Plasma etching equipment and etching method

A technology of etching equipment and plasma, applied in the direction of discharge tubes, electrical components, circuits, etc., can solve the problems of low fidelity, large distortion of the side wall of the pattern, etc., and achieve the effect of reducing the impact and protecting the side wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

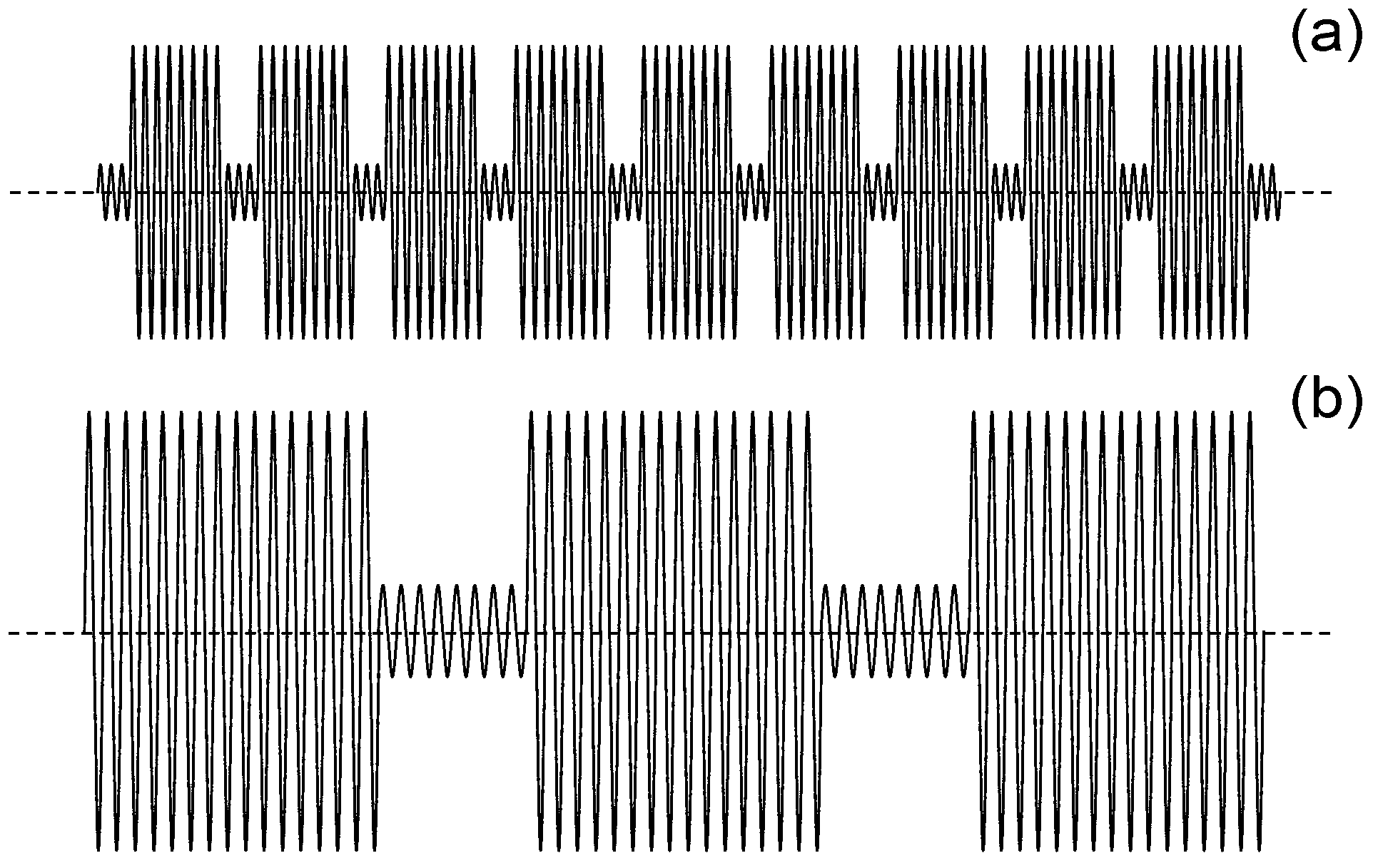

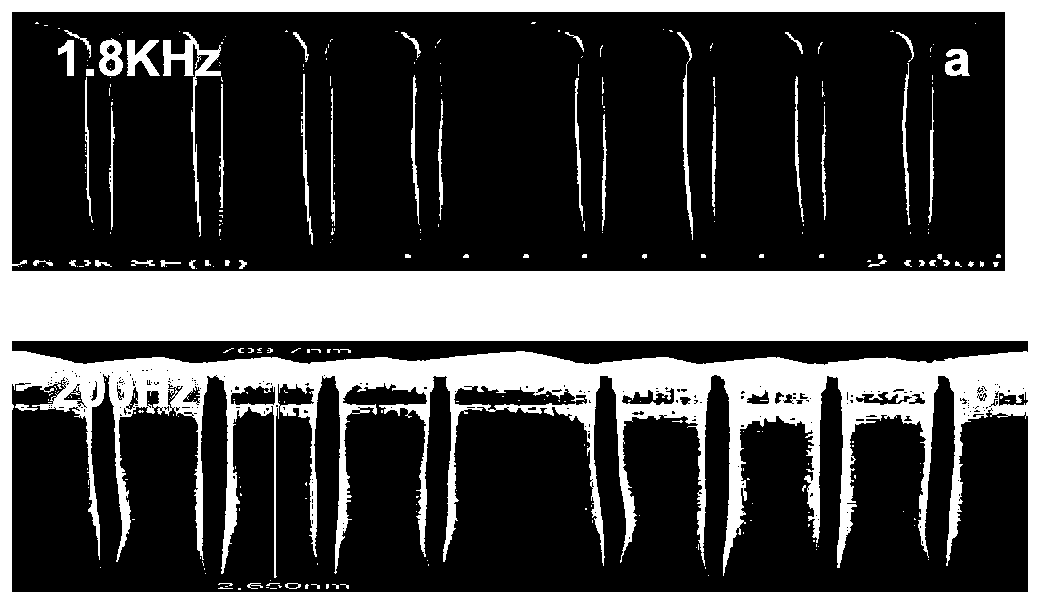

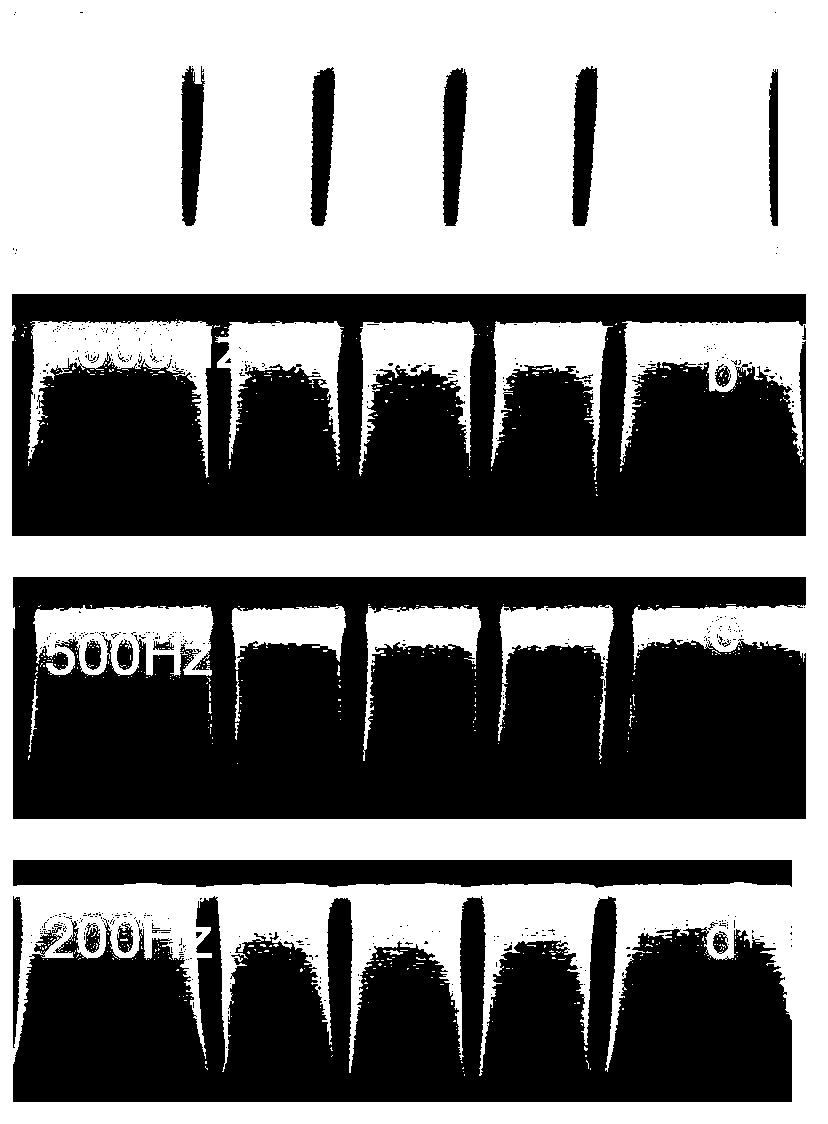

[0040] The inventor of the present invention provides a plasma etching equipment, including: an etching chamber; a first radio frequency power supply, the first radio frequency power supply provides a radio frequency power supply of 2MHz to 120MHz; a second radio frequency power supply, the second radio frequency power supply The power supply provides 2MHz to 40MHz radio frequency power; connect the power pulse controller of the first radio frequency power and the second radio frequency power, the power pulse controller controls the pulse of the first radio frequency power and the second radio frequency power, so that the first radio frequency The pulse frequency of the power supply is greater than 1000Hz and the pulse frequency of the second RF power supply is less than 1000Hz.

[0041] Specifically, the plasma etching device may be a capacitively coupled plasma etching device or an inductively coupled plasma etching device.

[0042] The first radio frequency power supply is ...

Embodiment 2

[0070] The inventor of the present invention provides a plasma etching equipment, including: an etching chamber; a first radio frequency power supply, the first radio frequency power supply provides a radio frequency power supply of 2MHz to 120MHz; a second radio frequency power supply, the second radio frequency power supply The power supply provides 2MHz to 40MHz radio frequency power; a power pulse controller connected to the first radio frequency power supply and the second radio frequency power supply, the power pulse controller controls the first radio frequency power supply pulse, so that the pulse frequency of the first radio frequency power supply is greater than 1000Hz .

[0071] Specifically, the plasma etching device may be a capacitively coupled plasma etching device or an inductively coupled plasma etching device. The first radio frequency power supply is a source radio frequency power supply (Source RF Power), and the first radio frequency power supply outputs a...

Embodiment 3

[0084] The inventor of the present invention provides a plasma etching equipment, including: an etching chamber; a first radio frequency power supply, the first radio frequency power supply provides a radio frequency power supply of 2MHz to 120MHz; a second radio frequency power supply, the second radio frequency power supply The power supply provides 2MHz to 40MHz radio frequency power; connected to the power pulse controller of the second radio frequency power, the power pulse controller controls the pulse of the second radio frequency power so that the pulse frequency of the second radio frequency power is less than 1000Hz.

[0085] Specifically, the plasma etching device may be a capacitively coupled plasma etching device or an inductively coupled plasma etching device. The first radio frequency power supply is a source radio frequency power supply (Source RF Power), and the first radio frequency power supply outputs a radio frequency power supply of 2MHz to 120MHz radio fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com