A livestock feeding device that reduces waste and facilitates collection

A livestock and feeding trough technology, applied in the field of livestock breeding, can solve the problem that the feed is easy to be pushed out by the livestock, and achieve the effects of increasing contact, facilitating collection, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

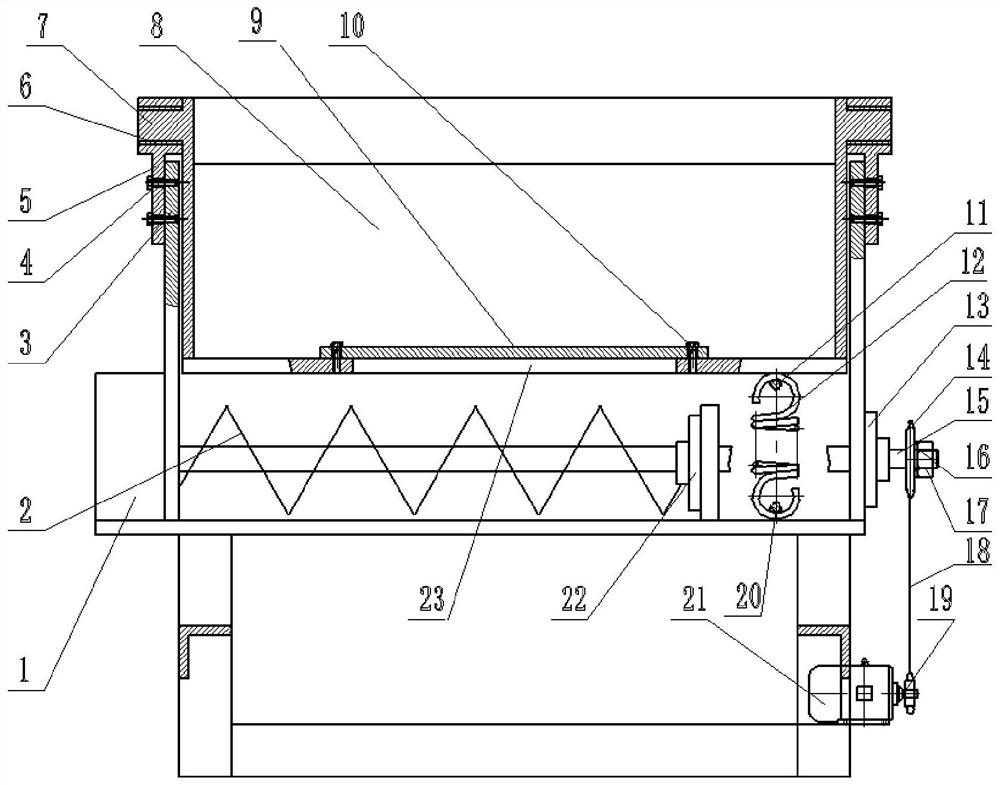

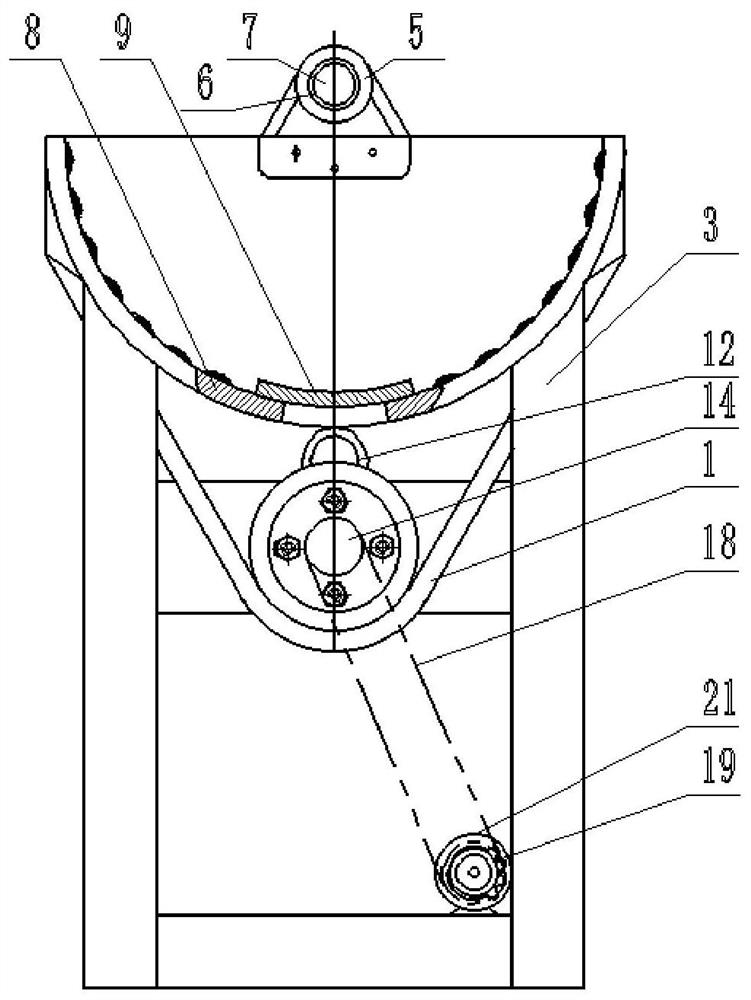

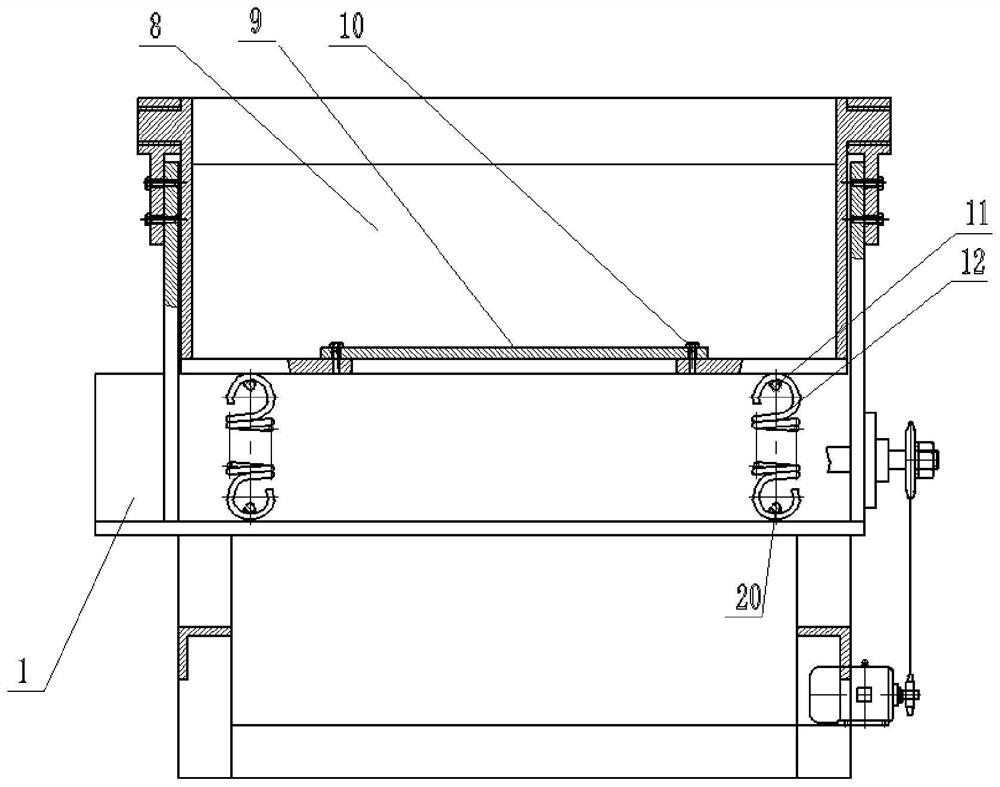

[0035] A livestock feeding device that reduces waste and facilitates collection, such as Figure 1~4 As shown, it includes auger tank 1, auger 2, bracket 3, bolt 4, upper bearing seat 5, sliding bearing 6, tank hinge shaft head 7, feeding trough 8, cover plate 9, round head screw 10, Upper holder 11, spring 12, right bearing holder 13, large sprocket 14, auger shaft 15, washer 16, nut 17, chain 18, small sprocket 19, lower holder 20, motor 21, left bearing holder 22, The discharge port 23 and the protrusion 24, wherein the auger tank body 1 is fixedly connected to the middle part of the support 3, the upper bearing seat 5 is fixedly connected to the top of the support 3 by bolts 4, and the upper bearing seat 5 is fixedly connected with a sliding bearing 6 , on both sides of the feeding trough 8, there are tank hinge shaft heads 7, and the tank body hinge shaft heads 7 are connected to the sliding bearing 6; there is a discharge port 23 at the lower end of the feeding tank 8, a...

Embodiment 2

[0038] A livestock feeding device that reduces waste and facilitates collection, such as Figure 1~4 As shown, it includes auger tank 1, auger 2, bracket 3, bolt 4, upper bearing seat 5, sliding bearing 6, tank hinge shaft head 7, feeding trough 8, cover plate 9, round head screw 10, Upper holder 11, spring 12, right bearing holder 13, large sprocket 14, auger shaft 15, washer 16, nut 17, chain 18, small sprocket 19, lower holder 20, motor 21, left bearing holder 22, The discharge port 23 and the protrusion 24, wherein the auger tank body 1 is fixedly connected to the middle part of the support 3, the upper bearing seat 5 is fixedly connected to the top of the support 3 by bolts 4, and the upper bearing seat 5 is fixedly connected with a sliding bearing 6 , on both sides of the feeding trough 8, there are tank hinge shaft heads 7, and the tank body hinge shaft heads 7 are connected to the sliding bearing 6; there is a discharge port 23 at the lower end of the feeding tank 8, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com