Linear compressor with combined spring supporting structure

A linear compressor and support structure technology, applied in the field of refrigeration compressors, can solve problems affecting the coaxiality of moving parts and stator parts, increase compressor power consumption, and reduce service life, etc., to reduce lateral offset and Effects of twisting, reducing ineffective power consumption, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

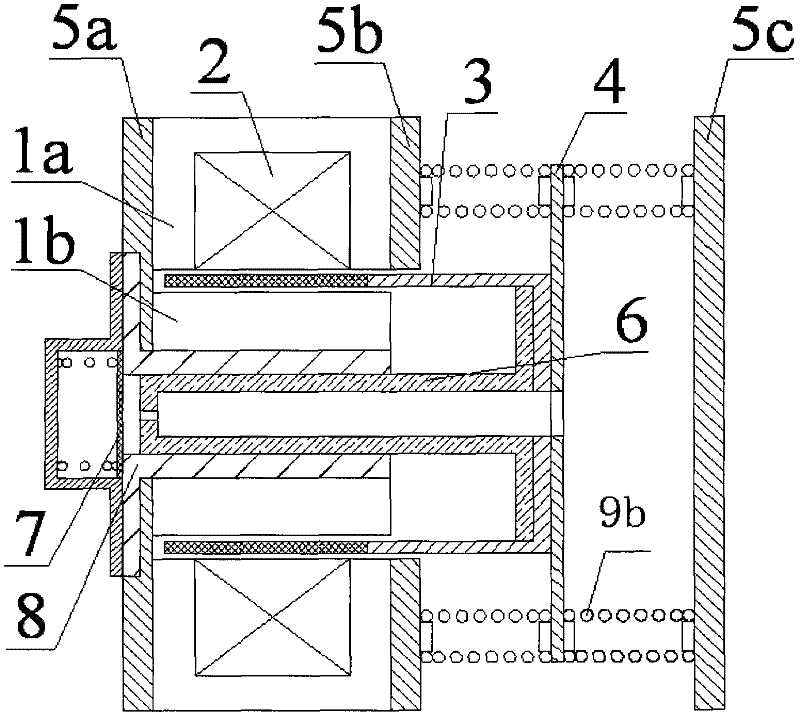

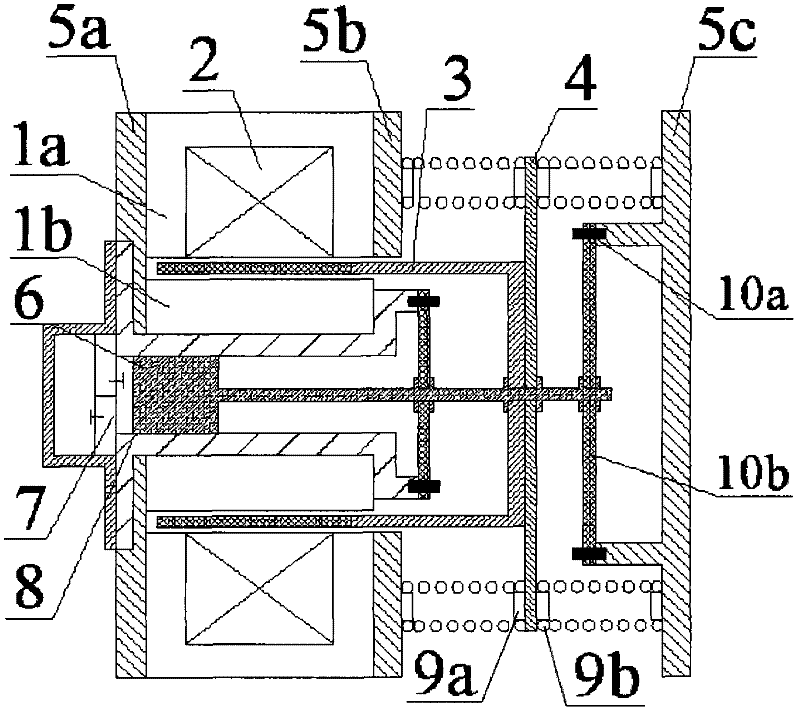

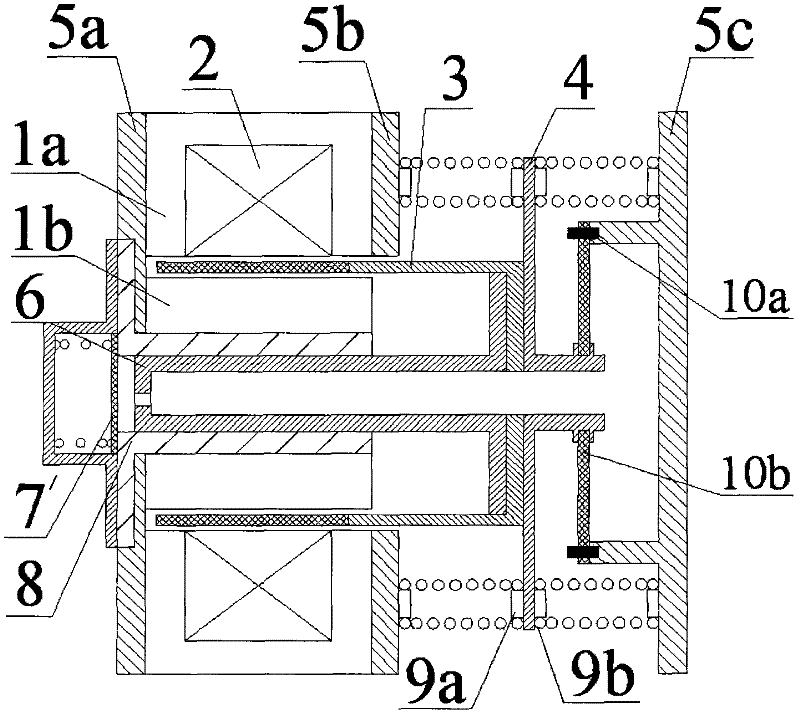

[0028] like figure 2 As shown, it is a structural cross-sectional view of a linear compressor with a combined spring support structure according to an embodiment of the present invention. The linear compressor provided by the present invention includes: a front end cover 5a, a middle end cover 5b, a rear end cover 5c, and a cylinder barrel 8 , the outer stator 1a, the inner stator 1b, the piston 6, the permanent magnet part 3, the movable connection part 4, the cylindrical resonant spring part 9b, the cylindrical resonant spring fixing part 9a, the plate resonant spring fixing part 10a and the plate resonant spring part 10b.

[0029] Among them, the front end cover 5a, the middle end cover 5b and the rear end cover 5c are fixed in the shell of the linear compressor sequentially and parallelly at a certain distance, and the three end covers ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com