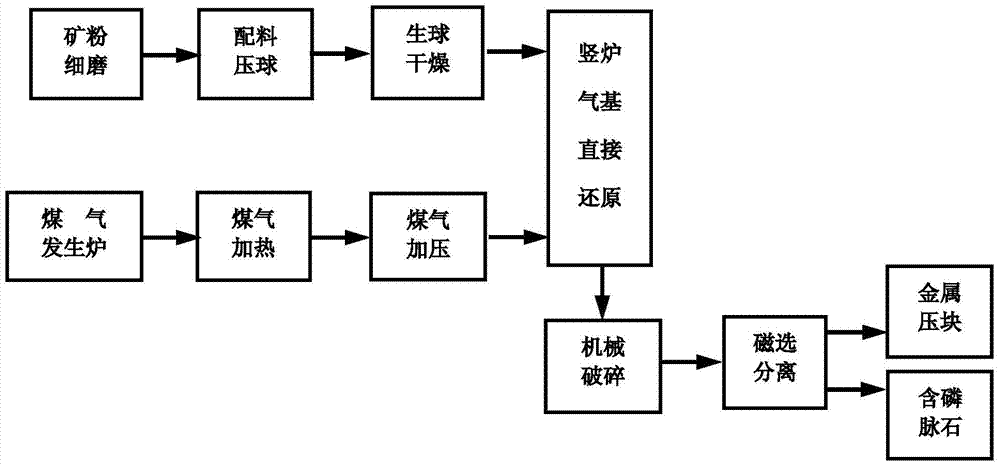

Method for preventing pellets from high temperature reduction bonding in high phosphorus oolitic hematite treatment shaft furnace

A technology of oolitic hematite and shaft furnace, which is applied to shaft furnaces, furnaces, furnace types, etc., can solve the problems of high temperature reduction and bonding of pellets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

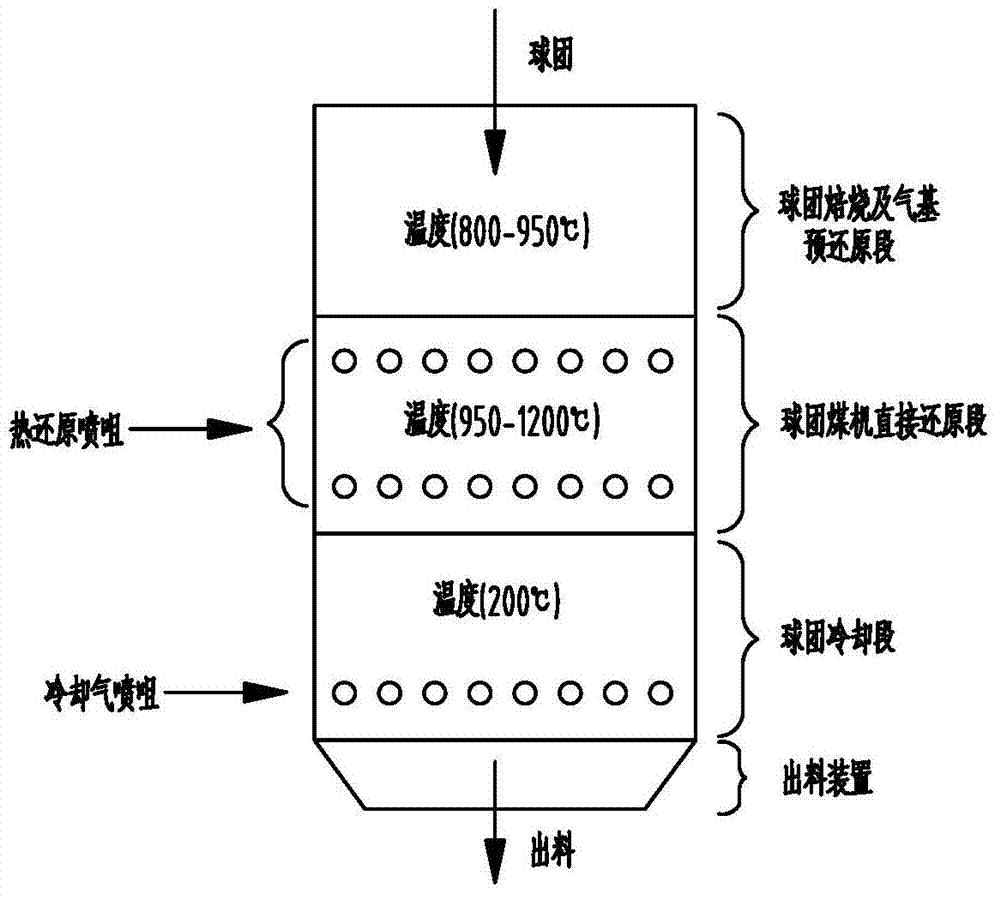

Method used

Image

Examples

Embodiment 1

[0031] The raw materials are TFe45.27%, SiO 2 8.21%, Al 2 o 3 5.61%, P0.58% oolitic hematite. According to the proportion: the weight percentage is 80% oolitic hematite, 8% coal, 7% slaked lime and 5% binder, mix evenly, and press the ball. Through the reduction shaft furnace, the reduction temperature is 1130°C, the reduction time is 1.5h, and the reduction gas composition is (H 2 :50%; CO: 42%; N 2 :8%), sealed and cooled to room temperature. The reduced ore is crushed and ground and subjected to weak magnetic separation to obtain a product with a weight percentage of TFe92% and a phosphorus content of 0.10%.

Embodiment 2

[0033] The raw materials are TFe42.1%, SiO 2 12.4%, Al 2 o 3 6.5%, P0.82% oolitic hematite. According to the proportion: the weight percentage is 78% oolitic hematite, 10% coal, 5% slaked lime and 7% binder, mix evenly, and press the ball. Through the reduction shaft furnace, the reduction temperature is 1200°C, the reduction time is 1.2h, and the reduction gas composition is (H 2 :52%; CO: 40%; N 2 :8%), sealed and cooled to room temperature. The reduced ore is crushed and ground and subjected to weak magnetic separation to obtain a product with a weight percentage of TFe94% and a phosphorus content of 0.13%.

Embodiment 3

[0035] The raw materials are TFe40.7%, SiO 2 14.4%, Al2 o 3 7.5%, P0.98% oolitic hematite. According to the proportion: the weight percentage is 82% oolitic hematite, 7% coal, 6% slaked lime and 5% binder, mix evenly, and press the ball. Through the reduction shaft furnace, the reduction temperature is 1150°C, the reduction time is 1.0h, and the reduction gas composition is (H 2 :50%; CO: 40%; N 2 :10%), sealed and cooled to room temperature. The reduced ore is crushed and ground and subjected to weak magnetic separation, and the obtained product has a weight percentage of TFe90% and a phosphorus content of 0.16.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com