Method for correcting tubular structure diameter distortion by flame

A technology for pyrotechnic correction and cylinder body, which is applied in the field of flame correction method, can solve the problems of scrapping the cylinder structure, increase the working cycle of correction, etc., and achieve the effects of good control, prevention of scrapping, and shortening of the cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

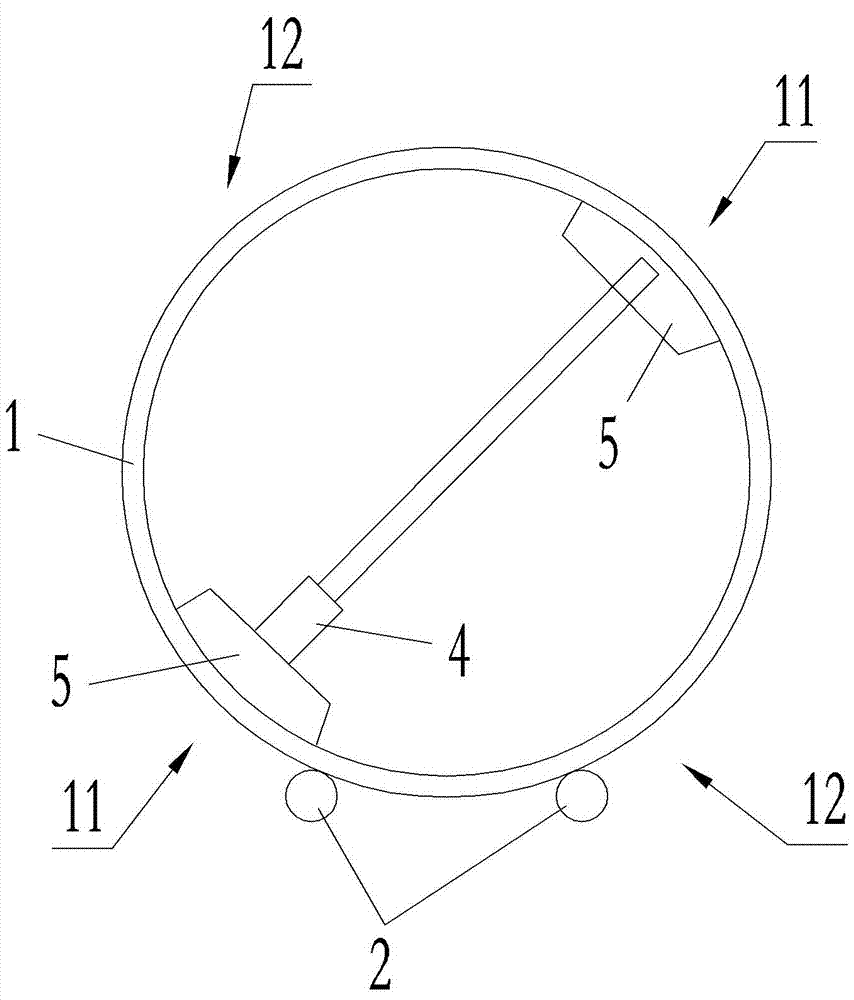

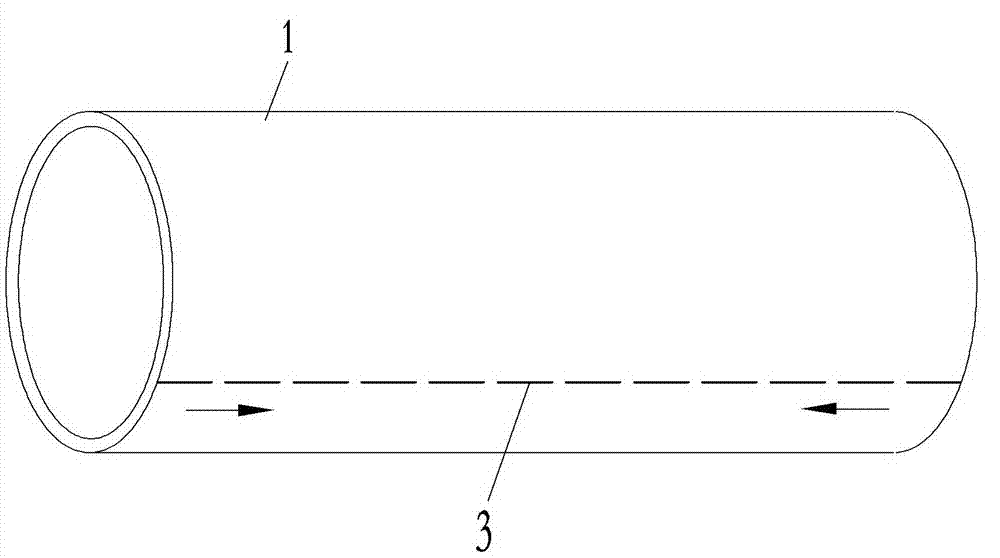

[0014] Such as figure 1 , figure 2 As shown, the pyrotechnic rectification method for the out-of-tolerance cylinder structure described in the present invention, at first, the cylinder structure 1 after welding and cooling is placed on the existing roller welding tool 2, and when the roller welding tool 2 is working, The cylinder structure 1 can be driven to rotate by the roller welding tool 2 to facilitate the measurement of the roundness of the cylinder structure 1 and record it; then, according to the measurement results, the inner wall of the area 11 where the roundness error value of the cylinder structure 1 is negative Apply a radially outward thrust, so that the area 11 with a negative roundness error value has an additional stress acting radially outward on this area in advance, and the outer wall axis of the area 12 where the roundness error of the cylindrical structure 1 is greater than the tolerance Draw the heating line 3 in the direction; then, along the heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com