Ductile iron casting and manufacturing method thereof

A manufacturing method and casting technology, which are applied in the field of ductile iron castings and their manufacturing, can solve the problems of high production cost and insufficient economic benefits, and achieve the effects of low production cost, good comprehensive mechanical properties, and good inoculation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

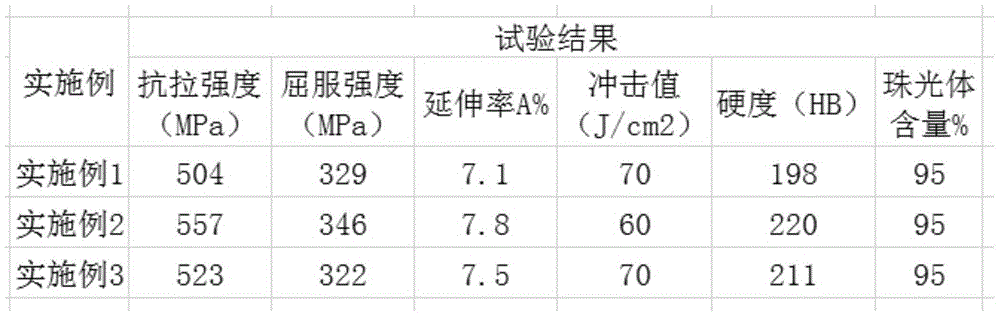

Embodiment 1

[0025] A ductile iron casting, its chemical composition is: C3.5%, Si2.5%, Mn0.4%, P≤0.1%, S≤0.03%, Ti<0.04%, Mg residual 0.030~0.045%, Re residual 0.005-0.015%, the rest is Fe.

Embodiment 2

[0027] A ductile iron casting, its chemical composition is: C3.7%, Si2.9%, Mn0.45%, P≤0.1%, S≤0.03%, Ti<0.04%, Mg residual 0.030~0.045%, Re residual 0.005-0.015%, the rest is Fe.

Embodiment 3

[0029] A ductile iron casting, its chemical composition is: C3.8%, Si3.2%, Mn0.5%, P≤0.1%, S≤0.03%, Ti<0.04%, Mg residual 0.030~0.045%, Re residual 0.005-0.015%, the rest is Fe.

[0030] The preparation process of ductile iron castings in the above embodiment may further comprise the steps:

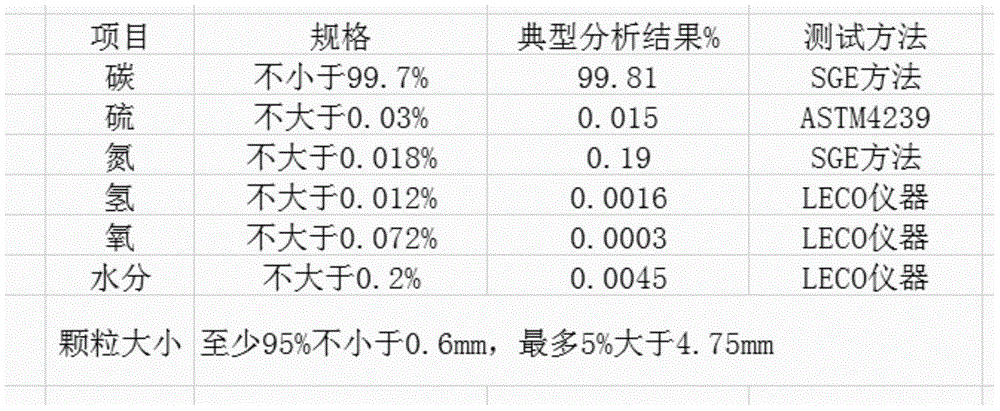

[0031] ①Raw material inspection: detect the content of C, Si, Mn, S, P in raw materials;

[0032] ② Proportion of raw materials: Raw materials that pass the inspection are fed into Q12 pig iron 56%, scrap steel 8%, and recycled materials 36% according to weight percentage;

[0033] ③Smelting molten iron: heating the raw materials with good ratio to make it into molten iron at 1500℃~1550℃ and smelting;

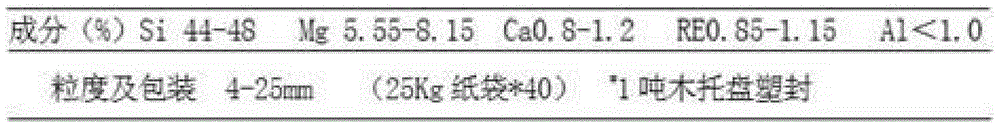

[0034] ④ Spheroidization and inoculation: add nodulizer to the smelted molten iron for spheroidization, and at the same time add inoculant for inoculation in the bag;

[0035] ⑤ Pouring: The temperature of pouring molten iron in the sand-covered iron mold is controlled at 1350°C to 1450...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com