of equipment, low utilization rate of materials, low production efficiency, etc., to save raw materials and improve organization. and performance, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

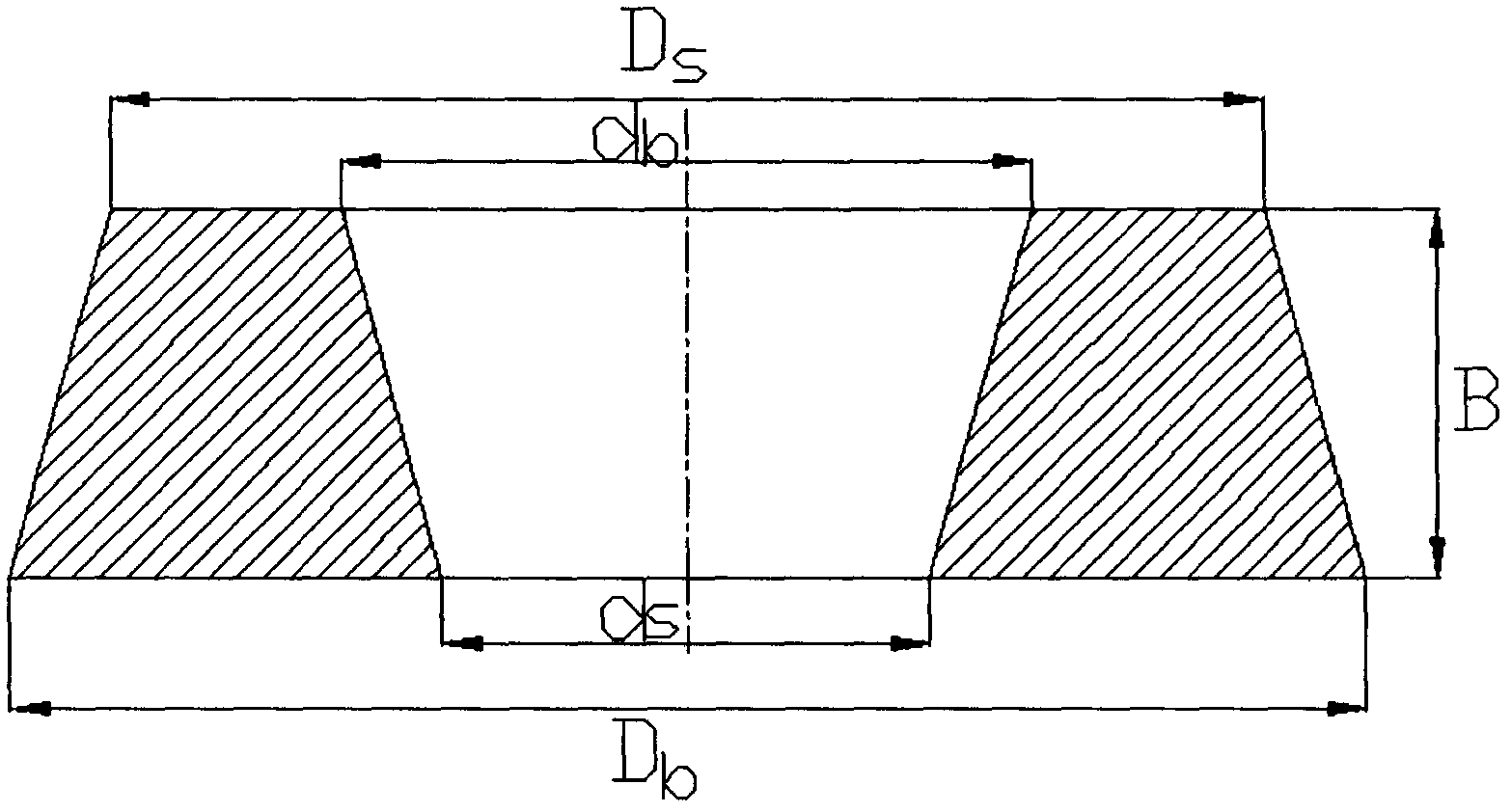

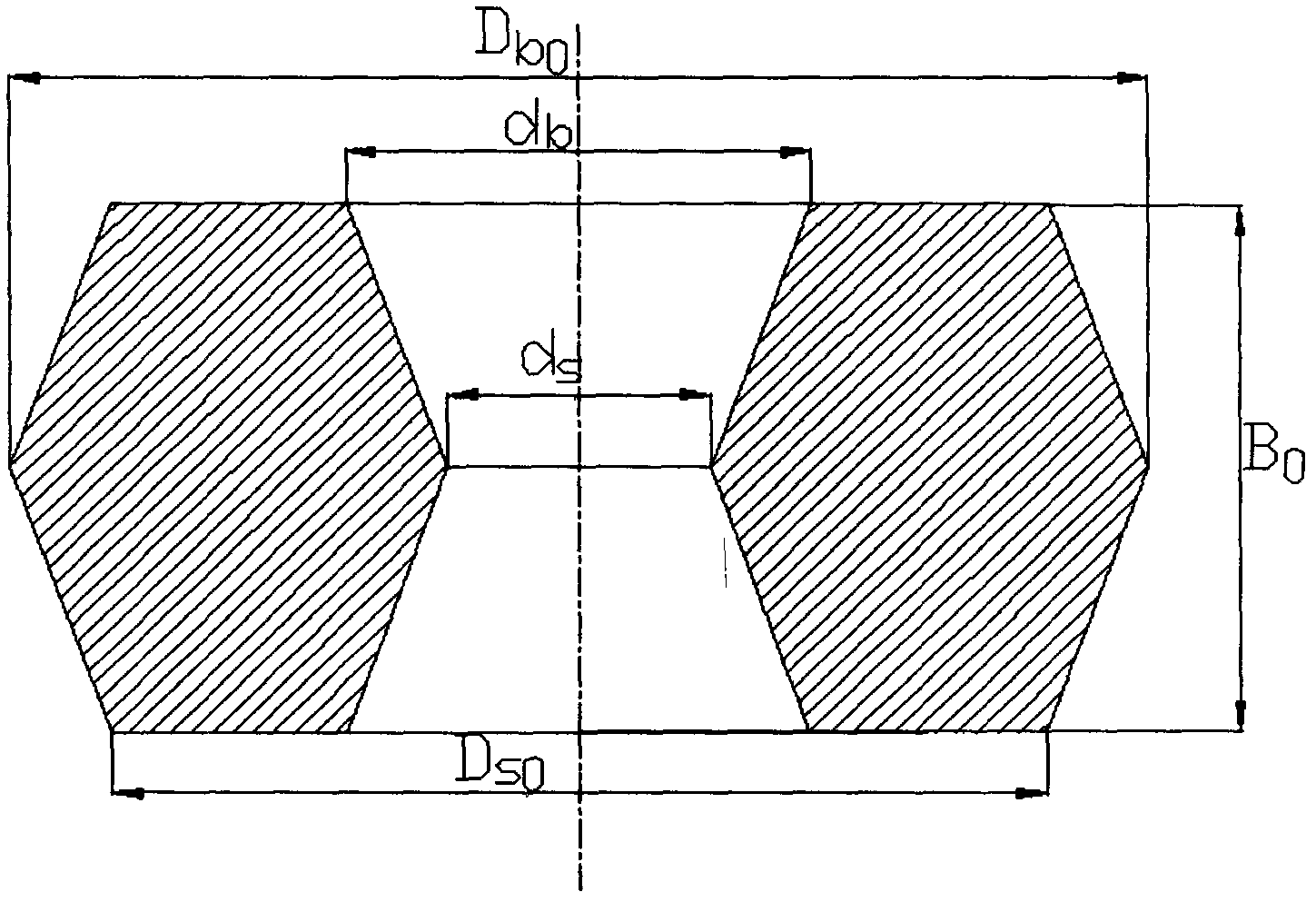

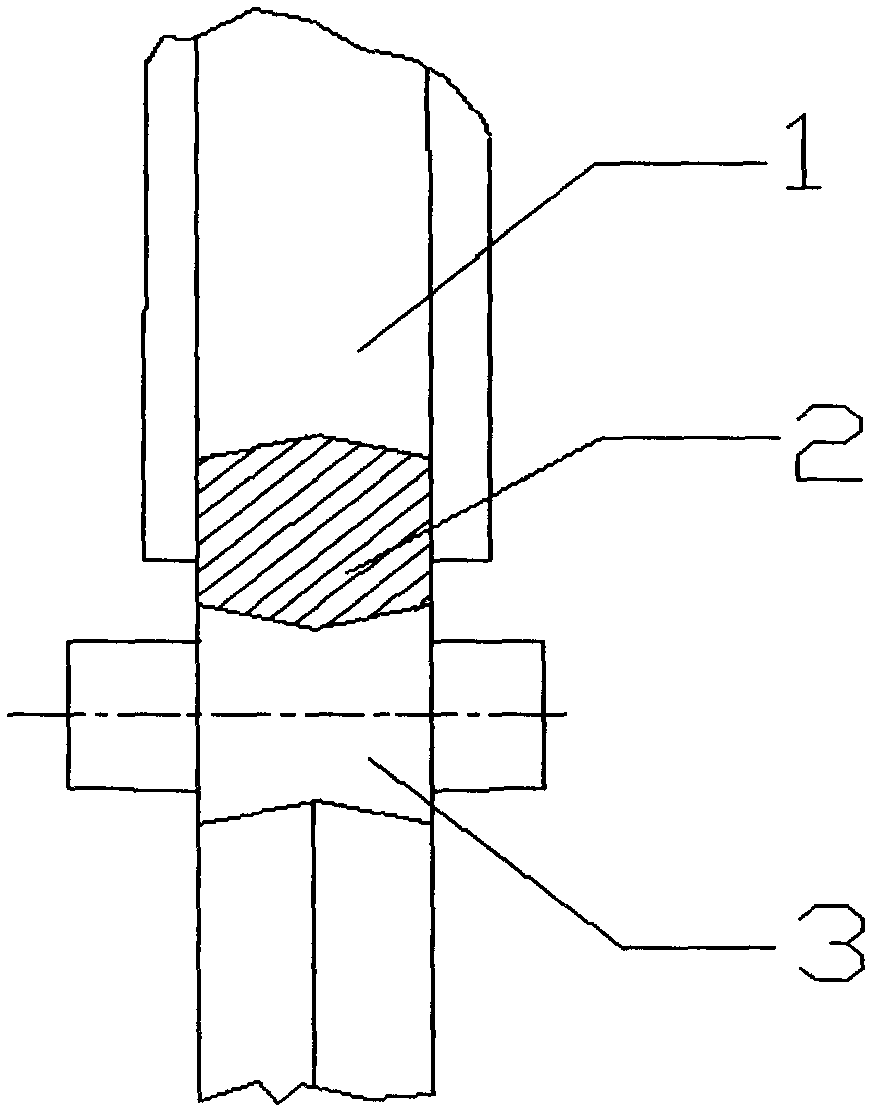

[0029] The method of rolling and expanding two trapezoidal cross-section flange ring forgings at the same time. The forging material is Q345E steel. The dimension of the trapezoidal cross-section flange ring forging required to be rolled is: the maximum outer diameter of the ring forging is D b 4000mm, minimum outer diameter D s is 3900mm, the minimum diameter of the inner hole of the ring forging is d s is 3600mm, the maximum diameter of the ring forging inner hole d b is 3700mm, and the axial dimension B of the ring forging is 200mm. The steps are as follows:

[0030] (1) Cutting the material, sawing the cylindrical steel billet into the material section; the length of the material section is L=3.5B=750mm, B is the axial height of the trapezoidal cross-section flange ring forging, and the diameter of the material section is based on the ring forging The condition that the volume is equal to the volume of the feed section is determined to be 1070mm.

[0031] (2) Slowly he...

Embodiment 2

[0036] The method of rolling and expanding two trapezoidal cross-section flange ring forgings at the same time. The forging material is Q345E steel. The dimension of the trapezoidal cross-section flange ring forging required to be rolled is: the maximum outer diameter of the ring forging is D b 3200mm, minimum outer diameter D s is 3100mm, the minimum diameter of the inner hole of the ring forging is d s is 2800mm, the maximum diameter of the ring forging inner hole d b is 2900mm, and the axial dimension B of the ring forging is 150mm. The steps are as follows:

[0037] (1) blanking, sawing the cylindrical steel billet into material sections; the length of the material section is L=4B=600mm, B is the axial height of the trapezoidal cross-section flange ring forging, and the diameter of the material section is based on the volume of the ring forging The condition equal to the volume of the feed section is determined to be 800mm.

[0038] (2) Slowly heat the above material s...

Embodiment 3

[0043] The method of rolling and expanding two trapezoidal cross-section flange ring forgings at the same time. The forging material is Q345E steel. The dimension of the trapezoidal cross-section flange ring forging required to be rolled is: the maximum outer diameter of the ring forging is D b 2500mm, minimum outer diameter D s is 2450mm, the minimum diameter of the inner hole of the ring forging is d s is 2200mm, the maximum diameter of the inner hole of the ring forging d b is 2250mm, and the axial dimension B of the ring forging is 140mm. The steps are as follows:

[0044] (1) blanking, sawing the cylindrical steel billet into material sections; the length of the material section is L=4B=640mm, B is the axial height of the trapezoidal cross-section flange ring forging, and the diameter of the material section is based on the volume of the ring forging The condition equal to the volume of the feed section is determined to be 630mm.

[0045] (2) Slowly heat the above mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com