A treatment process for deep heat collection and purification of flue gas

A technology for processing technology and flue gas, which is applied in gas processing, heat exchangers, indirect heat exchangers, etc. Corrosion and other problems, to achieve the effect of eliminating "white smoke" pollution, ultra-low emission, and realizing emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

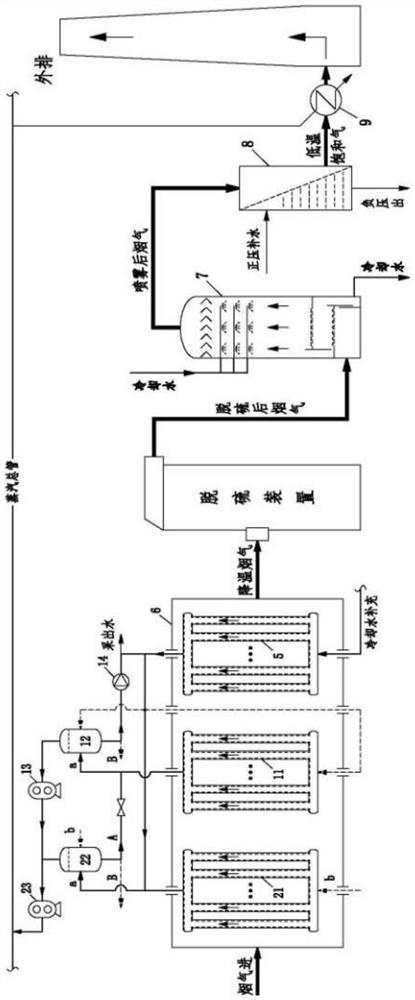

[0056] Such as figure 2 As shown, a treatment process for deep heat collection and purification of flue gas is used for flue gas treatment of natural gas boilers. The flue gas parameters of natural gas boilers are shown in Table 1. The process of this embodiment only includes waste heat recovery units.

[0057] The waste heat recovery unit device includes: a heat exchange area, a circulating pump, and a water preheating section 5, wherein the heat exchange area is separated from the gas-liquid outside the flue 6 by the tube side in the flue 6 as a self-wetting heat exchange tube bundle for cooling water package, steam compressor, and cooling water replenishment nozzle and production nozzle; the self-wetting heat exchange tube bundle in the heat exchange area is connected with the vapor-liquid isolation package; the steam pipe at the top of the vapor-liquid isolation package is connected with the inlet of the steam compressor, The outlet of the steam compressor communicates wi...

Embodiment 2

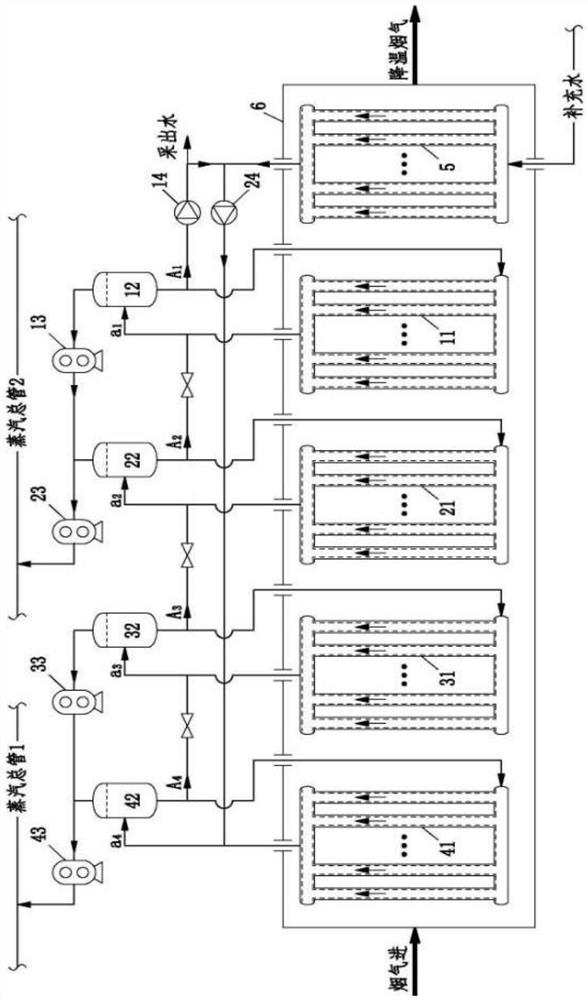

[0070] Such as image 3 As shown, a treatment process for deep heat collection and purification of flue gas is used for refining flue gas treatment. It consists of a waste heat recovery unit, a desulfurization unit, and a purification and white smoke elimination unit. The refining flue gas parameters are shown in Table 2.

[0071] The waste heat recovery unit device includes: a heat exchange area, a circulating pump, and a water preheating section 5, wherein the heat exchange area consists of a self-wetting heat exchange tube bundle in which the tube side in the flue 6 is cooling water, and the vapor-liquid outside the flue 6 Isolation package, steam compressor, and cooling water supply nozzle and production nozzle; the self-wetting heat exchange tube bundle in the heat exchange area is connected with the vapor-liquid isolation package; the steam pipe at the top of the vapor-liquid isolation package is connected with the inlet of the steam compressor , the outlet of the steam ...

Embodiment 3

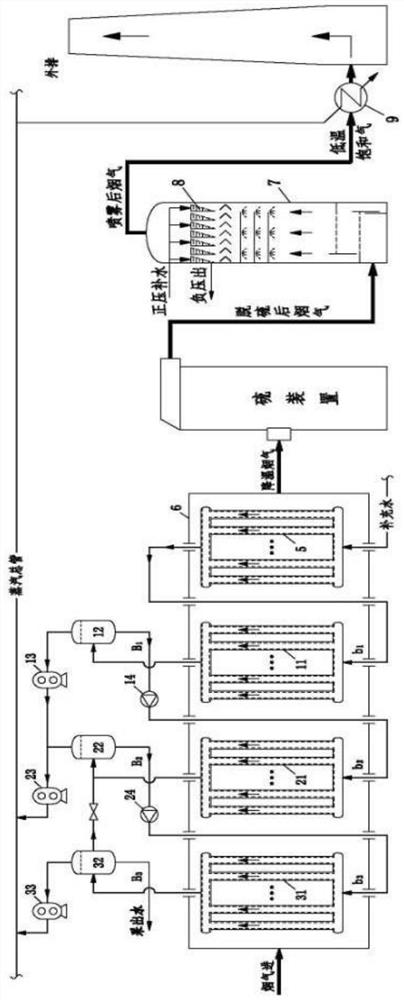

[0087] Such as Figure 4 As shown, a treatment process for deep heat collection and purification of flue gas is used for flue gas treatment in coking plants. It is composed of waste heat recovery unit, desulfurization unit and white smoke purification unit.

[0088] The waste heat recovery unit device includes: a heat exchange area, a circulating pump, and a water preheating section 5, wherein the heat exchange area consists of a self-wetting heat exchange tube bundle in which the tube side in the flue 6 is cooling water, and the vapor-liquid outside the flue 6 Isolation package, steam compressor, and cooling water supply nozzle and production nozzle; the self-wetting heat exchange tube bundle in the heat exchange area is connected with the vapor-liquid isolation package; the steam pipe at the top of the vapor-liquid isolation package is connected with the inlet of the steam compressor , the outlet of the steam compressor is connected with the steam main pipe; the bottom of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com