Patents

Literature

41results about How to "Reduce ineffective power consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

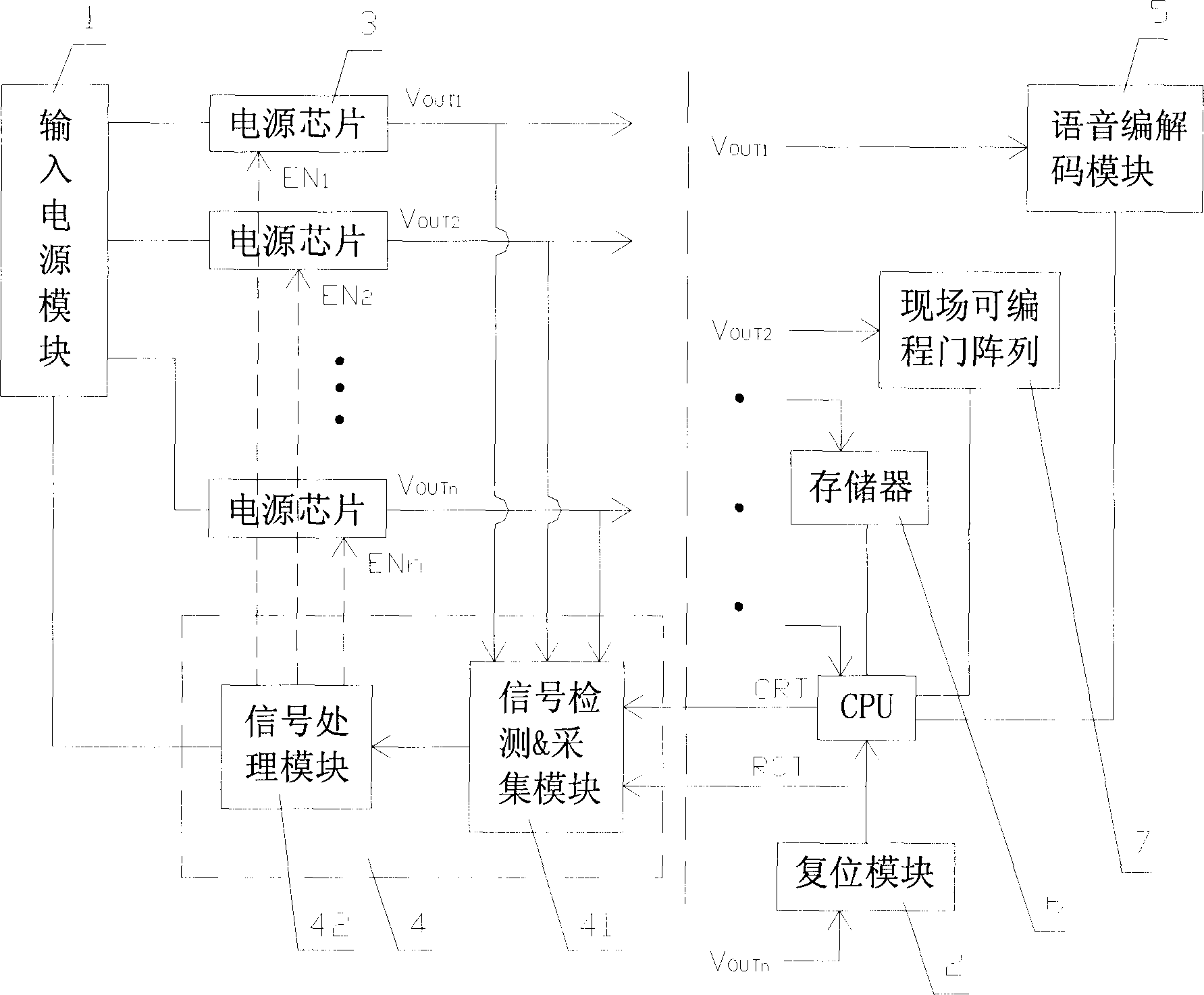

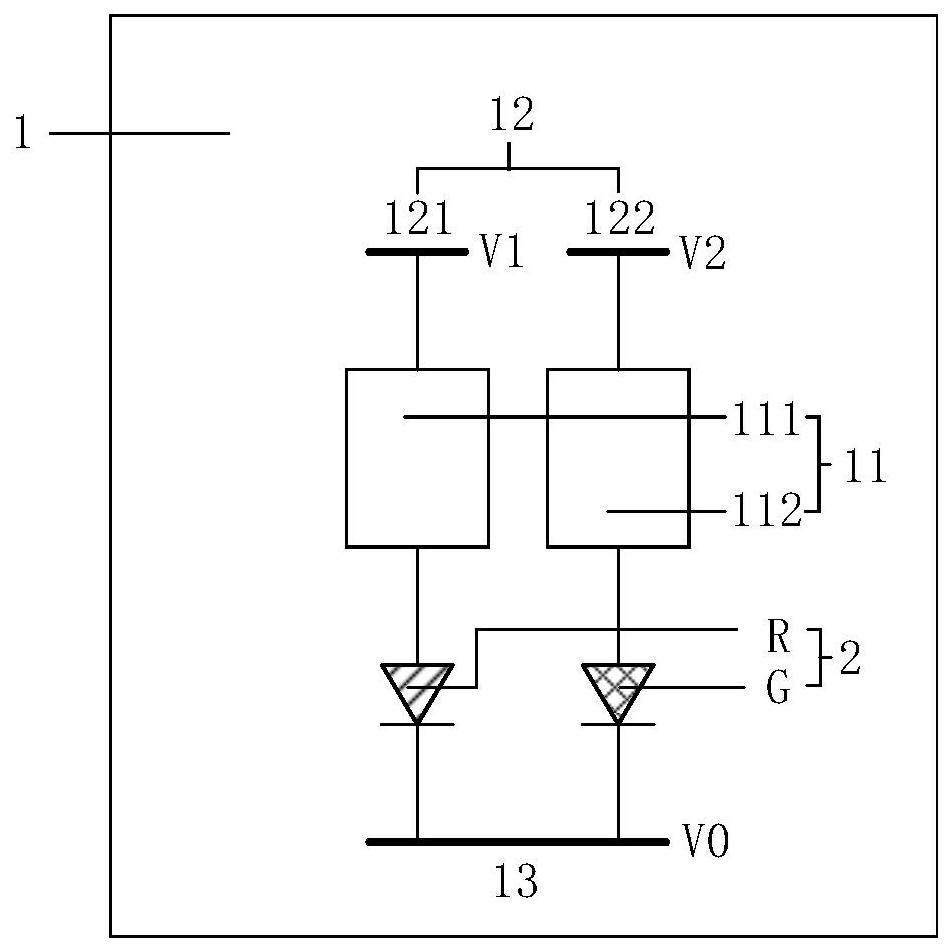

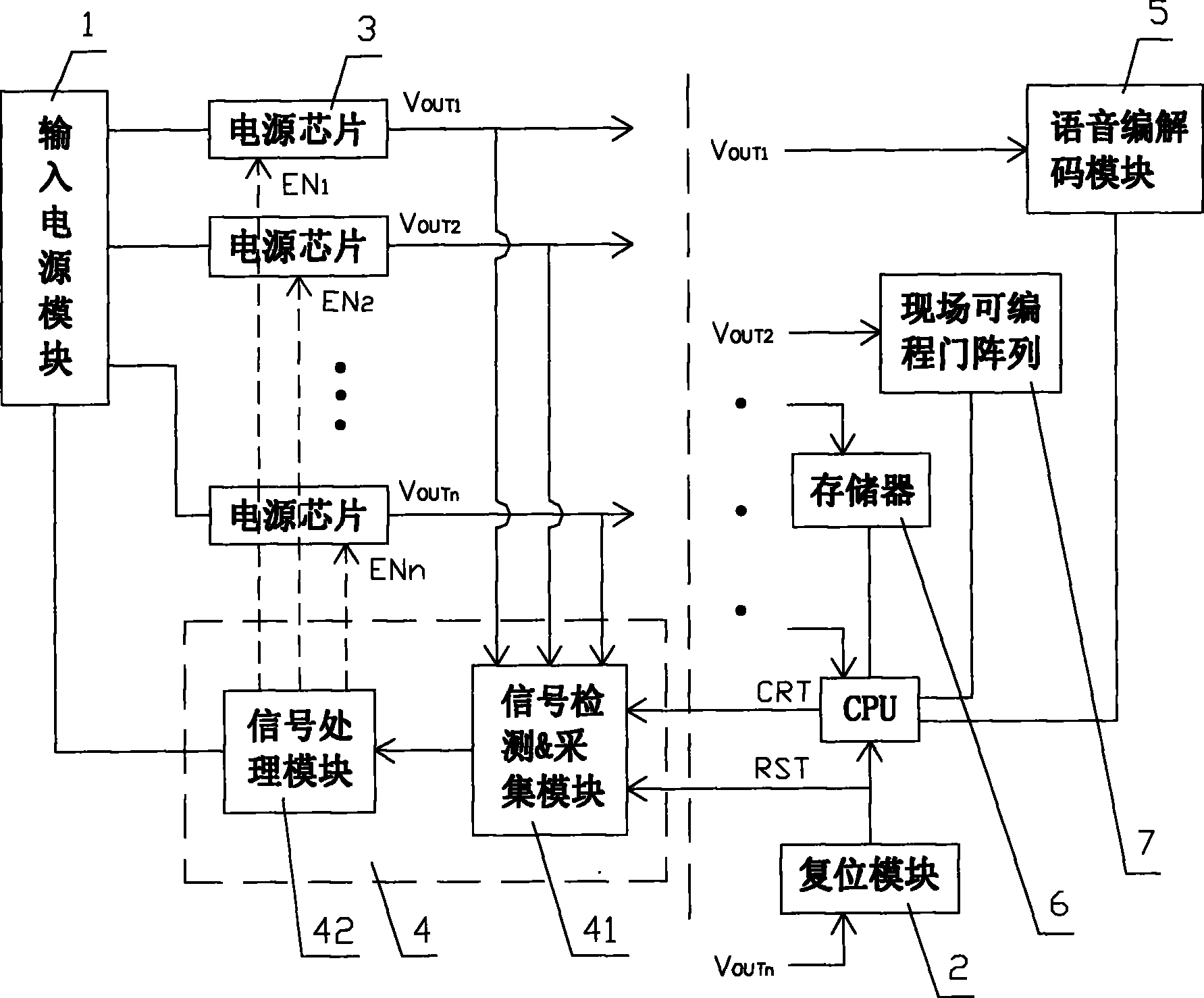

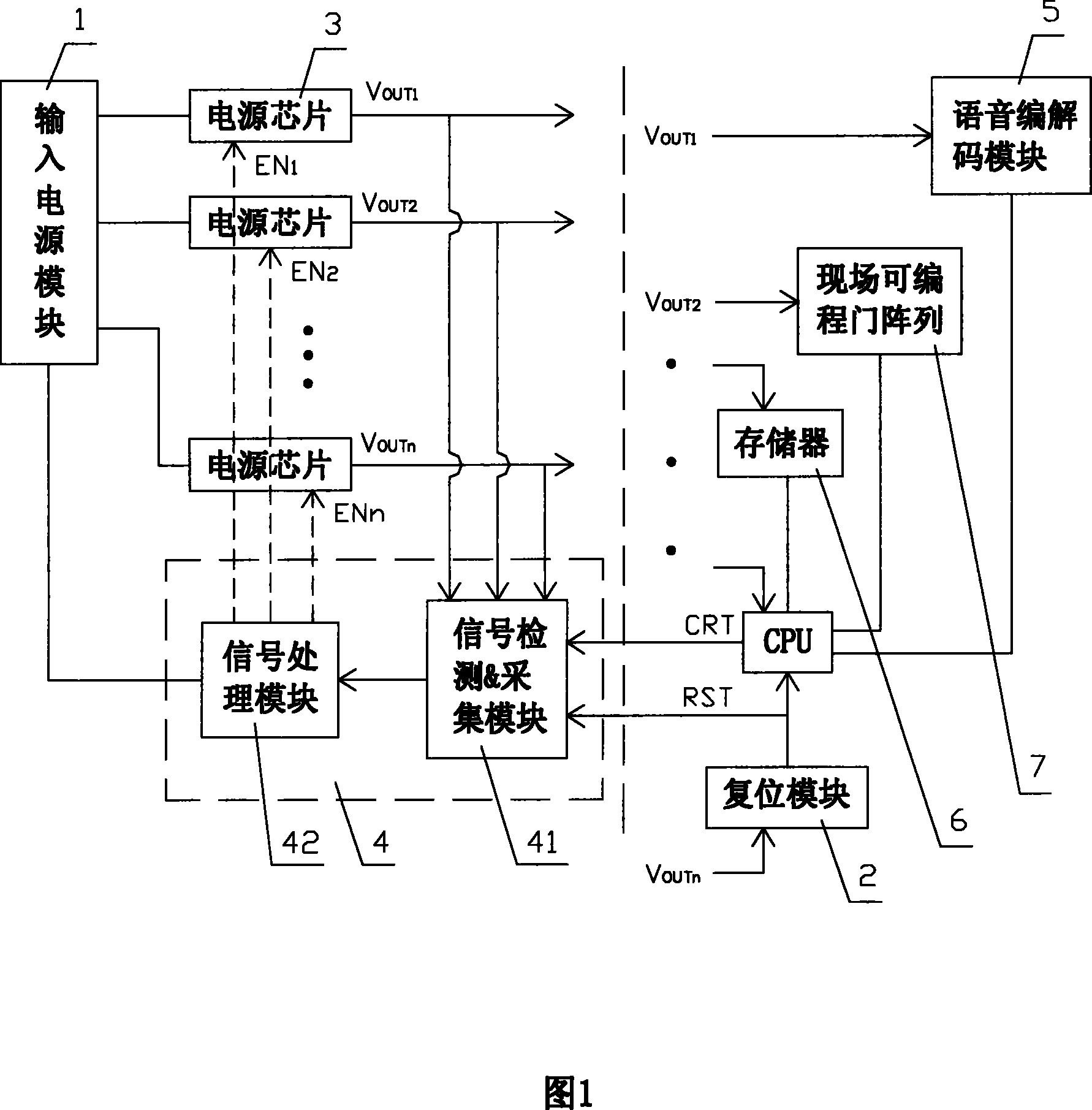

Power supply controlling method and system for telecommunication system

InactiveCN1780348AAvoid failure or damageReduce ineffective power consumptionCurrent supply arrangementsEmergency protective arrangements for automatic disconnectionElectricityEngineering

For multi-way power chip, the method detects its output state. According to output state of multi-way power chip, makes following operation: when the output state of multi-way power chip shows an un-recovering failure, making relevant powering off operation by controlling the state of enabling signal in power chip. In the procedure of powering off, the powering off operation can be made for all power chips in single board, or only be made for the power chip relating to failure; it can also be made by selecting the reset signal sent out from collection and reset module or by detecting signal from CPU, and based on the frequency of reset and detecting signal from CPU implementing relevant powering off operation.

Owner:HUAWEI TECH CO LTD

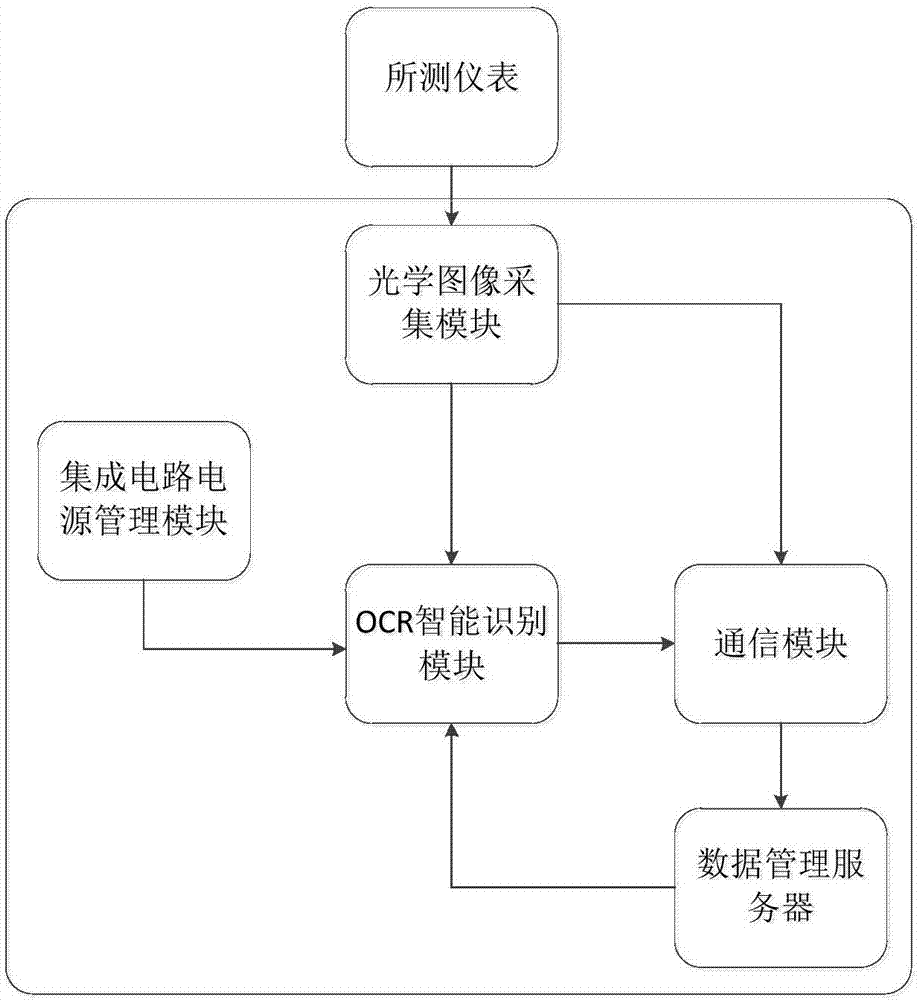

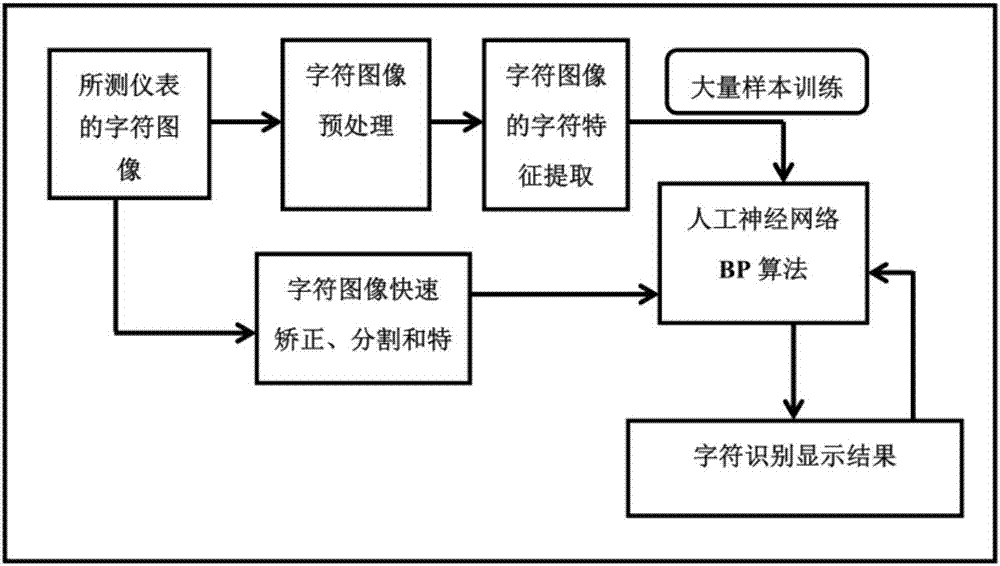

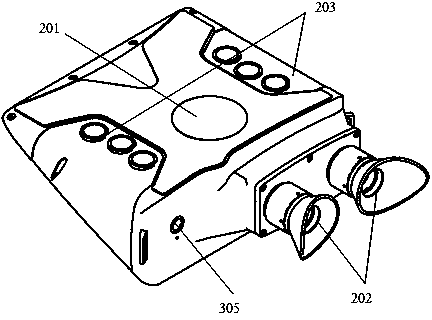

Low power consumption meter remote self-help meter reading terminal and method based on OCR recognition

InactiveCN106874910AReal-time recognition processingGet rid of the process of pure manual identificationImage enhancementImage analysisSupply managementData acquisition

The invention discloses a low power consumption meter remote self-help meter reading terminal and method based on OCR recognition. The self-help meter reading terminal comprises an optical image acquisition module, an OCR intelligent recognition module, an integrated circuit power supply management module, a communication module and a data management server. The self-help meter reading method comprises the steps that the optical image acquisition module acquires the optical image information of a measured meter and sends the information to the OCR intelligent recognition module; according to a pre-processed character image, the OCR intelligent recognition module extracts character features and sends the character features to the data management server; and the OCR character recognition module of the data management server recognizes the character features to acquire the display result of the measured meter, and the character features are stored and backed up. According to the invention, remote meter data acquisition is realized, and the low power consumption meter remote self-help meter reading terminal and method have the advantages of low power consumption, intelligent recognition, remote data transmission and high recognition rate.

Owner:广州优库电子有限公司

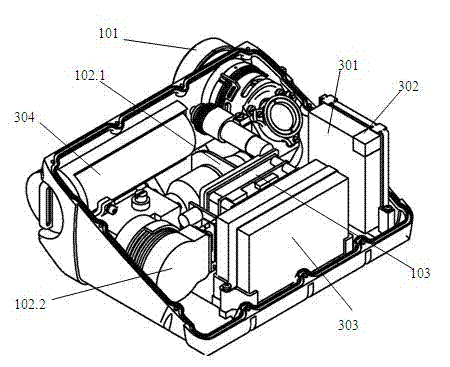

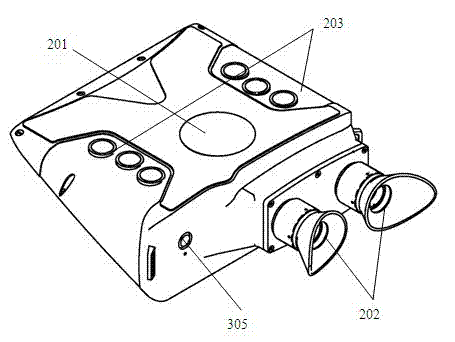

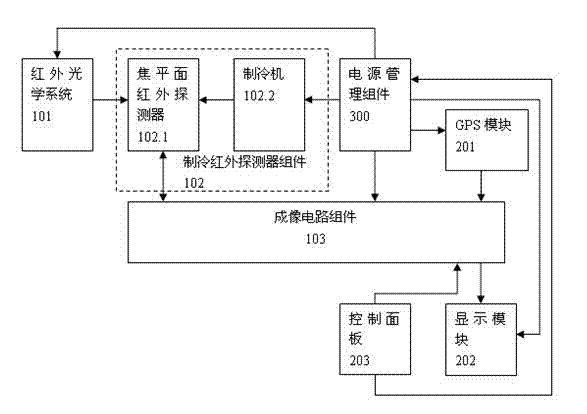

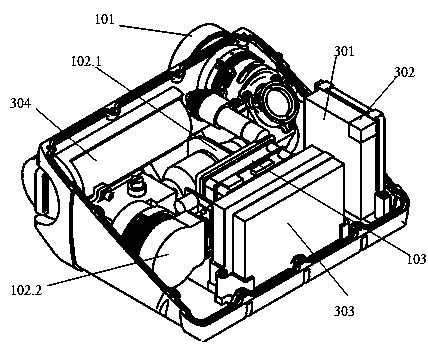

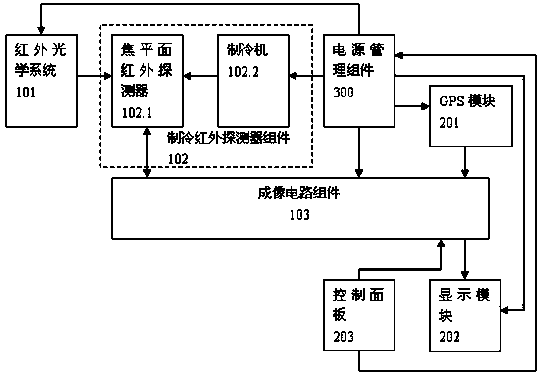

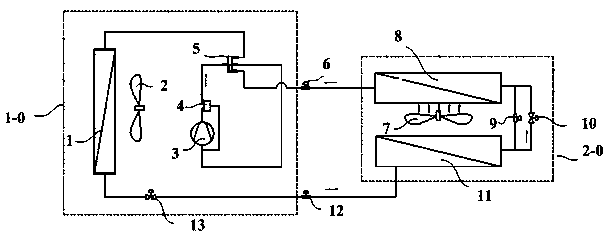

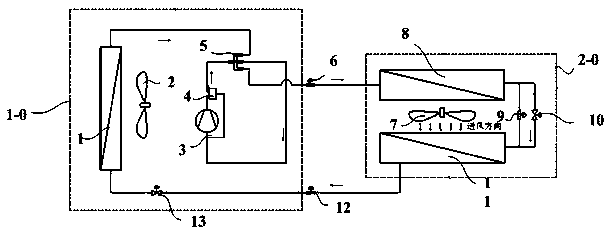

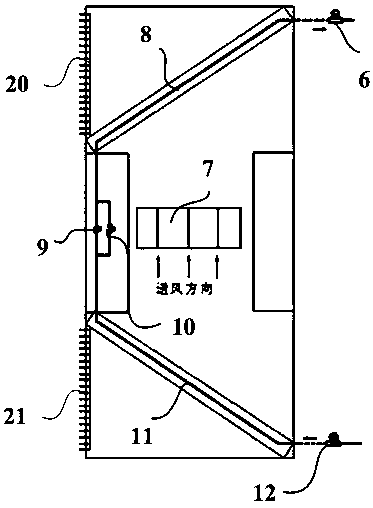

Refrigeration thermal infrared imager and power supply management method thereof

ActiveCN102735346AExtend working time and lifeReduce interference and ineffective power consumptionEnd cell switching arrangementsPyrometry using electric radation detectorsIr detectorElectrical battery

The invention relates to a refrigeration thermal infrared imager and a power supply management method of the refrigeration thermal infrared imager. The refrigeration thermal infrared imager comprises an infrared optical system, a refrigeration infrared prober assembly, an imaging circuit assembly, a power supply management assembly, a GPS (global position system) module, a display module and a control panel; the refrigeration infrared prober assembly consisting of a focal plane infrared prober and a refrigerator is connected behind the infrared optical system; the imaging circuit assembly is further respectively connected with the GPS module, the display module and the control panel; and the power supply management assembly is respectively connected with the infrared optical system, the refrigerator, the imaging circuit assembly, the GPS module, the display module and the control panel. The refrigeration thermal infrared imager provided by the invention has the advantages as follows: hot switching and hot plugging of power supply can be realized, so that a target can be continuously detected and monitored; electric amount of a battery and external power supply voltage can be monitored in real time; a circuit board has no standby current after the refrigeration thermal infrared imager is switched off, so that the working time and the service life of the battery can be prolonged; the over-current, overvoltage, short circuit protection in power supply output, and manual charge and inverse charge protection of the battery can be realized; and the refrigeration thermal infrared imager uses isolation output, so that mutual interference and invalid power consumption can be reduced.

Owner:NO 717 INST CHINA MARINE HEAVY IND GRP

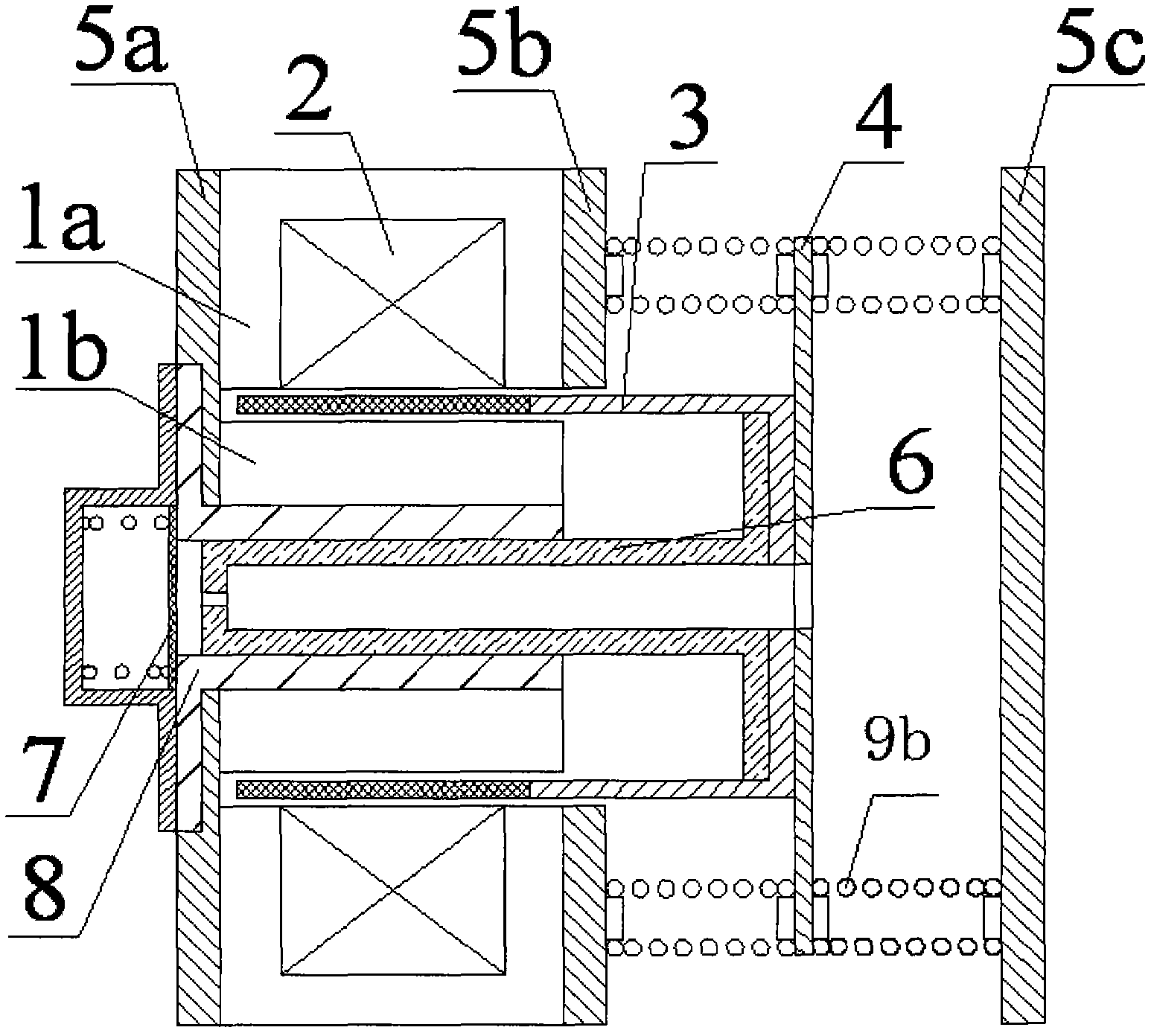

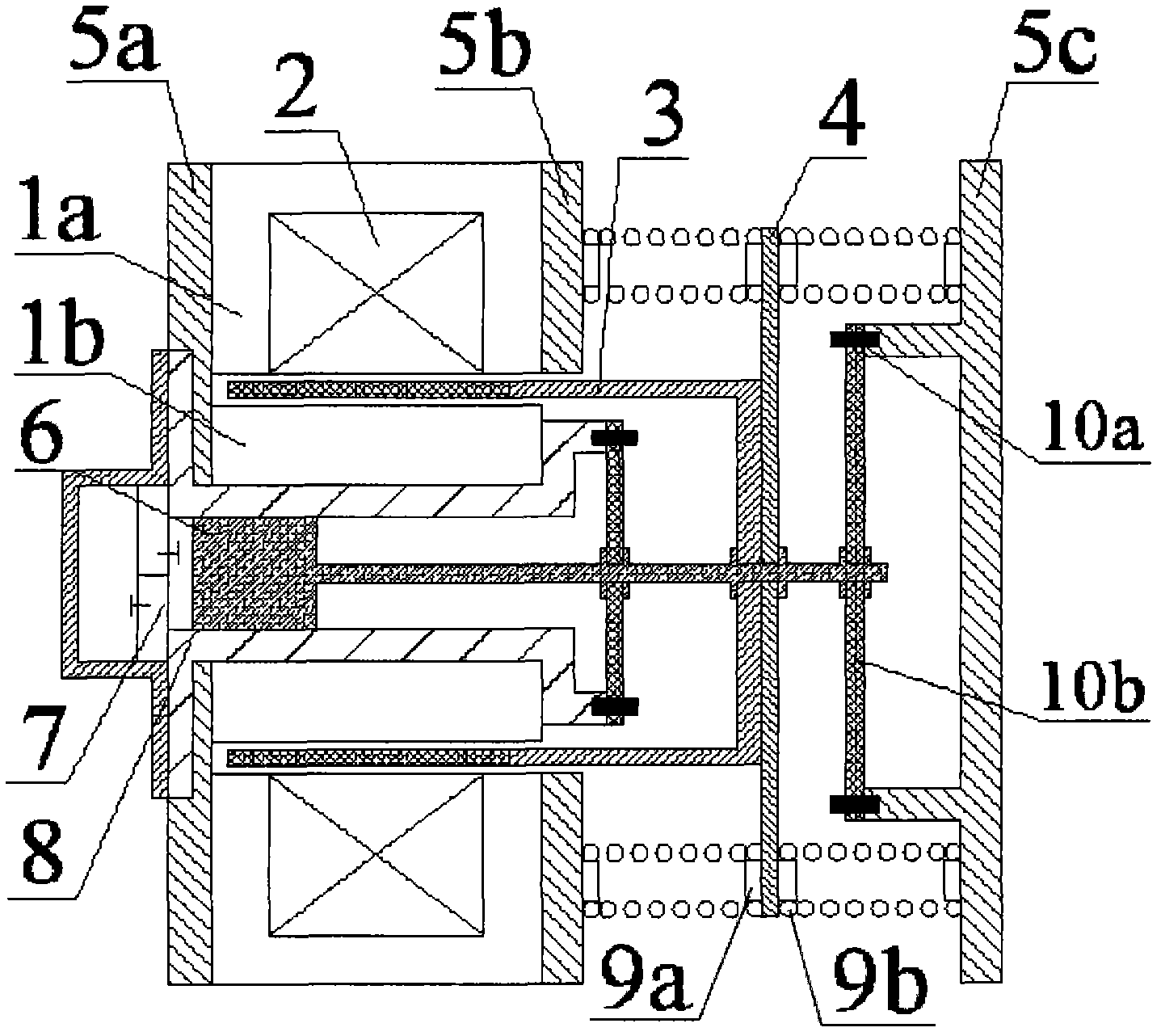

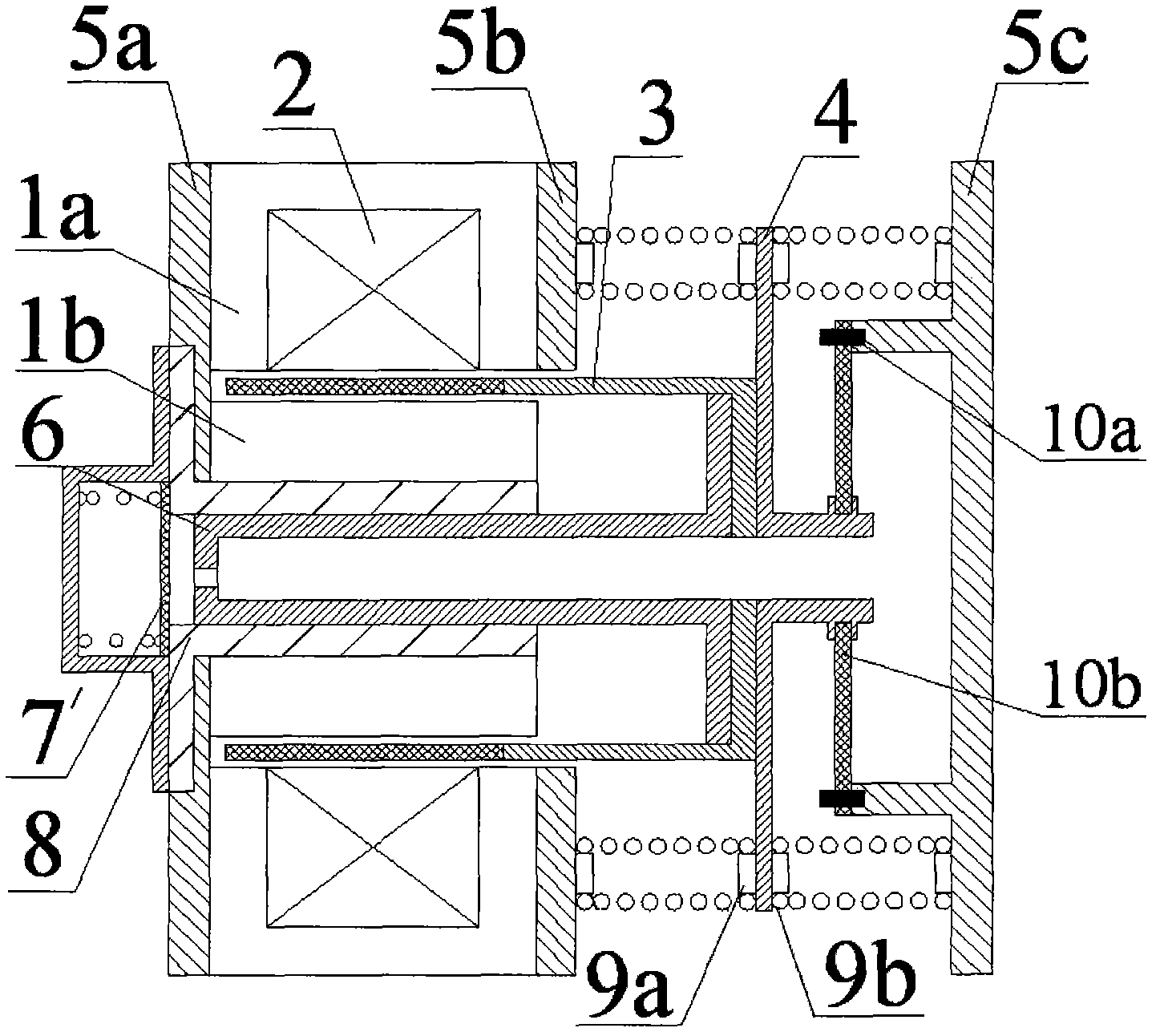

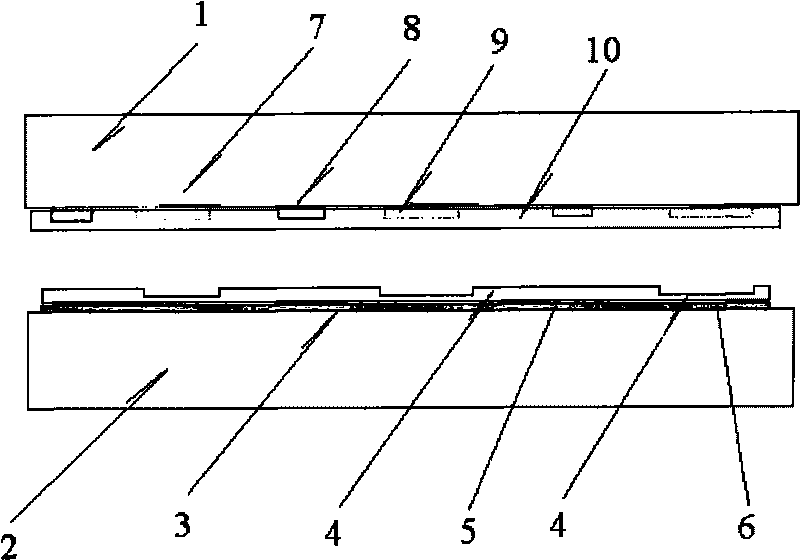

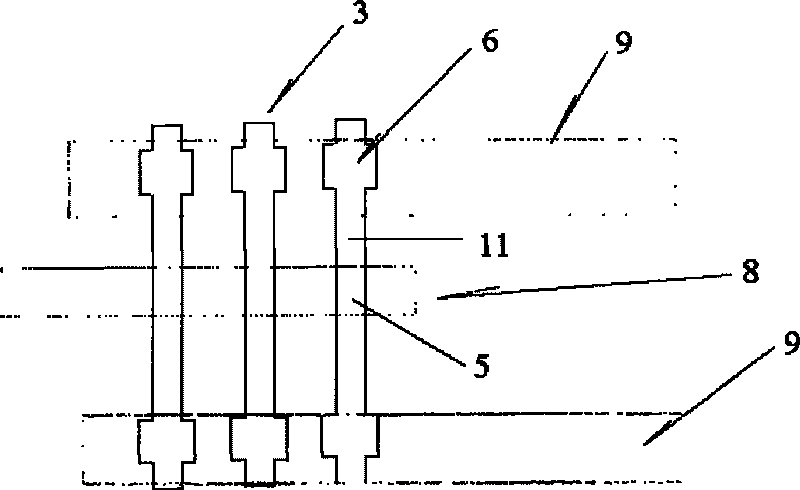

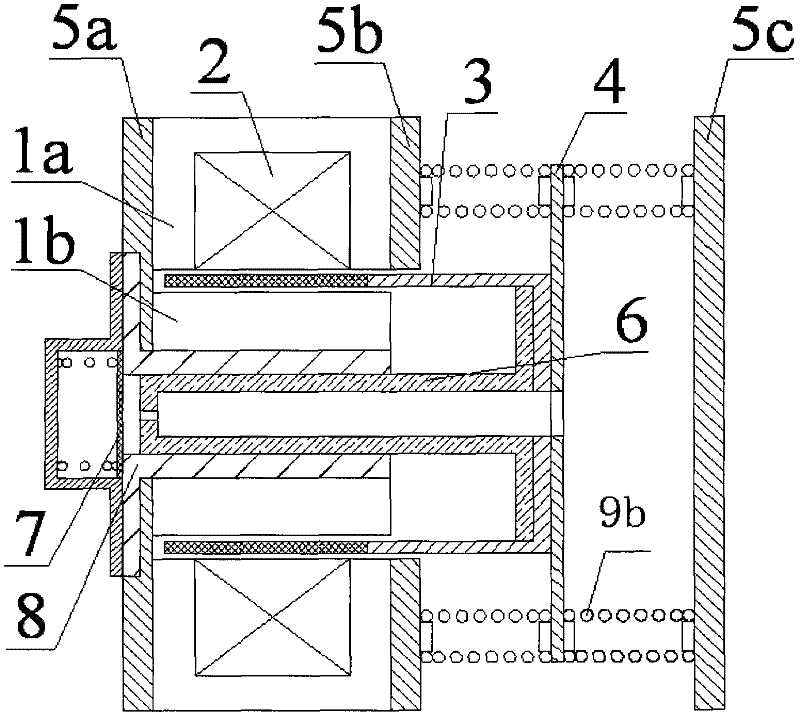

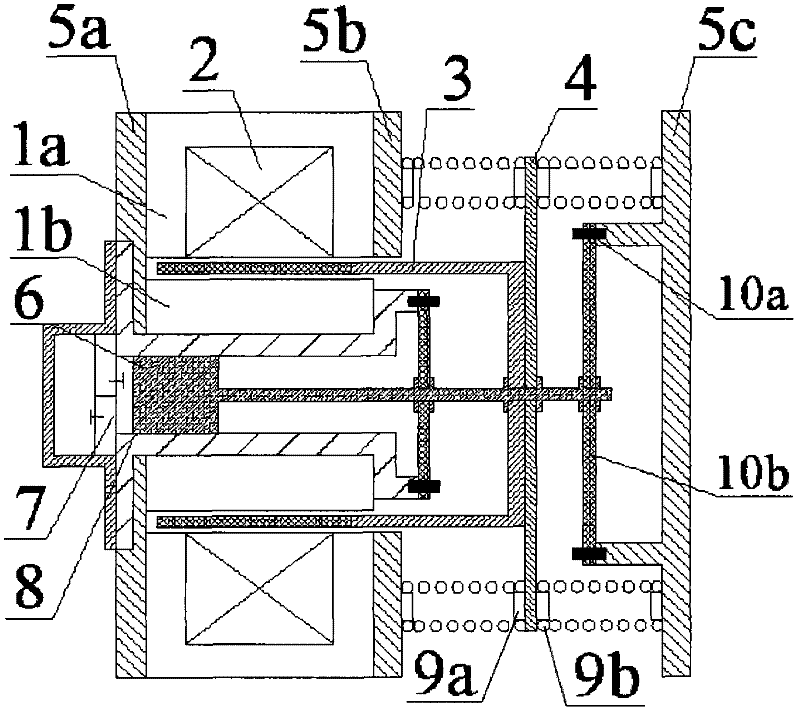

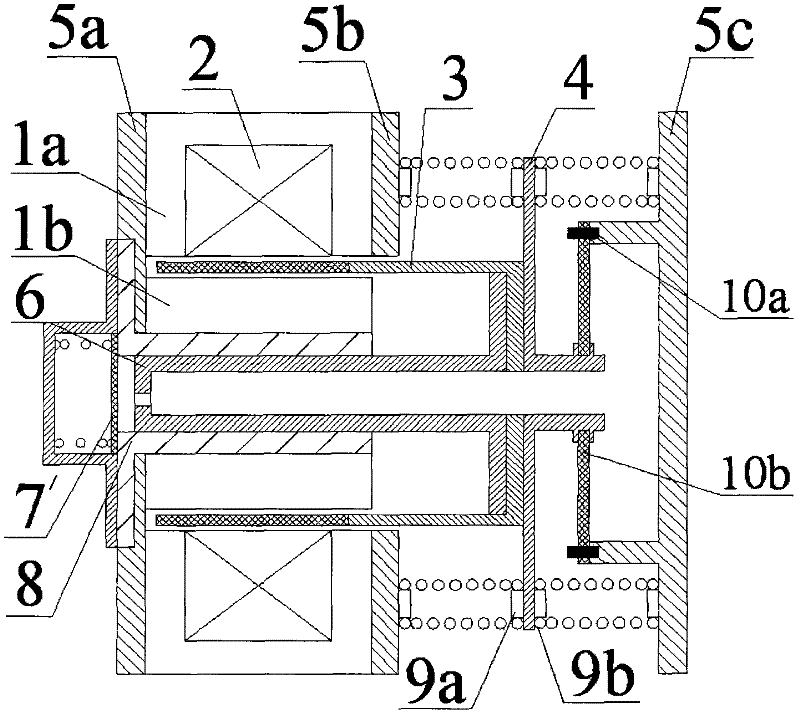

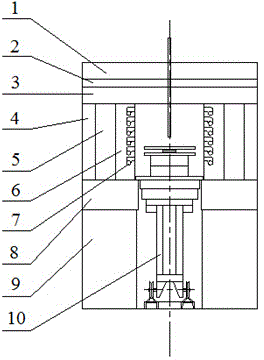

Linear compressor with combined spring supporting structure

ActiveCN101975151AExtended service lifeReduce ineffective power consumptionPiston pumpsPositive-displacement liquid enginesRefrigeration compressorResonance

The invention relates to the field of refrigeration compressors and provides a linear compressor with a combined spring supporting structure. The linear compressor comprises a front end cover, a middle end cover, a rear end cover, a cylinder barrel, an inner stator, an outer stator, a piston, a permanent magnet part, a movable connection part, a first columnar resonance spring part, a second columnar resonance spring part, a first platy resonance spring part and a second platy resonance spring part, wherein the front end cover, the middle end cover and the rear end cover are sequentially and fixedly arranged inside the shell of the linear compressor in parallel at certain interval, and the first platy resonance spring part and the second platy resonance spring part are respectively arranged between the movable connection part and the rear end cover and between the cylinder barrel and the movable connection part and are fixedly connected with the rear end cover and the cylinder barrel. By the combinational use of the columnar resonance springs and the platy resonance springs, the linear compressor provided in the invention reduces the lateral offset and torsion of motion parts and friction during moving and lowers invalid power consumption.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

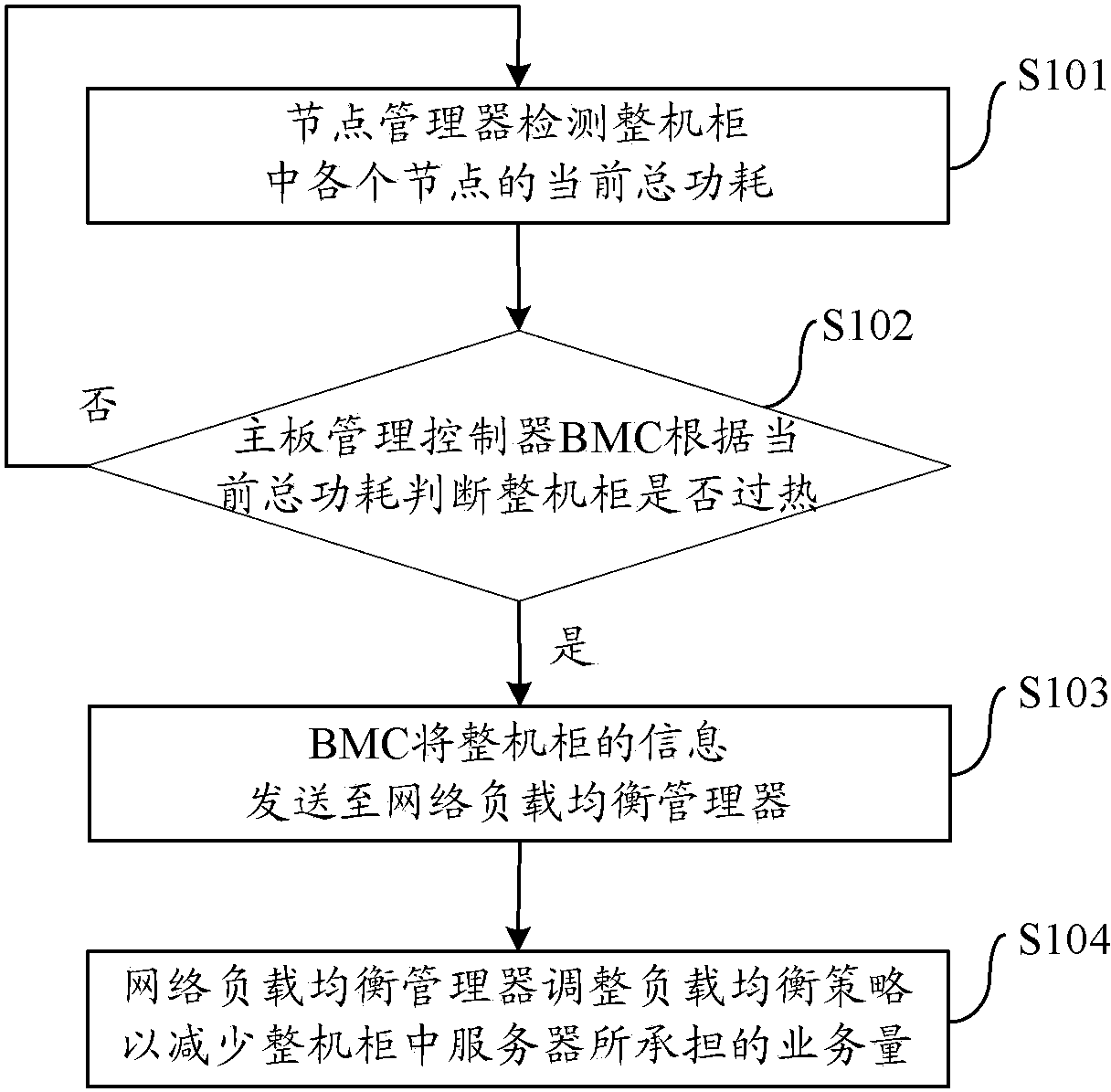

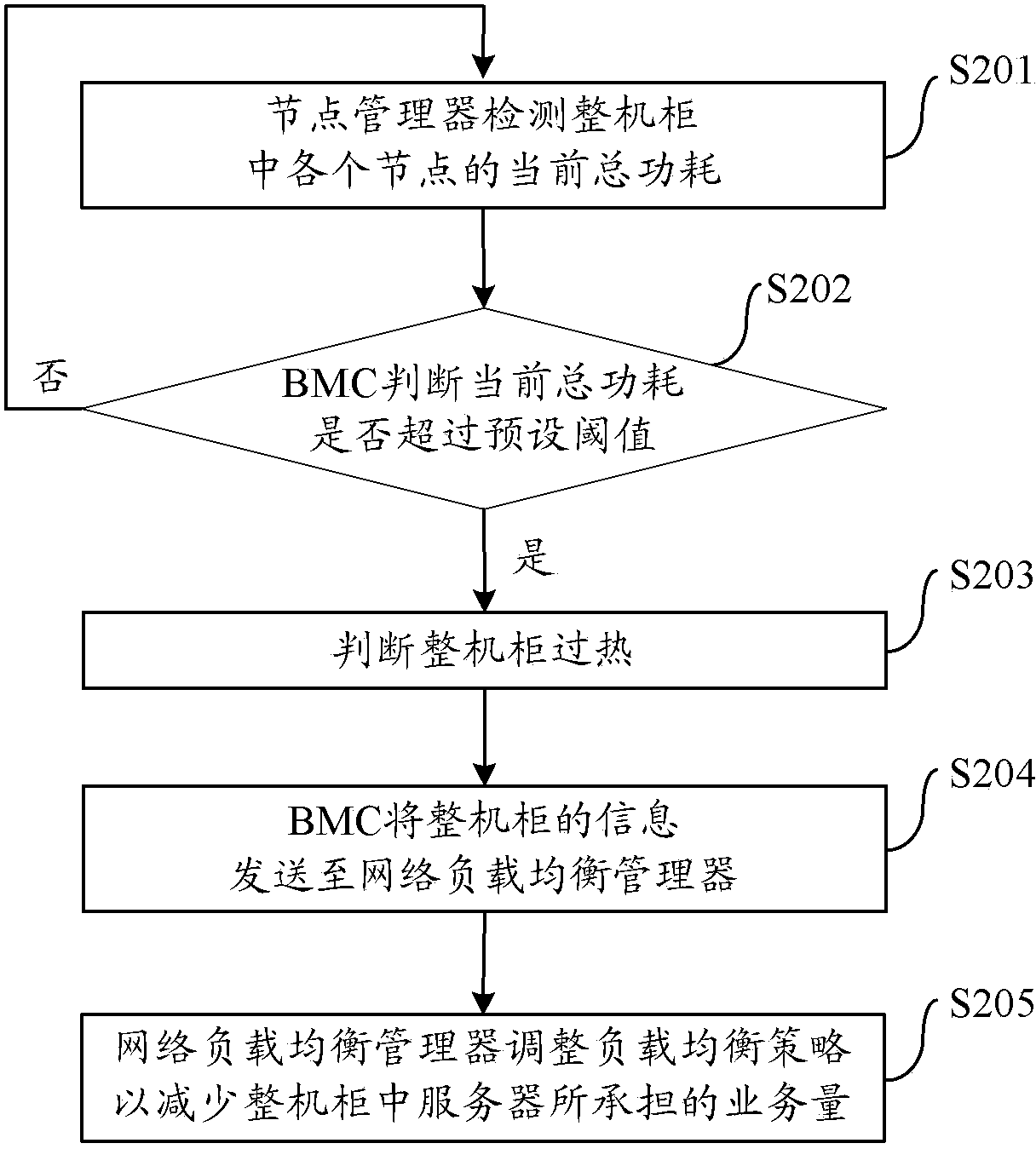

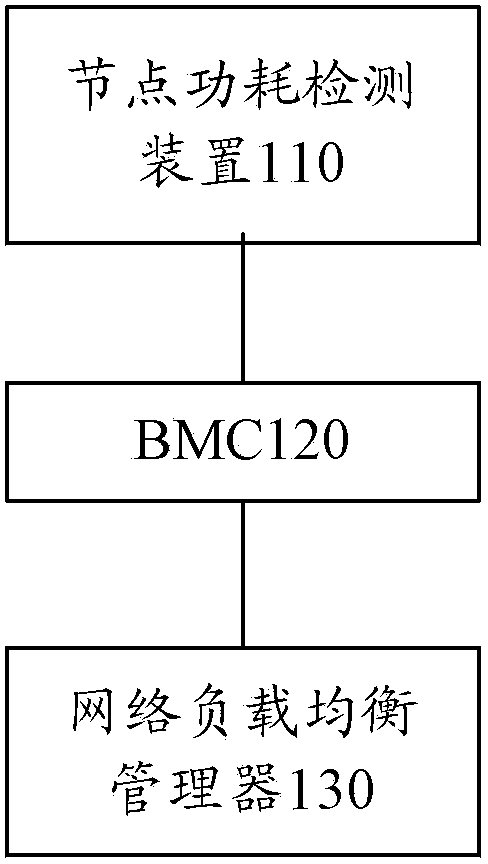

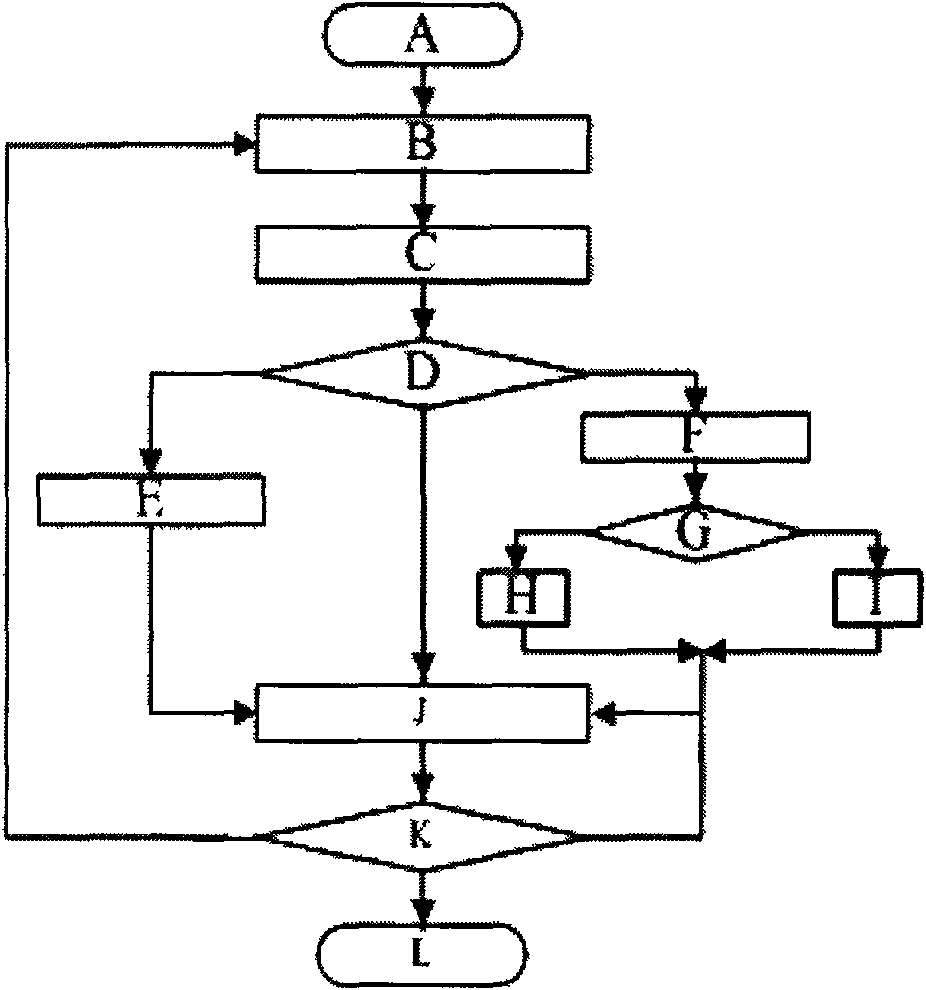

Power consumption management method of whole cabinet and system thereof, and the whole cabinet

InactiveCN103516537APower Management ImplementationPower management automationData switching networksElectricityEngineering

The invention provides a power consumption management method of a whole cabinet and a system thereof, and the whole cabinet. The method comprises the following steps that a node manager detects current total power consumption of each node in the whole cabinet; a mainboard management controller BMC determines whether the whole cabinet is overheating according to the current total power consumption; if the whole cabinet is determined to be overheating, the BMC sends information of the whole cabinet to a network load balancing manager; the network load balancing manager adjusts a load balancing strategy so as to reduce a service volume undertaken by a server in the whole cabinet. According to the method in an embodiment of the invention, power consumption management of the automatic whole cabinet can be realized; a local hot spot generated by non-uniform electricity utilization caused by imbalance of the service volume of the whole cabinet is effectively prevented; service equilibrium between the servers of the whole cabinet in a whole network is realized so that concentrated heat dissipation is used maximumly; invalid power consumption is reduced and cost is further reduced too.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

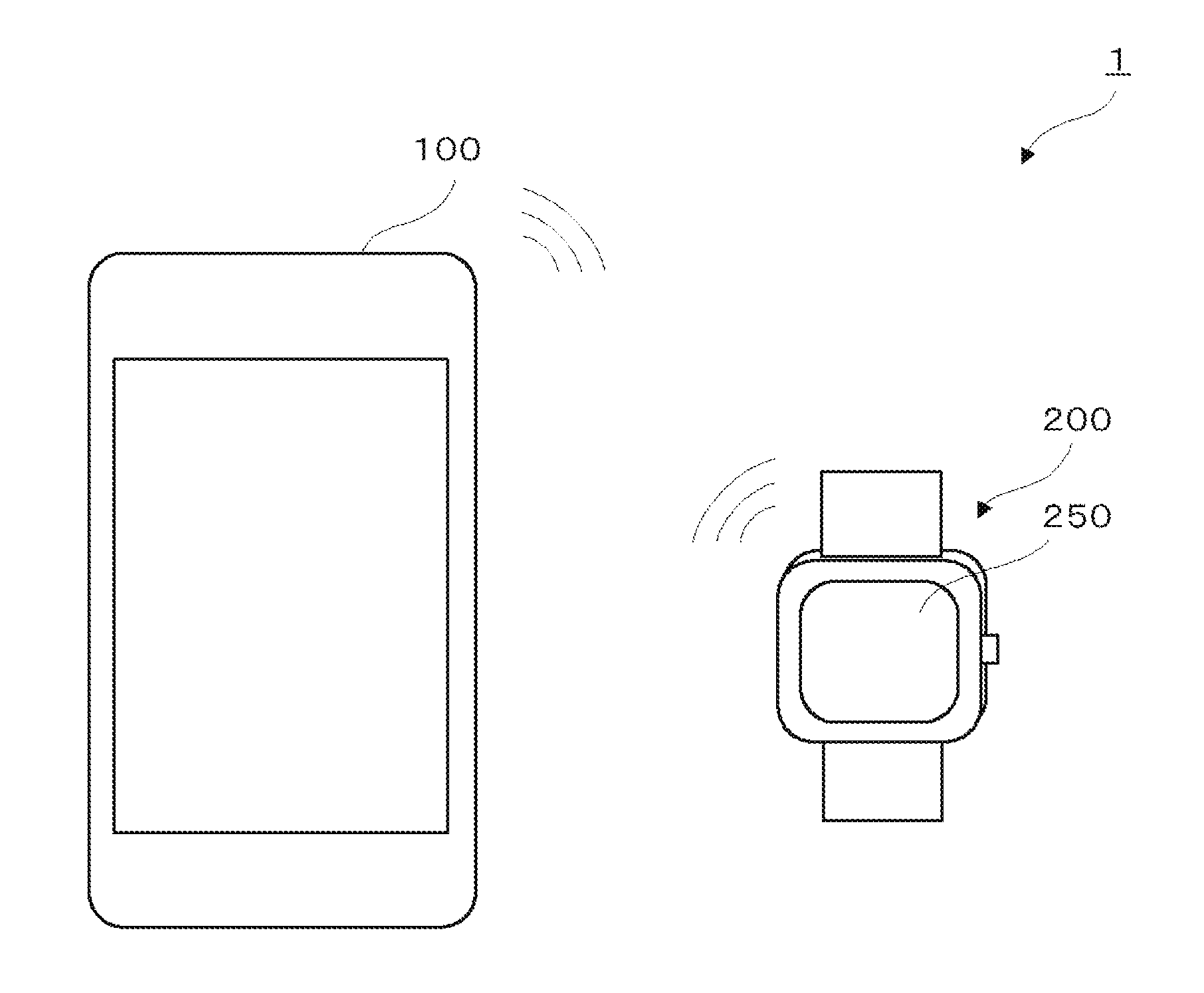

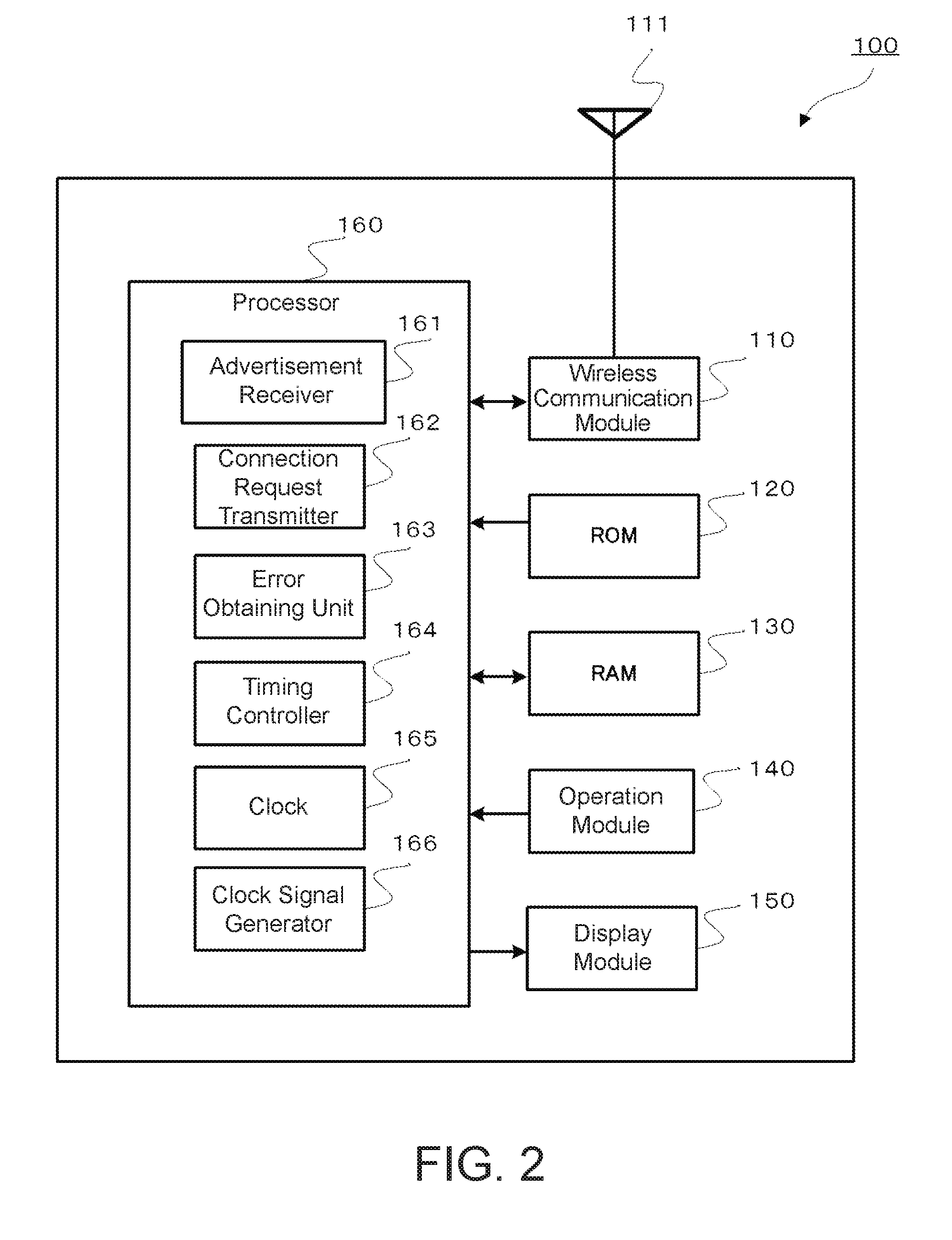

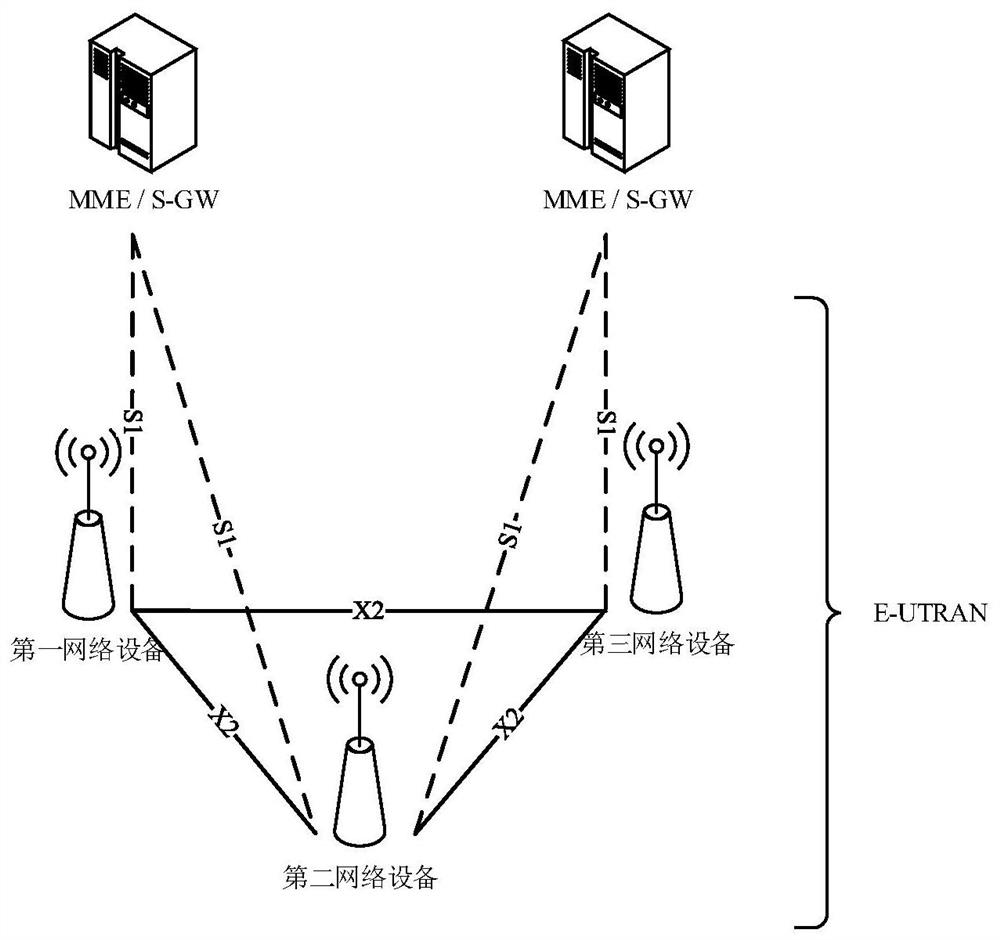

Wireless communication device, wireless communication method, and storage medium

ActiveUS20160286511A1Reduce ineffective power consumptionInefficient power consumptionPower managementSynchronisation arrangementComputer scienceCommunication device

A wireless communication device includes: a wireless communication module configured to receive a plurality of notification signals that are successively transmitted from another wireless communication device; and a processor that is connected to the wireless communication module, the processor calculating a clock error between a clock in the wireless communication device and a clock in the other wireless communication device based on one or more of the notification signals that are received, and determining a timing at which to make the wireless communication module ready to receive a next notification signal from the other wireless communication device in accordance with the calculated clock error and a time interval at which the next notification signal will be transmitted from the other wireless communication device, the time interval being a predetermined fixed time interval or contained in the notification signal that has been received immediately prior to the next notification signal.

Owner:CASIO COMPUTER CO LTD

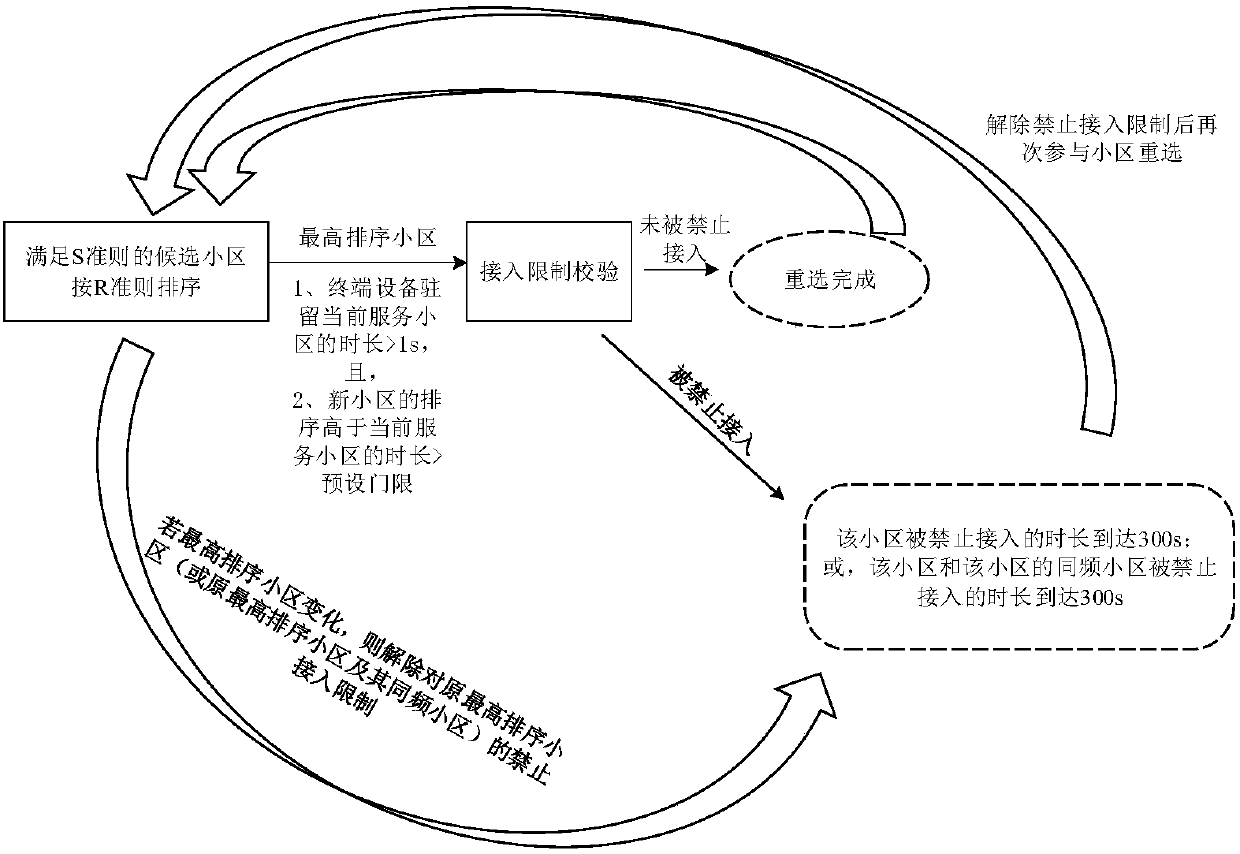

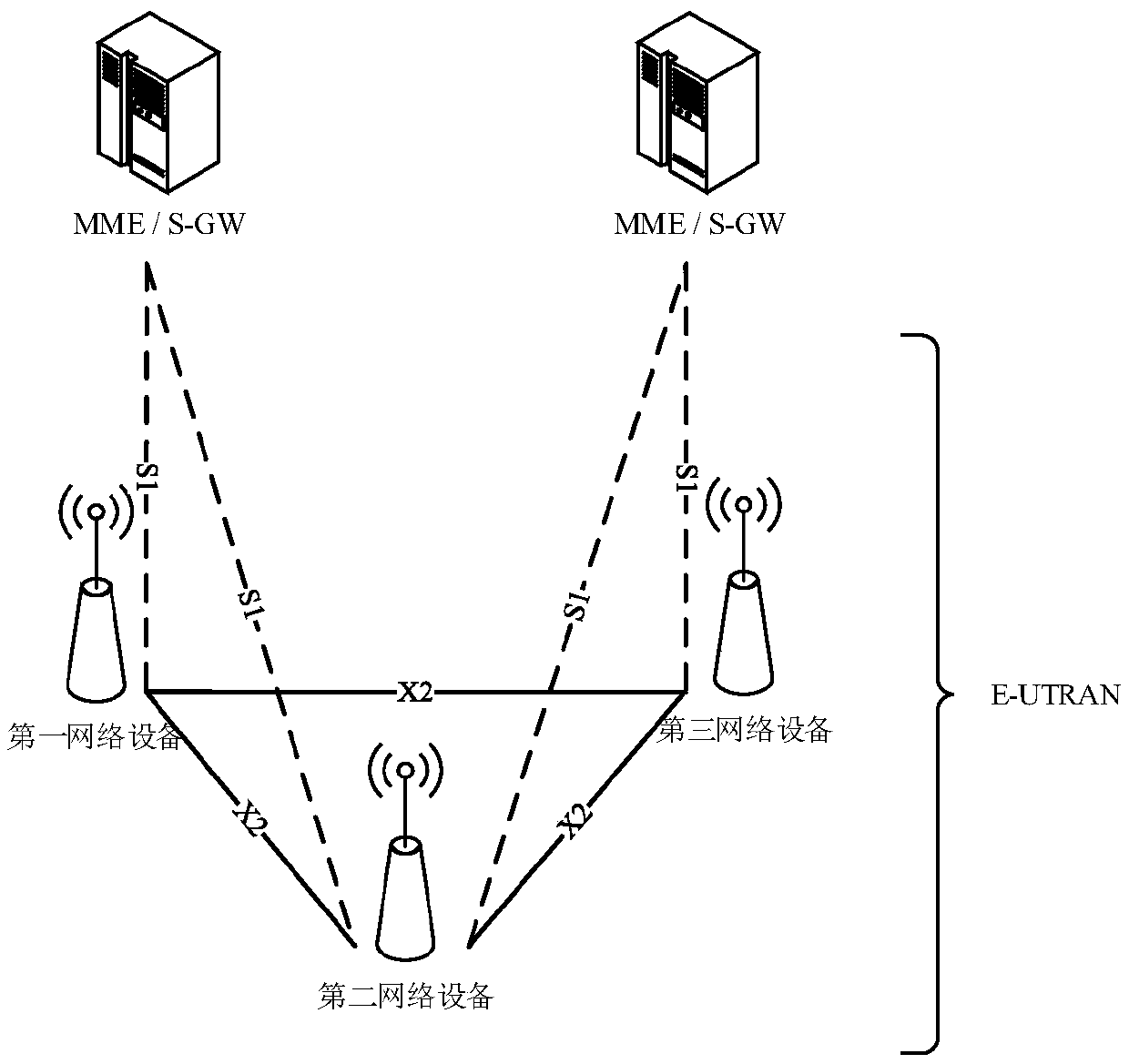

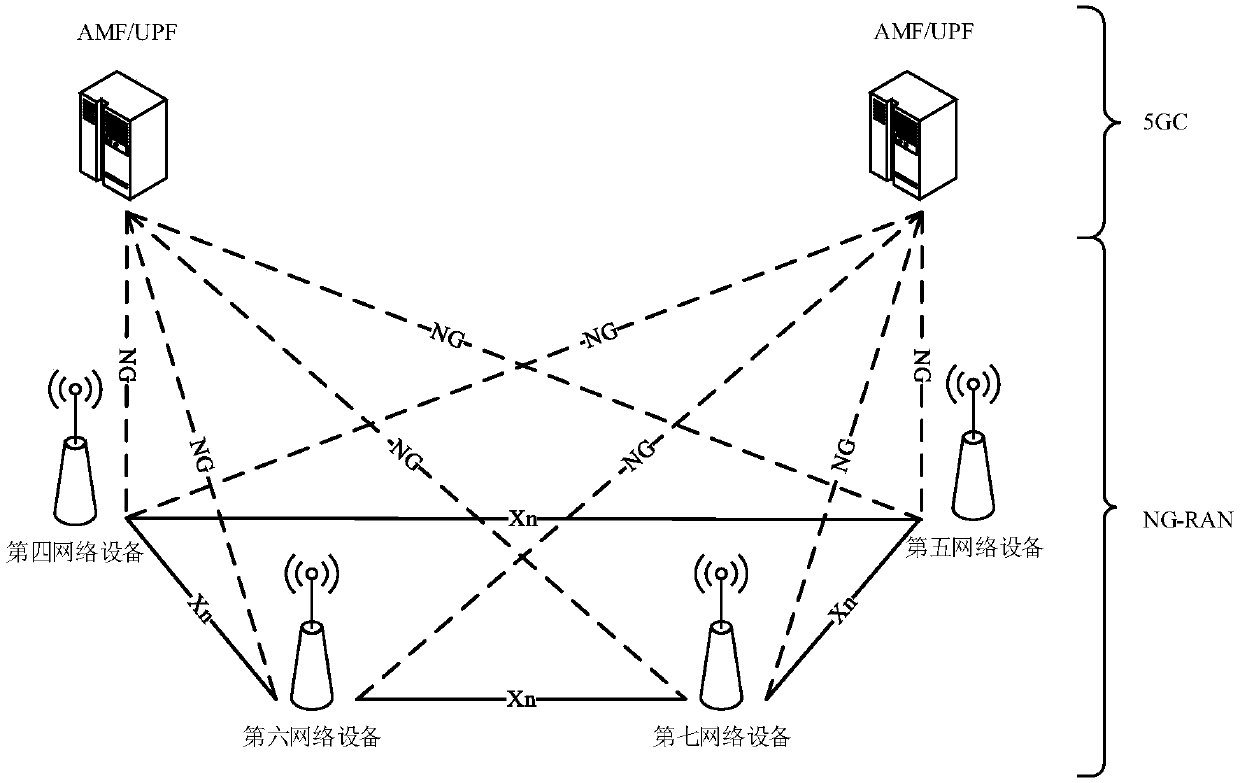

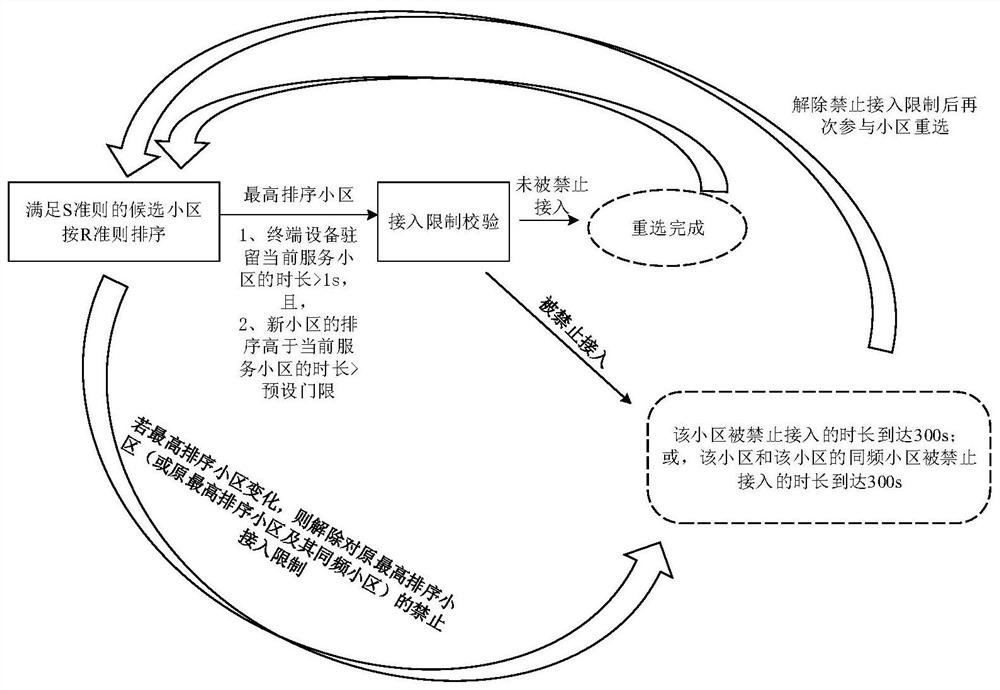

Cell reselection method and equipment

ActiveCN111148173AReduce the number of checksImprove effectivenessPower managementAssess restrictionTerminal equipmentEmbedded system

The invention provides a cell reselection method and device, the method comprising: in a cell reselection process, determining that a second cell is prohibited from access; determining a highest sorting cell according to a cell reselection criterion; and when the highest sorting cell changes and a first condition is satisfied, releasing access forbidding restriction on at least one cell, the at least one cell being a cell forbidden to be accessed in the cell reselection process, and the at least one cell comprising the second cell and / or a co-frequency cell of the second cell. Through the first condition, when one cell is forbidden to be accessed, the terminal equipment can reduce the frequency of checking the cell as much as possible, so that the invalid power consumption of the terminalequipment is reduced, and the effectiveness of checking the cell by the terminal equipment is higher.

Owner:HUAWEI TECH CO LTD

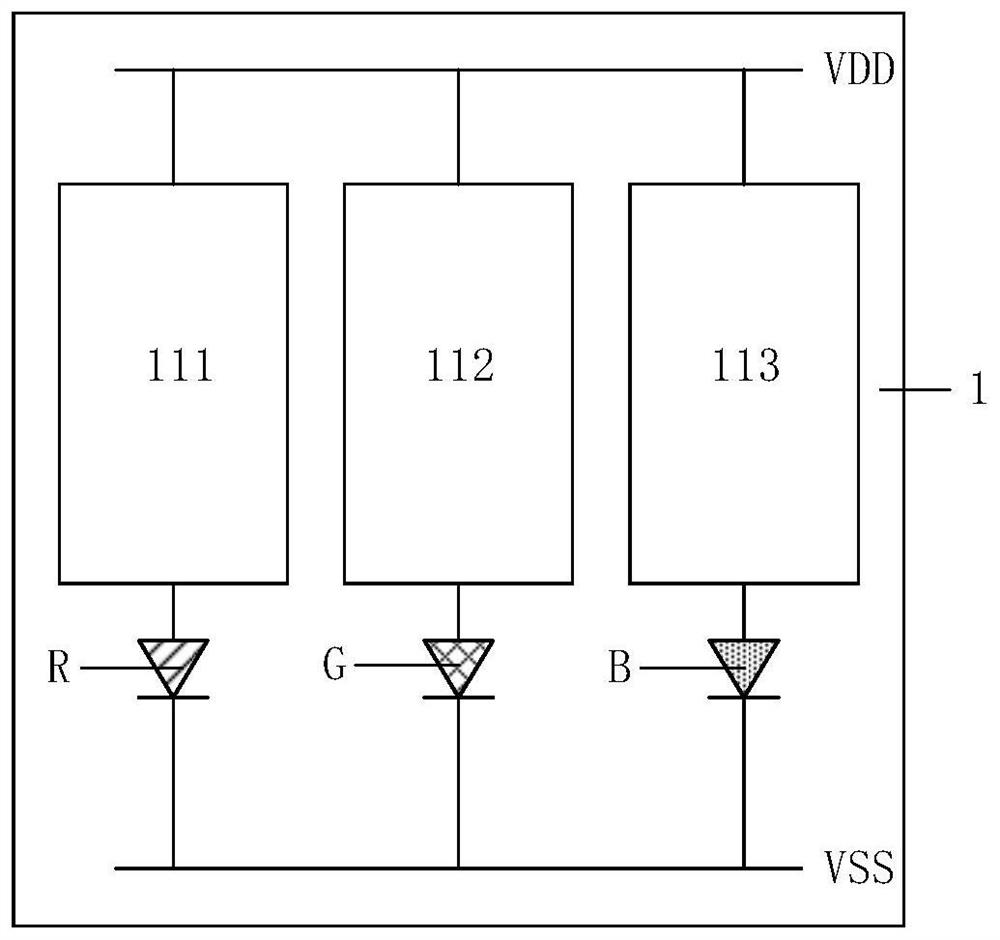

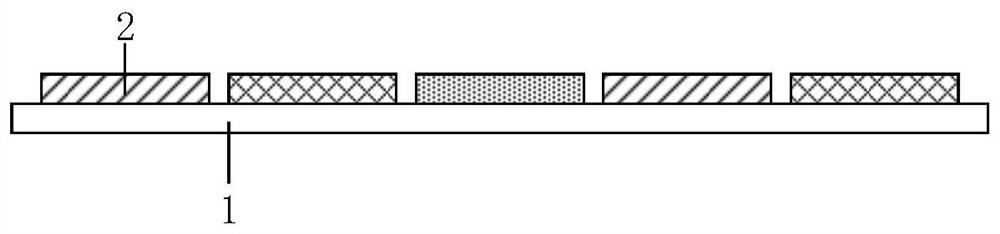

Array substrate, display panel and display device

PendingCN113327541AReduce power consumptionReduce ineffective power consumptionStatic indicating devicesSolid-state devicesHemt circuitsComputer hardware

The embodiment of the invention provides an array substrate, a display panel and a display device. The array substrate bears a plurality of light-emitting units with different colors and comprises a plurality of pixel driving circuits and a plurality of light-emitting units, wherein the pixel driving circuits comprise a first driving circuit and a second driving circuit which are used for driving the light-emitting units with the different colors; the first power supply input end comprises a first sub-input end electrically connected with the first driving circuit and a second sub-input end electrically connected with the second driving circuit, the first sub-input end inputs a first voltage to the first driving circuit, and the second sub-input end inputs a second voltage different from the first power supply to the second driving circuit. According to the array substrate, the non-light-emitting invalid power consumption of the light-emitting unit needing small driving current can be reduced, so that the power consumption of the array substrate is reduced.

Owner:BOE TECH GRP CO LTD

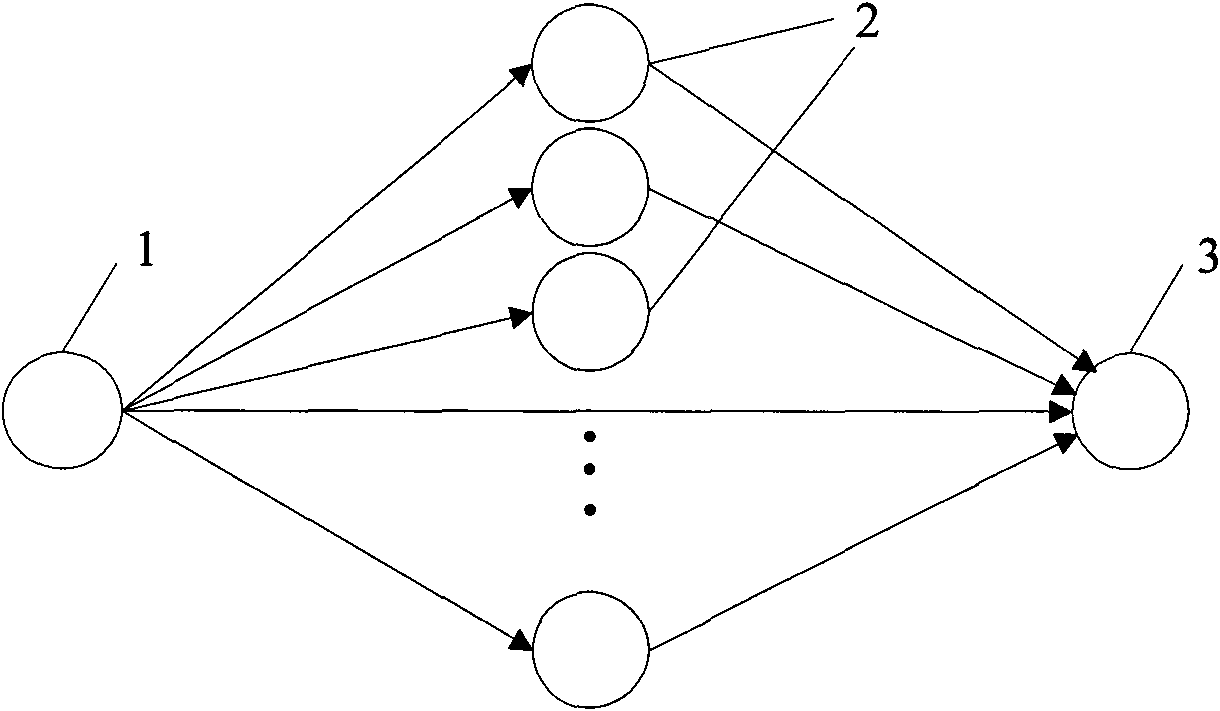

Narrow pulse-based relaying method for cooperative ultra wideband communication system

InactiveCN102111209BExcellent ranging characteristicsReduce overheadEnergy efficient ICTActive radio relay systemsIdle listeningThroughput

The invention discloses a narrow pulse-based relaying method for a cooperative ultra wideband communication system, which belongs to the field of wireless communication. The system comprises a single information source node, a multiple relay node and a single target node. In the method, a channel state is characterized by distance information, and a control frame is required to be transmitted for one time only to determine distances among the nodes and a channel scene under the condition that communication nodes are still, so that overhead for transmitting control information is saved, and the throughput of the system is improved. Instantaneous information is not required to be exchanged, so ineffective power consumption for idle listening and control message overhead can be saved; therefore, node power consumption is lowered, and working time is prolonged. By the method, an adaptive relay protocol converting method is introduced to the relay node, the bit error rate of the cooperative ultra wideband system is reduced to the maximum, and the performance of the system is improved.

Owner:SHANDONG UNIV

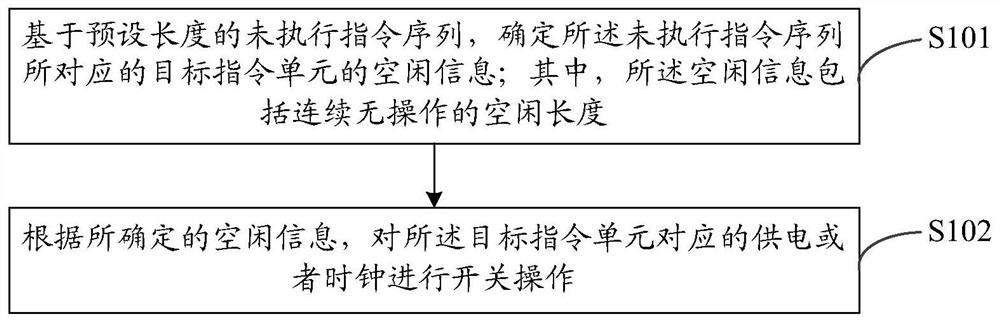

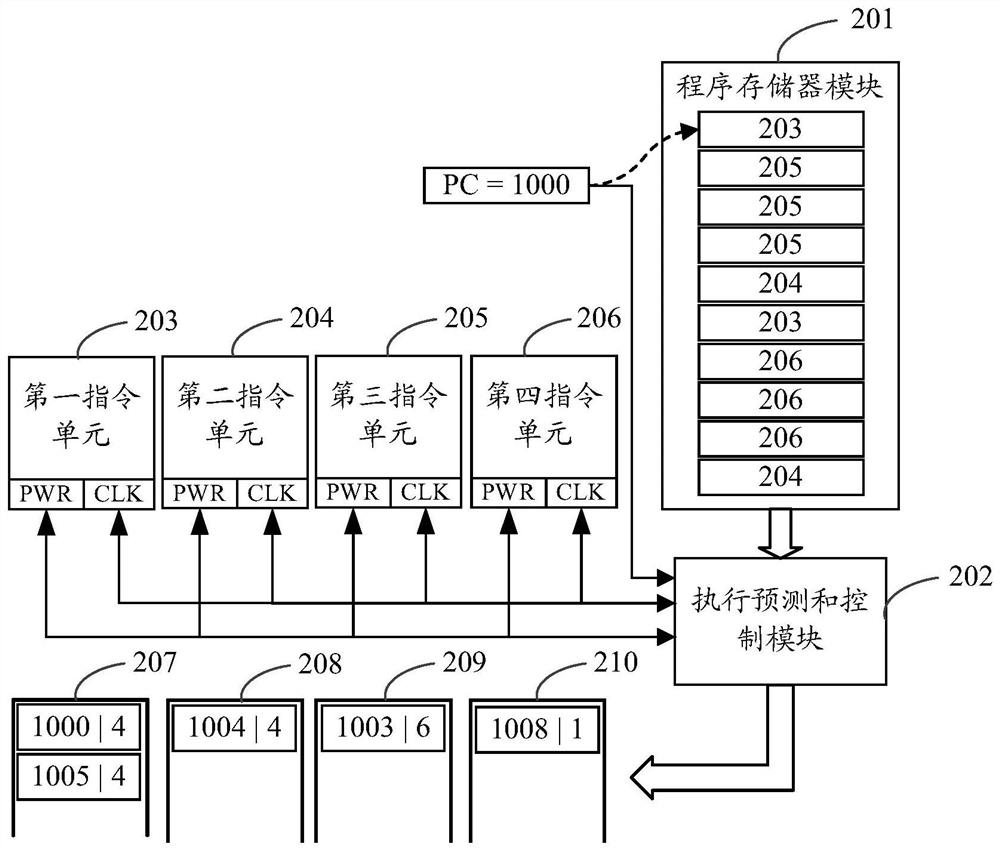

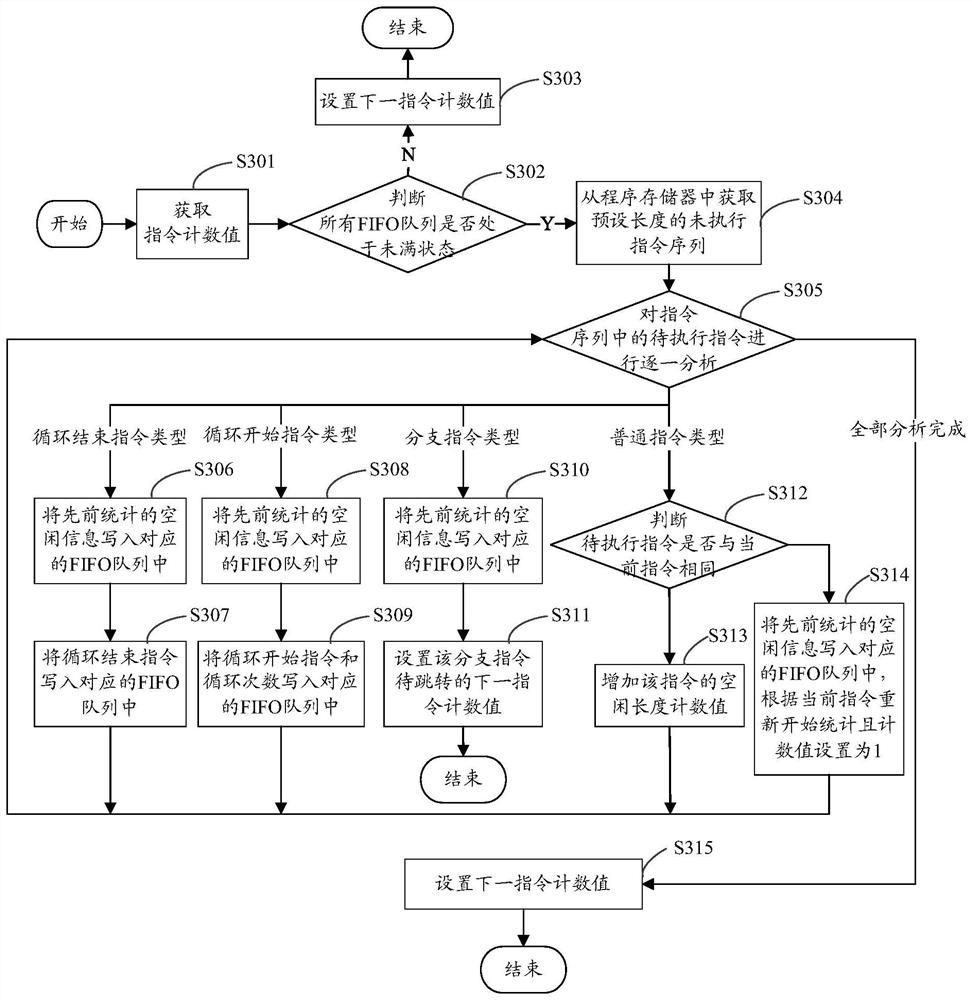

Signal processor control method, device and equipment and storage medium

ActiveCN112147931AReduce ineffective power consumptionImprove power efficiencyProgramme controlComputer controlInstruction unitInstruction sequence

The embodiment of the invention discloses a signal processor control method, device and equipment and storage medium. The method comprises the steps that based on an unexecuted instruction sequence with a preset length, idle information of a target instruction unit corresponding to the unexecuted instruction sequence is determined, wherein the idle information comprises an idle length without continuous operation; and according to the determined idle information, a power supply or a clock corresponding to the target instruction unit is switched on or off. In the abovementioned way, the power consumption efficiency of the signal processor in a working state can be improved, and the purpose of saving power consumption can be achieved.

Owner:ZEKU TECH (BEIJING) CORP LTD

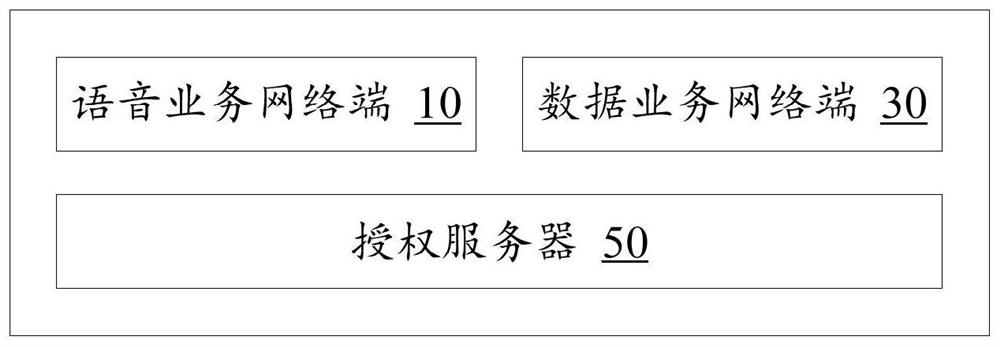

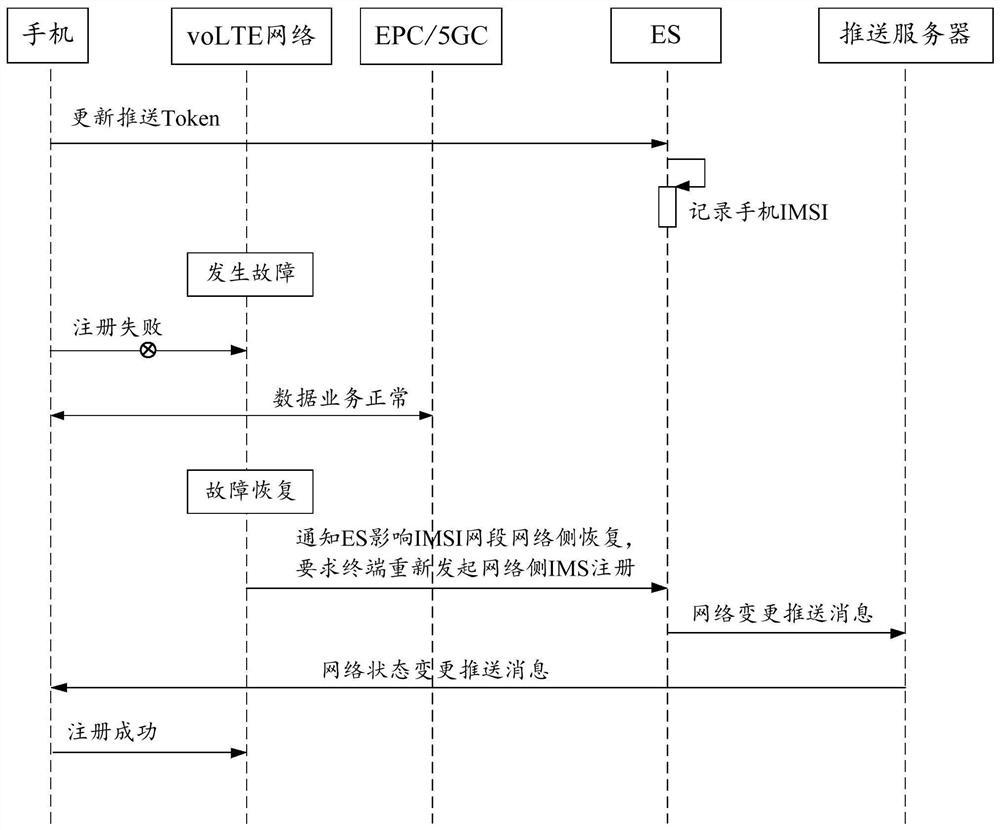

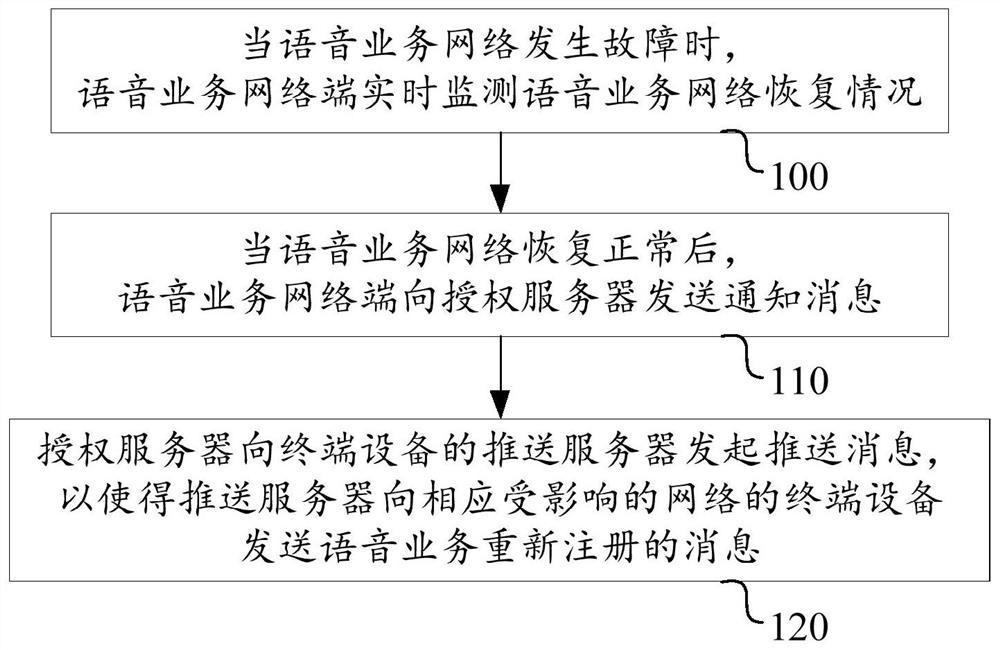

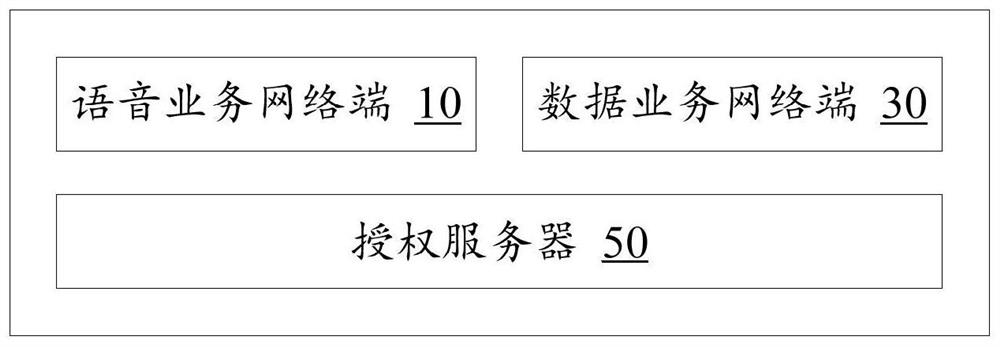

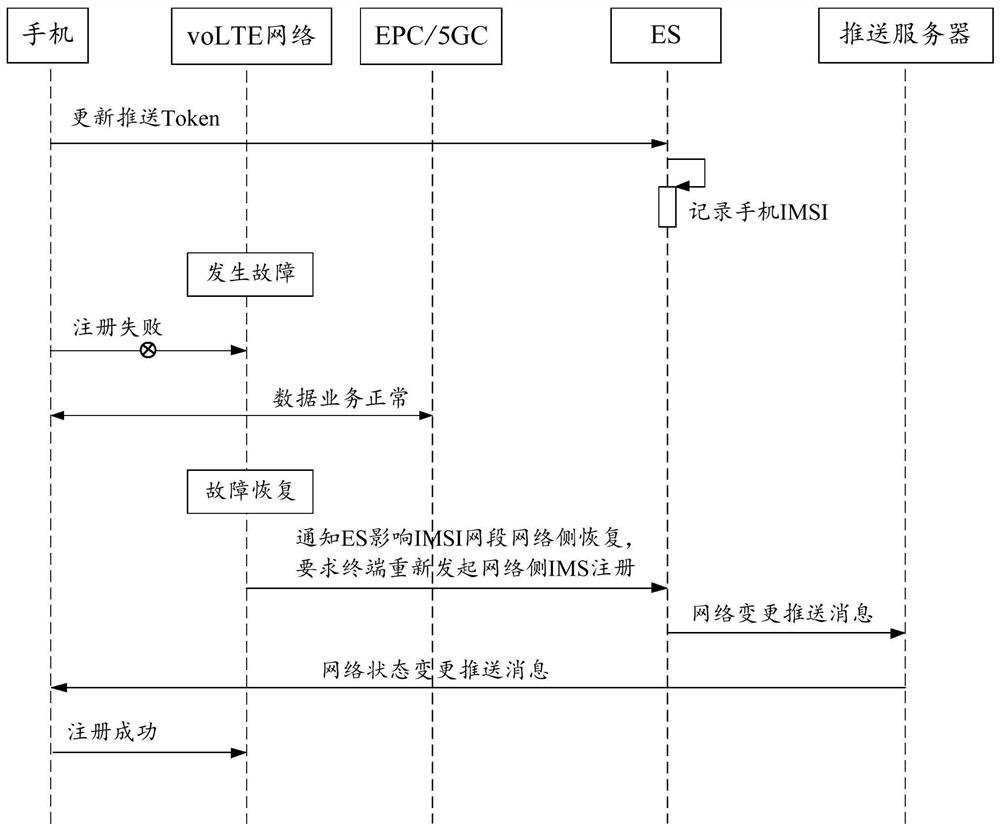

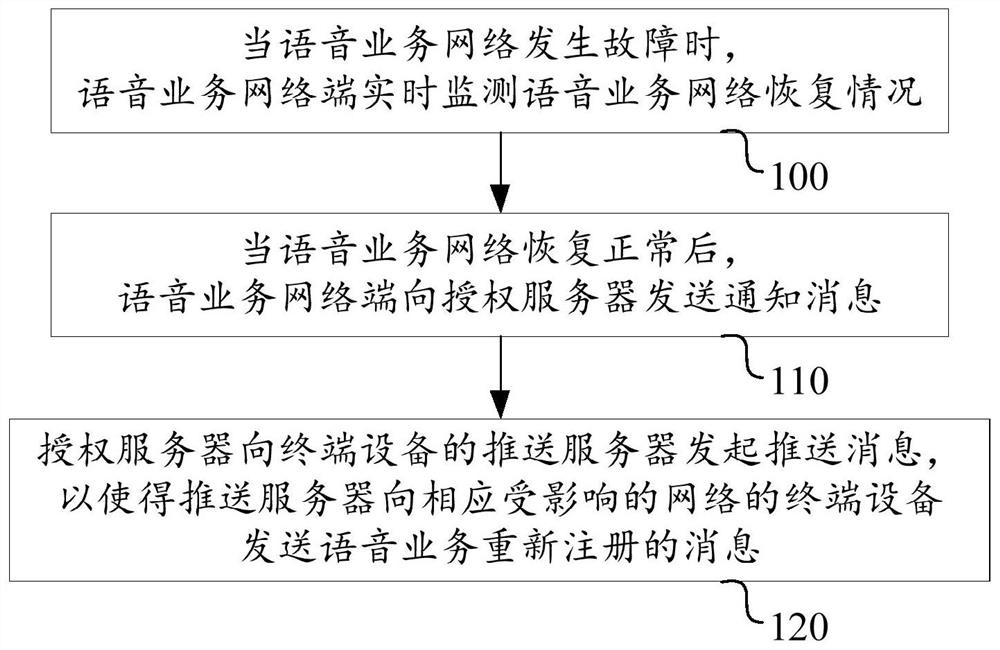

Network fault recovery method based on authorization server and operator system

ActiveCN112584414AReduce ineffective power consumptionEliminate invalidInterconnection arrangementsTransmissionAuthorizationNetwork recovery

The invention discloses a network fault recovery method based on an authorization server and an operator system, and the method comprises the steps: enabling a voice service network end to monitor therecovery condition of a voice service network in real time when the voice service network breaks down; after the voice service network returns to normal, enabling the voice service network side to send a notification message to an authorization server so as to inform the authorization server that the voice service network returns to normal and terminal equipment of an affected network segment needs to be recovered; and enabling the authorization server to initiate a push message to a push server of the terminal device, so that the push server sends a voice service re-registration message to the terminal device of the corresponding affected network, wherein the voice service re-registration message enables the received terminal device to re-initiate a registration message to the voice service network end, thereby recovering the voice service.

Owner:SHENZHEN JETLINK TECH CO LTD

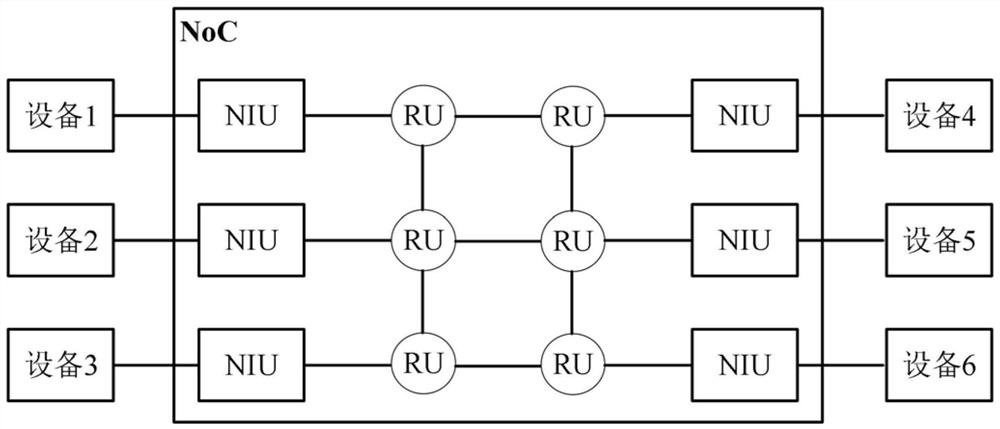

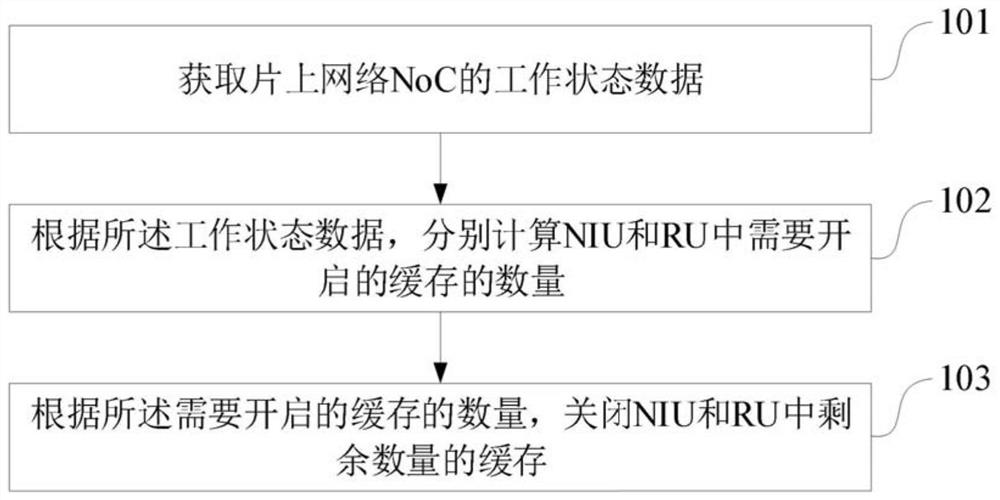

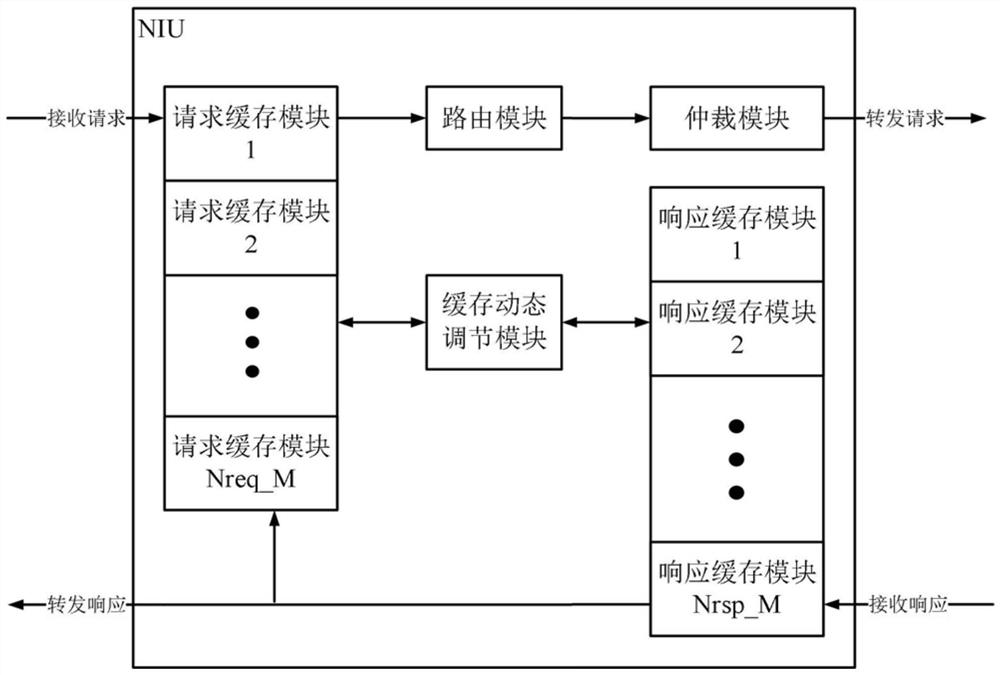

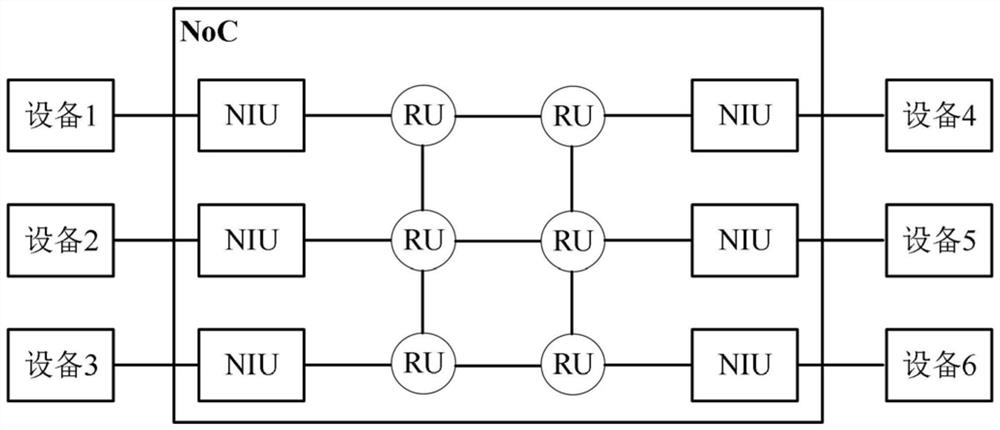

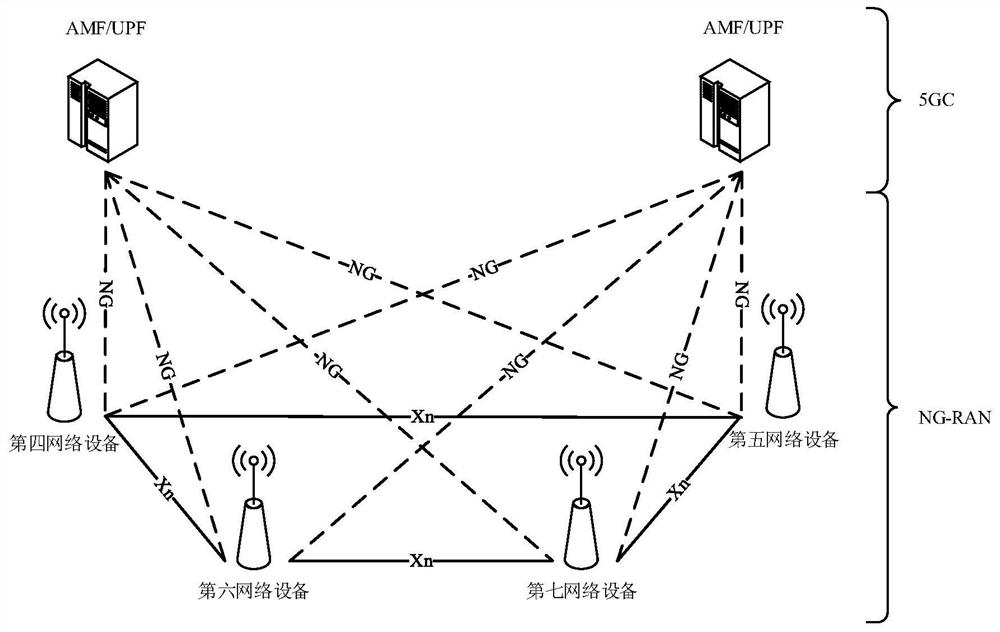

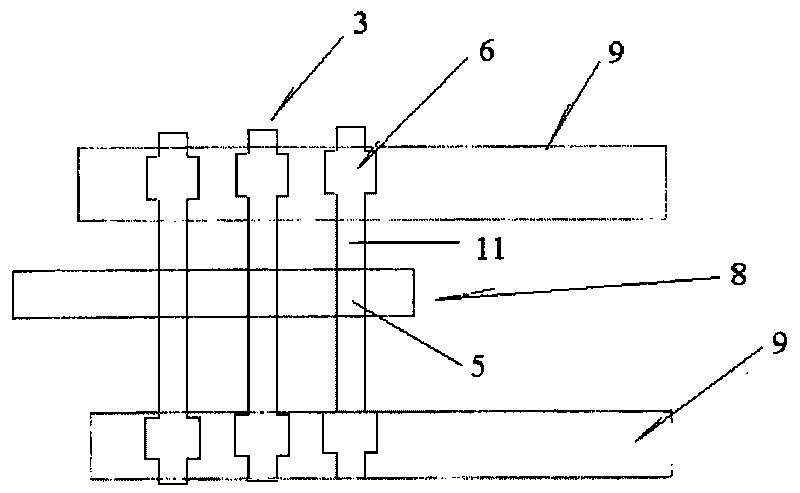

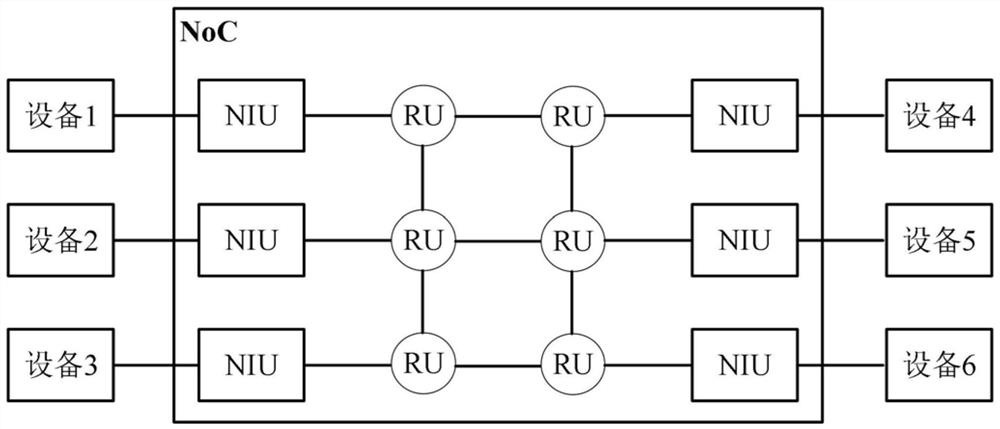

Method and device for reducing network-on-chip power consumption, CPU chip and server

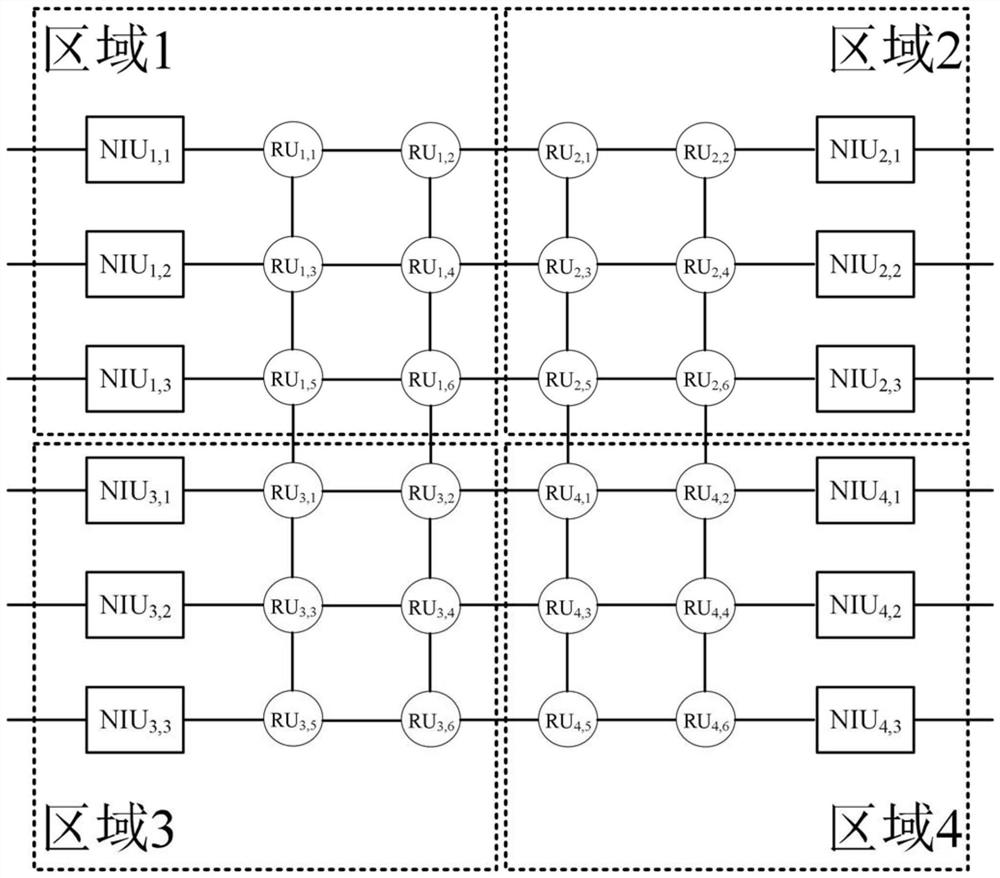

ActiveCN112363612AReduce power consumptionReduce ineffective power consumptionDigital data processing detailsEnergy efficient computingComputer architectureNetworks on chip

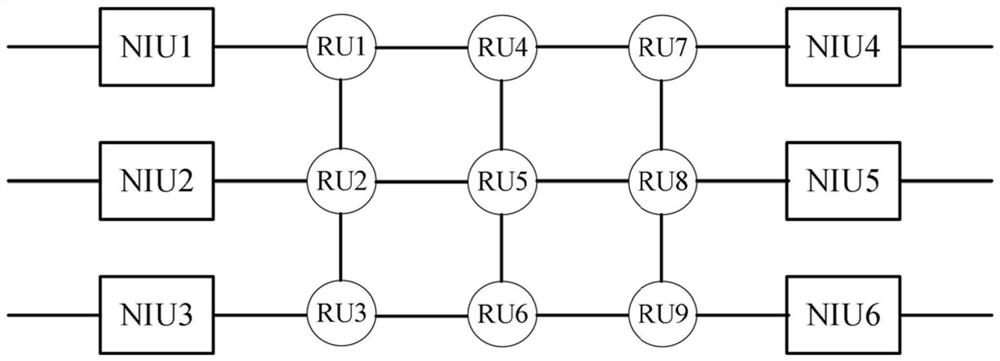

The embodiment of the invention discloses a method and device for reducing network-on-chip power consumption, a CPU chip and a server, relates to the technical field of computers, and can effectivelyreduce the network-on-chip power consumption. The method comprises the following steps: acquiring working state data of a network-on-chip (NoC), wherein the working state data comprises one or more ofthe maximum number of caches used in an NIU (Network Interface Unit) in the latest period of time and the maximum number of caches used in an RU (Remote Unit) in the latest period of time; accordingto the working state data, the number of caches needing to be opened in the NIU and the RU is calculated respectively; and closing the remaining number of caches in the NIU and the RU according to thenumber of the caches required to be opened. The method is suitable for occasions of reducing network-on-chip power consumption.

Owner:HYGON INFORMATION TECH CO LTD

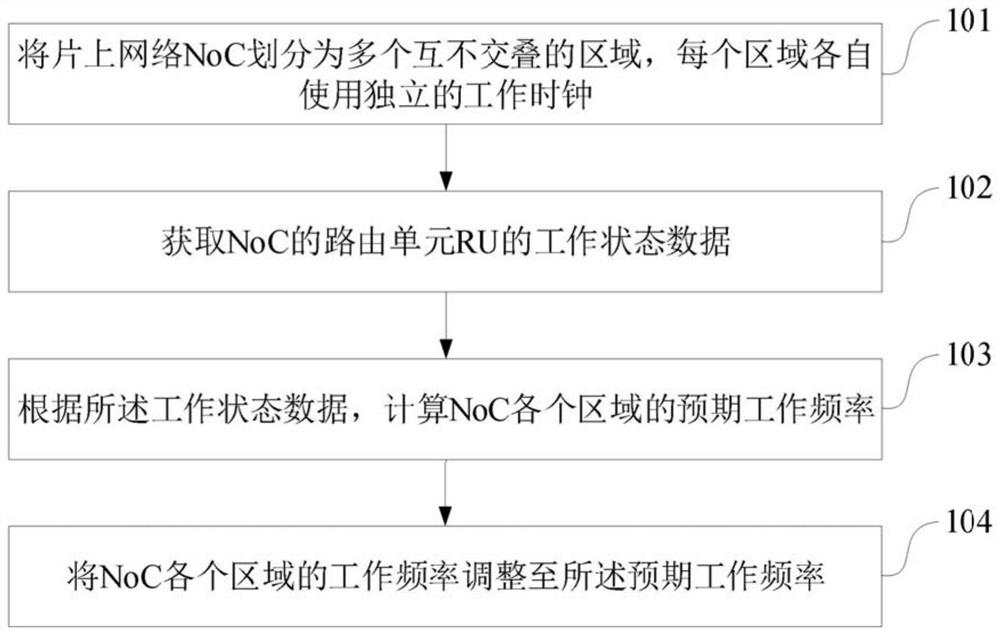

Method and device for reducing network-on-chip power consumption, CPU chip and server

ActiveCN112394807AReduce power consumptionImprove performanceDigital data processing detailsEnergy efficient computingComputer hardwareNetworks on chip

The embodiment of the invention discloses a method and device for reducing network-on-chip power consumption, a CPU chip and a server, relates to the technical field of computers, and can effectivelyreduce the network-on-chip power consumption. The method comprises the following steps: dividing a network-on-chip (NoC) into more than two regions which are not overlapped with each other, wherein each region uses an independent working clock; acquiring working state data of a routing unit RU of the NoC; calculating the expected working frequency of each region of the NoC according to the workingstate data; and adjusting the working frequency of each region of the NoC to the expected working frequency. The invention is suitable for occasions of reducing network-on-chip power consumption.

Owner:HYGON INFORMATION TECH CO LTD

A cell reselection method and device

ActiveCN111148173BReduce the number of checksImprove effectivenessPower managementAssess restrictionTerminal equipmentProcess engineering

Owner:HUAWEI TECH CO LTD

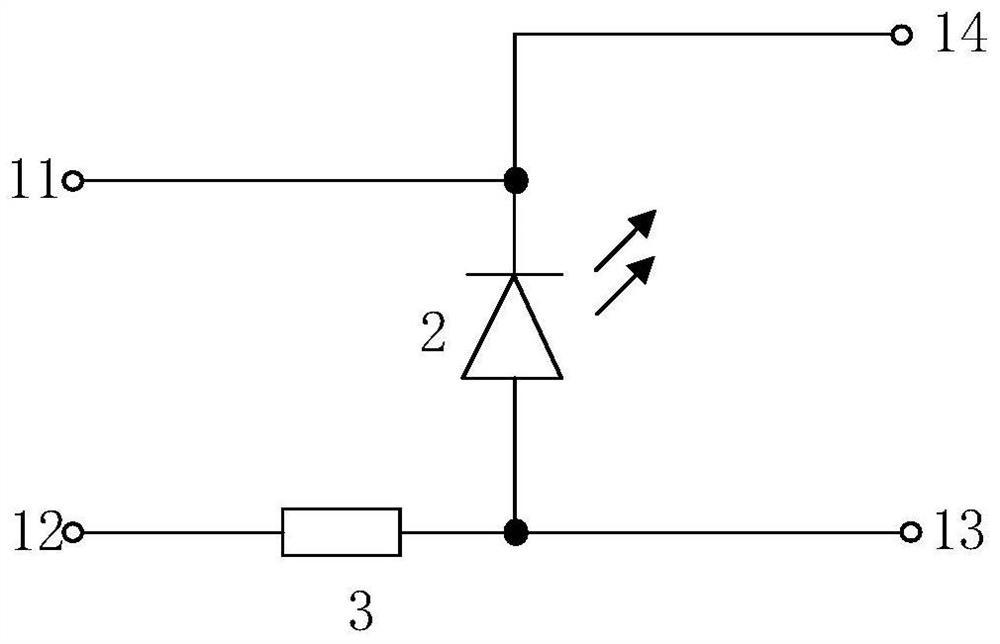

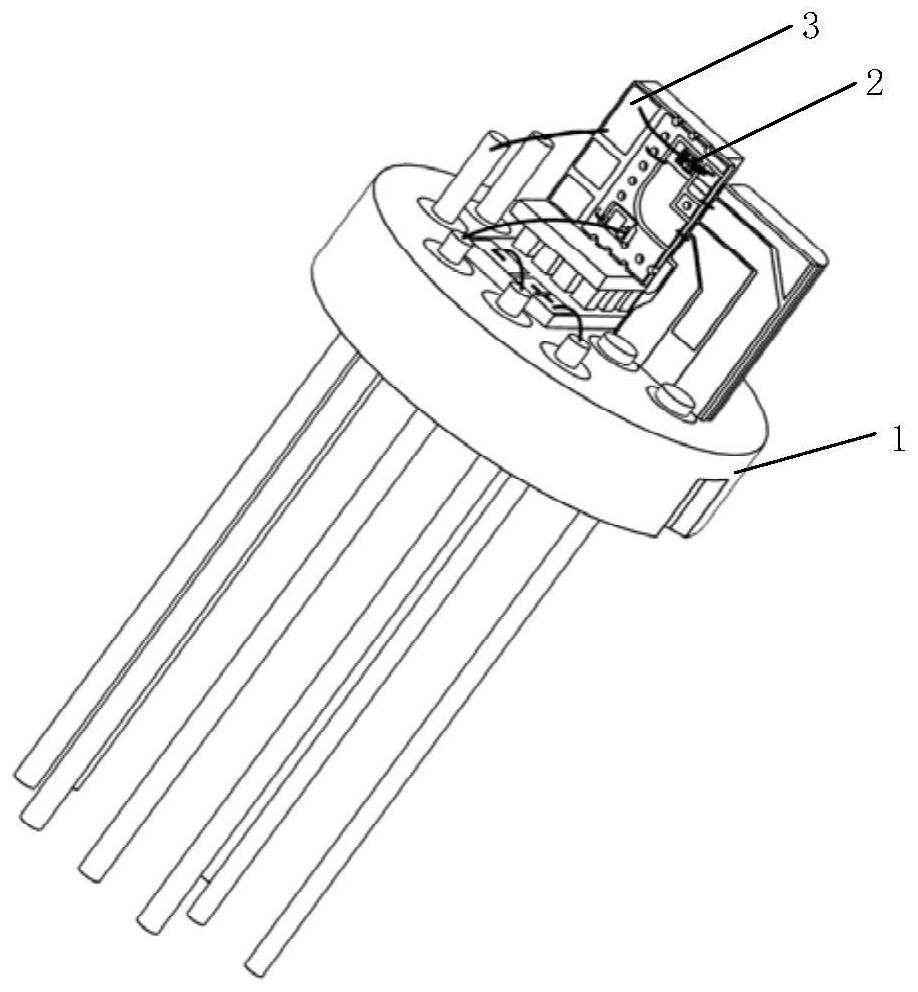

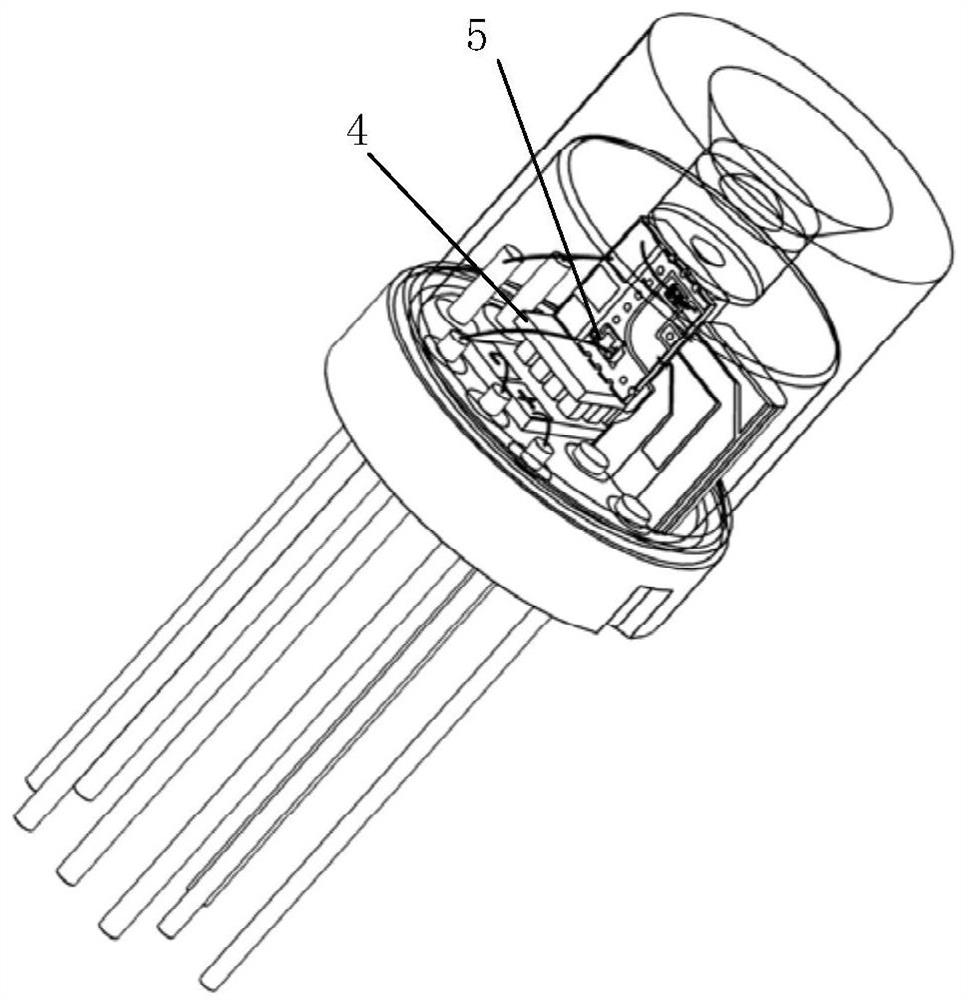

High-speed signal TO-CAN structure

PendingCN114709709AImprove integrityIntegrity guaranteedLaser detailsElectromagnetic transmittersElectrical connectionEngineering

The invention relates to the technical field of optical communication devices, and provides a high-speed signal TO-CAN structure. Which comprises a TO base and a laser, and is characterized in that two laser high-frequency signal pins are arranged on the TO base and are respectively used for establishing electrical connection with one end of a matched resistor and one end of the laser; wherein the other end of the matched resistor is interconnected with the other end of the laser; and the two ends of the laser are respectively connected with two laser static working pins on the TO base. A modulation signal line and a bias signal line are separated, a matched resistor is additionally arranged on the modulated high-speed signal line to keep the integrity of signals, the matched resistor does not pass through the bias line, and therefore power consumption increase caused by the matched resistor is avoided. The internal space of the existing TO is utilized to the greatest extent to complete the integrity processing of the signal.

Owner:GUANGXUN SCI & TECH WUHAN

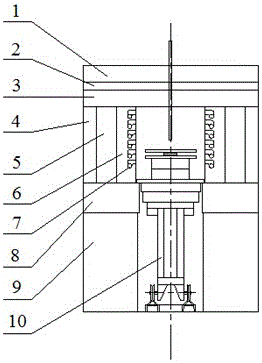

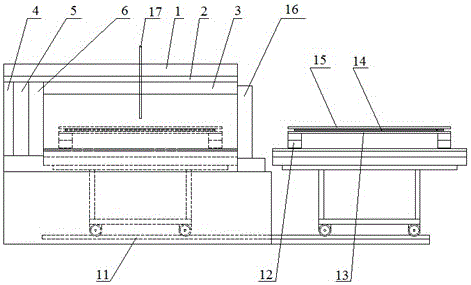

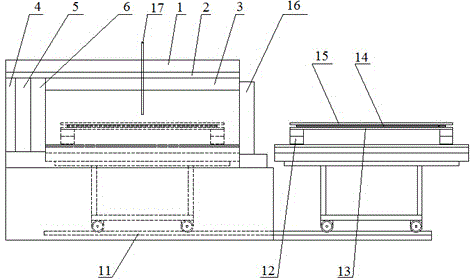

Resistance furnace and brazing method for brazing zinc electrolytic anode conductive beam

ActiveCN104923877BGood for occupational healthImprove working environmentHeating appliancesWelding/soldering/cutting articlesElectrolysisReciprocating motion

The invention discloses a resistance furnace for brazing a zinc electrolysis anode electric conducting cross beam and a brazing method. The resistance furnace comprises a U-shaped base horizontally arranged, wherein the base has a furnace bottom; a rail is arranged on the bottom surface of the base, and is provided with an advancing furnace car capable of performing a reciprocating motion; a furnace body is arranged on the furnace bottom; a cavity is formed in the furnace body; electric furnace wires are arranged on the side wall of the cavity; a front furnace gate is formed in the side wall of the furnace body; the advancing furnace car is pushed into the base in use; and the working surface of the advancing furnace car and the cavity of the furnace body are formed to an empty cavity. A copper plate and lead plates with two specifications are prepared; one lead plate, the copper plate and the other one lead plate are laminated on the working surface of the advancing furnace car in sequence; brazing filler metals are laid in gaps among the plates; a pressure plate is covered; the advancing furnace car enters the base; after the segmented temperature rise and insulation is performed, the plates are discharged from the furnace for air cooling; the lead plates are welded; and the copper plate is sealed in the lead plates. The brazing method applies a brazing technology to weld heterogeneous metals, and solves the surface-surface metallurgic bonding problem of copper / lead heterogeneous metals.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

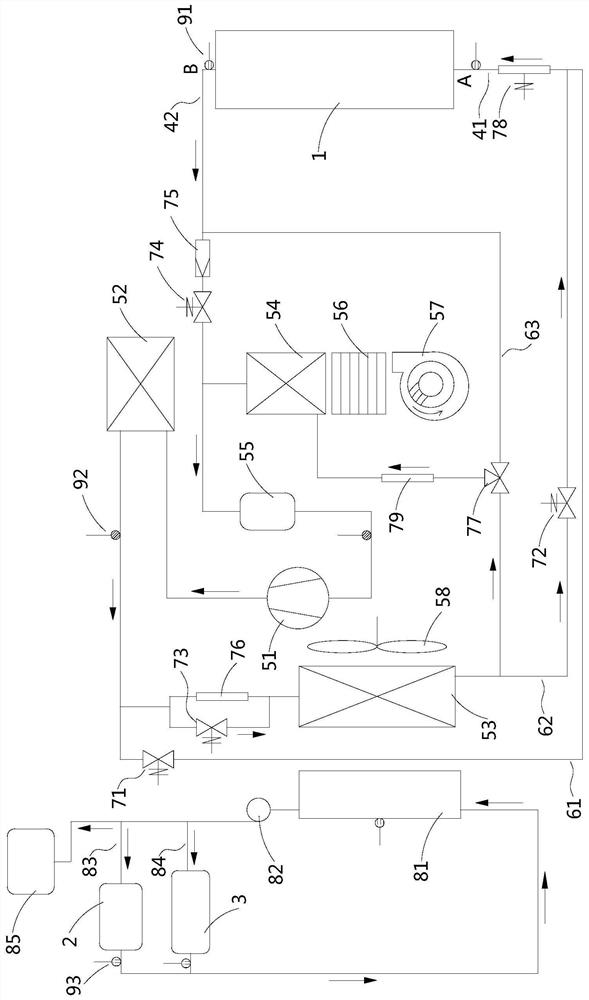

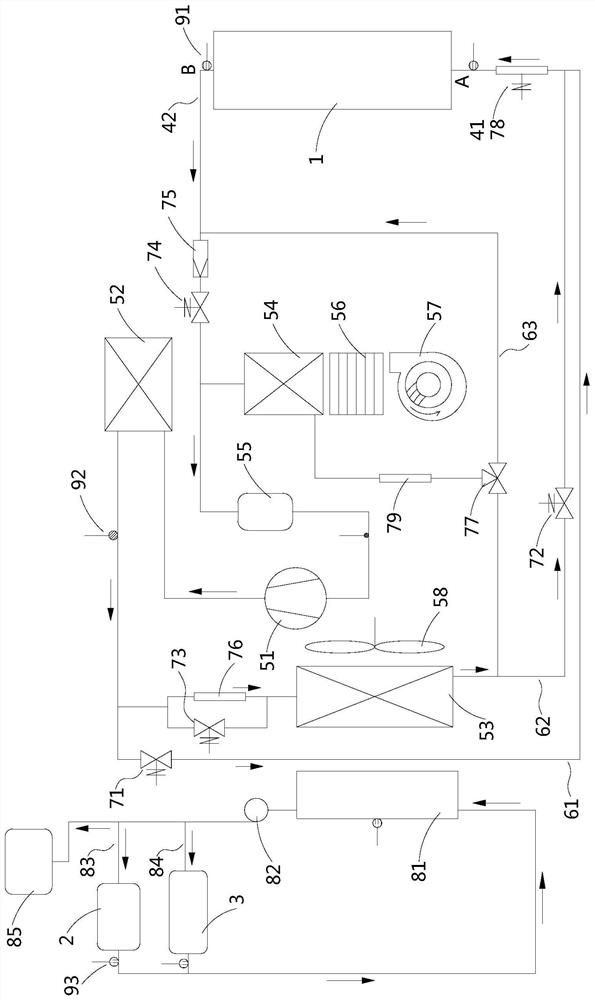

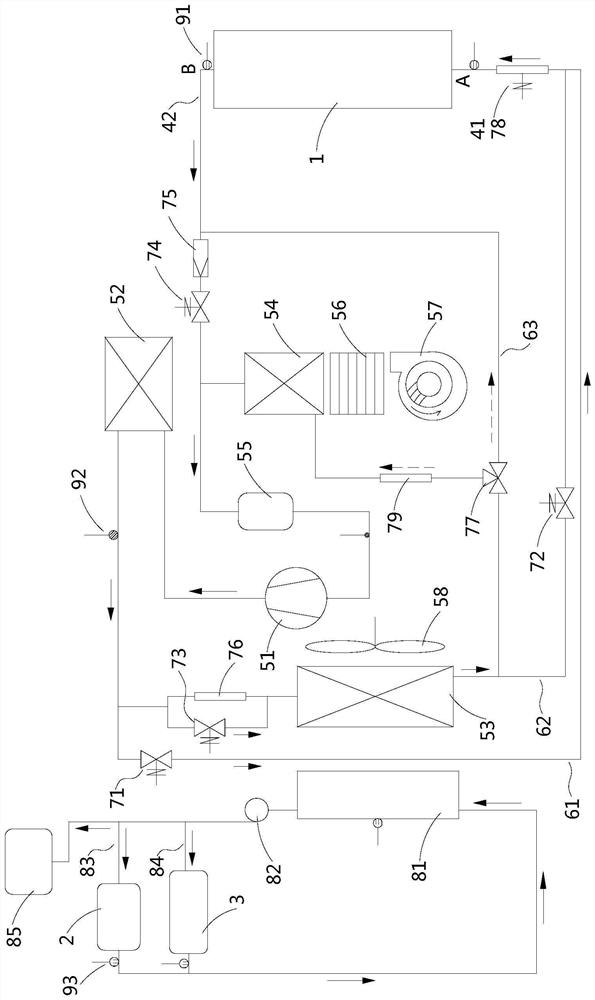

A thermal management system for an electric vehicle

ActiveCN107914538BReduce weightReduce ineffective power consumptionAir-treating devicesVehicle heating/cooling devicesPower batteryElectrical battery

The invention discloses an electric vehicle thermal management system, belonging to the technical field of electric vehicles, comprising an air conditioning circuit and a motor cooling circuit, the motor cooling circuit is used for cooling the motor and power components, and also includes a battery cooling circuit used for cooling a power battery pack, The battery cooling circuit is connected to the air conditioning circuit, and the air conditioning circuit and the motor cooling circuit are independent of each other. The electric vehicle thermal management system provided by the invention improves the thermal management system of the existing electric vehicle, sets the battery cooling circuit and the air conditioning circuit into an integrated structure, and saves the water circulation structure for cooling the power battery pack. The components of the battery cooling circuit are greatly reduced, the overall weight of the electric vehicle is effectively reduced, and it is beneficial to optimize the electric vehicle and reduce the ineffective power consumption when the electric vehicle is running.

Owner:DUNAN ENVIRONMENT TECH

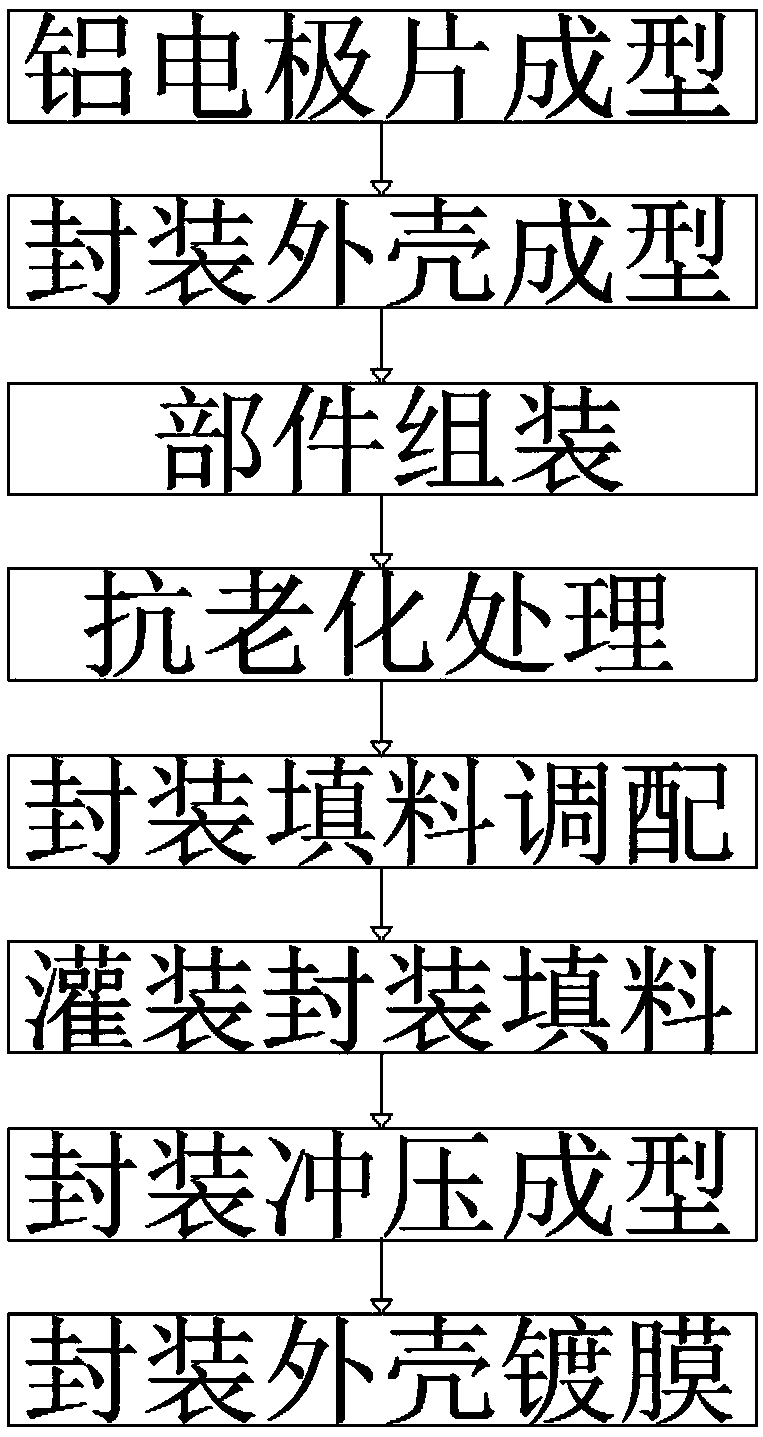

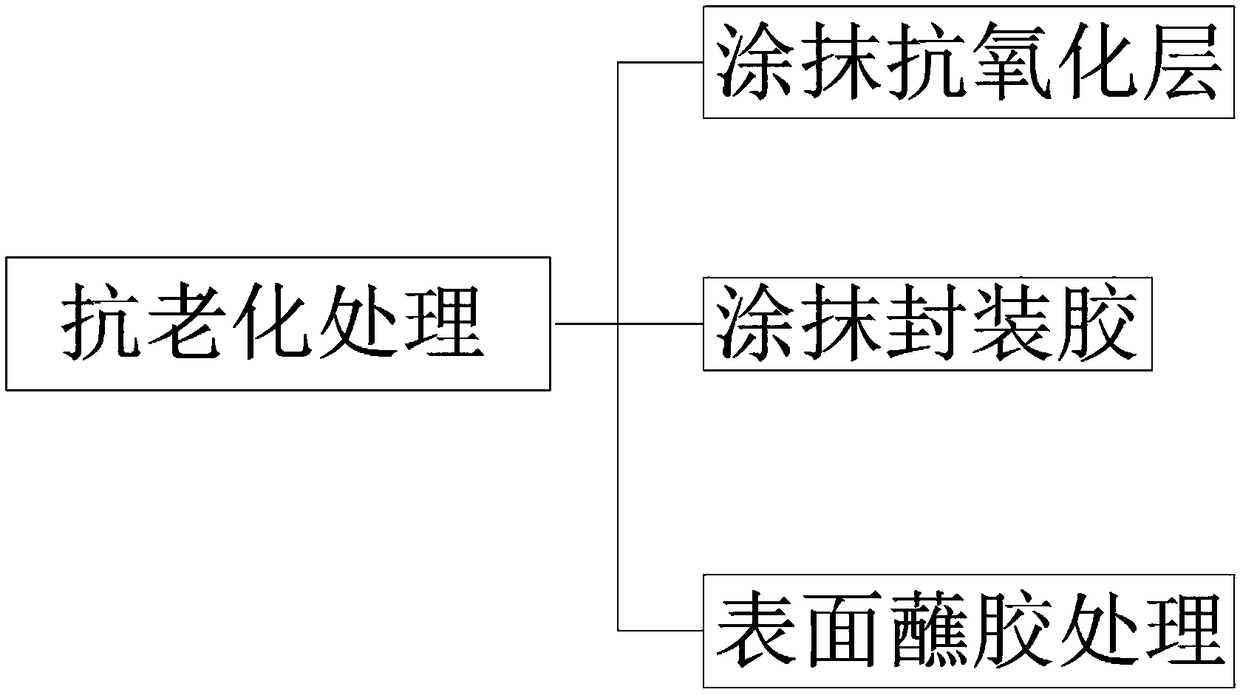

Processing method of anti-ageing PTC heating component

InactiveCN108601103AImprove anti-aging propertiesExtended service lifeOhmic-resistance electrodesCeramic layered productsScreen printingMetallic materials

The invention discloses a processing method of an anti-ageing PTC heating component. The processing method comprises the following steps: aluminum electrode plate forming: performing cutting forming on the aluminum electrode plate through cutting equipment, and performing nickel-plating treatment on the surface of the aluminum electrode plate; package shell forming: performing punch forming on themetal material to form an appropriate shell shape through punch equipment, and performing surface electroplating treatment on the semi-finished product of the punch-formed shell; components assembling: pasting two aluminum electrode plates after the nickel-plating treatment on two sides of the PTC plate, and enabling two aluminum electrode plates to form electric connection with two electrodes ofthe PTC plate through the metal silk-screen printing; and anti-ageing treatment: coating antioxidant layers on surfaces of two aluminum electrode plates and the PTC plate after the assembling. Through the processing method disclosed by the invention, the anti-ageing performance of the aluminum electrode plate can be improved, the service life of the PTC heating component is improved, the heat transfer efficiency is improved at the same time, so that the heat conductivity of the PTC heating component is higher, and the production cost is saved.

Owner:浙江欧兰顿电器科技有限公司

Power supply controlling method and system for telecommunication system

InactiveCN1780348BAvoid damageAvoid failureCurrent supply arrangementsEmergency protective arrangements for automatic disconnectionCommunications systemMonoboard

Owner:HUAWEI TECH CO LTD

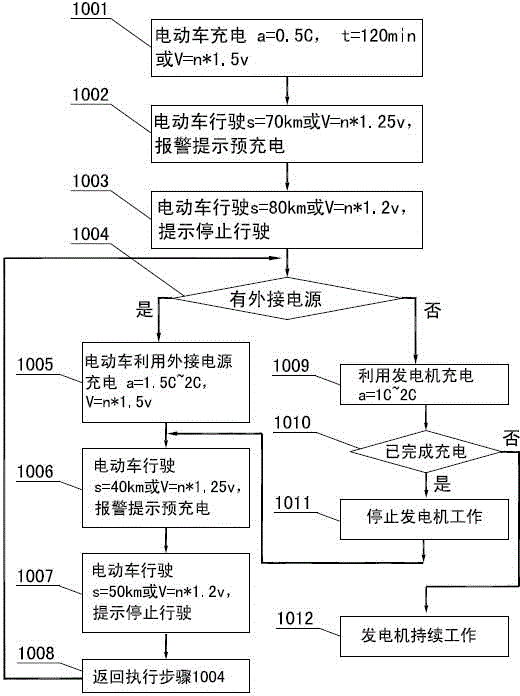

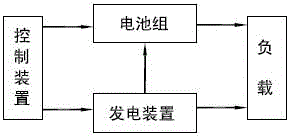

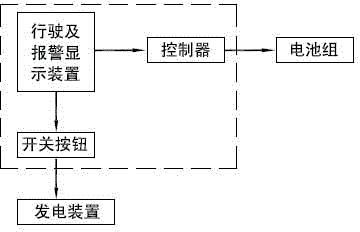

Charging method of asymmetric hybrid power supply device for extended-range small electric vehicle

ActiveCN103241133BMeet emergency needsReduce use costVehicular energy storageElectric propulsionElectricityDisplay device

The invention provides a charging method of an asymmetric hybrid power supply device for an extended-range small electric car and belongs to the field of electric car equipment. The charging method uses a battery pack, a power generation device and a load, wherein the power generation device is connected with the battery pack, and the battery pack and the power generation device are simultaneously connected with the load. The charging method is characterized in that a control device which is composed of a traveling and alarm display device, a switch knob and a controller and used for monitoring and controlling working states of the battery pack and the power generation device is arranged, the traveling and alarm display device is simultaneously connected with the switch knob and the controller, the switch knob is connected with the power generation device, and the controller is connected with the battery pack. The charging method of the asymmetric hybrid power supply device for the extended-range electric car is simple in structure, reliable in performance and capable of achieving large-current rapid charging and discharging. In normal traveling of the extended-range small electric car, an engine can supply electricity to and charge the battery pack when electricity of the battery pack is not enough. By means of the charging method, people can select charging modes.

Owner:淄博国利新电源科技有限公司

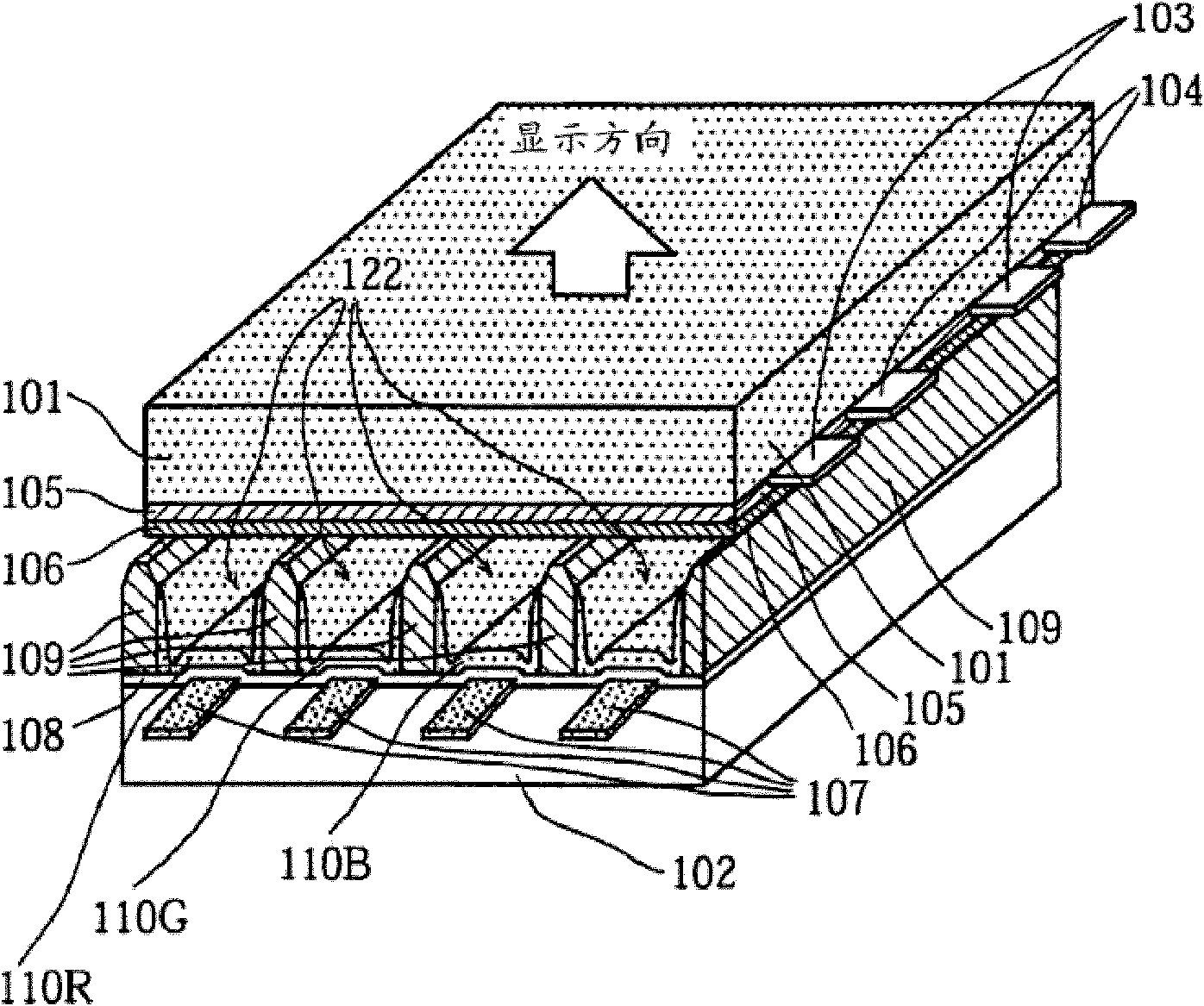

Plasma display panel and lower substrate thereof

InactiveCN101728158AIncrease widthReduce widthSolid cathode detailsCold-cathode tubesCapacitanceEffective power

The invention provides a plasma display panel and a lower substrate thereof, wherein the lower substrate comprises an addressing electrode and a medium arranged on the addressing electrode; the addressing electrode is provided with a first part and a second part; the first part corresponds to the position of a sustaining electrode of an upper substrate, and the second part corresponds to the position of a scanning electrode of the upper substrate; and the second part is wider than the first part. In the invention, the width of the addressing electrode of a part corresponding to a Y electrode is increased, and the widths of the addressing electrodes of other parts are reduced so as to improve the addressing efficiency and reduce the capacitance and the non-effective power consumption of the addressing electrodes.

Owner:SICHUAN COC DISPLAY DEVICES

Method and device for reducing network-on-chip power consumption, CPU chip and server

ActiveCN112363609AReduce power consumptionGuaranteed performanceDigital data processing detailsArchitecture with single central processing unitNetworks on chipTime windows

The embodiment of the invention discloses a method and device for reducing network-on-chip power consumption, a CPU chip and a server, relates to the technical field of computers, and can effectivelyreduce the network-on-chip power consumption. The method comprises the following steps: acquiring working state data of a network-on-chip (NoC), wherein the working state data comprises one or more ofthe number of non-responsive requests initiated by equipment in an NIU in a period of time window, the number of requests and responses cached in an RU in a period of time window, and NoC historicalbandwidth statistical data; calculating the expected working frequency of the NoC according to the working state data; and adjusting the working frequency of the NoC according to the expected workingfrequency. The method is suitable for occasions of reducing network-on-chip power consumption.

Owner:HYGON INFORMATION TECH CO LTD

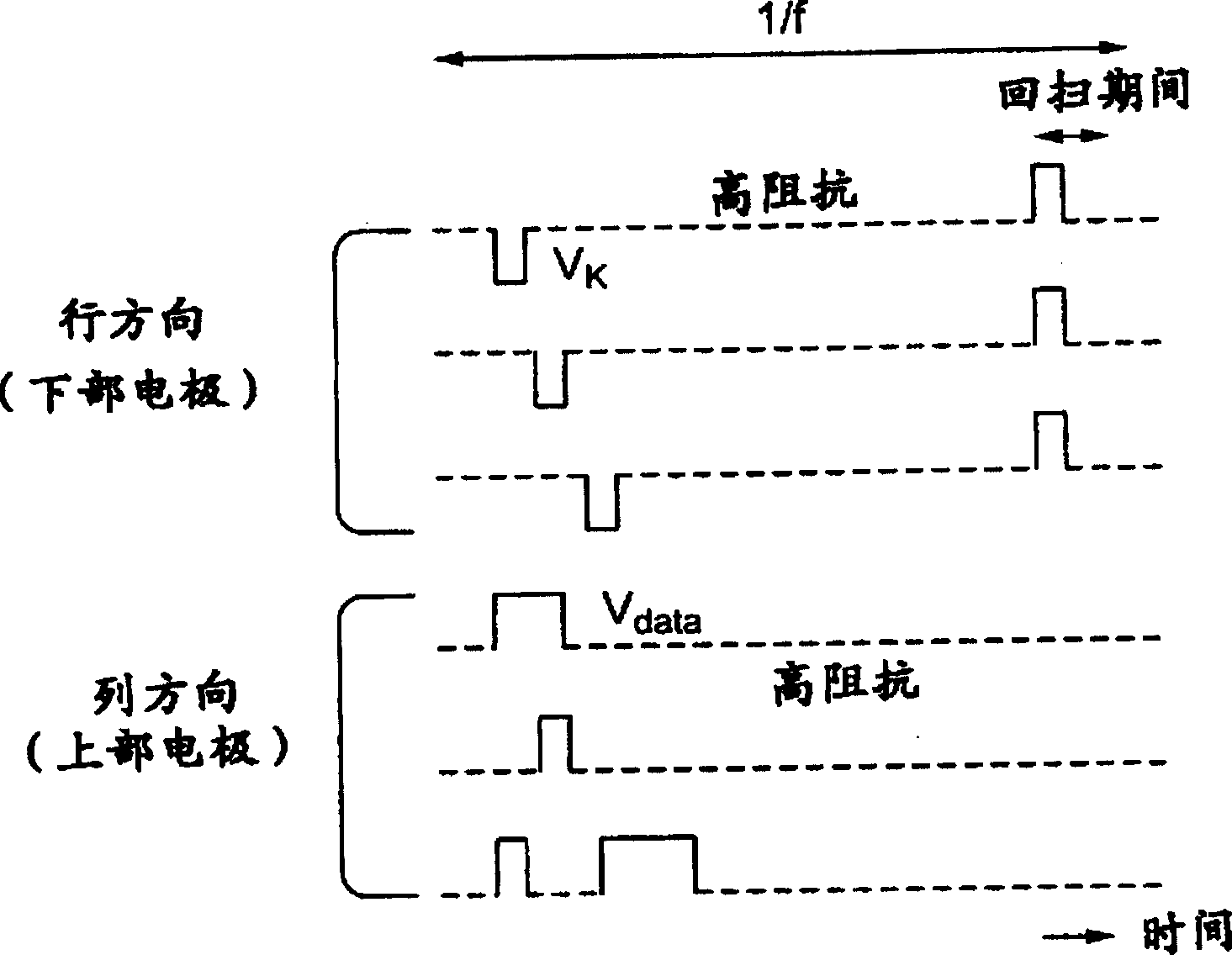

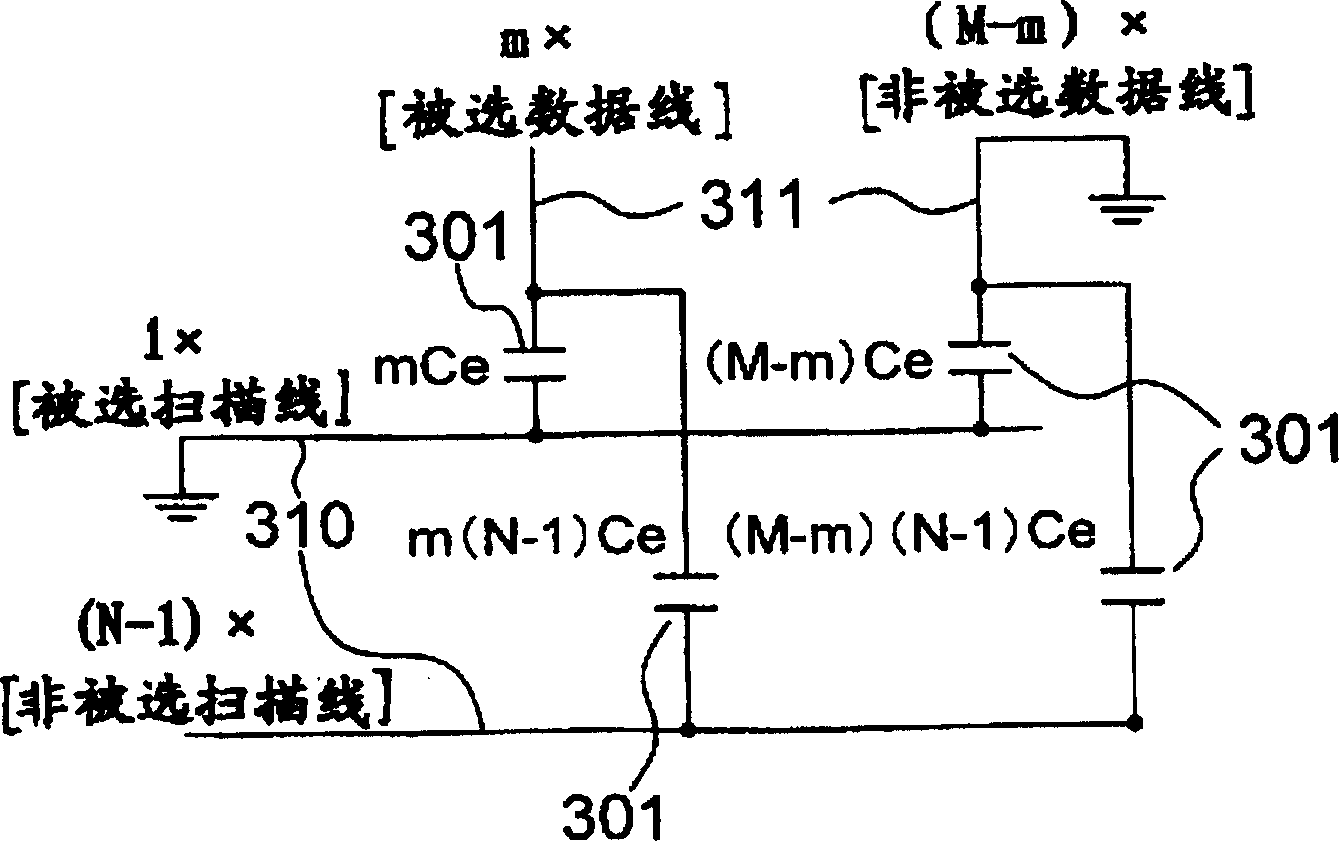

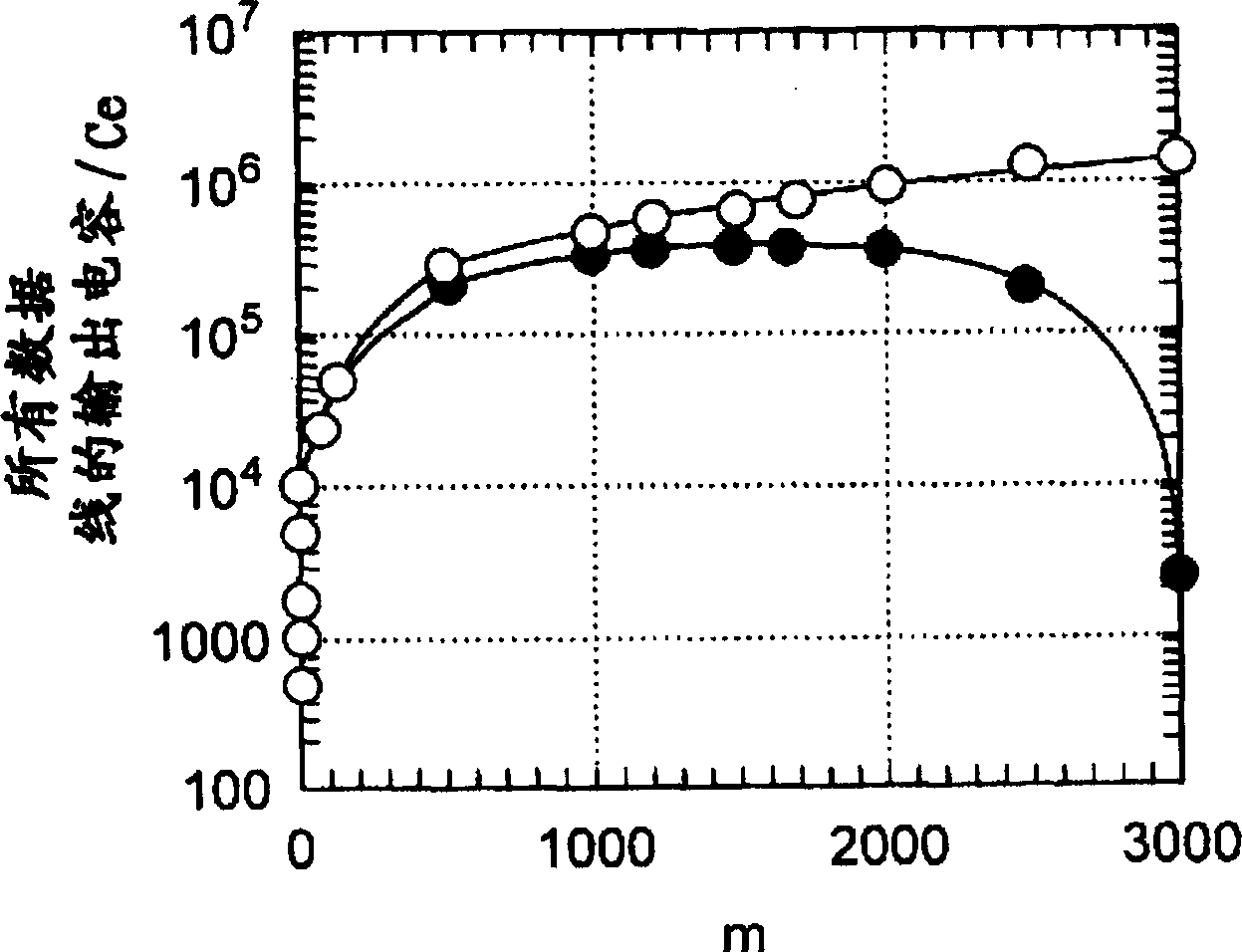

Image display device using brilliance modulation device and its driving method

InactiveCN1266666CReduce ineffective power consumptionElectroluminescent light sourcesSolid-state devicesElectricityDisplay device

A display apparatus includes a plurality of luminance modulation elements each modulated in luminance by a voltage of a positive polarity applied thereto, each of the luminance modulation elements being not modulated in luminance by a voltage of an opposite polarity applied thereto; a plurality of first lines electrically coupled to first electrodes of the plurality of luminance modulation elements; a plurality of second lines electrically coupled to second electrodes of the plurality of luminance modulation elements, the plurality of second lines intersecting the plurality of first lines; a first drive unit coupled to the plurality of first lines outputting scanning pulses; and a second driver unit coupled to the plurality of second lines. The first drive unit sets the first lines in a nonselection state to a high impedance state having a higher impedance as compared with the first lines in a selection state.

Owner:HITACHI LTD

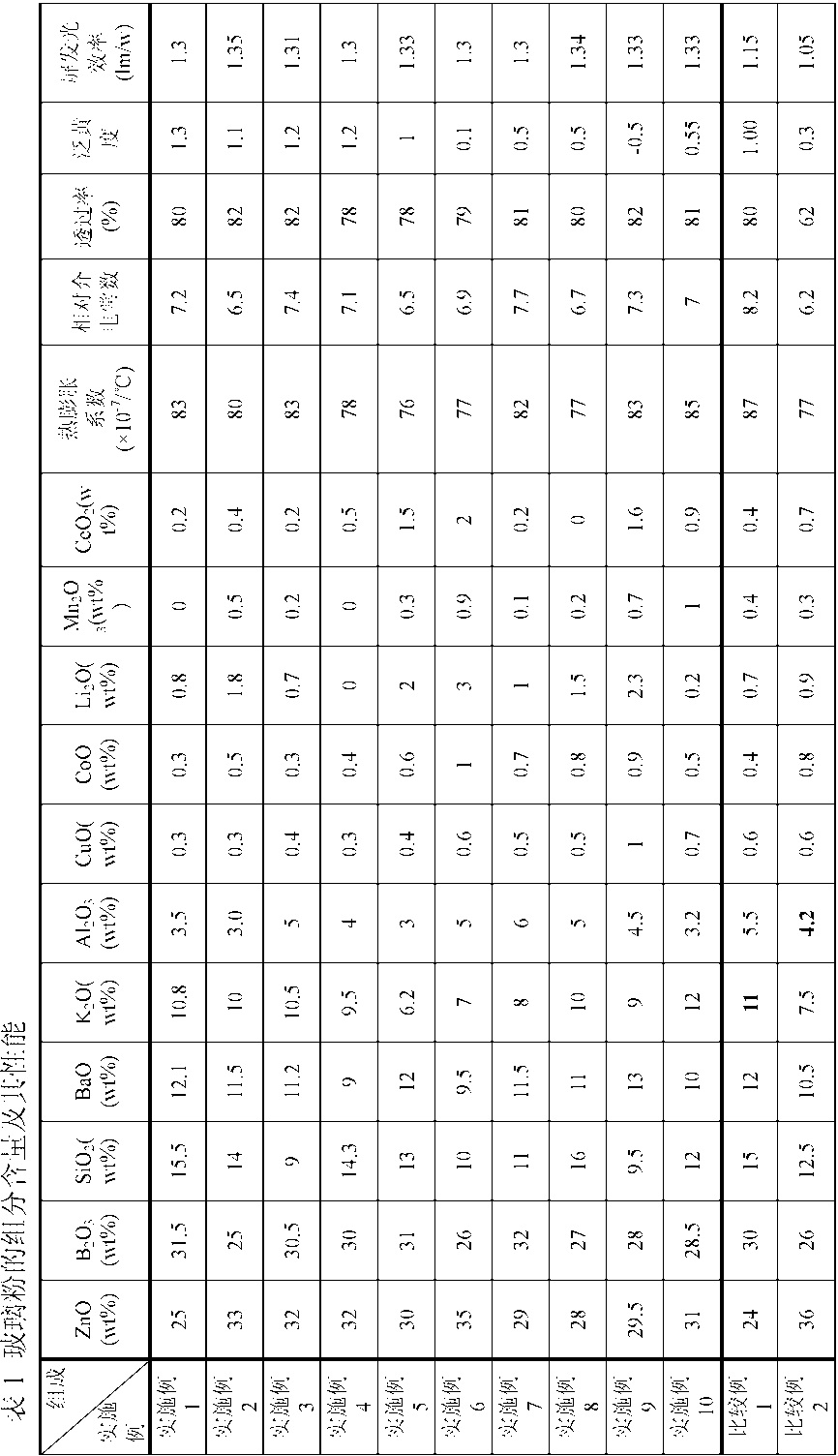

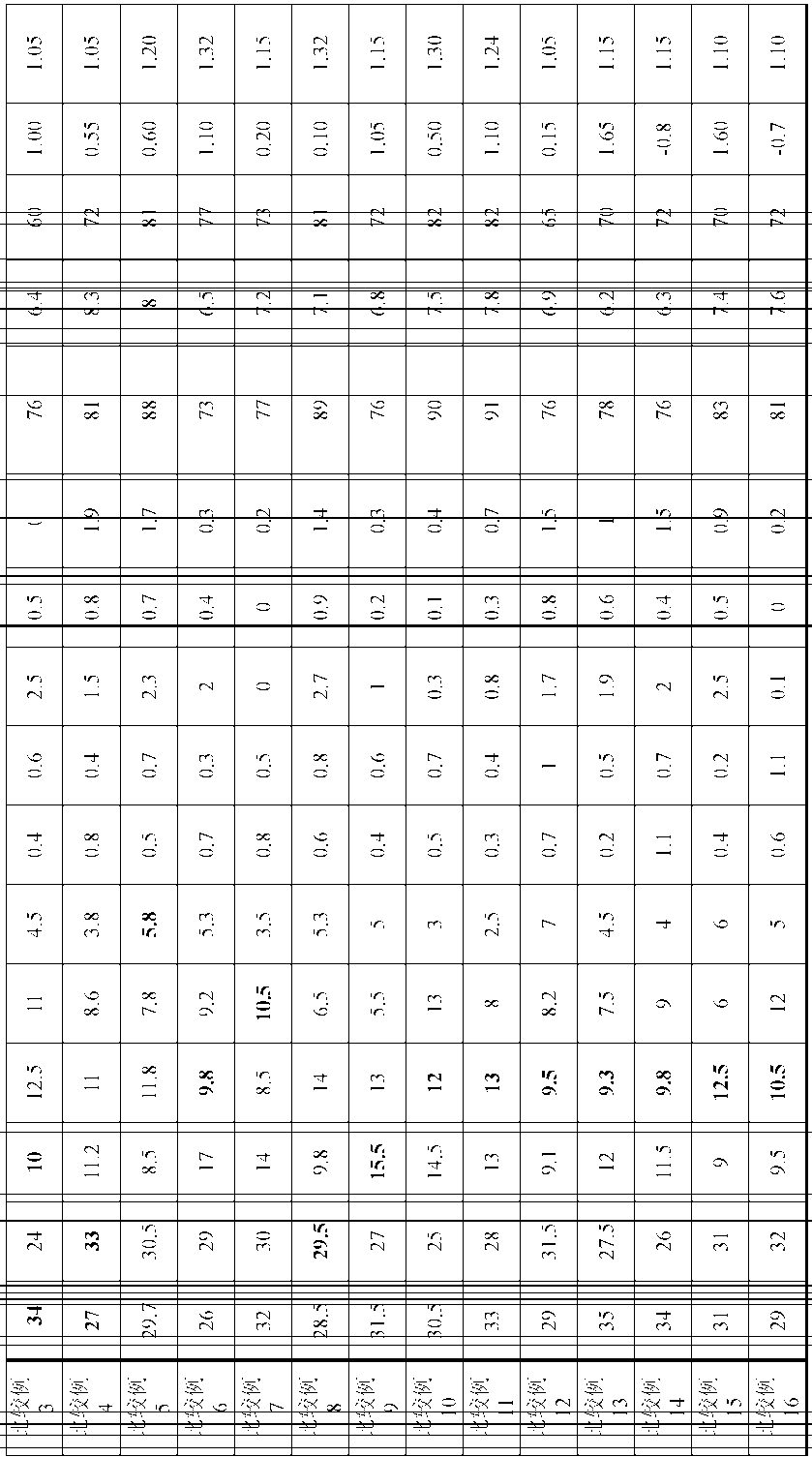

Dielectric glass powder for plasma display panel

InactiveCN102082056BImprove luminous efficiencyLow costSolid cathode detailsCold-cathode tubesSlurrySolvent

The invention provides dielectric glass powder for a plasma display panel, front panel dielectric slurry containing the dielectric glass powder, resin and solvent, and a dry film. The dielectric glass powder contains 25 to 35 weight percent of ZnO, 25 to 32 weight percent of B2O3, 9 to 16 weight percent of SiO2, 9 to 13 weight percent of BaO, 6 to 12 weight percent of K2O, 3 to 6 weight percent of Al2O3, 0.3 to 1 weight percent of CoO and 0.3 to 1 weight percent of CuO. Moreover, the glass powder can also contain 0 to 3 weight percent of Li2O, 0 to 2 weight percent of CeO2 and 0 to 1 weight percent of Mn2O3. The invention also provides the plasma display panel of a dielectric layer made of the glass powder. The glass powder prepared by using the formula provided by the invention does not contain toxic or harmful heavy metals such as lead, bismuth and the like, so that the cost is low; and the sintered front panel dielectric layer has low dielectric constant and low corresponding preparation thickness, meanwhile, the luminous efficiency of a plasma display is obviously improved.

Owner:SICHUAN COC DISPLAY DEVICES

A network fault recovery method and operator system based on authorization server

ActiveCN112584414BImprove controllabilityImprove service qualityInterconnection arrangementsTransmissionTerminal equipmentCarrier system

A network fault recovery method based on an authorization server and an operator system. When a fault occurs in a voice service network, the voice service network terminal monitors the recovery situation of the voice service network in real time; when the voice service network returns to normal, the voice service network The terminal sends a notification message to the authorization server to inform the authorization server that the voice service network is back to normal, and the terminal device on the affected network segment needs to be restored; the authorization server initiates a push message to the push server of the terminal device, so that the push The server sends a voice service re-registration message to the terminal equipment of the corresponding affected network, and the voice service re-registration message will cause the received terminal equipment to re-initiate a registration message to the voice service network, thereby restoring the voice service.

Owner:SHENZHEN JETLINK TECH CO LTD

Refrigeration thermal infrared imager and power supply management method thereof

ActiveCN102735346BContinuously workingRealize switchingEnd cell switching arrangementsPyrometry using electric radation detectorsElectrical batteryShort circuit protection

The invention relates to a refrigeration thermal infrared imager and a power supply management method of the refrigeration thermal infrared imager. The refrigeration thermal infrared imager comprises an infrared optical system, a refrigeration infrared prober assembly, an imaging circuit assembly, a power supply management assembly, a GPS (global position system) module, a display module and a control panel; the refrigeration infrared prober assembly consisting of a focal plane infrared prober and a refrigerator is connected behind the infrared optical system; the imaging circuit assembly is further respectively connected with the GPS module, the display module and the control panel; and the power supply management assembly is respectively connected with the infrared optical system, the refrigerator, the imaging circuit assembly, the GPS module, the display module and the control panel. The refrigeration thermal infrared imager provided by the invention has the advantages as follows: hot switching and hot plugging of power supply can be realized, so that a target can be continuously detected and monitored; electric amount of a battery and external power supply voltage can be monitored in real time; a circuit board has no standby current after the refrigeration thermal infrared imager is switched off, so that the working time and the service life of the battery can be prolonged; the over-current, overvoltage, short circuit protection in power supply output, and manual charge and inverse charge protection of the battery can be realized; and the refrigeration thermal infrared imager uses isolation output, so that mutual interference and invalid power consumption can be reduced.

Owner:NO 717 INST CHINA MARINE HEAVY IND GRP

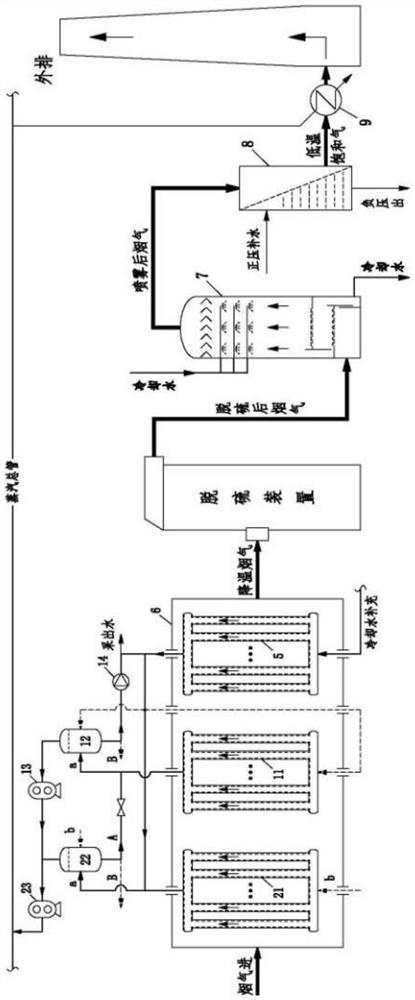

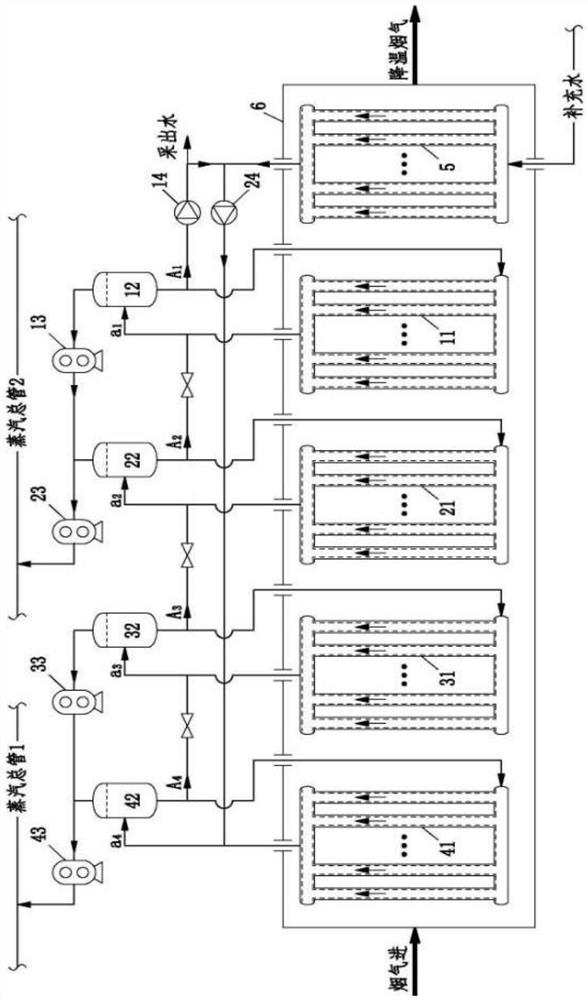

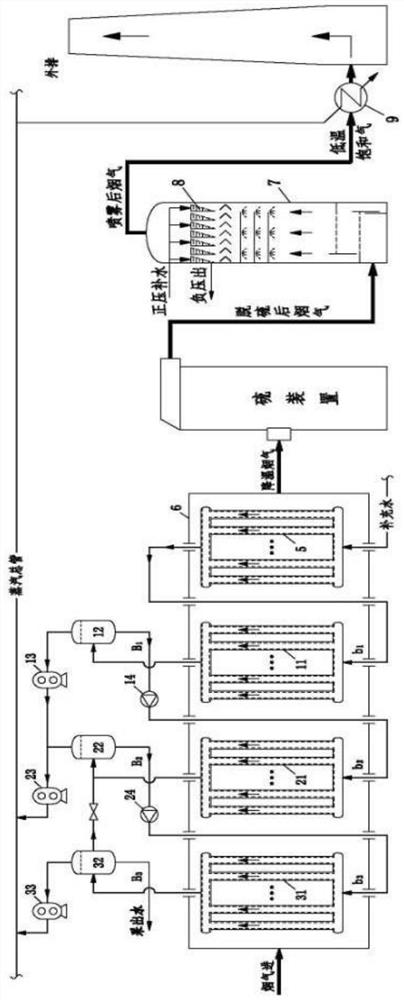

A treatment process for deep heat collection and purification of flue gas

ActiveCN109126364BSmall scaleLarge heat transfer temperature differenceGas treatmentRecuperative heat exchangersWaste heat recovery unitFlue gas

The invention relates to a treatment process for deep heat collection and purification of flue gas, which relates to the technical fields of heating technology and waste gas purification. The present invention is composed of three units of waste heat recovery, desulfurization and purification of white smoke. Boiling point vaporization absorbs heat, so that the waste heat of the flue gas is recovered in the form of steam, and then discharged through the preheating section; the cooled flue gas after heat absorption can reduce the water evaporation when it enters the desulfurization unit; the flue gas discharged from the desulfurization unit is purified and whitened The smoke unit is discharged after spray cooling, film demisting, and reheating of the flue gas. On the one hand, the present invention can recover more waste heat of the flue gas in the form of steam with higher heat enthalpy, and on the other hand, can further purify the flue gas deeply, realizing ultra-low emission without "white smoke" at the flue gas outlet.

Owner:南京圣卡孚科技有限公司

Linear compressor with combined spring supporting structure

ActiveCN101975151BExtended service lifeReduce ineffective power consumptionPiston pumpsPositive-displacement liquid enginesRefrigeration compressorLinear compressor

The invention relates to the field of refrigeration compressors and provides a linear compressor with a combined spring supporting structure. The linear compressor comprises a front end cover, a middle end cover, a rear end cover, a cylinder barrel, an inner stator, an outer stator, a piston, a permanent magnet part, a movable connection part, a first columnar resonance spring part, a second columnar resonance spring part, a first platy resonance spring part and a second platy resonance spring part, wherein the front end cover, the middle end cover and the rear end cover are sequentially and fixedly arranged inside the shell of the linear compressor in parallel at certain interval, and the first platy resonance spring part and the second platy resonance spring part are respectively arranged between the movable connection part and the rear end cover and between the cylinder barrel and the movable connection part and are fixedly connected with the rear end cover and the cylinder barrel.By the combinational use of the columnar resonance springs and the platy resonance springs, the linear compressor provided in the invention reduces the lateral offset and torsion of motion parts and friction during moving and lowers invalid power consumption.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Resistance furnace for brazing zinc electrolysis anode electric conducting cross beam and brazing method

ActiveCN104923877AGood for occupational healthImprove working environmentHeating appliancesWelding/soldering/cutting articlesElectrolysisReciprocating motion

The invention discloses a resistance furnace for brazing a zinc electrolysis anode electric conducting cross beam and a brazing method. The resistance furnace comprises a U-shaped base horizontally arranged, wherein the base has a furnace bottom; a rail is arranged on the bottom surface of the base, and is provided with an advancing furnace car capable of performing a reciprocating motion; a furnace body is arranged on the furnace bottom; a cavity is formed in the furnace body; electric furnace wires are arranged on the side wall of the cavity; a front furnace gate is formed in the side wall of the furnace body; the advancing furnace car is pushed into the base in use; and the working surface of the advancing furnace car and the cavity of the furnace body are formed to an empty cavity. A copper plate and lead plates with two specifications are prepared; one lead plate, the copper plate and the other one lead plate are laminated on the working surface of the advancing furnace car in sequence; brazing filler metals are laid in gaps among the plates; a pressure plate is covered; the advancing furnace car enters the base; after the segmented temperature rise and insulation is performed, the plates are discharged from the furnace for air cooling; the lead plates are welded; and the copper plate is sealed in the lead plates. The brazing method applies a brazing technology to weld heterogeneous metals, and solves the surface-surface metallurgic bonding problem of copper / lead heterogeneous metals.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Air conditioning system and air conditioner indoor terminal applied in the air conditioning system

ActiveCN106765571BImprove heat transfer efficiencyImprove energy efficiency ratioMechanical apparatusSpace heating and ventilation detailsEngineeringAir conditioning

The present invention provides an air conditioning system, including an indoor terminal and an outdoor terminal. The indoor terminal is provided with an indoor-end heat exchanger, and the outdoor terminal is provided with an outdoor-end heat exchanger. The refrigerant circulation is connected, and the indoor end heat exchanger includes a first indoor heat exchanger and a second indoor heat exchanger, and a refrigerant branch circuit is arranged between the first indoor heat exchanger and the second indoor heat exchanger, and the refrigerant branch circuit Including the first branch and the second branch arranged in parallel, a bypass valve is set on the first branch, a first throttling mechanism is set on the second branch, the outdoor end heat exchanger is connected to the second indoor heat exchanger, and the outdoor A second throttling mechanism is arranged between the end heat exchanger and the second indoor heat exchanger. Also disclosed is an indoor terminal of an air conditioner. The present invention can improve the air flow resistance and temperature distribution characteristics in the room to the greatest extent through the double improvement of the refrigerant circulation pipeline and the drainage port, and improve the user's comfort.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com