Composite decarbonization solvent for eliminating carbon dioxide in natural gases

A carbon dioxide and natural gas technology, applied in the direction of gas fuel, chemical instruments and methods, through absorption, etc., can solve the problems of increased solution loss, unstable thermal degradation of diethanolamine, and large solvent loss, etc., to achieve lower regeneration temperature and regeneration Energy consumption, reduced solution circulation energy consumption, and strong solution absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

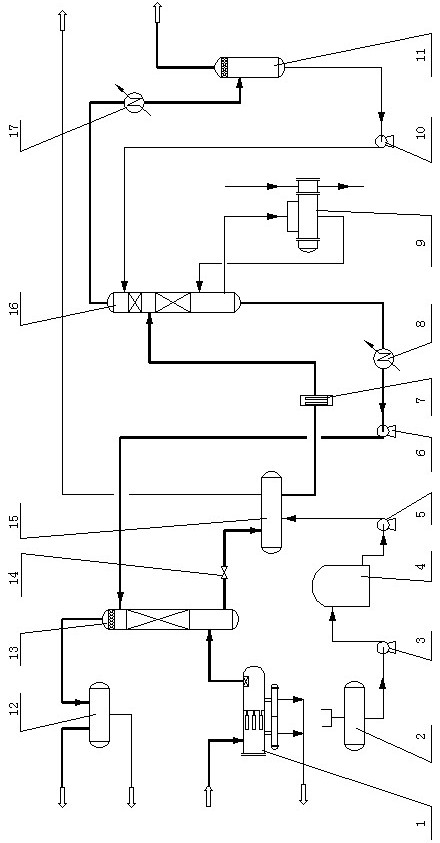

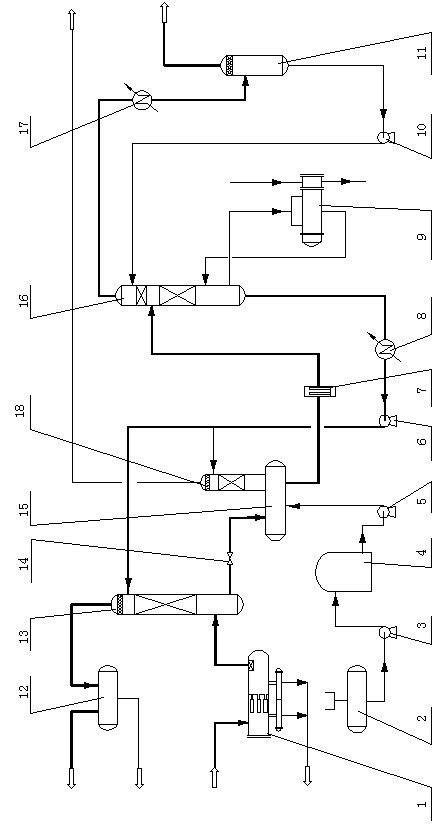

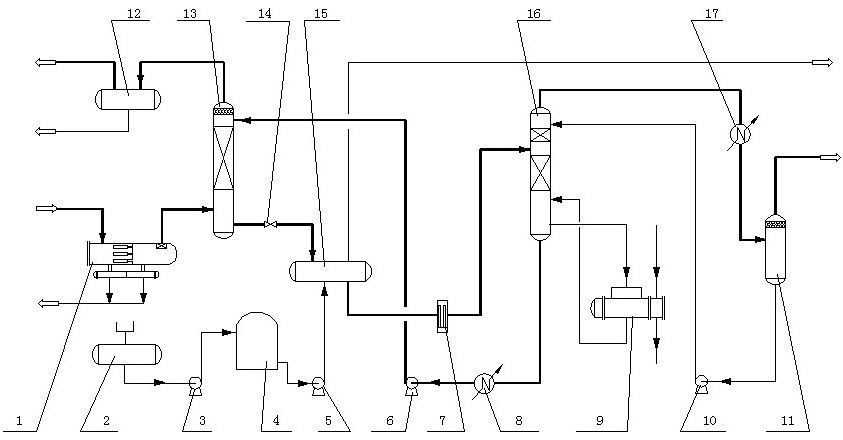

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: A compound type decarburization solvent for removing carbon dioxide in natural gas consists of the following components:

[0042] 910 kilograms of N-methyldiethanolamine solvent, the mass percentage of N-methyldiethanolamine in this solvent is 99.0%~99.5%;

[0043] Activator: 70 kg of piperazine, 5 kg of N-methyl monoethanolamine, 5 kg of diglycolamine;

[0044] Antifoaming agent: 4 kg of simethicone oil;

[0045] Corrosion inhibitor: 3 kilograms of methylthiourea;

[0046] Antioxidant: 4-methoxyphenol 3 kg.

[0047] The preparation method of the composite type decarburization solvent for removing carbon dioxide in natural gas, the steps are:

[0048] 1) Add the activator, antifoam agent, corrosion inhibitor and antioxidant to the N-methyldiethanolamine solvent;

[0049] 2) Mix according to the above mass ratio at normal temperature and pressure, and form a compound high-efficiency decarburization solvent for removing carbon dioxide in natural gas after ...

Embodiment 2

[0050] Embodiment 2: A compound type decarburization solvent for removing carbon dioxide in natural gas consists of the following components:

[0051] 964.5 kilograms of N-methyldiethanolamine solvent, the mass percentage of N-methyldiethanolamine in this solvent is 99.0%~99.5%;

[0052] Activator: 30 kg of piperazine, 2 kg of N-methyl monoethanolamine, 2 kg of diglycolamine;

[0053] Antifoaming agent: 0.5 kg of simethicone oil;

[0054] Corrosion inhibitor: 0.5 kg of thiourea;

[0055] Antioxidant: Diethylglycine 0.5 kg.

[0056] Its preparation method is with embodiment 1.

Embodiment 3

[0057] Embodiment 3: A compound type decarburization solvent for removing carbon dioxide in natural gas consists of the following components:

[0058] 925 kilograms of N-methyldiethanolamine solvent, the mass percent of N-methyldiethanolamine in this solvent is 99.0%~99.5%;

[0059] Activator: 60 kg of piperazine, 4 kg of N-methyl monoethanolamine, 4 kg of diglycolamine;

[0060] Antifoaming agent: 3 kg of simethicone;

[0061] Corrosion inhibitor: 2 kilograms of methylthiourea;

[0062] Antioxidant: 4-methoxyphenol 2 kg.

[0063] Its preparation method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com