Bearing inner sleeve screening device

A technology of bearing inner sleeve and screening device, applied in the field of bearing processing, can solve the problems of processing equipment damage, bearing scrap, product waste, etc., and achieve the effect of avoiding product waste and preventing bearing scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

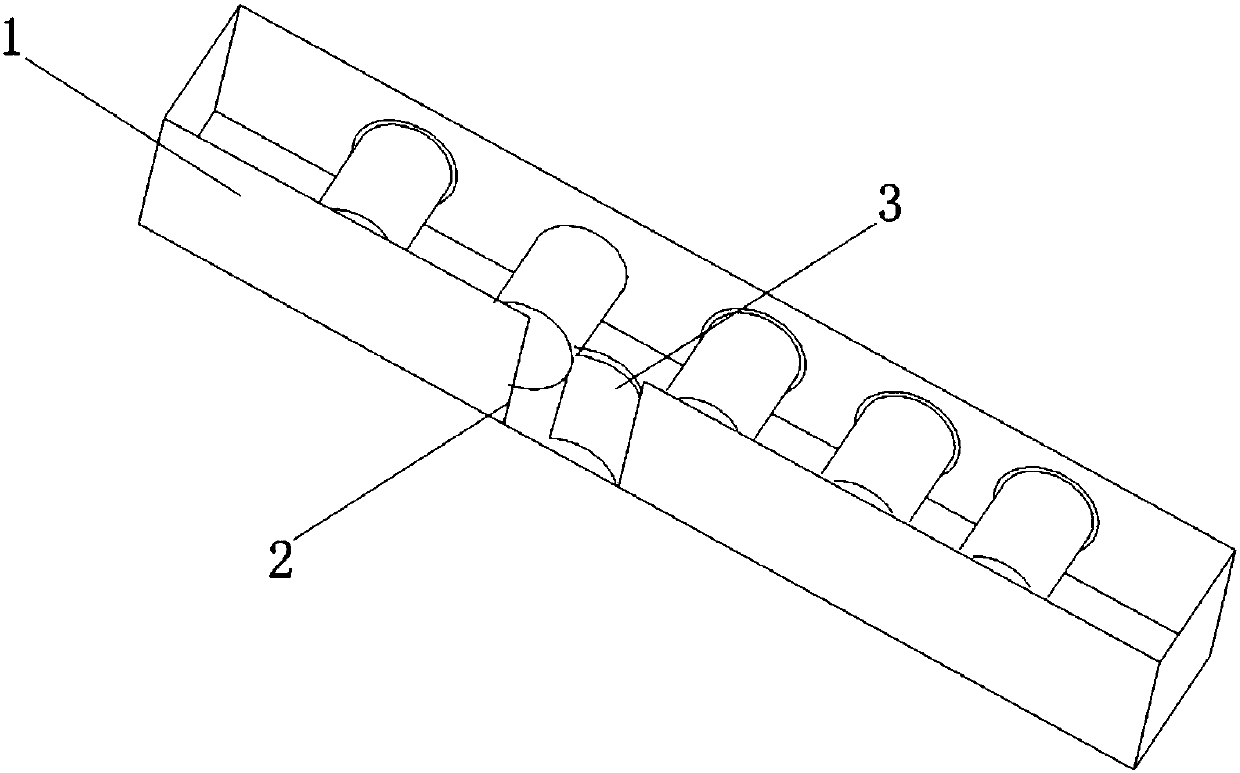

[0009] see figure 1 , a bearing inner sleeve screening device, its scheme is as follows:

[0010] It includes a guide groove 1. One end of the guide groove 1 is high and the other end is low. The width of the guide groove 1 is slightly wider than the width of the bearing inner sleeve. An opening 2 is arranged on the middle side of the guide groove 1. The opening 2 is slightly longer than the length of the bearing inner sleeve. , Weld a circular arc piece 3 at the lower part of the opening 2, the arc top of the circular arc piece 3 faces inward, and the distance between the arc top of the circular arc piece 3 and the chord is 1.5cm.

[0011] When screening is required, put the bearing inner sleeves to be assembled into the guide groove from a high place in order with the end of the smaller diameter facing the opening. The bearing inner sleeves with the correct direction will pass through the guide groove directly, while the bearing inner sleeves with the opposite direction will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com