Dielectric glass powder for plasma display panel

A display panel and glass frit technology, applied in the fields of dielectric paste and dry film, low dielectric constant dielectric glass frit, lead-free and bismuth-free, can solve the problems of increased product cost, high price of bismuth oxide, and reduced ineffective power consumption , The effect of improving luminous efficiency and low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

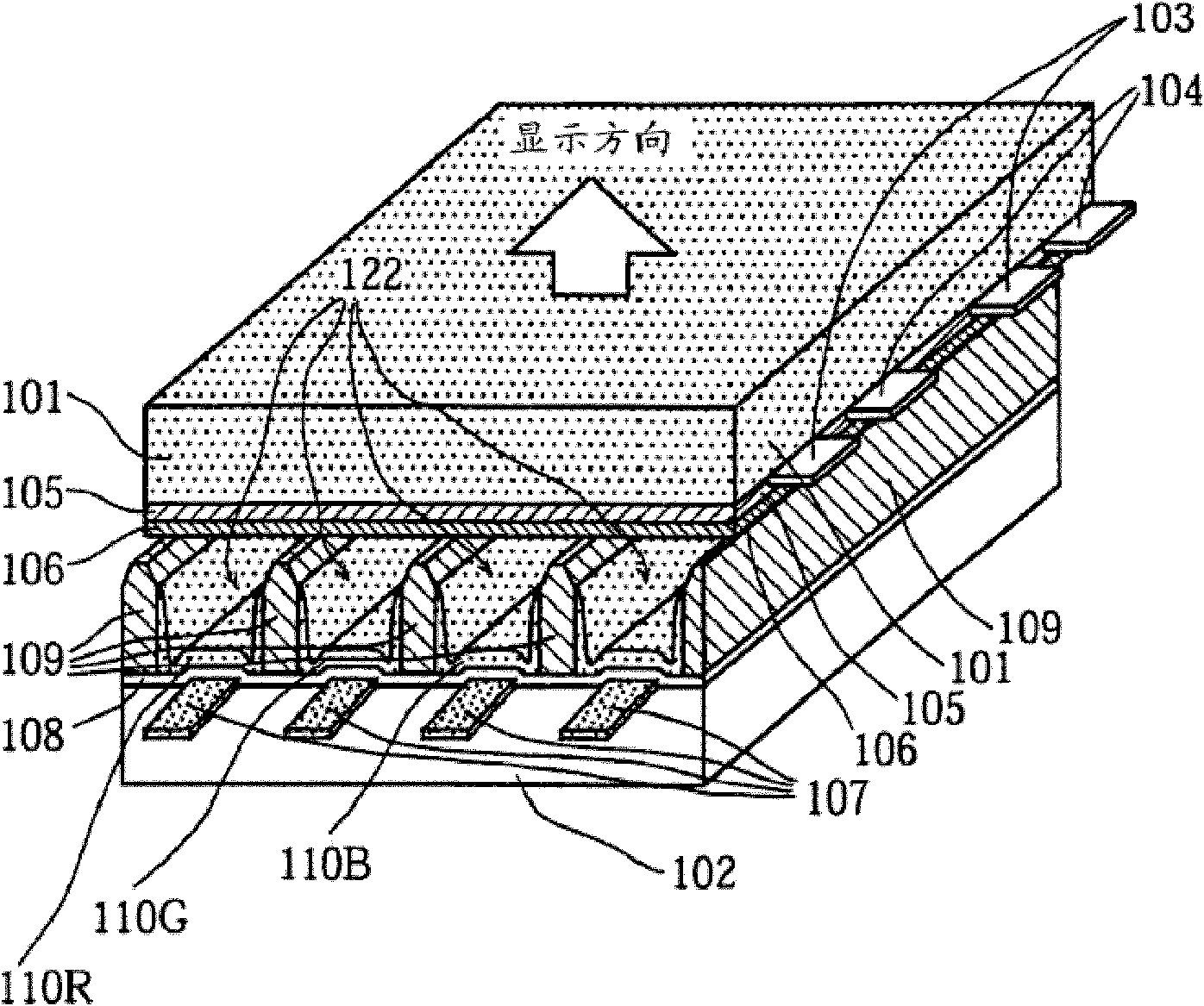

Image

Examples

Embodiment 1

[0047] Preparation of glass powder and related performance test

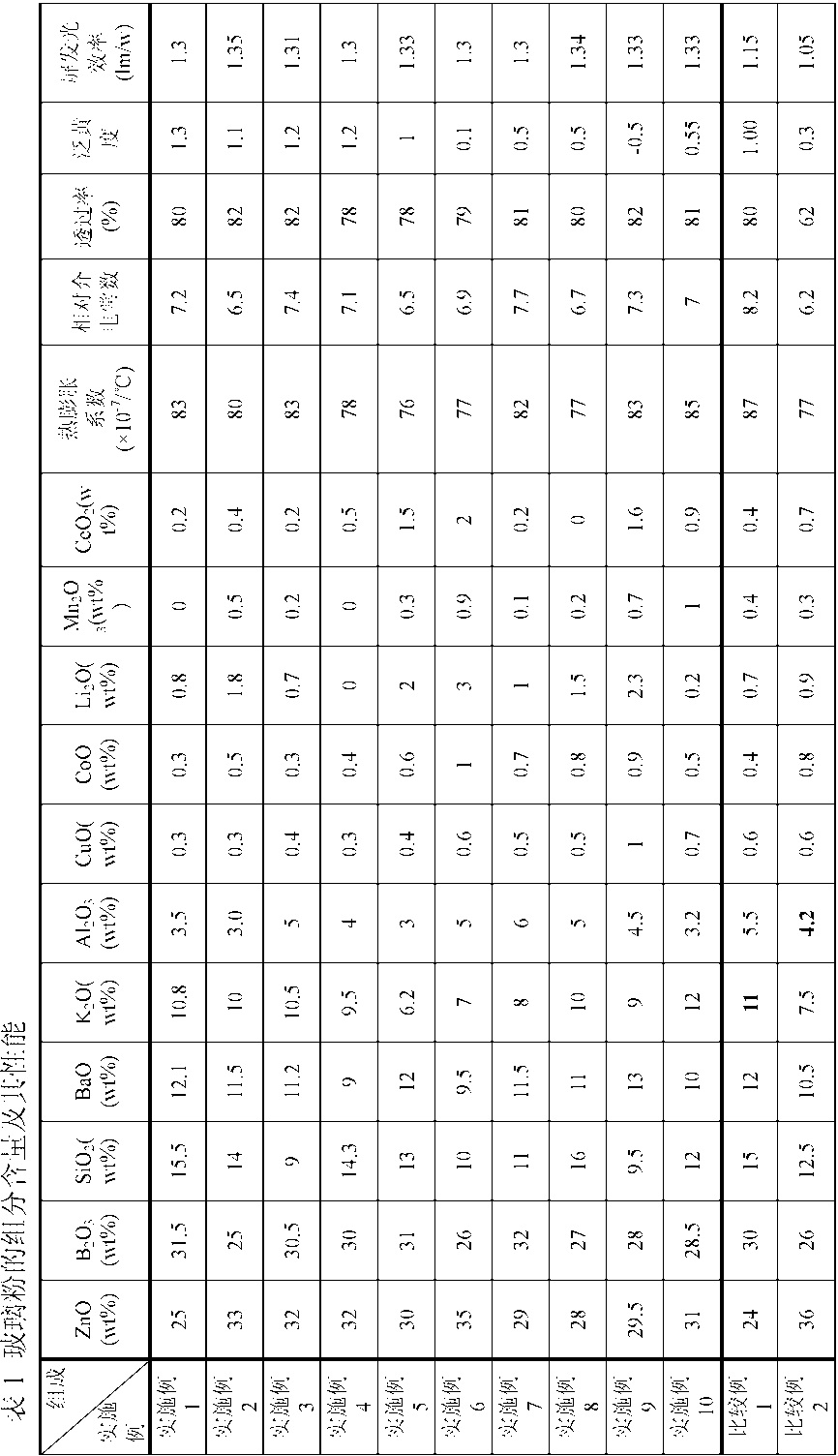

[0048] First, 25wt% (wt%) of ZnO, 31.5wt% of B 2 o 3 , 15.5wt% SiO 2 , 12.1wt% BaO, 10.8wt% K 2 O, 3.5 wt% Al 2 o 3 , 0.3wt% CuO, 0.3wt% CoO, 0.8wt% Li 2 O, 0.2wt% CeO 2 , Weigh various oxides, add to the V-type mixer and mix until uniform. The raw materials of various components in the glass powder come from zinc oxide, boric anhydride, silicon dioxide, barium carbonate, potassium carbonate, etc. Then, place the platinum crucible in a sintering furnace to preheat for a period of time until the temperature of the platinum crucible reaches the temperature in the furnace. The preheating time is usually related to the outer cladding of the crucible and the size and power of the furnace body, usually more than 5 minutes. Then take out the platinum crucible, pour the uniformly mixed raw materials into the platinum crucible, and then put it into a sintering furnace for melting. The preheating and melting tempe...

Embodiment 2-10

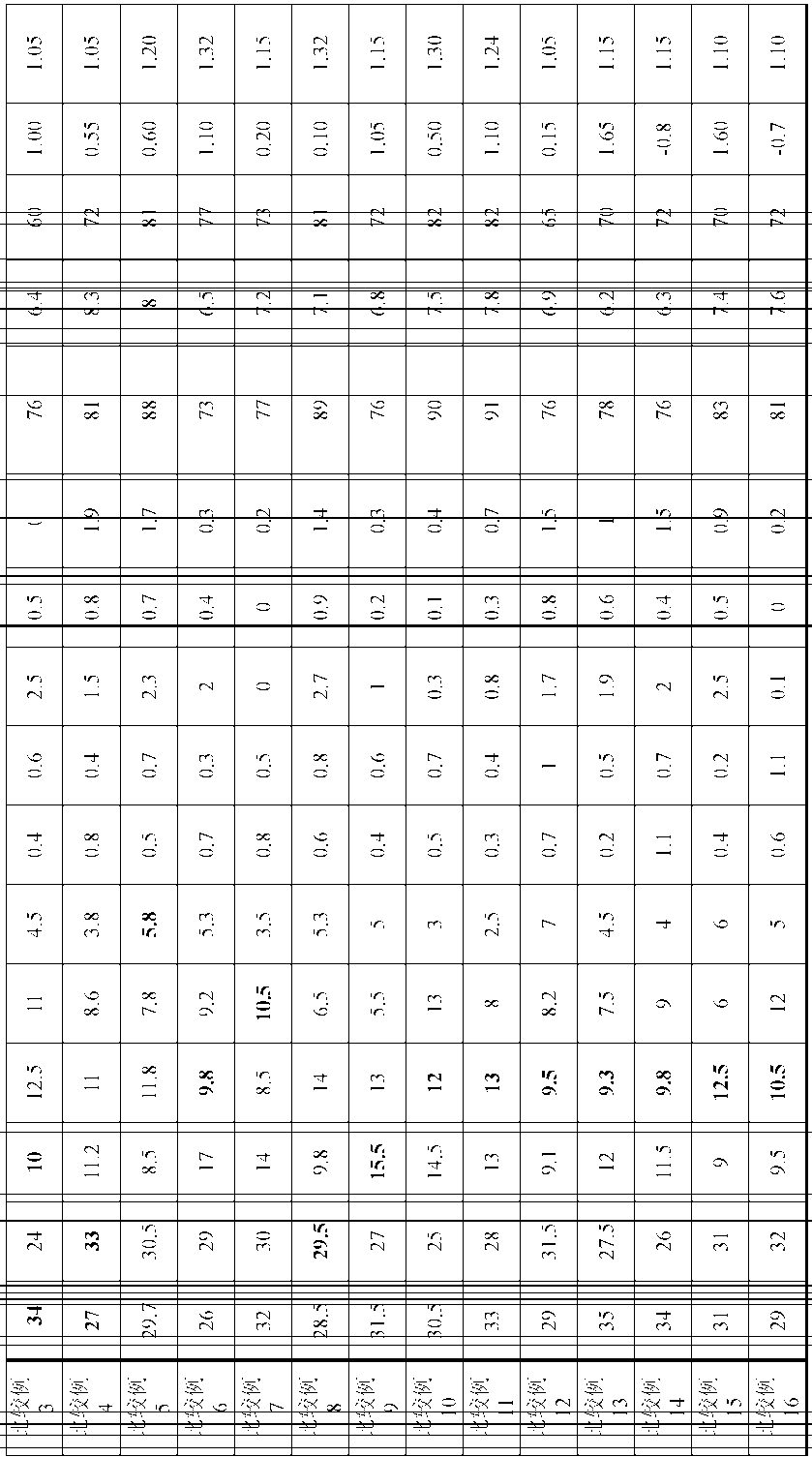

[0060] The same operation as the above-mentioned Example 1 was adopted, except that the glass frit and the dielectric paste used in Examples 2-10 were prepared according to the contents of the components listed in Table 1.

[0061] Table 1 shows the component compositions of Examples 1-10 of the glass frit used in the present invention, where the percentages refer to weight percentages (wt%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com