A kind of preparation device and method of metal lithium alloy negative electrode

A preparation device and technology for lithium metal, applied in the direction of negative electrode, metal material coating process, lithium battery, etc., can solve problems such as uneven deposition of metal lithium, shorten battery life, complicated production process, etc., and achieve slowing down of lithium metal adhesion Effects of roll and surface defects, reduction of segregation of internal elements, and suppression of lithium dendrite formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

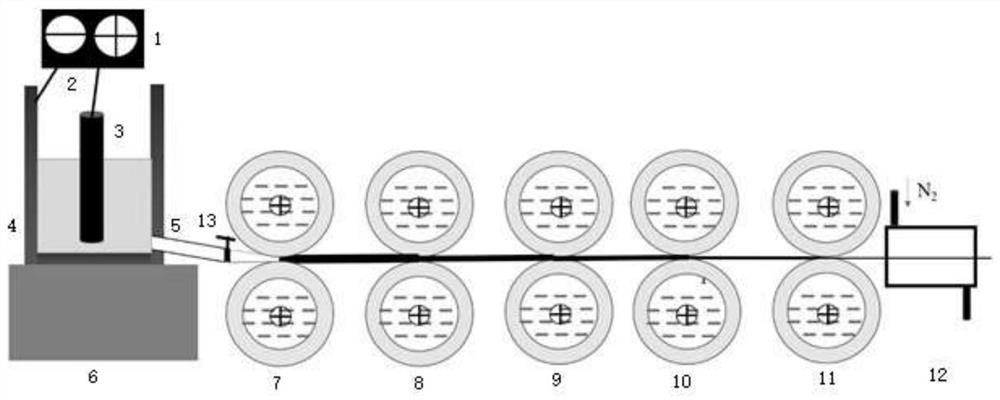

[0029] The present invention provides a preparation device for lithium metal composite negative electrode, the device includes a heating container 4, a roller machine and a nitrogen reaction container 12, the heating container is an induction furnace 4, and a crucible is arranged inside the induction furnace 4. The inside of the heating container 4 is provided with a graphite electrode 3, and the graphite electrode 3 and the heating container 4 are respectively connected with an external power supply 1 through a wire 2; the heating container 4 is connected with the roller machine through a pipeline 5, and the pipeline 5 One end near the roll machine is provided with a valve 13, and the roll machine includes a continuous casting roll 7 and a multi-stage roll, and the multi-stage roll includes a first roll 8, a second roll 9, a third roll 10 and a fourth roll 11, the A nitrogen reaction vessel 12 is provided at the end of the roll mill. The device also comprises a platform 6 on ...

Embodiment 2

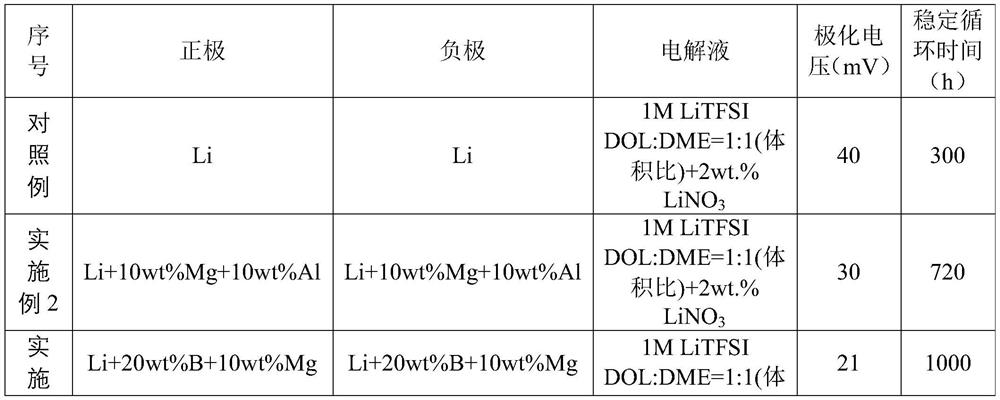

[0031] Add metal lithium ingot, metal aluminum and metal magnesium into the induction furnace at a mass ratio of 8:1:1, heat the lithium ingot to a molten state at 700°C, and apply a voltage of 0.5V between the outer wall of the crucible and the graphite electrode to maintain the temperature and voltage for 4 hours, and carry out slag removal treatment at the same time; open the valve so that the lithium melt flows into the nip area of the casting roll through the pipeline, and the gap in the nip area is 6mm; The temperature of the rolls in the first section is kept at 120°C, the temperature of the last three rolls is kept at 50°C, and the gap between the upper and lower two rolls is: the first section: 3mm, the second section: 0.75mm; the third section: 0.3mm; Four sections: 0.1mm; put the composite lithium metal strip into a container filled with nitrogen after coming out of the fourth section roll, make the composite lithium metal strip react with nitrogen, wind up the com...

Embodiment 3

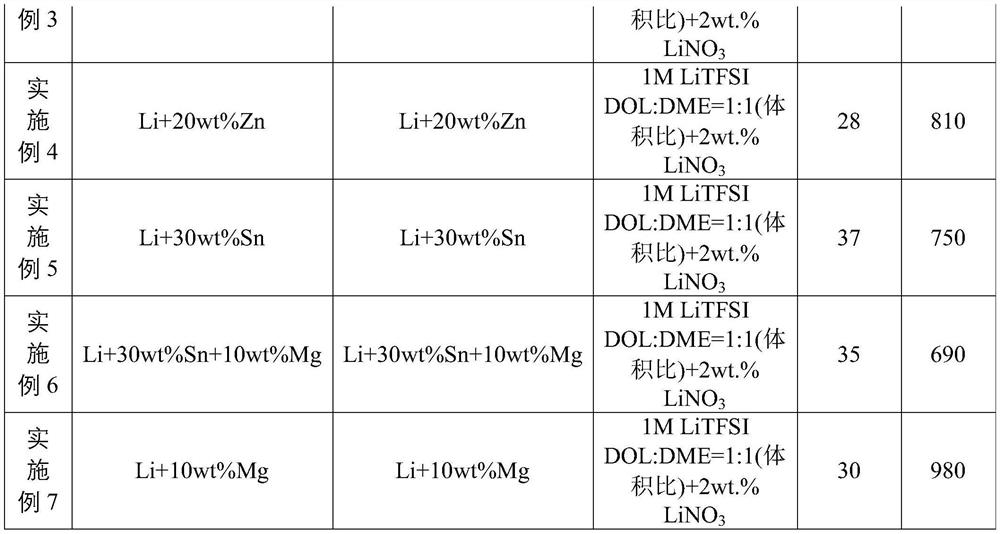

[0033] Add metal lithium ingot, metal boron and metal magnesium into the induction furnace according to the mass ratio of 7:2:1, heat to 400°C to make the lithium ingot into a molten state, and apply a voltage of 1.0V between the outer wall of the crucible and the graphite electrode to maintain the temperature and voltage for 3 hours, and carry out slag removal treatment at the same time; open the valve so that the lithium melt flows into the nip area of the casting roll through the pipeline, and the gap in the nip area is 8mm; The temperature of the rolls in the first section is kept at 120°C, and the temperature of the last three rolls is kept at 60°C. The gap between the upper and lower rolls is: the first section: 4mm, the second section: 1.2mm; the third section: 0.3mm; Four sections: 0.1mm; put the composite lithium metal strip into a container filled with nitrogen after coming out of the fourth section roll, make the composite lithium metal strip react with nitrogen, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com