A high-efficiency multifunctional polymer emulsion drying equipment

A polymer emulsion and drying equipment technology, which is applied in the direction of evaporator adjustment/control, spray evaporation, evaporator accessories, etc., can solve the problems of long production stoppage time, slow cooling and disposal, and high operation risk, so as to improve production efficiency, Avoid agglomeration and alleviate the effect of tower wall adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

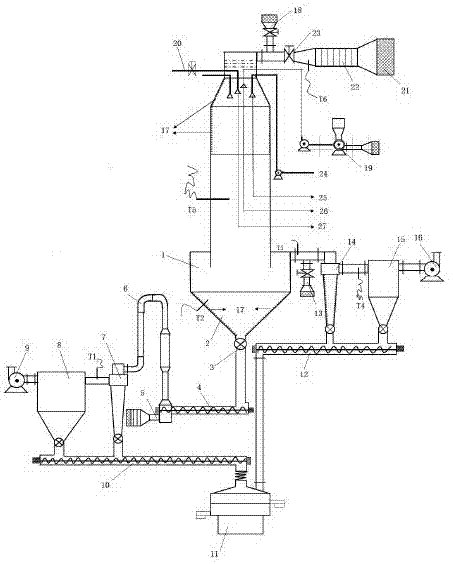

[0022] The present invention will be further described in conjunction with the accompanying drawings and embodiments.

[0023] Such as figure 1 As shown, a high-efficiency multifunctional polymer emulsion drying equipment includes a pressure spray drying system, a pulse air flow cooling system and a control system. The pressure spray drying system includes a drying tower body, a spray device, a hot air extraction device entering the tower, Material collection and transportation and tail gas treatment device, powder additive spray adding device 19, tail gas air cooling device 13, rapid air cooling device 18 and fire extinguishing spray device 20; the pulse air cooling system includes pulse air cooling device and material Collection, transportation and exhaust gas disposal device.

[0024] The drying tower body is connected with the spraying device and the hot air preparation device entering the tower. The drying tower body includes an air distribution chamber, a spray chamber,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com