Guide discharge device

A technology of discharging device and material, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of collision, inability to clamp, and small clamping area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the accompanying drawings and preferred embodiments, but the embodiments of the present invention are not limited thereto.

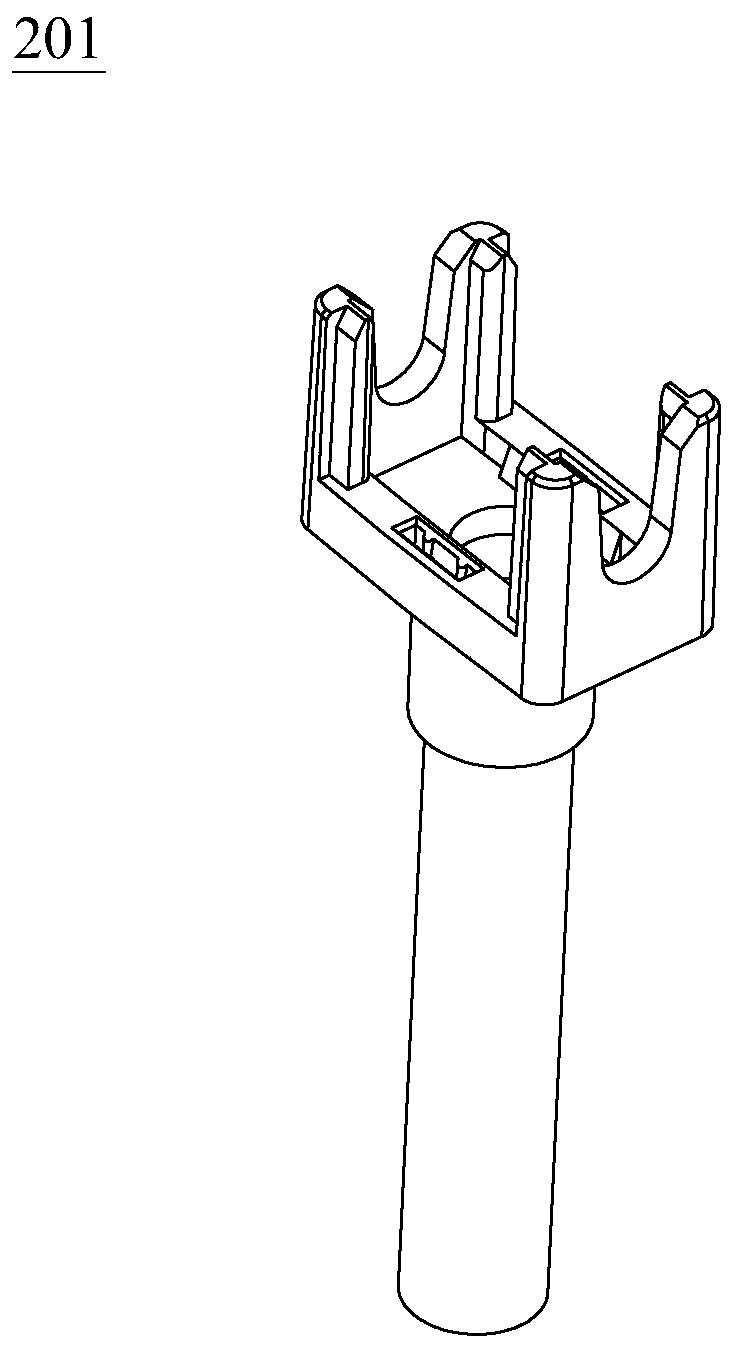

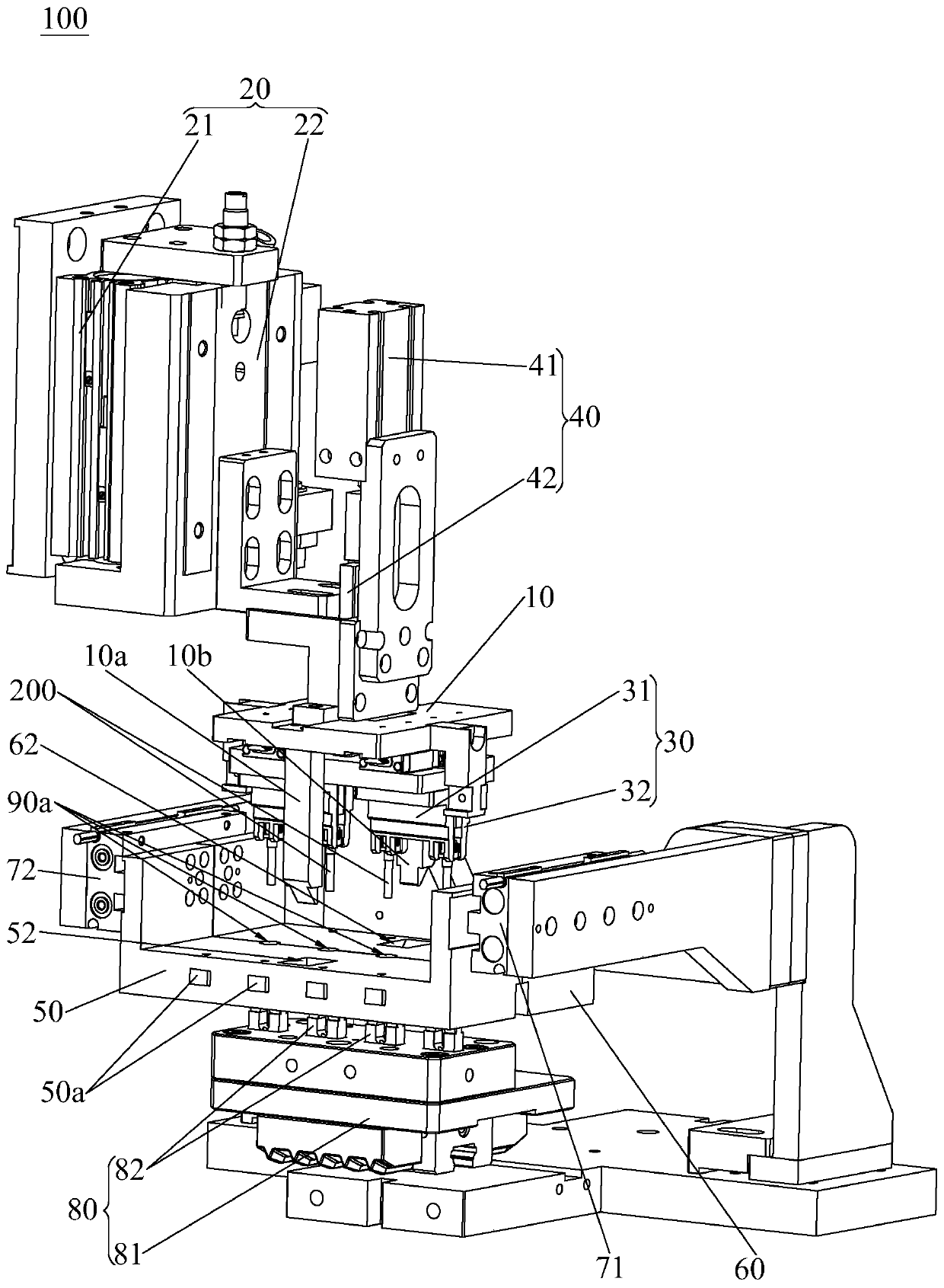

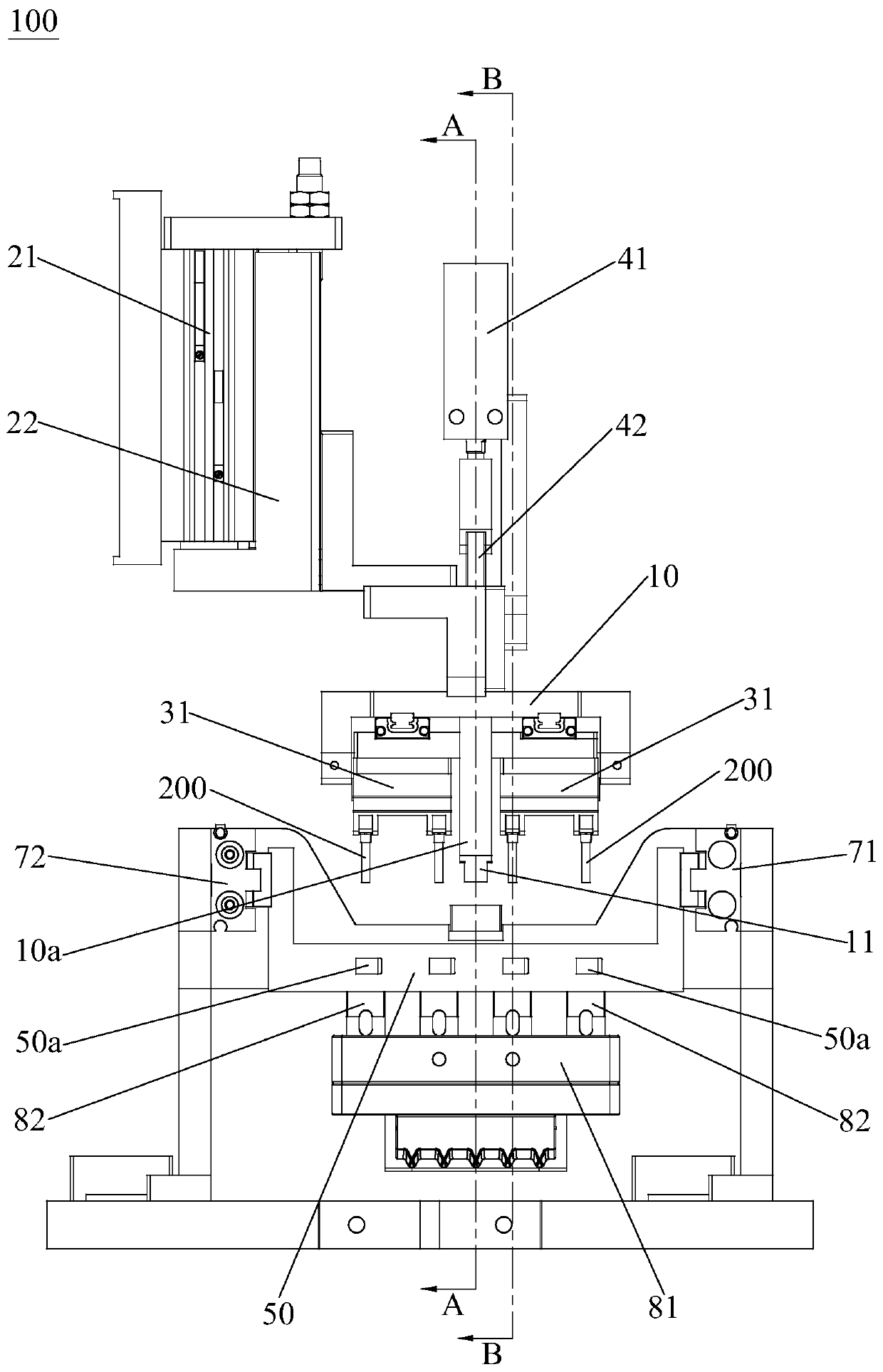

[0029] see Figure 2 to Figure 10 , the guiding and discharging device 100 of the present invention is suitable for guiding the material 200 when discharging, wherein the guiding and discharging device 100 of the present invention includes a lifting frame 10, a lifting drive mechanism 20, a clamping mechanism 30, a clamping The opening and closing drive mechanism 40, the first straightening splint 50, the second straightening splint 60, the first stretching guide post 10a, the second stretching guide post 10b and the straightening and closing drive mechanism (not marked in the figure), the lifting frame 10 is set On the lifting driving mechanism 20, the lifting driving mechanism 20 drives the lifting frame 10 to move vertically up and down. The clamping mechanism 30 and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com