Ironmaking technical furnace top charging technology

A furnace top charging and process technology, applied in the direction of fluidized bed furnace, etc., can solve the problems of inconvenient construction, high overall height of equipment, heat loss of sponge iron, etc., and achieve the effects of reducing energy consumption, increasing productivity, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

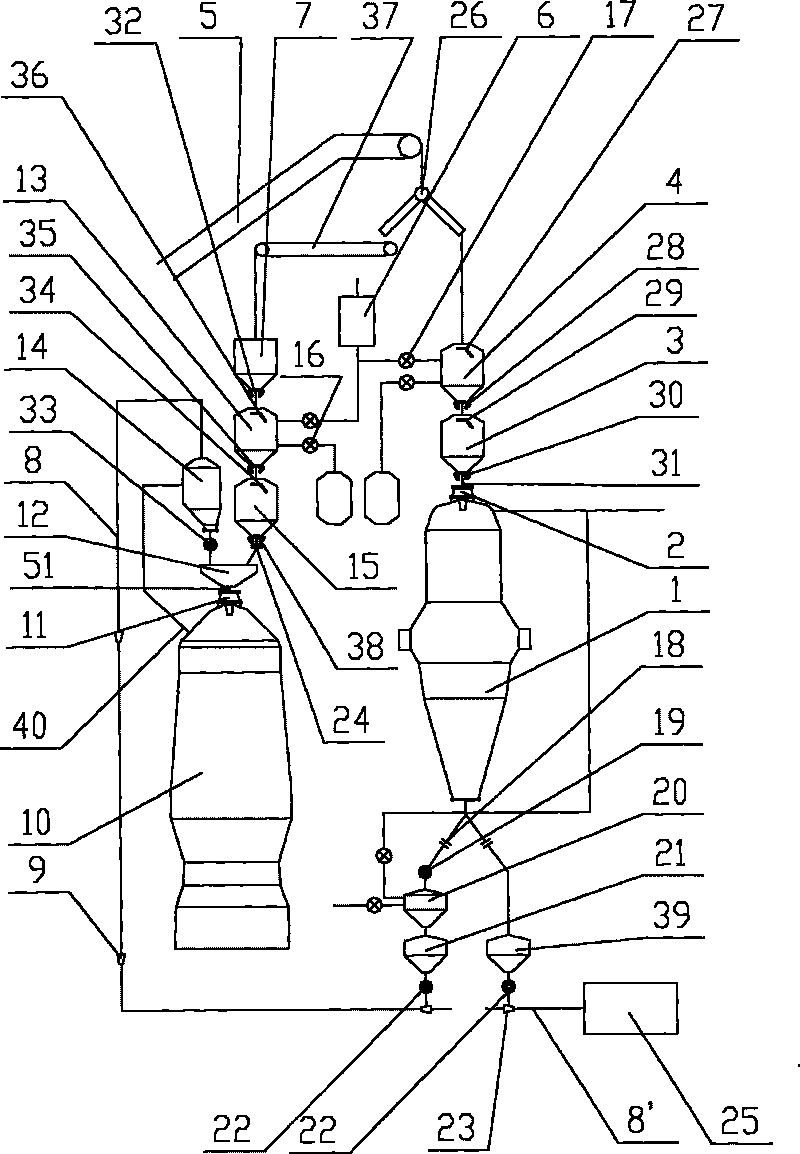

[0033] Embodiment 1: as figure 1 , the raw materials, fuel and auxiliary materials are transported to the top of the direct reduction furnace 1 and the melting furnace 10 through a belt conveyor 5 in batches, and the raw materials are sent to the top charging system of the direct reduction furnace 1 through a swing chute 26, The fuel and auxiliary materials are fed into the top charging system of melting furnace 10 .

[0034] The top charging system of direct reduction furnace 1 consists of pressure equalization bin 4, middle bin 3, equal pressure discharge system 17, upper sealing valve 27, lower sealing valve 29, material gate 28, material flow regulating valve 30, and corrugated compensator 31. Distributor 2 is composed. After the pressure equalization chamber is exhausted, open the upper sealing valve 27, the raw material enters the pressure equalization chamber 4, close the upper sealing valve 27, fill in nitrogen for pressure equalization, and after the pressure is cons...

Embodiment 2

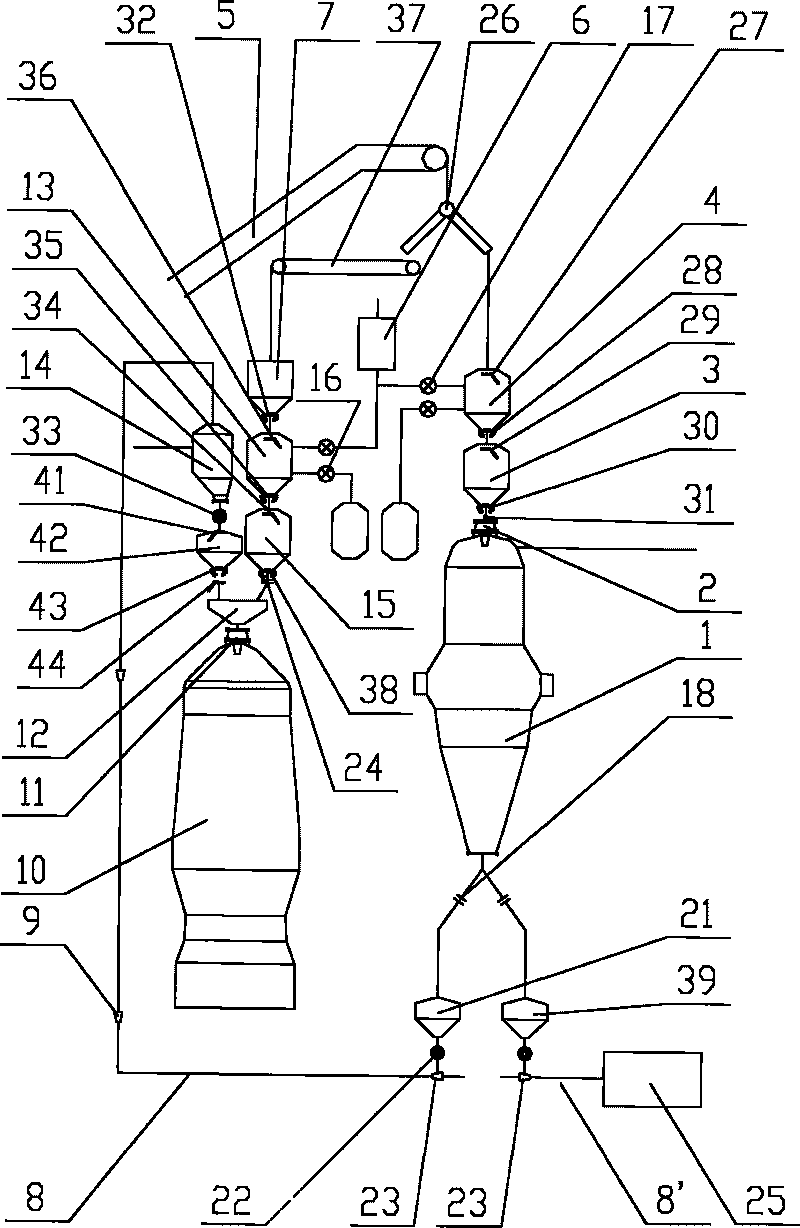

[0044] Embodiment 2: as figure 2 , The charging of raw material, fuel and auxiliary material of this embodiment is consistent with embodiment 1 scheme, and its difference is the delivery of hot state sponge iron.

[0045] The output of the hot sponge iron from the reduction shaft furnace 1 is sent to other process flow 25 in one way, and to the material gas separator 14 on the top of the melting furnace 10 in the other way. The pressure at other process flow 25 and the furnace top material gas separator 14 of melting furnace 10 is all less than the pressure in the reduction shaft furnace 1, therefore, the sponge iron enters the sending chamber 39 through the shut-off valve 18, enters the nozzle 23 through the rotary valve 22, At the nozzle 23, the transport medium gas is transported to other process flows 25 and the top material gas separator 14 of the melting furnace 10 through the pipeline 8.

[0046] The pressure in the furnace top material gas separator 14 of the melting...

Embodiment 3

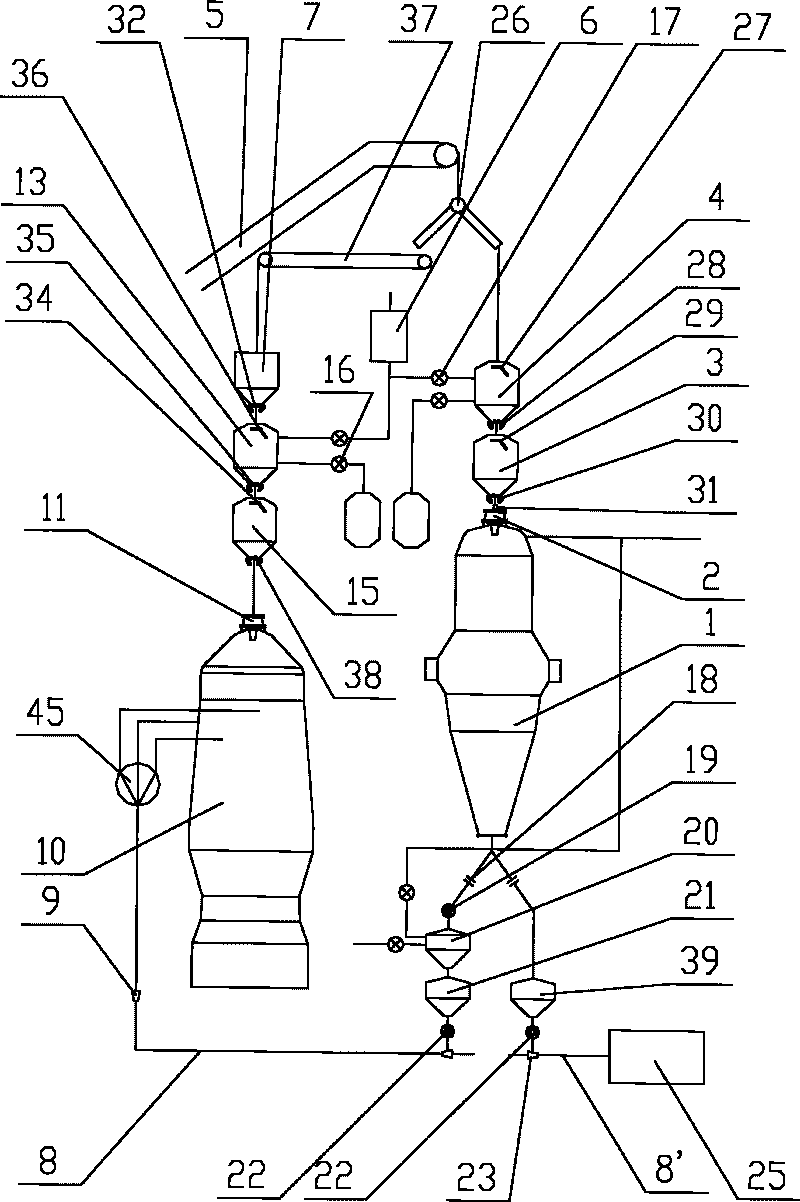

[0048] Embodiment 3: as image 3 , The charging of raw materials, fuels and auxiliary materials of this embodiment is consistent with the scheme shown in Example 1, the difference being the delivery of hot sponge iron.

[0049] This scheme saves the material gas separator 14 at the top of the melting furnace, and instead sends the sponge iron directly into the melting furnace 10 . After the hot sponge iron is discharged from the reduction shaft furnace 1, its delivery method is the same as figure 1 The scheme shown sends the sponge iron to the melting furnace top material gas separator 14, and after the sponge iron is transported to the distributor 45 through the pipeline 8, the sponge iron is distributed uniformly from the outlet of the melting furnace 10 in several pipelines. into the melting furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com